Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47 results about "Zinc diffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal diffusion galvanizing, or Sherardizing, provides a zinc diffusion coating on iron- or copper-based materials. Parts and zinc powder are tumbled in a sealed rotating drum. Around 300 °C (572 °F), zinc will diffuse into the substrate to form a zinc alloy.

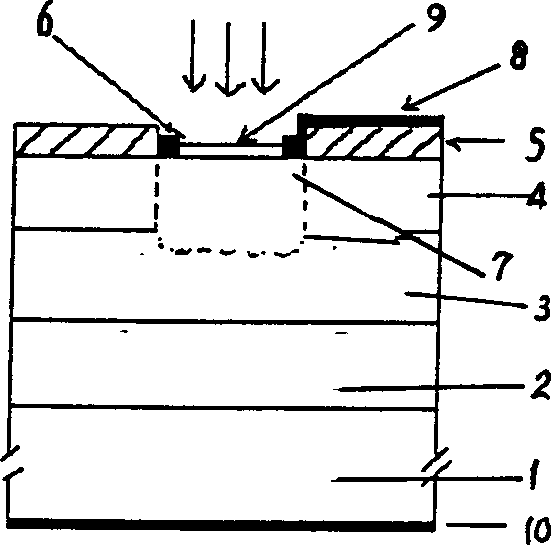

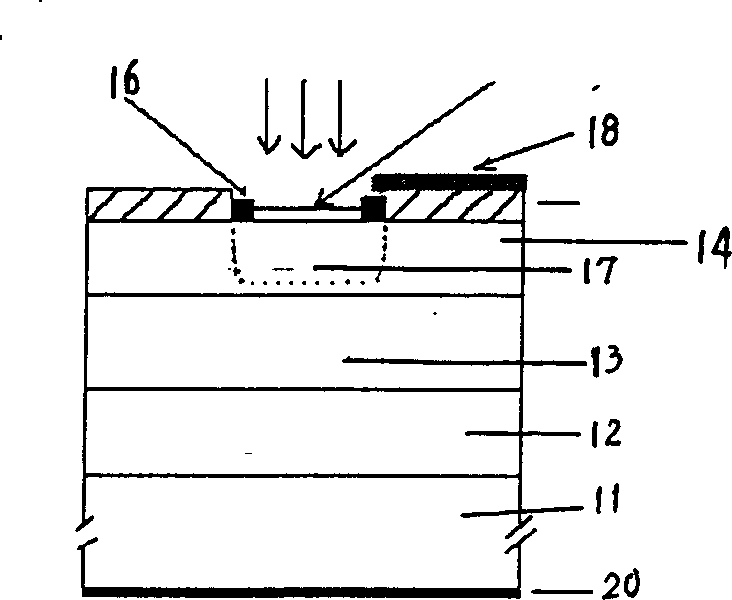

InGaAs/InP PIN photo electric detector and its manufacturing technology

InactiveCN1414642AStable growth conditionsEasy to controlFinal product manufactureSolid-state devicesManufacturing technologySignal-to-noise ratio (imaging)

A InGaAs / InP PIN photoelectric detector relating to a semiconductor component has the structure of double hetergeneous material in four layer of i-In0.53 Ga 0.47As photosensitive layer / i-InP buffer layer / N+-Inp substrate. There is P+ zinc diffusion layer which is close to i-In 0.53 Ga0.47 As photosensitive layer but not reach the photosensitive layer at the top layer. It is prepared by the following steps, growing a passivation film of aluminium oxide on the epitaxial sheet and carrying out open-type zinc diffusion by using zinc as a diffusion source, depositing high quality film of aluminiumoxide on InP material by directly using evapouration to reduce dark current, and raising the signal to noise ratio. The film obtained can be used in passivation film of InP material.

