Method for preparing CuWCr composite material through electric arc melting and infiltration method

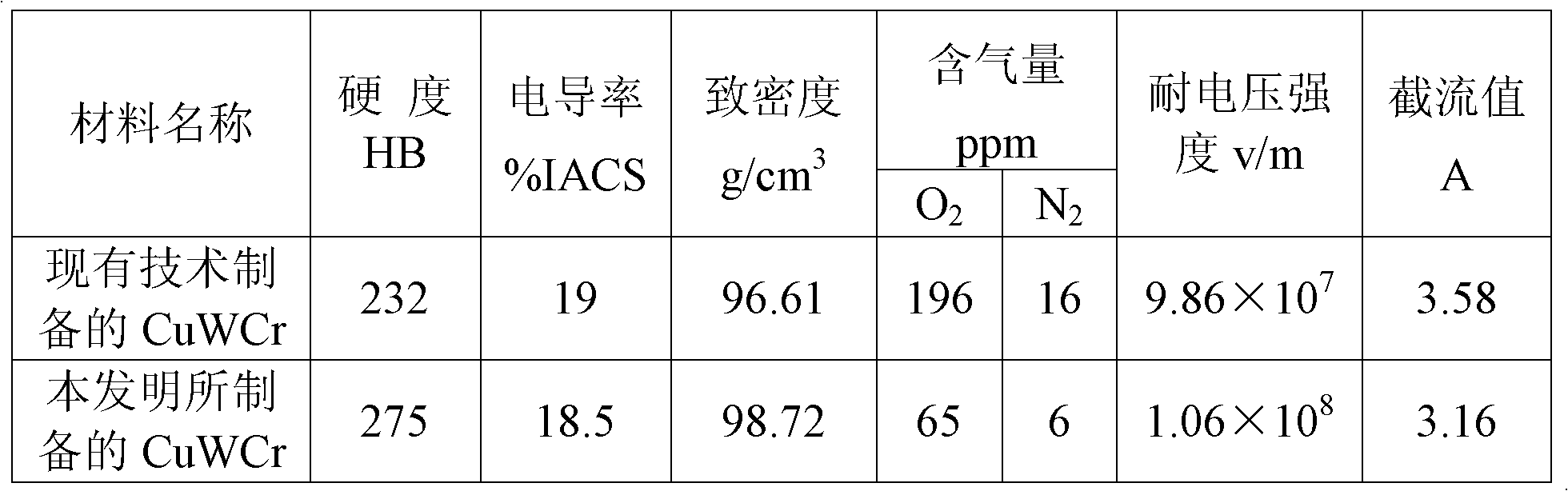

A technology of arc melting and composite materials, which is applied in the field of material preparation, can solve the problems of low conductivity, high impurity content, and low withstand voltage strength, and achieve the effect of high conductivity, less impurity content, and high withstand voltage strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] Preparation of CuCr Infiltrated Billet

[0018] Weigh 25% to 66% of Cu powder with a purity of not less than 99% and 34% to 75% of Cr powder with a purity of not less than 99.7% by mass percentage and put them into a mixer and mix them for 3 to 6 hours. The powder is molded at 400MPa or cold isostatic pressed at 260MPa, and the pressed billet is placed in a vacuum sintering furnace at a vacuum degree of not less than 10 -2 Raise the temperature to 900°C to 1050°C in a vacuum environment of Pa, and sinter for 60 minutes to 120 minutes to obtain a CuCr infiltrated billet;

[0019] Preparation of W skeleton

[0020] The W powder is pressed into a billet, and the porosity of the billet is controlled at 35% to 40%. The billet is placed in a vacuum sintering furnace, and the vacuum degree is not less than 10 -2 Raise the temperature to 1050°C-1500°C in a vacuum environment of Pa, and sinter for 90-150 minutes to make it sintered into a skeleton;

[0021] Arc melting and po...

Embodiment 1

[0025] First, put 66% of Cu powder and 34% of Cr powder into a mixer and mix for 3 hours, mold the mixed powder at 400MPa, put the pressed billet in a vacuum sintering furnace, and put it in a vacuum degree greater than 10 -2 The temperature was raised to 900° C. under a vacuum environment of Pa, and sintered for 120 minutes to obtain a CuCr infiltrated billet.

[0026] Then, the W powder is molded into a billet under 400MPa, the porosity of the billet is controlled to 40%, and the billet is placed in a vacuum sintering furnace. -2 The temperature was raised to 1050° C. under a vacuum environment of Pa, and sintered for 150 minutes to make it sintered into a skeleton.

[0027] Finally, the prepared W skeleton is placed at the bottom of the water-cooled copper crucible of the consumable electrode arc melting furnace, and the prepared CuCr infiltration billet is placed on the W skeleton, and the vacuum degree is not less than 10 -3 Under the vacuum environment of Pa, adjust th...

Embodiment 2

[0029] First, 25% of Cu powder and 75% of Cr powder were put into a mixer and mixed for 6 hours. The mixed powder was subjected to cold isostatic pressing at 400 MPa, and the pressed billet was placed in a vacuum sintering furnace. Vacuum degree greater than 10 -2 The temperature was raised to 1050° C. under a vacuum environment of Pa, and sintered for 60 minutes to obtain a CuCr infiltrated billet.

[0030] Then, the W powder is subjected to cold isostatic pressing at 260MPa, the porosity of the billet is controlled to 35%, and the billet is placed in a vacuum sintering furnace. -2 The temperature was raised to 1500° C. under a vacuum environment of Pa, and sintered for 90 minutes to make it sintered into a skeleton.

[0031] Finally, the prepared W skeleton is placed at the bottom of the water-cooled copper crucible of the consumable electrode arc melting furnace, and the prepared CuCr infiltration billet is placed on the W skeleton, and the vacuum degree is not less than 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com