Method for improving hardness of CuW alloy

A hardness and alloy technology, applied in the field of improving the hardness of CuW alloys, can solve problems such as the inability to meet performance requirements, and achieve the effects of increasing hardness, reducing electrical conductivity and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

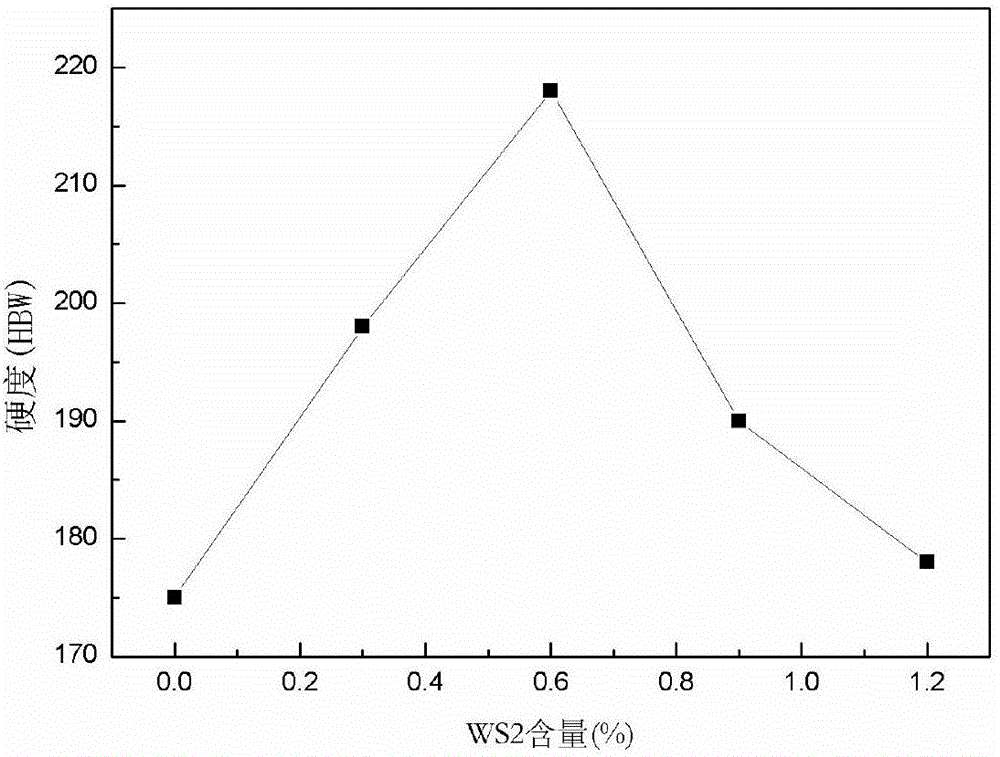

[0031] Mix submicron tungsten powder, copper powder and WS2 according to the mass ratio of 1000:50:3, put them into the mixer, and add tungsten carbide grinding balls according to 1:1 of the total powder mass Mix the powder at a speed of 120r / min for 4 hours. The mechanically mixed powder is bonded, dried, and sieved. The powder is pressed through a cold press mold with a pressing pressure of 350KN and held for 30 seconds to form a blank. The blank formed by pre-pressing , place the copper block on the blank and then sinter at 900°C for 2h and infiltrate at 1320°C for 2h under a hydrogen protective atmosphere. The hardness of the obtained CuW alloy is 198HB, the electrical conductivity is 27MS / m, and the withstand voltage strength is 3.40×10 7 V / M.

Embodiment 2

[0033] Mix submicron tungsten powder, copper powder and WS2 according to the mass ratio of 1000:60:6, put them into the mixer, and add tungsten carbide grinding balls according to 1:1 of the total powder mass Mix the powder at a speed of 120r / min for 4 hours. The mechanically mixed powder is bonded, dried, and sieved. The powder is pressed through a cold pressing mold with a pressing pressure of 400KN and held for 35 seconds to form a blank. The blank formed by pre-pressing , place the copper block on the blank and then sinter at 940°C for 2h and infiltrate at 1350°C for 2h under a hydrogen protective atmosphere. The hardness of the obtained CuW alloy is 218HB, the electrical conductivity is 25MS / m, and the withstand voltage strength is 3.20×10 7 V / M.