Owner:XIAMEN UNIV

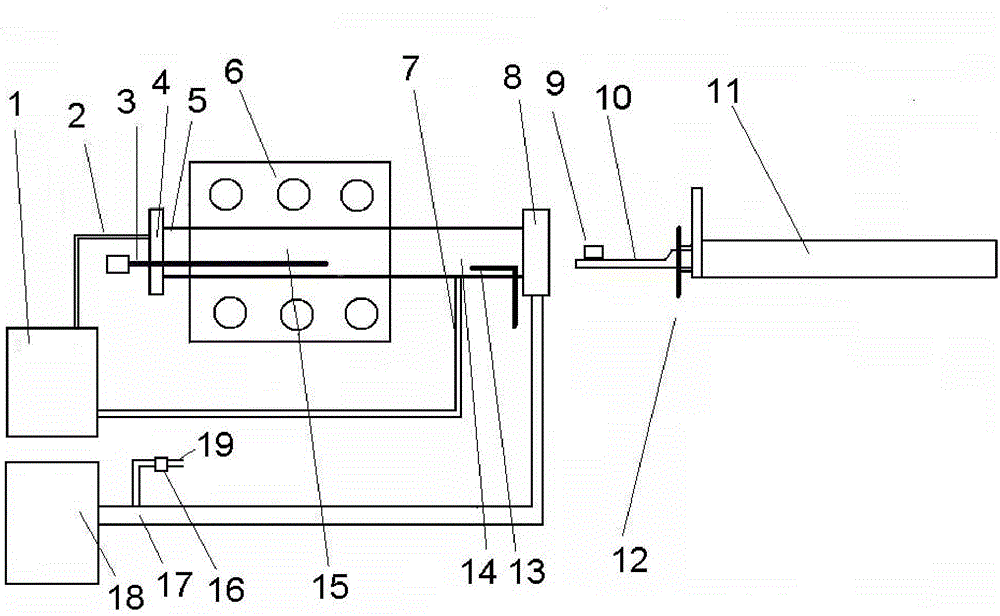

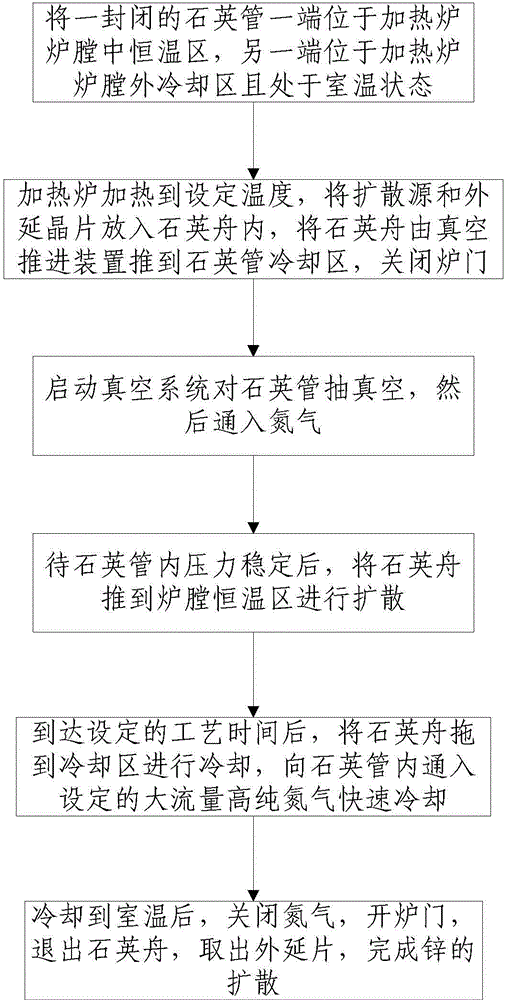

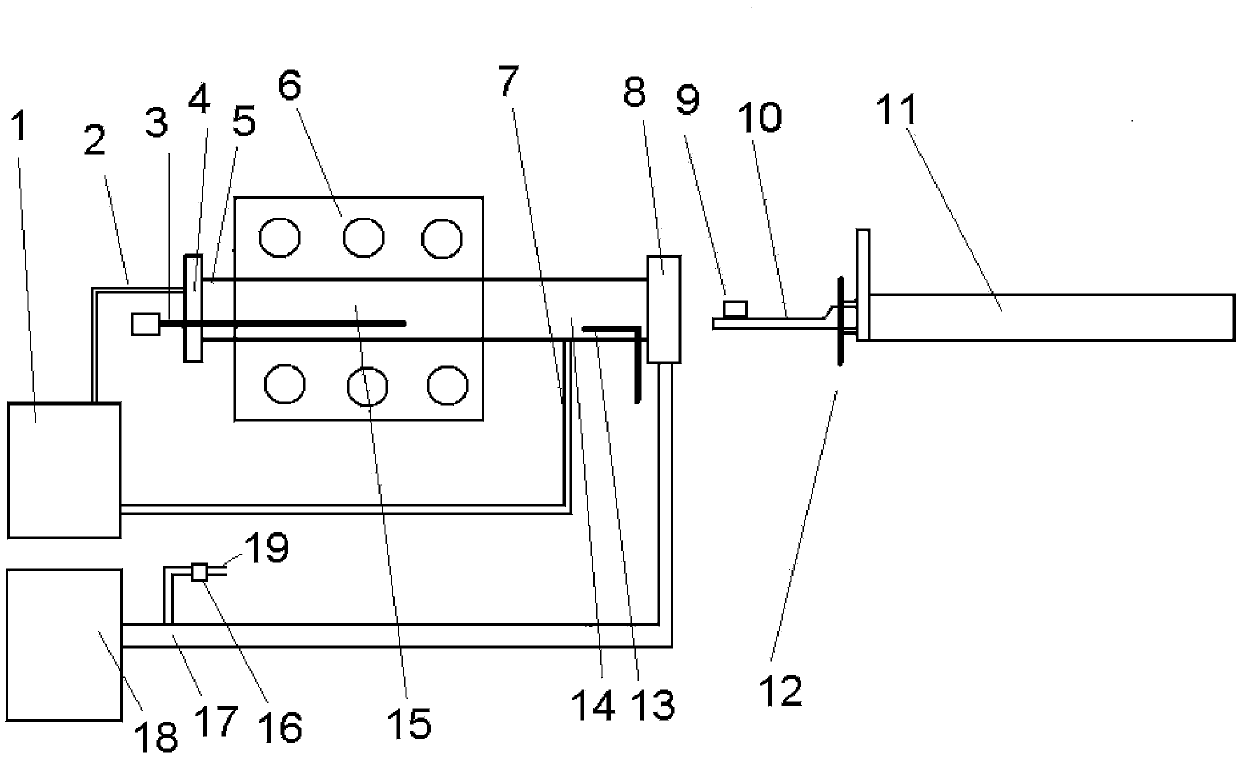

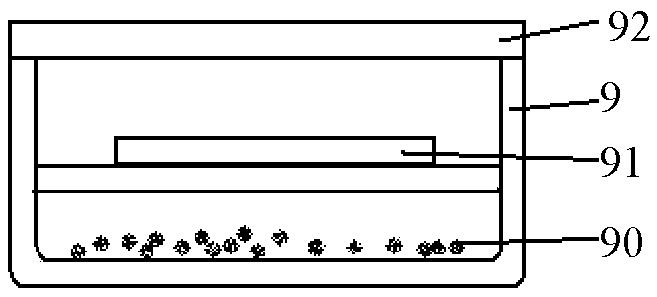

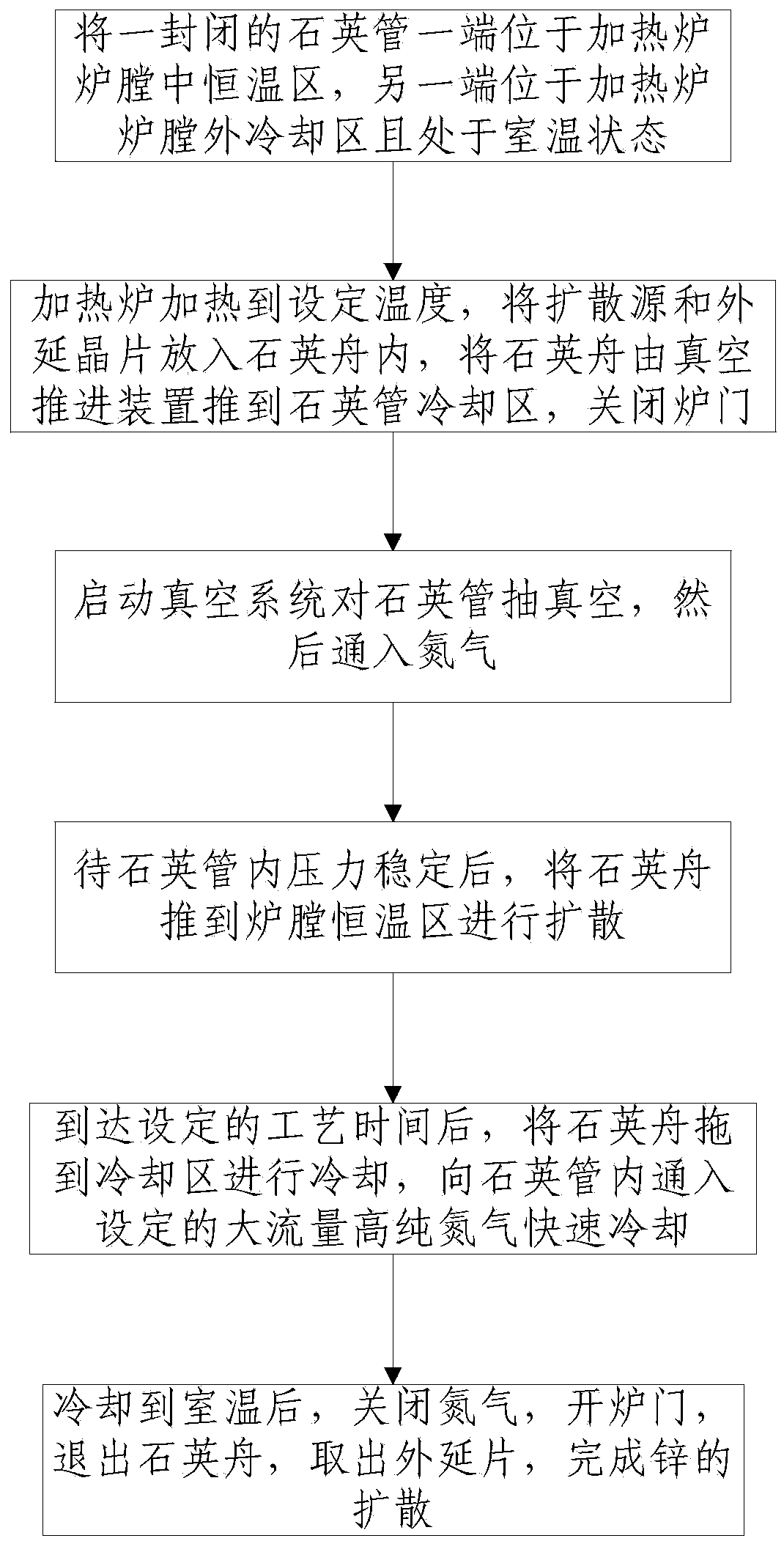

Zinc diffusion device and diffusion method thereof in manufacturing of photoelectric detector

ActiveCN103151248ADiffusion temperature fluctuations are smallSuitable for diffusion process requirementsSemiconductor/solid-state device manufacturingDiffusion methodsSlag

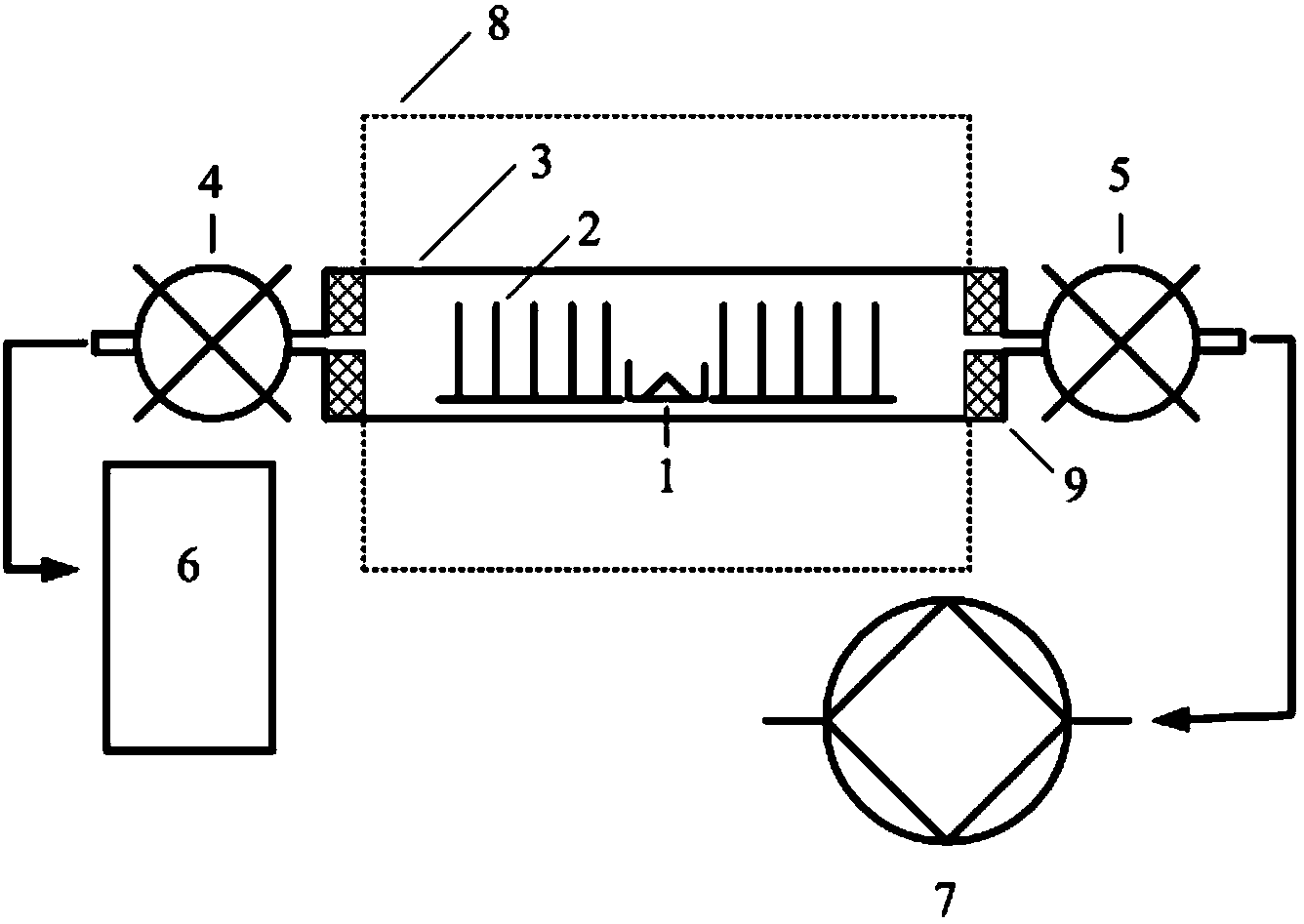

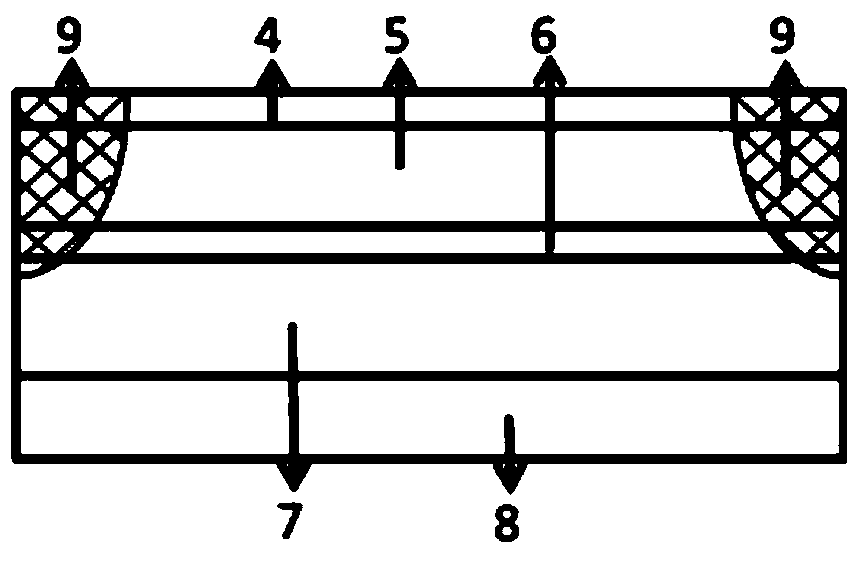

The invention discloses a zinc diffusion device and a diffusion method thereof in manufacturing of a photoelectric detector. The device comprises a heating furnace, a quartz tube, a gas control system, a vacuum system, a quartz boat and a vacuum pushing device, wherein both ends of the quartz tube are sealed, the quartz boat is used for accommodating a diffusion source and an epitaxial wafer to be diffused, the vacuum pushing device is used for pushing the quartz boat into the quartz tube, one end of the quartz tube is positioned in a hearth of the heating furnace and is used as a constant-temperature area, the other end of the quartz tube is positioned on the outside of the hearth of the heating furnace, is used as a cooling area and is maintained in a room temperature state, the gas control system is used for filling nitrogen into the quartz tube, and the vacuum system is used for vacuumizing the quartz tube by a vacuum pipeline. The method has the advantages that the risk of using an oxy-hydrogen flame to seal the quartz tube in the traditional tube-closing diffusion process is avoided, the pollution at the epitaxial wafer by sucking residual slag into the quartz tube at the negative pressure in the quartz tube when the quartz tube is opened is avoided, and the problems of nonuniform temperature, difficult control of diffusion depth and overlong cooling time in the traditional tube-opening diffusion process are solved. The method is favorable for batch diffusion.

