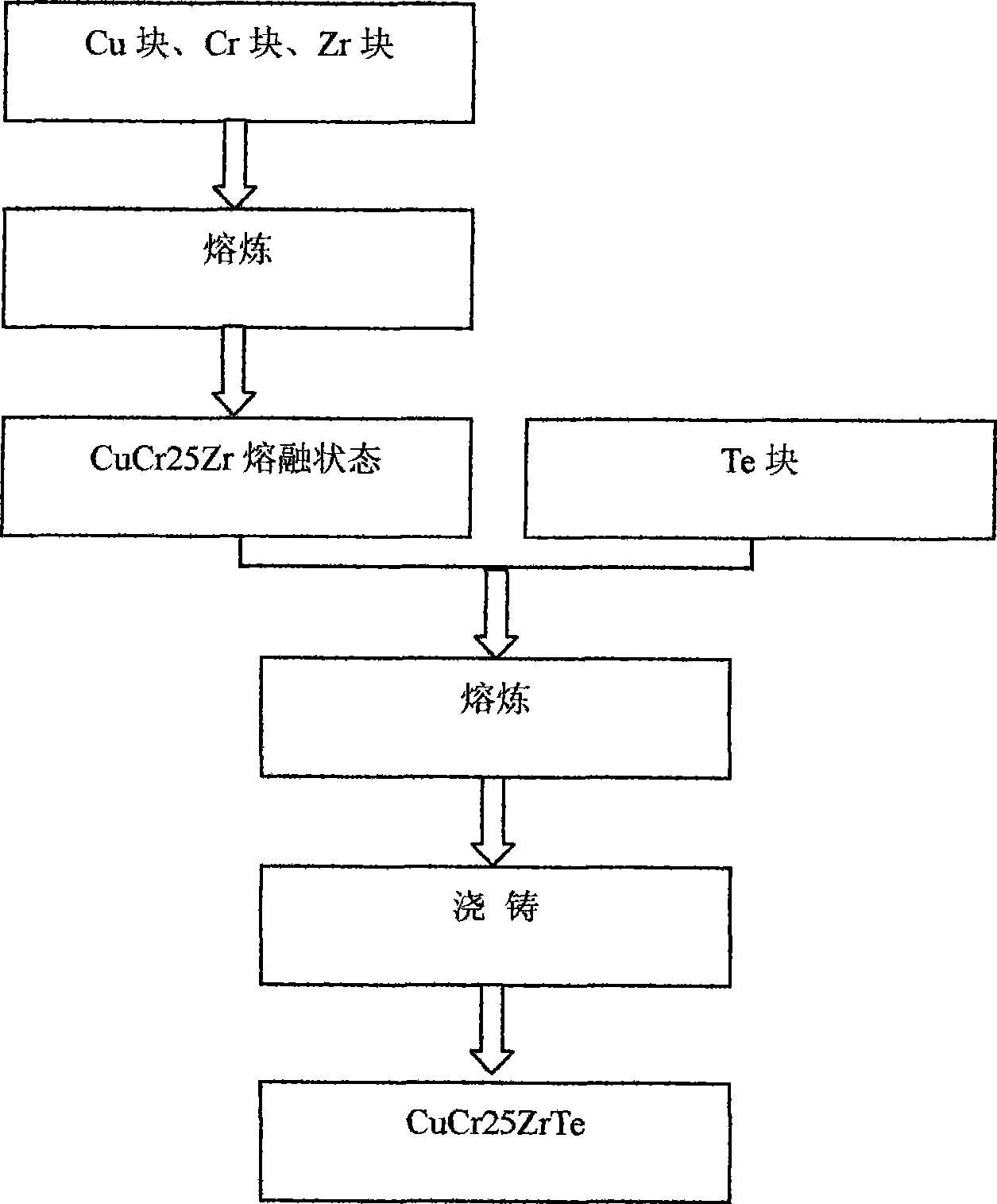

Method for preparing CuCr25ZrTe contact tip by vacuum casting process

A kind of electric contact material and electric contact technology, applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems that affect the performance of contact materials, CuCr alloy contacts can resist welding and the cut-off value is not ideal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh 1.75kg of Cr block, 5.25Kg of Cu block, and 0.0021Kg of Zr block in proportion and put them into the vacuum furnace. -2 Heating at a speed of 80°C / min under a vacuum of Pa, when the temperature rises to 1200°C, keep it warm for 60 minutes, put 0.0007Kg of Te into the alloy solution, keep it warm for 10 minutes; fast casting. After cooling, the CuCr25ZrTe electrical contact material is obtained.

Embodiment 2

[0020] Weigh 2.5kg of Cr block, 7.4Kg of Cu block, and 0.03Kg of Zr block in proportion and put them into the vacuum furnace, at P≤8×10 -2 Heating at a speed of 80°C / min under a vacuum of Pa, when the temperature rises to 1300°C, keep it for 40 minutes, put 0.03Kg of Te into the alloy solution, keep it for 7 minutes; fast casting. After cooling, the CuCr25ZrTe electrical contact material is obtained.

Embodiment 3

[0022] Weigh 1.25kg of Cr block, 3.75Kg of Cu block, and 0.0015Kg of Zr block in proportion and put them into the vacuum furnace. -2 Heating at a speed of 80°C / min under a vacuum of Pa, when the temperature rises to 1500°C, keep it warm for 30 minutes, put 0.0005Kg of Te into the alloy solution, keep it warm for 5 minutes; fast casting. After cooling, the CuCr25ZrTe electrical contact material is obtained.

[0023] The composite material prepared by the invention has excellent comprehensive properties. The performance comparison between the prepared CuCr25ZrTe composite material and CuCr composite material is shown in Table 1.

[0024] Table 1 Performance comparison of CuCr25ZrTe and CuCr25 composite materials of the present invention

[0025] material name

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com