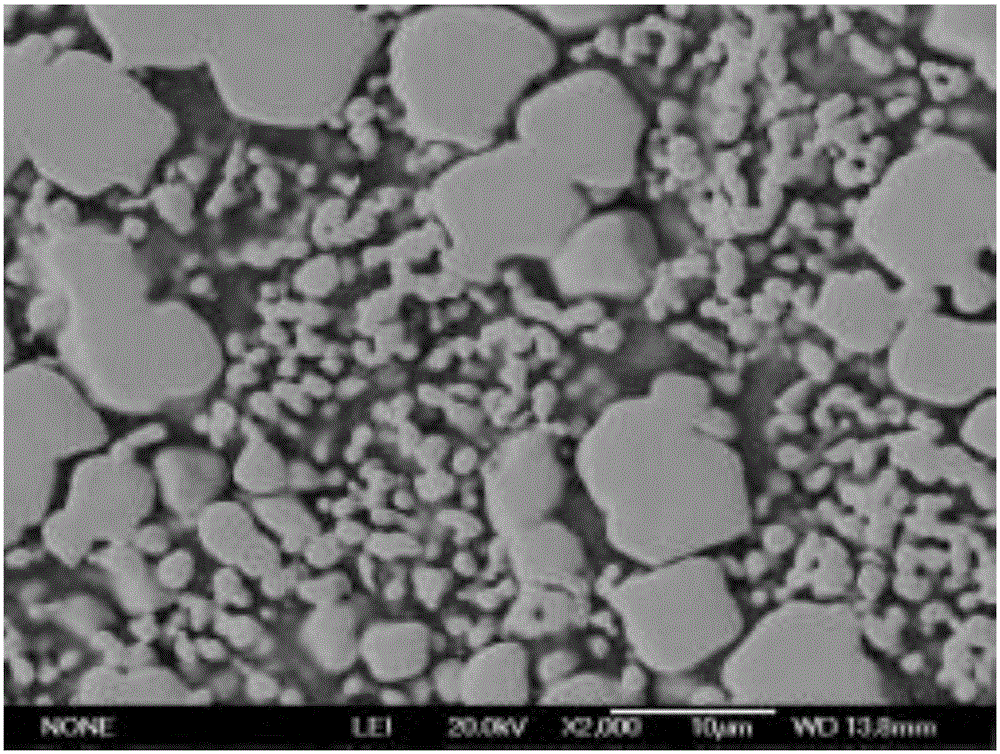

[0034] figure 1 It is a CuW alloy structure without lubricating phase WS2, which has spherical W 50 Two types of W powder, granule and production W granule;

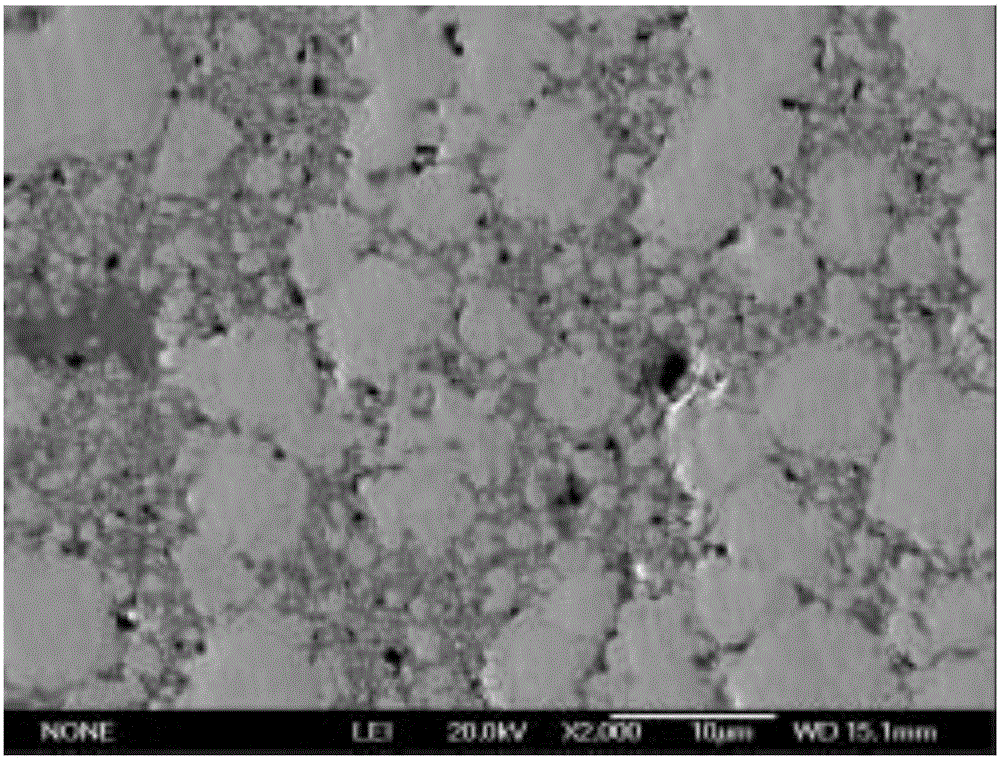

[0035] figure 2 It is the CuW alloy structure added with lubric...

Embodiment 3

[0038] Mix submicron tungsten powder, copper powder and WS2 according to the mass ratio of 1000:70:9 and put them into the mixer, and add tungsten carbide grinding balls according to 1:1 of the total powder mass Mix the powder at a speed of 120r / min for 4 hours. The mechanically mixed powder is bonded, dried, and sieved. The powder is pressed through a cold pressing die with a pressing pressure of 500KN and held for 40 seconds to form a blank. The blank formed by pre-pressing , place the copper block on the blank and then sinter at 960°C for 2h and infiltrate at 1300°C for 2h under a hydrogen protective atmosphere. The hardness of the obtained CuW alloy is 190HB, the electrical conductivity is 23.5MS / m, and the withstand voltage strength is 3.0×10 7 V / M.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com