Owner:WUHAN TELECOMM DEVICES

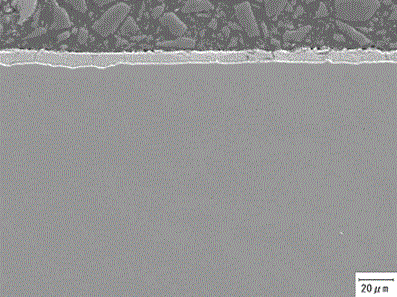

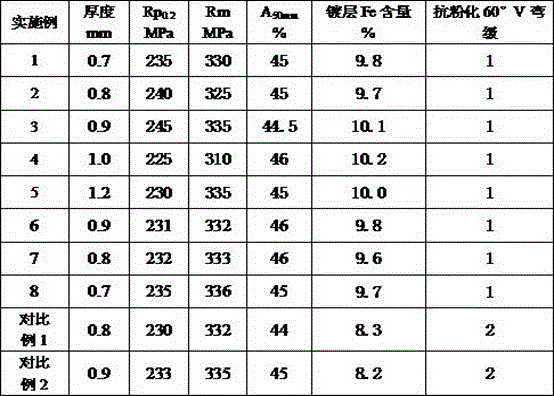

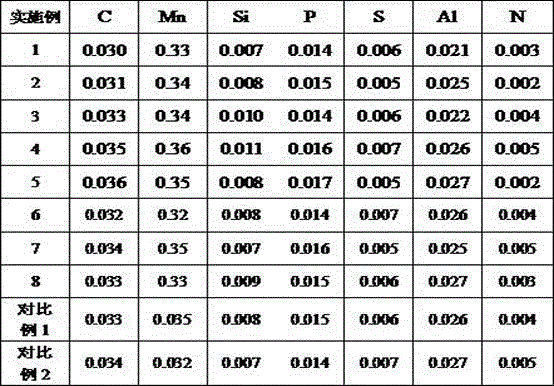

Iron-zinc coated steel plate with yield strength being 210 MPa and production method thereof

ActiveCN106086633AGuaranteed use of mechanicsDense surface structureHot-dipping/immersion processesSolid state diffusion coatingSheet steelChemical composition

An iron-zinc coated steel plate with the yield strength being 210 MPa comprises chemical compositions including, by weight, 0.03-0.04% of C, 0.007-0.015% of Si, 0.32-0.4% of Mn, less than or equal to 0.02% of P, less than or equal to 0.01% of S, 0.015-0.05% of Als and less than or equal to 0.05% of N. The production method comprises the production steps that continuous hot-dip galvanizing is conducted on a cold-rolled steel plate; the steel plate is sent to an iron-zinc diffusion treatment heating furnace by taking insulation measures; the galvanized steel plate is subjected to high-temperature zinc-iron diffusion treatment first and then low-temperature zinc-iron diffusion treatment; and the steel plate is cooled naturally to the roor temperature for standby application. By means of the production method, on the premise of guaranteeing the application mechanics of the steel plate, a galvanneal coating can be compact in surface structure and free of obvious microcrack defects, and zinc-iron grains on the surface of the coating are fine and uniform in size distribution. The coating is bound firmly to a steel base plate. The coating is not prone to pulverization and shedding during stamping forming.

Owner:武汉钢铁有限公司

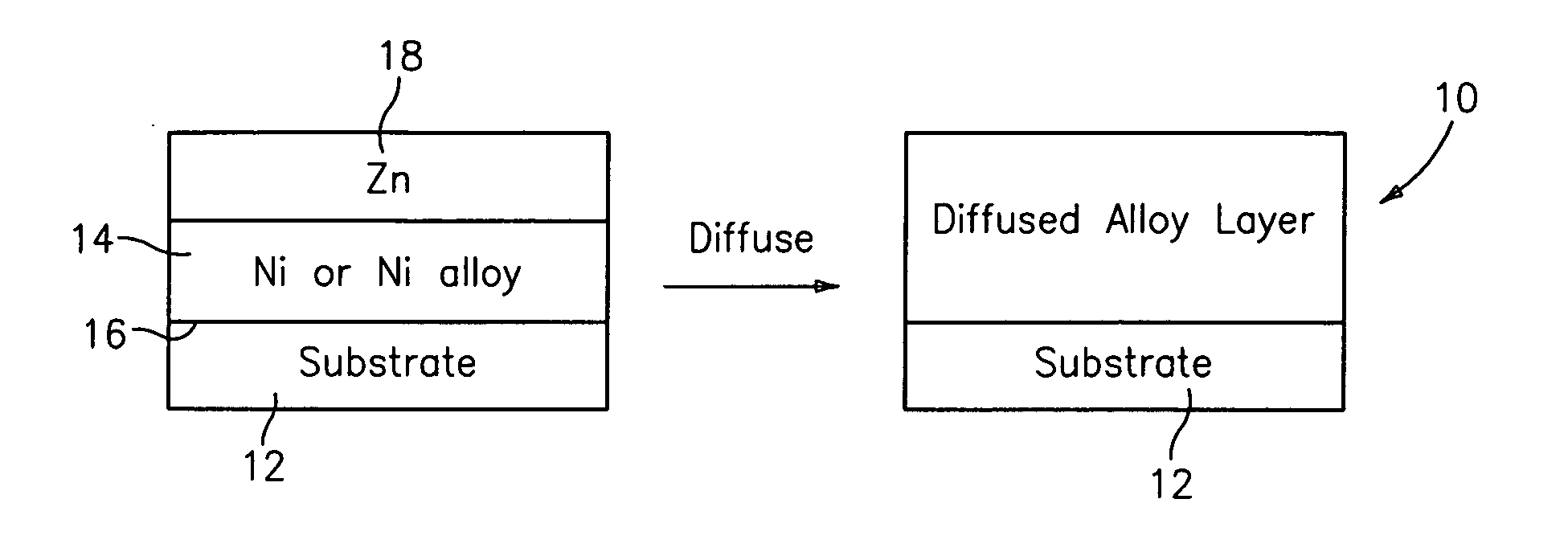

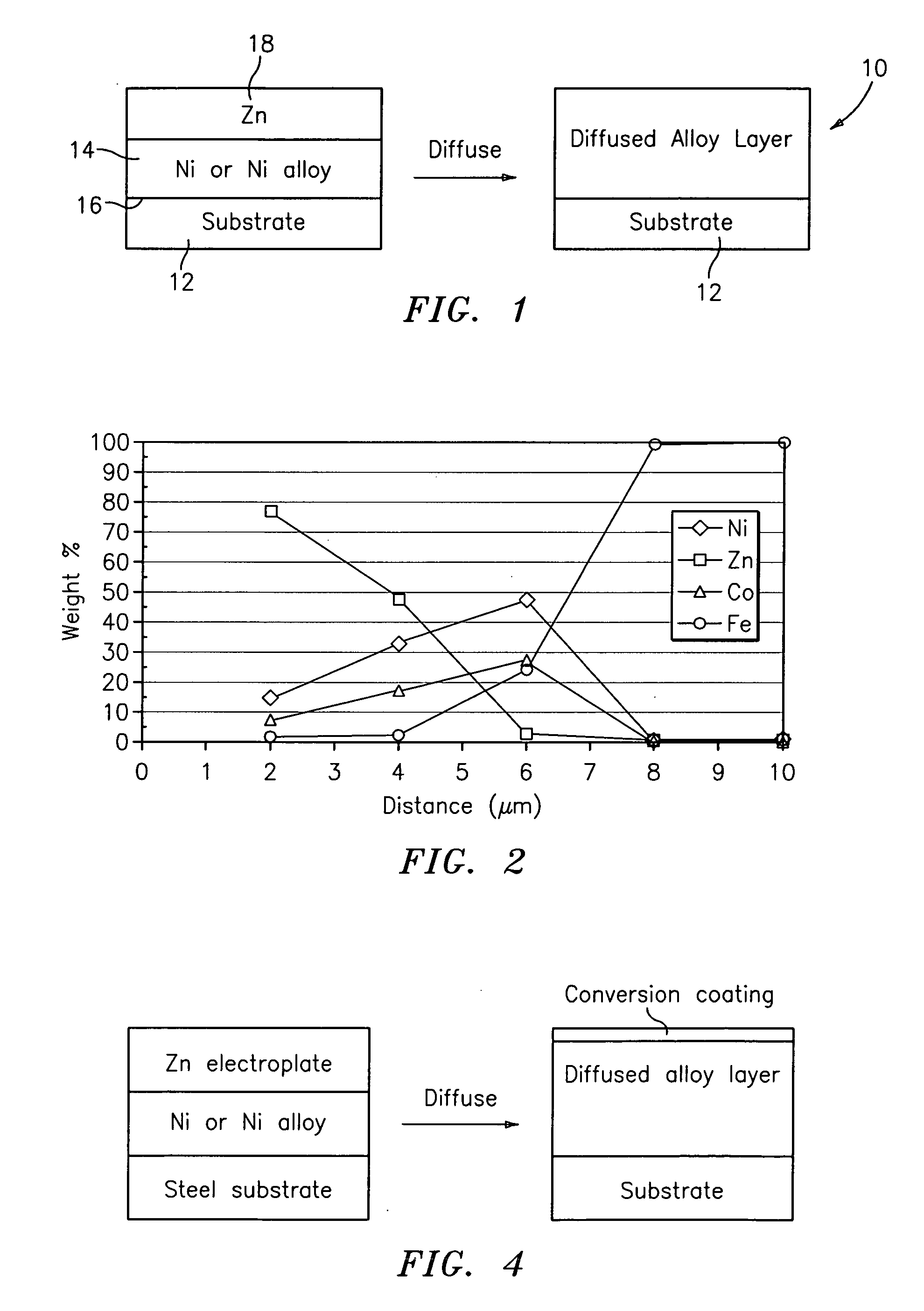

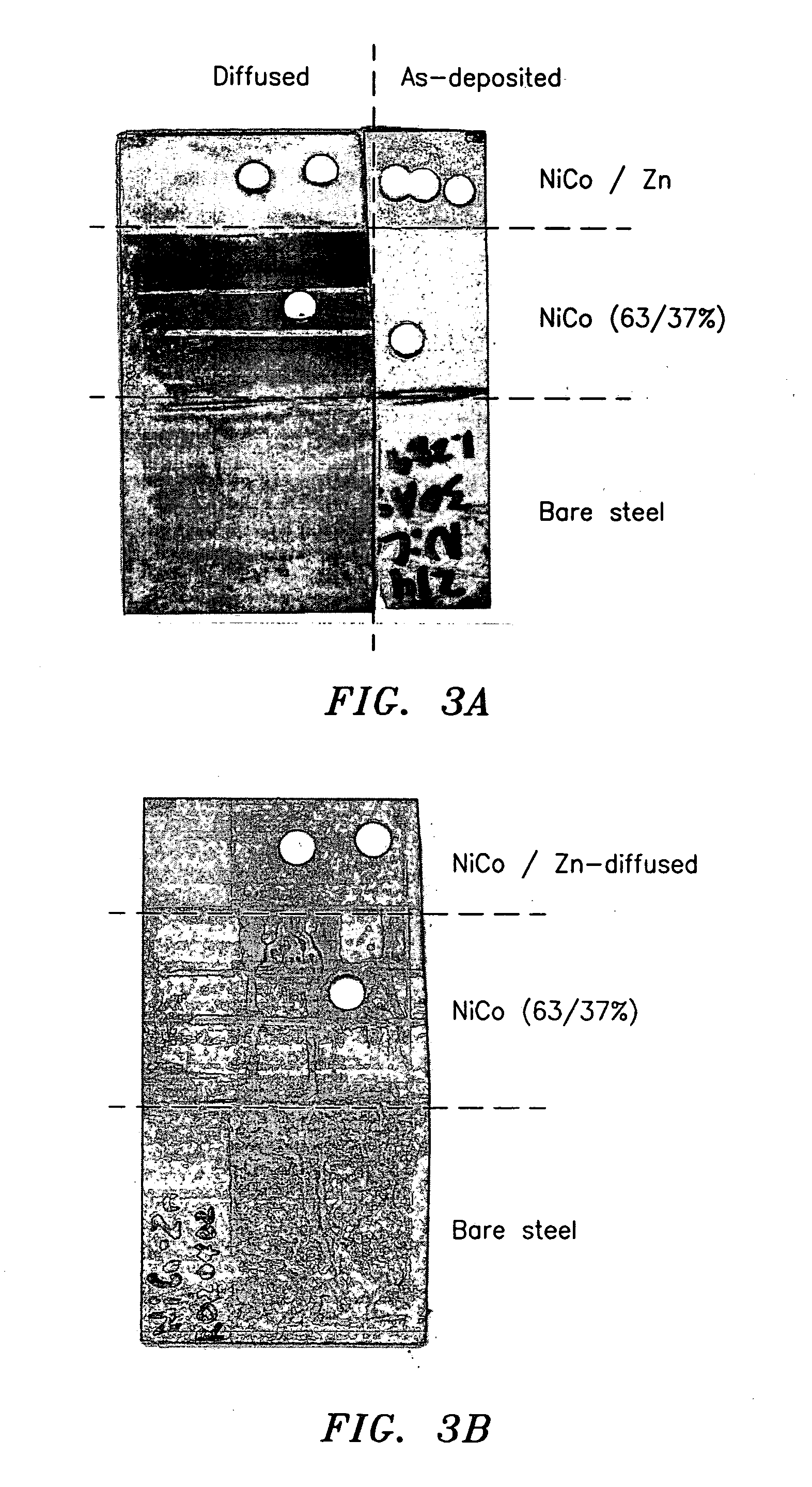

Zinc-diffused alloy coating for corrosion/heat protection

The present invention relates to a zinc-diffused nickel alloy coating for corrosion and heat protection and to a method for forming such a coating. The coating method broadly comprises the steps of forming a plain nickel or nickel alloy coating layer on a substrate, applying a layer of zinc over the nickel or nickel alloy coating layer, and thermally diffusing the zinc into the nickel alloy coating layer. The coating method may further comprise immersing the coated substrate in a phosphated trivalent chromium conversion solution either before or after the diffusing step. The substrate may be a component used in a gas turbine engine, which component is formed from a steel material.

Owner:RTX CORP

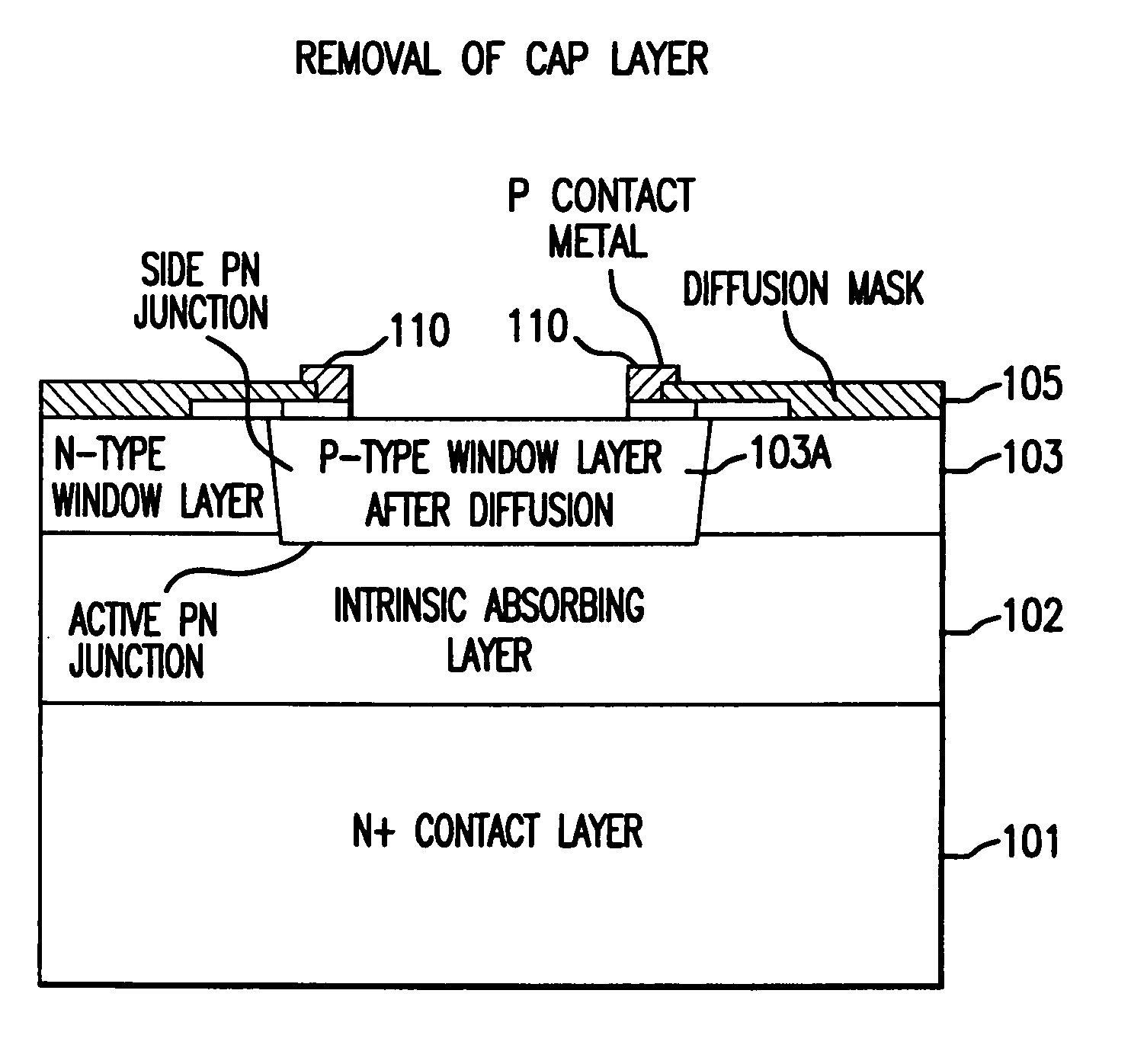

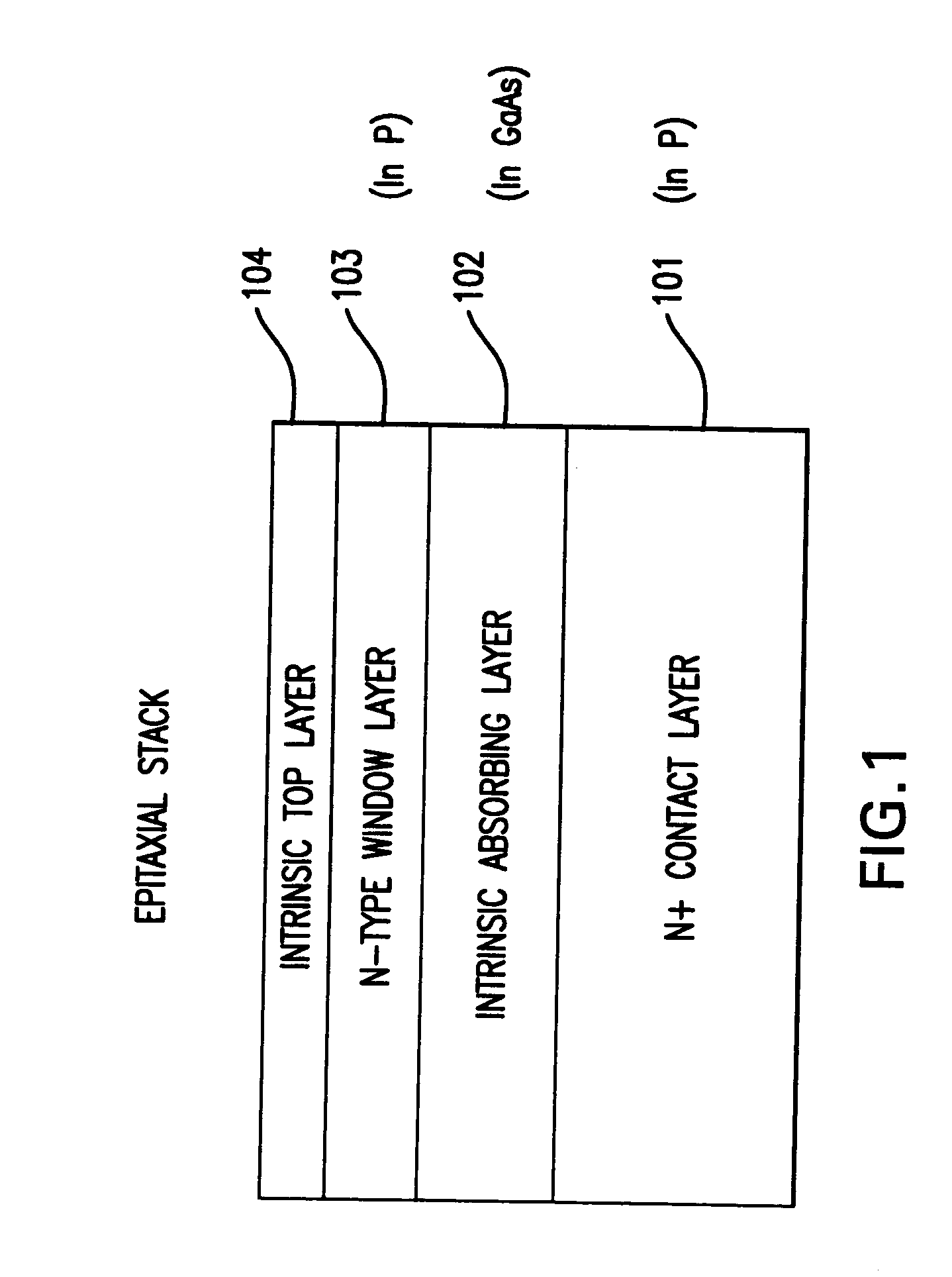

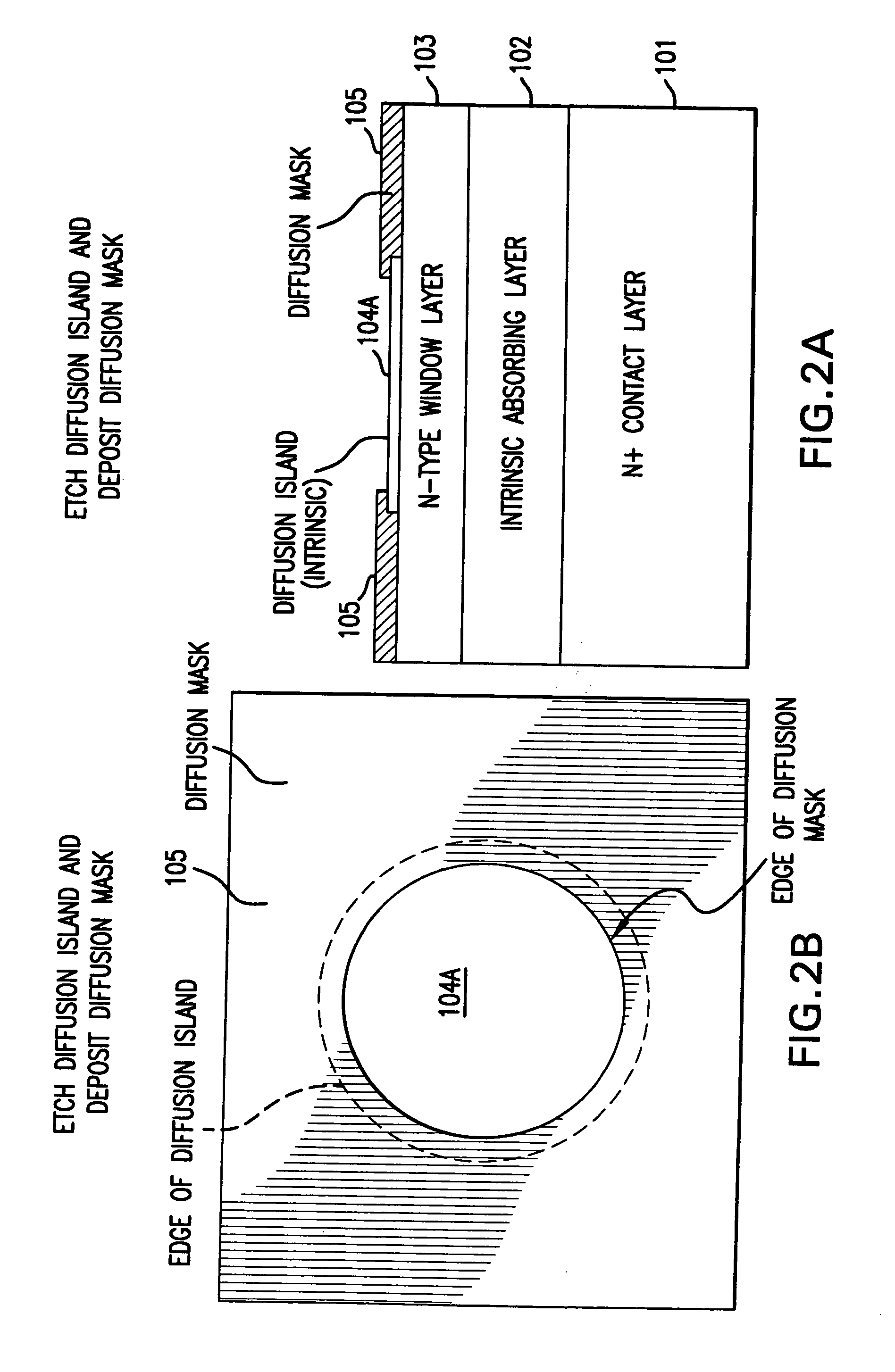

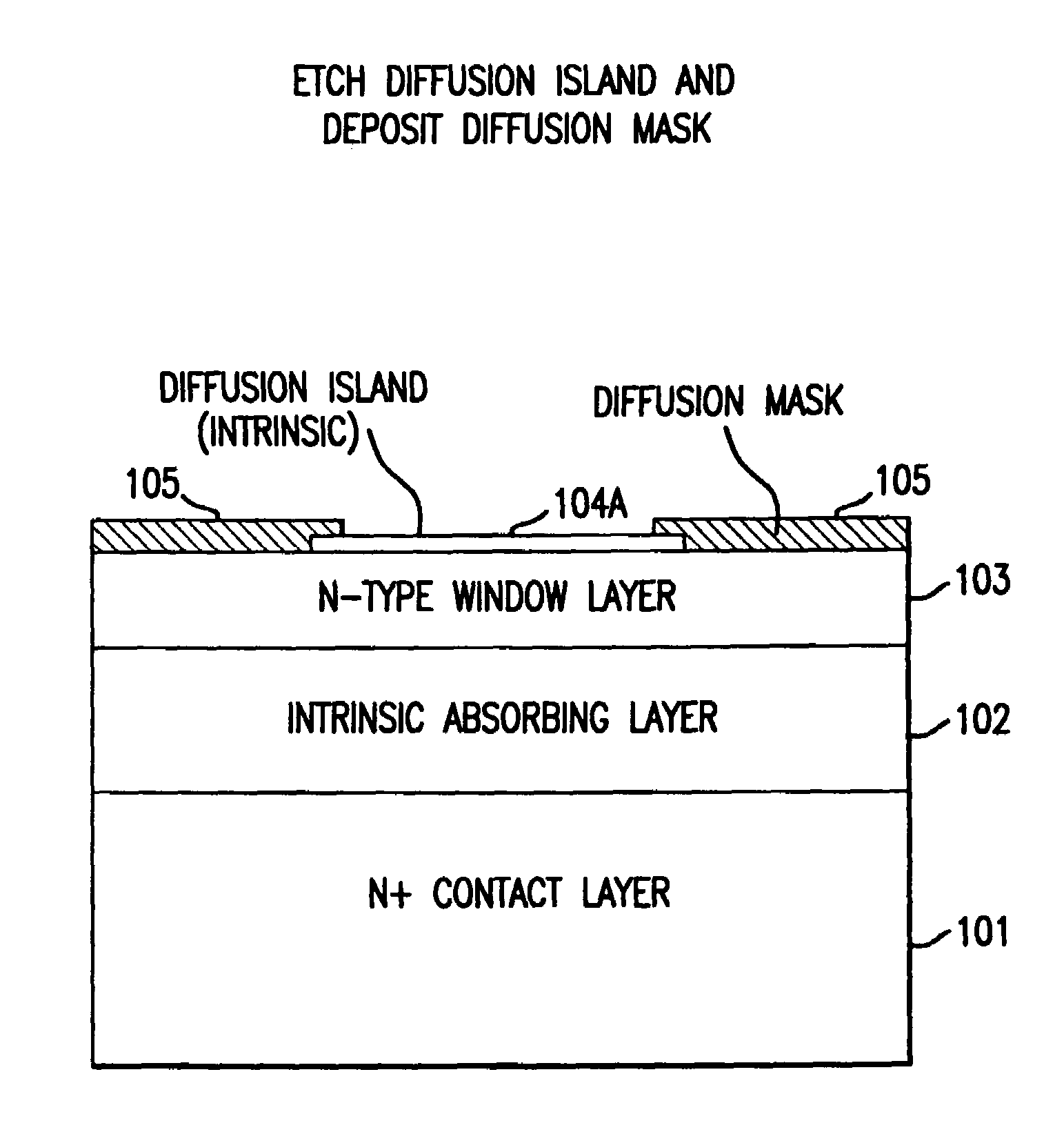

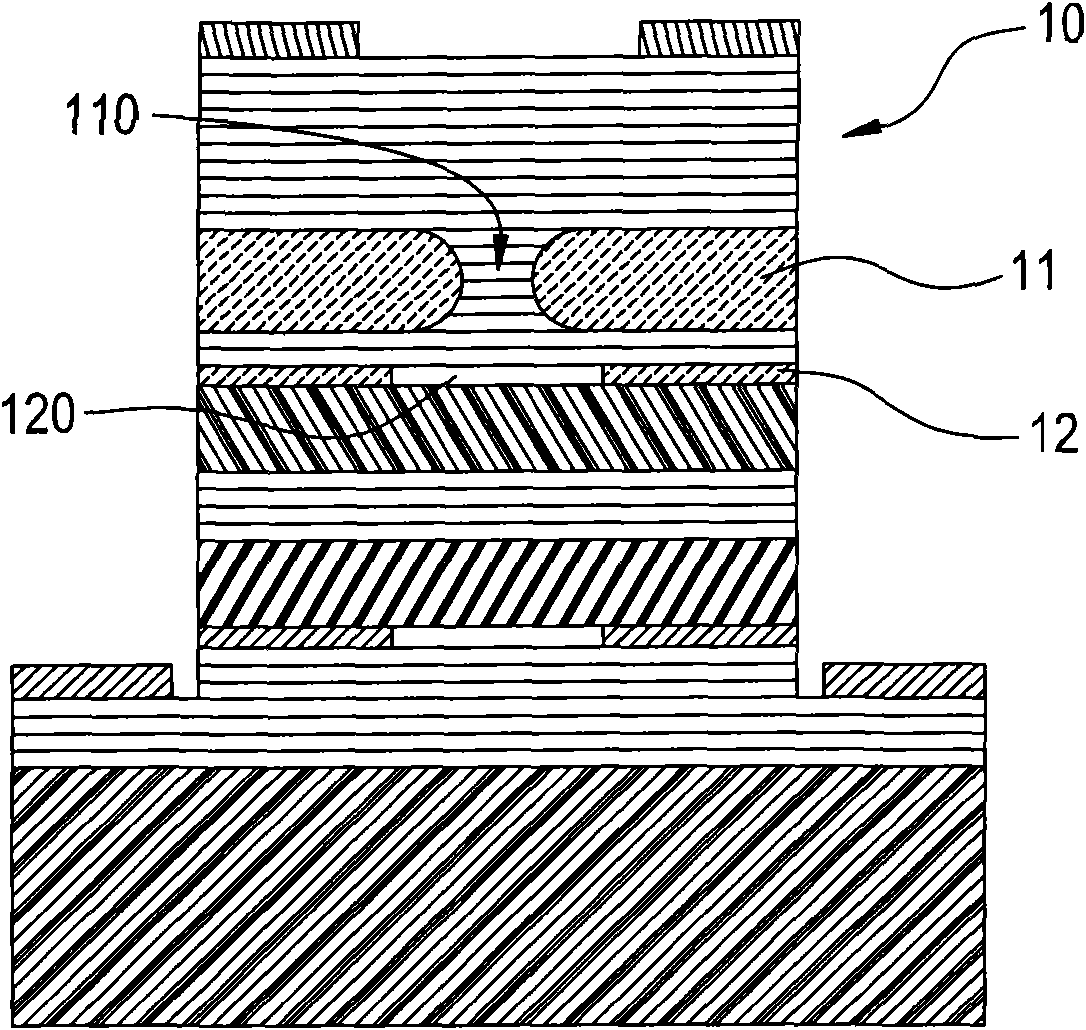

PIN diode structure with zinc diffusion region

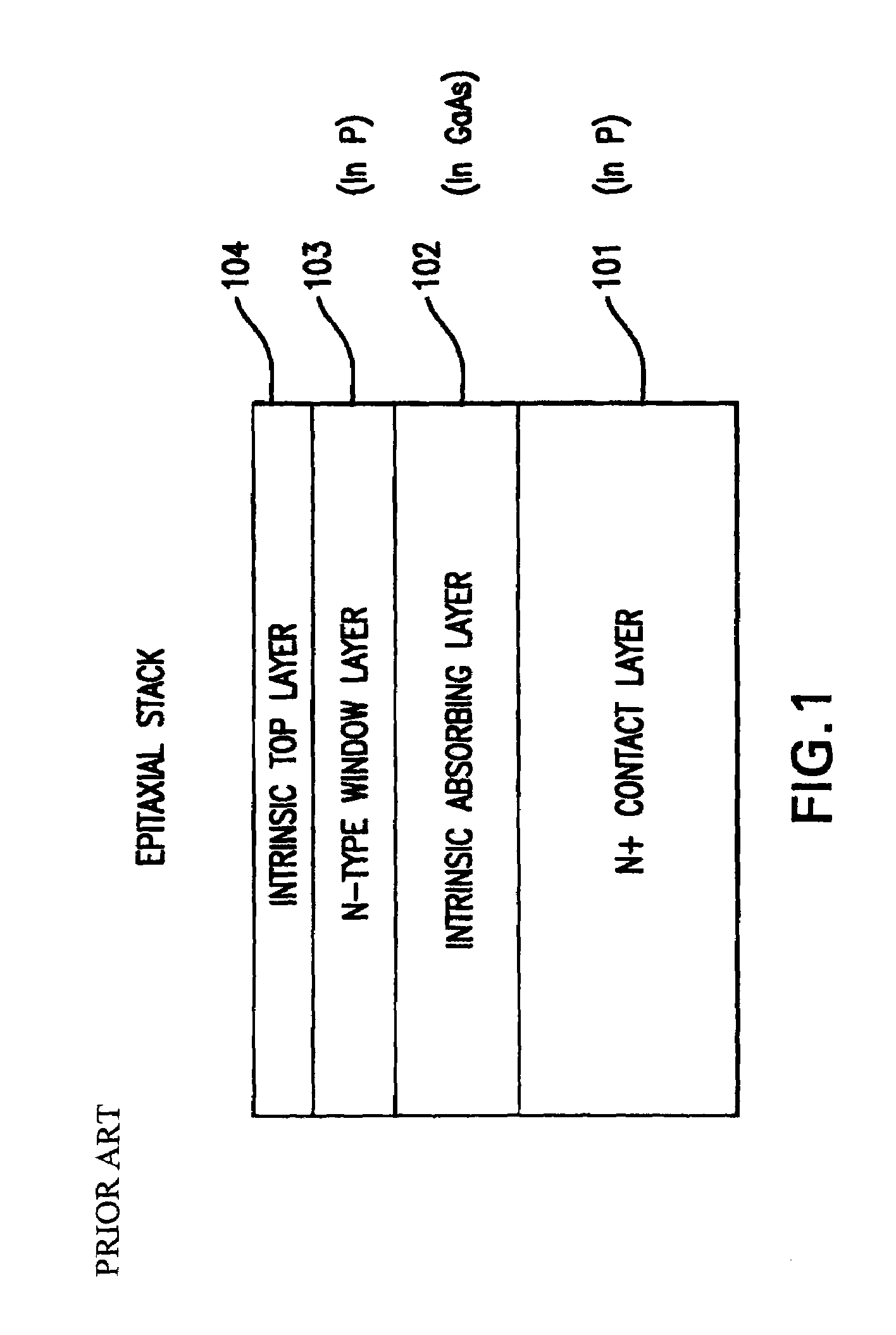

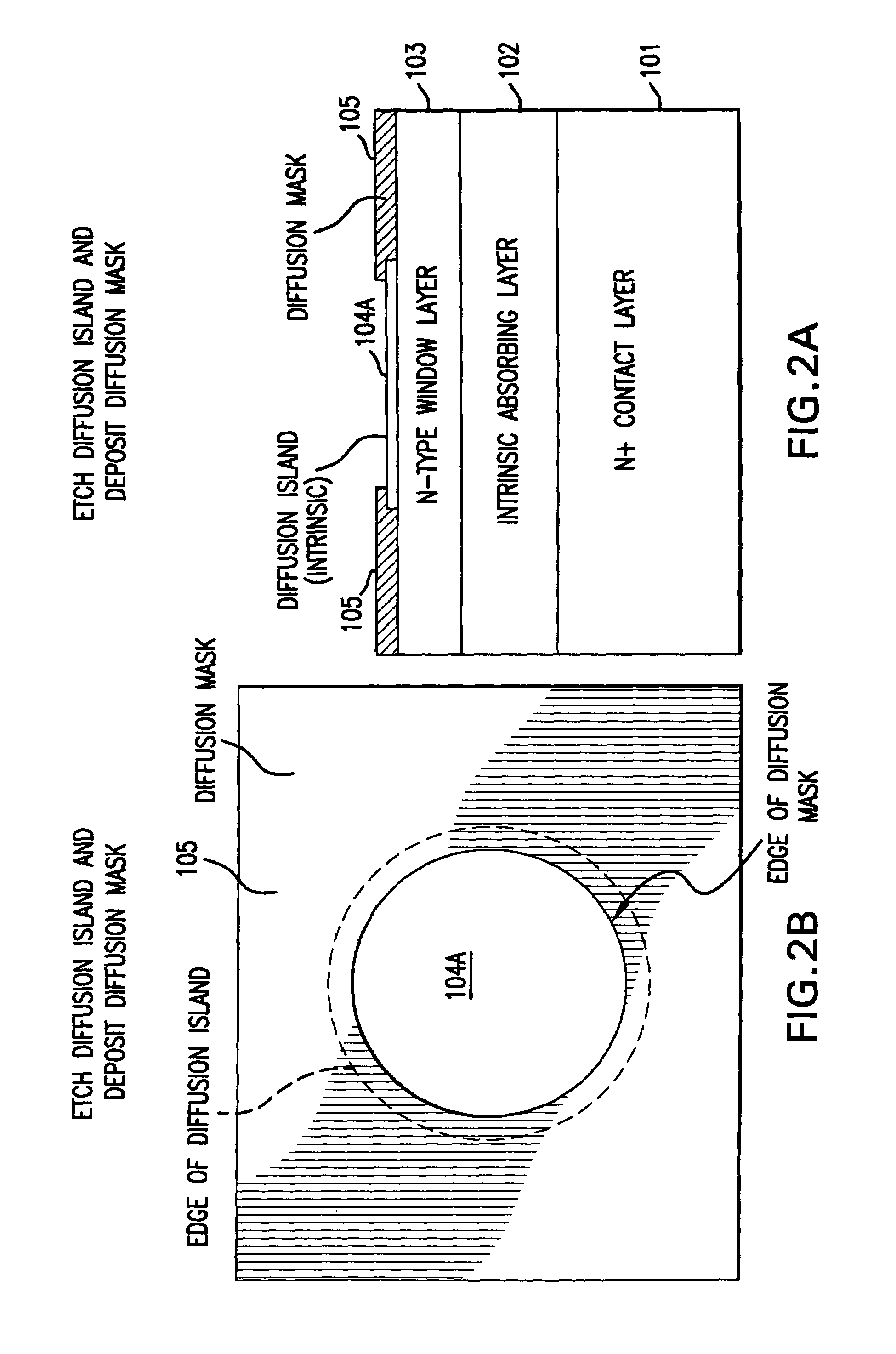

InactiveUS20060060933A1Improved semiconductor structureSolid-state devicesSemiconductor devicesDopantEngineering

A PIN photodiode having a substrate, a first type electrode layer disposed on the substrate, a first layer of intrinsic material disposed over a portion of the first-type electrode layer, a first type window layer disposed over said intrinsic layer. An island shaped region of intrinsic material is disposed over the window layer and a dielectric layer disposed over the island region and at least the peripheral portion of said island shaped region whereby an opening is formed in the island shaped region. A dopant is diffused through the opening so as to form a PN junction that extends into the first layer of intrinsic material.

Owner:EMCORE INC

Environment-friendly multi-alloy carbonitriding agent and multi-alloy diffusion corrosion-resistant layer production process

InactiveCN111926286AExtension of timeImprove wear resistanceSolid state diffusion coatingSurface layerCarbonization

The invention belongs to the technical field of metal corrosion-resistant treatment, and specifically discloses an environment-friendly multi-alloy carbonitriding agent and a multi-alloy diffusion corrosion-resistant layer production process. The environment-friendly multi-alloy carbonitriding agent comprises an infiltrating agent, a filling agent and an activating agent, wherein the infiltratingagent is prepared from zinc-containing multi-alloy metal powder; the filling agent is made of metal; and the filling agent is granular or flaky. The metal filling agent is high in wear resistance andmore in heat accumulation, and can be used repeatedly for preventing dust pollution. The activating agent is prepared from ammonium chloride or urea. The multi-alloy diffusion corrosion-resistant layer production process adopts the environment-friendly multi-alloy carbonitriding agent, and specifically comprises workpiece classification, carbonization oil removal, shot blasting rust removal and zinc impregnation to obtain a workpiece of which the surface layer is a multi-alloy carbonitriding agent diffusion corrosion-resistant layer, so that the salt spray corrosion resistance performance andduration of a zinc diffusion layer are improved and prolonged, and the corrosion resistance of the workpiece is enhanced.

Owner:LUOYANG XINYIDA IND INSTALLATIONS CO LTD

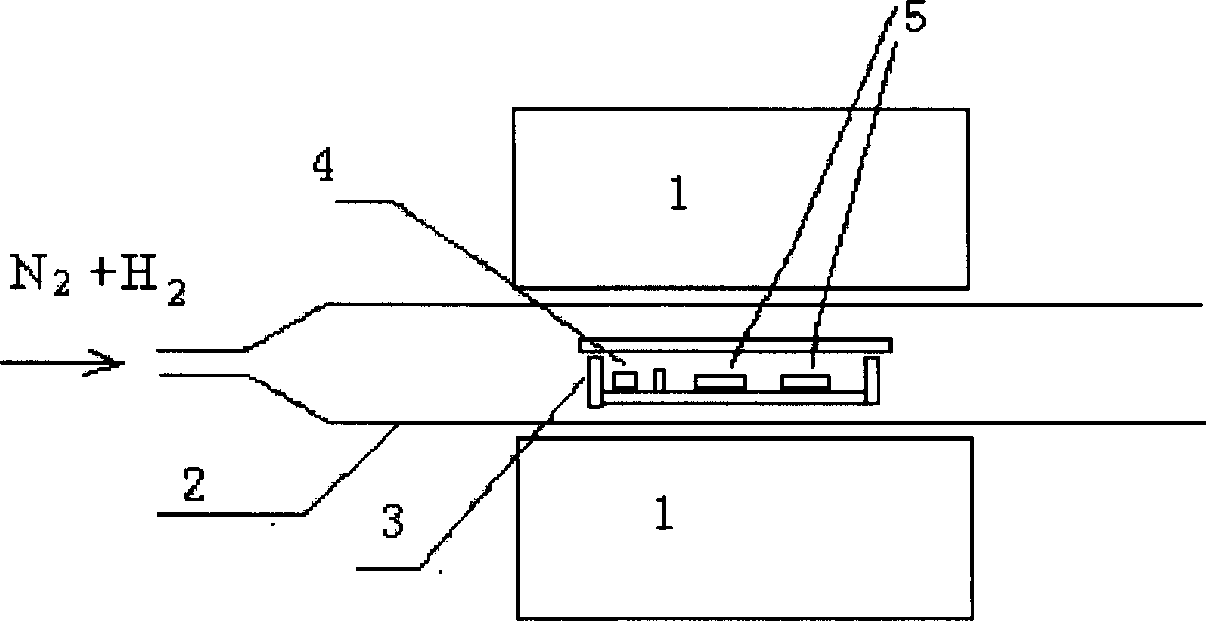

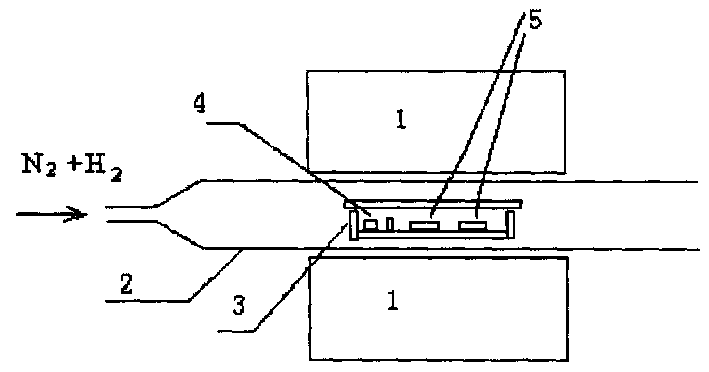

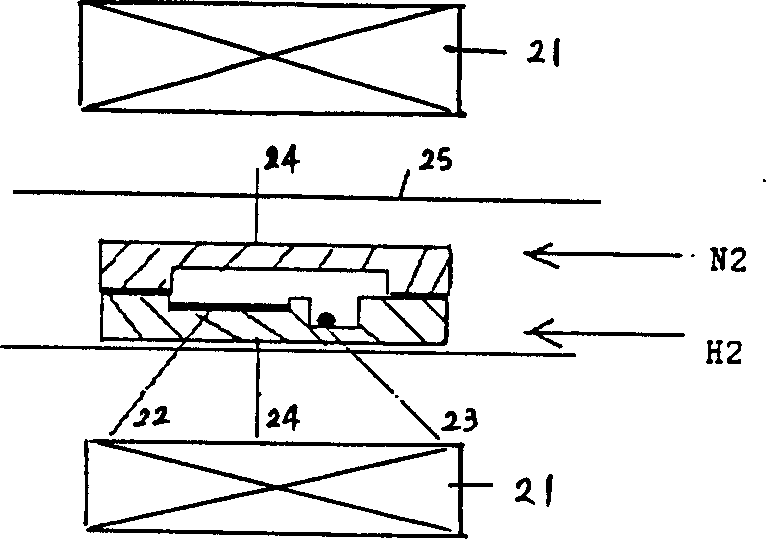

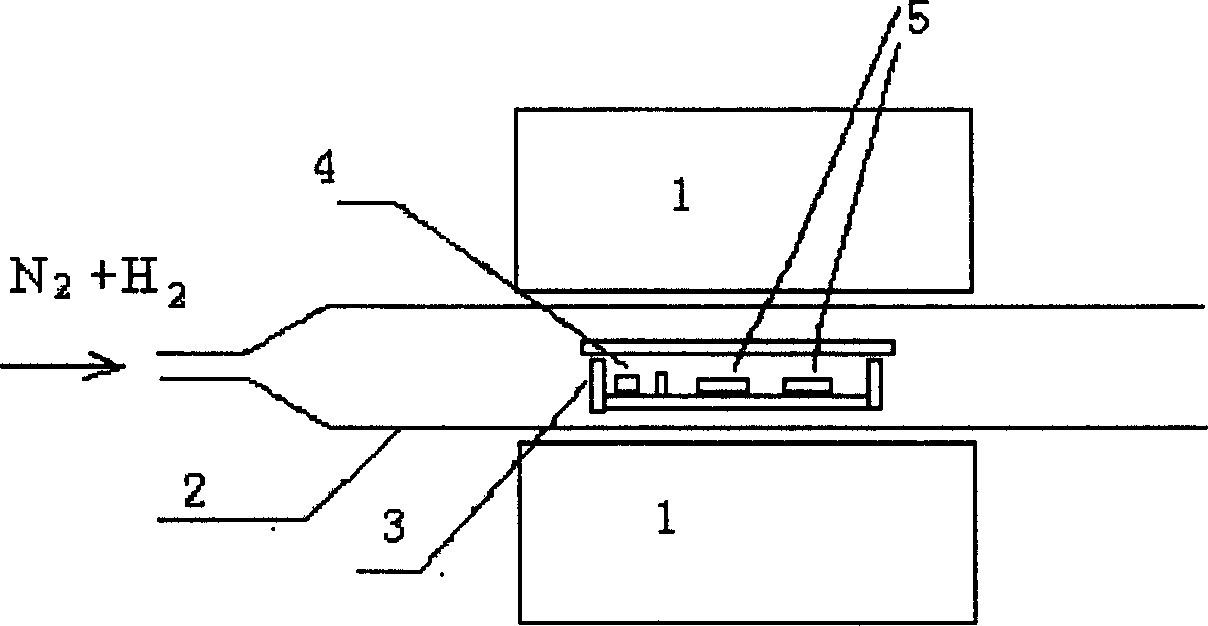

Open tube zinc diffusing method for producing indium-gallium-arsenic photoelectric detector

InactiveCN1409379ADiffusion process is simpleEasy to operateFinal product manufactureSemiconductor/solid-state device manufacturingIndiumShielding gas

This invention discloses an open tube zinc diffusion method for the production of In-Ga-As photo-electric detectors relating to the diffusion technique of semiconductor photoelectric apparatus. The method includes applying a structure of open tubew diffusion quartz tube structure to intake the protecting gases of hydrogen and nitrogen, and putting zinc and semiconductor wafers into a carbon diffusion boat to carry out high temperature diffusion under normal pressure, and finishing the zinc diffusion technique of the semiconductor wafer. This invention has uniform and repeated diffusion, result, good property of junction with simple production technique and dimenision of semiconductor wafer can be increased along with the enlarging of the diffusion furnace, and the diffusion boat and the source can be used repeatedly.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

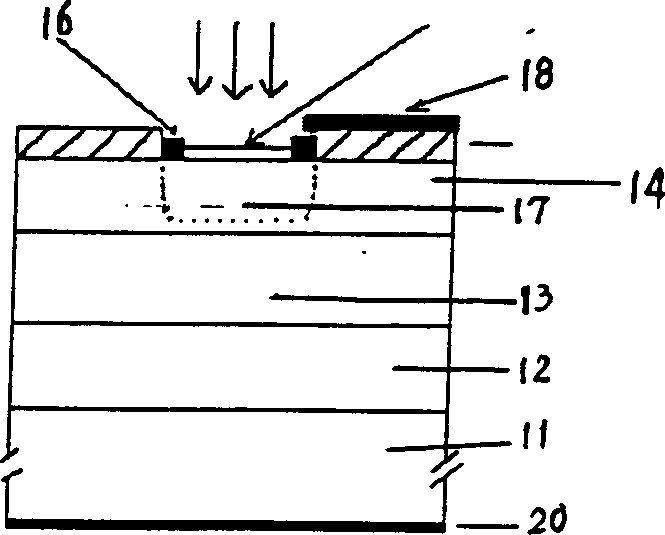

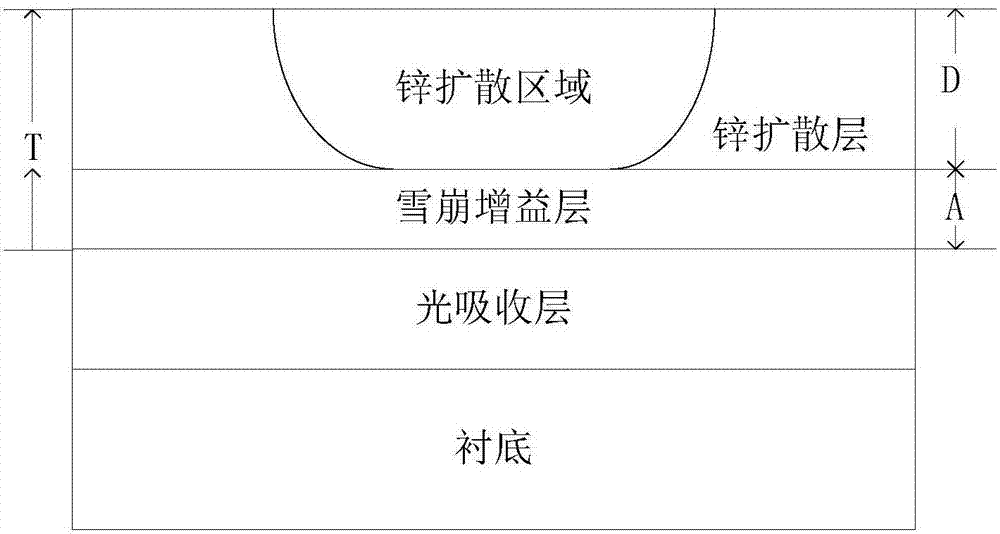

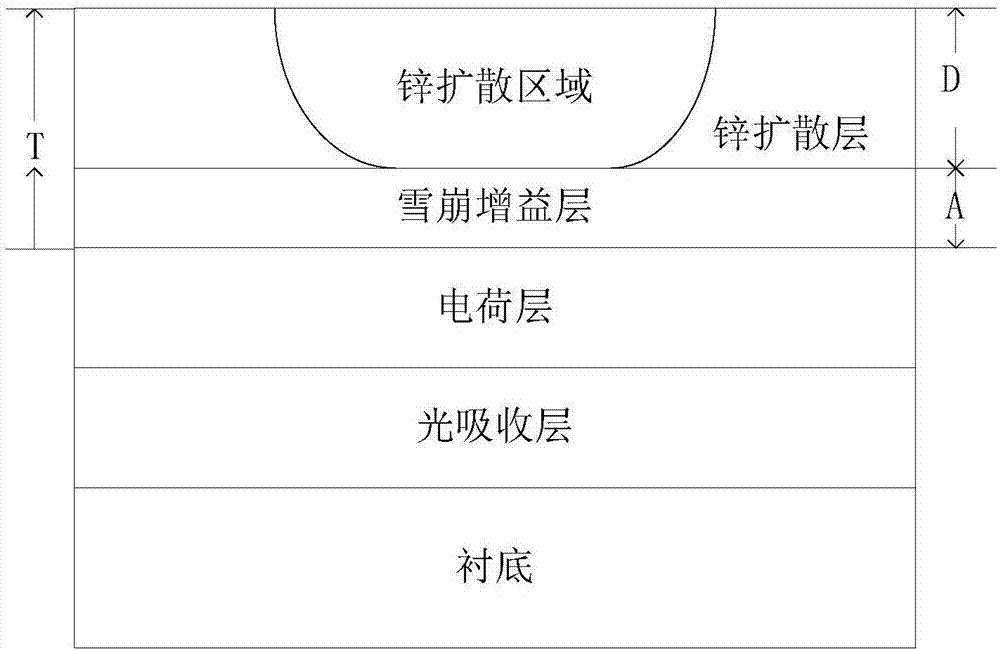

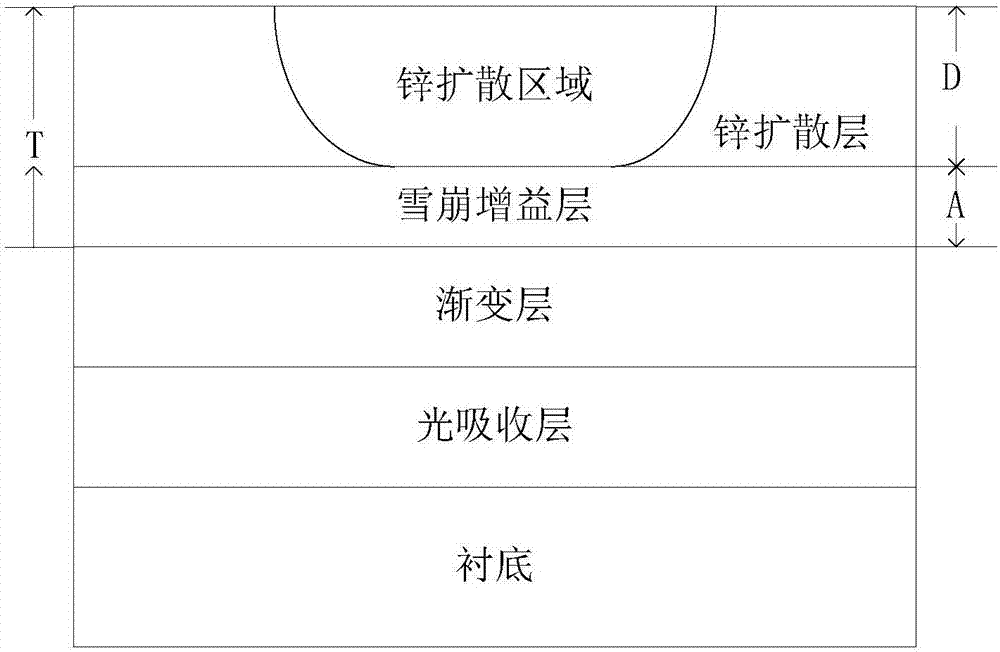

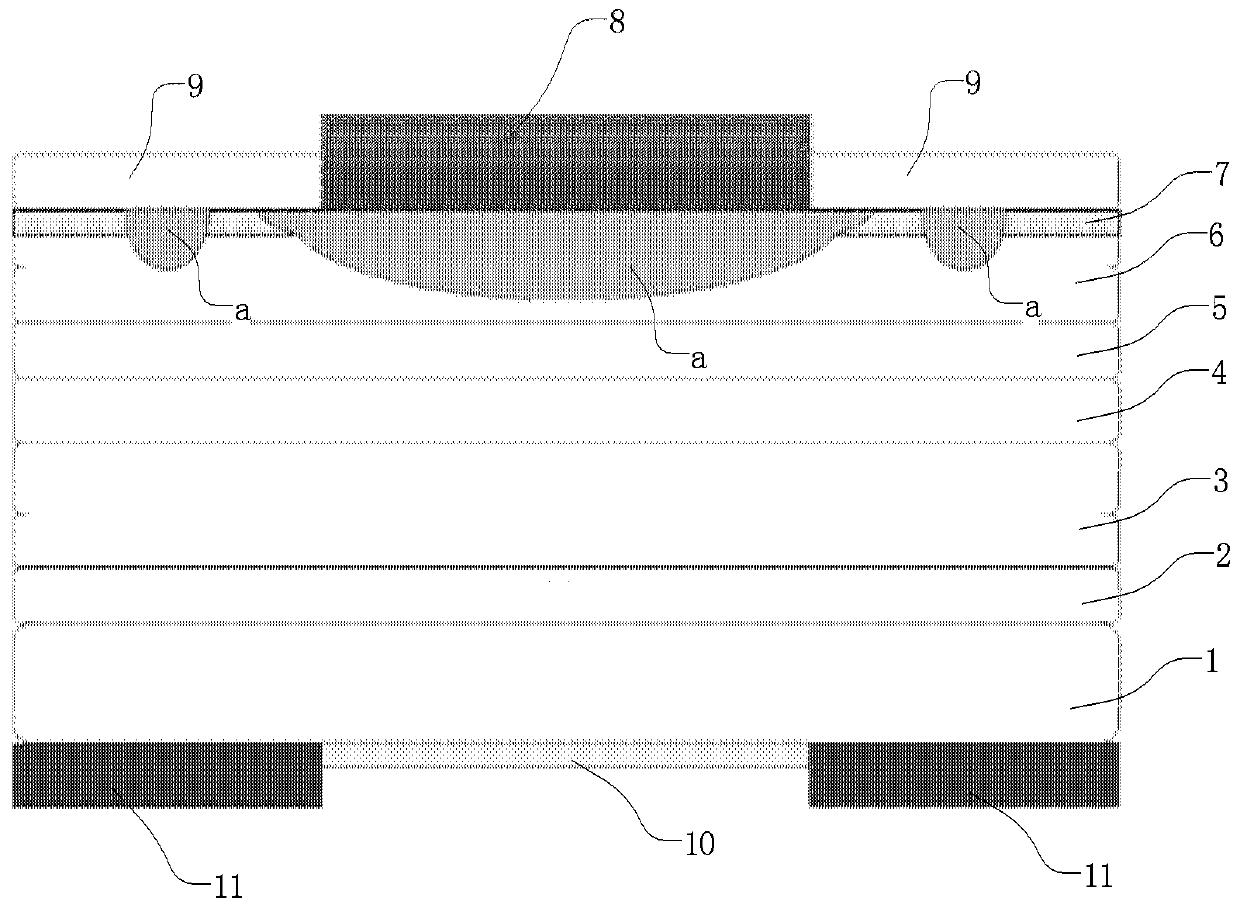

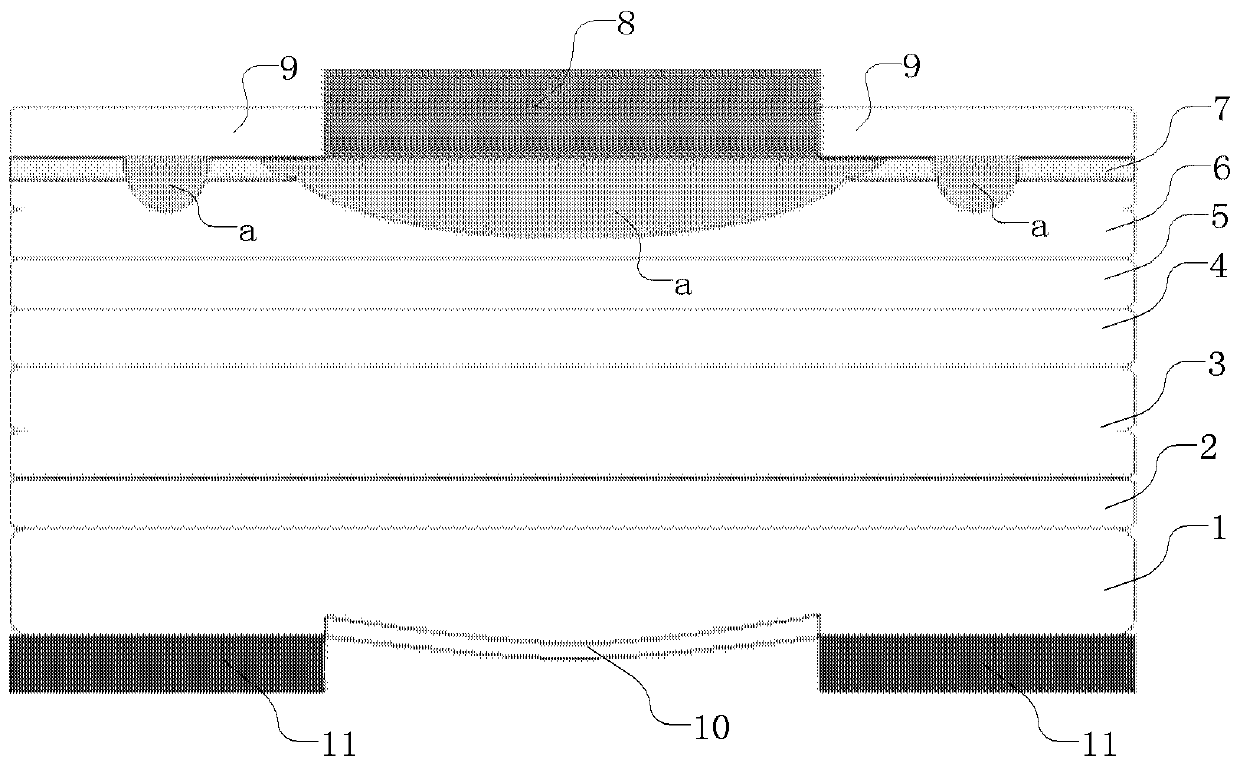

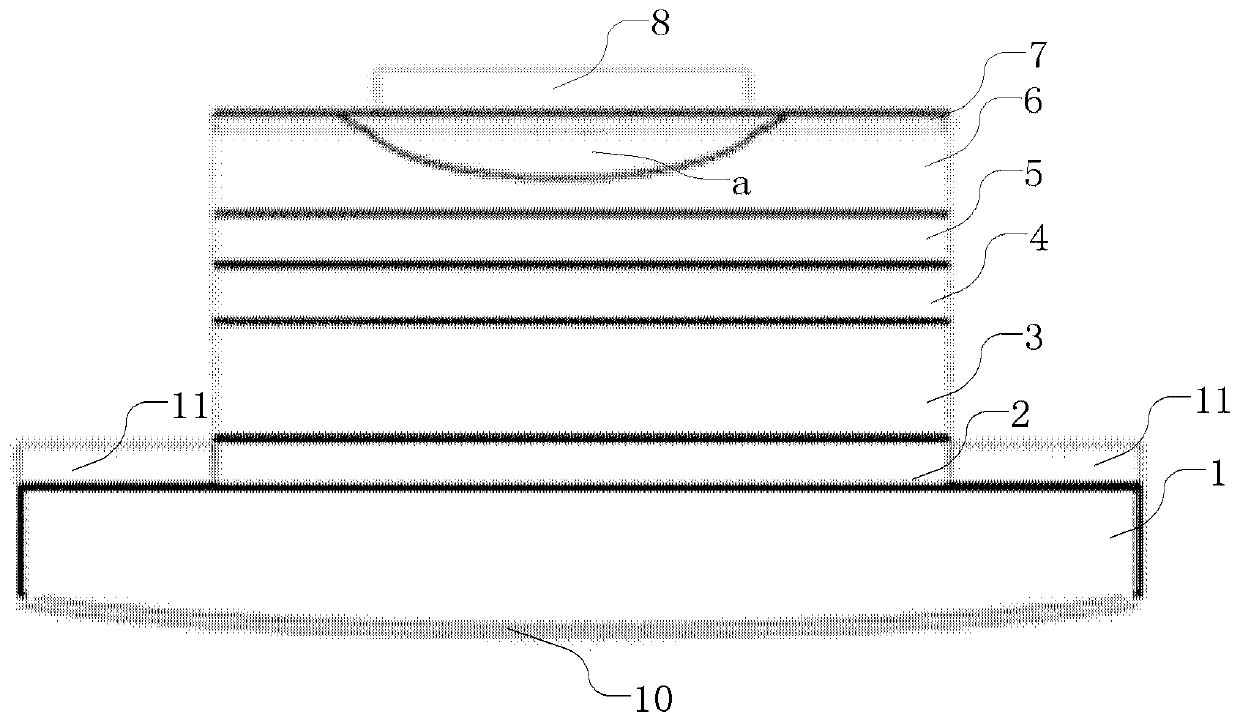

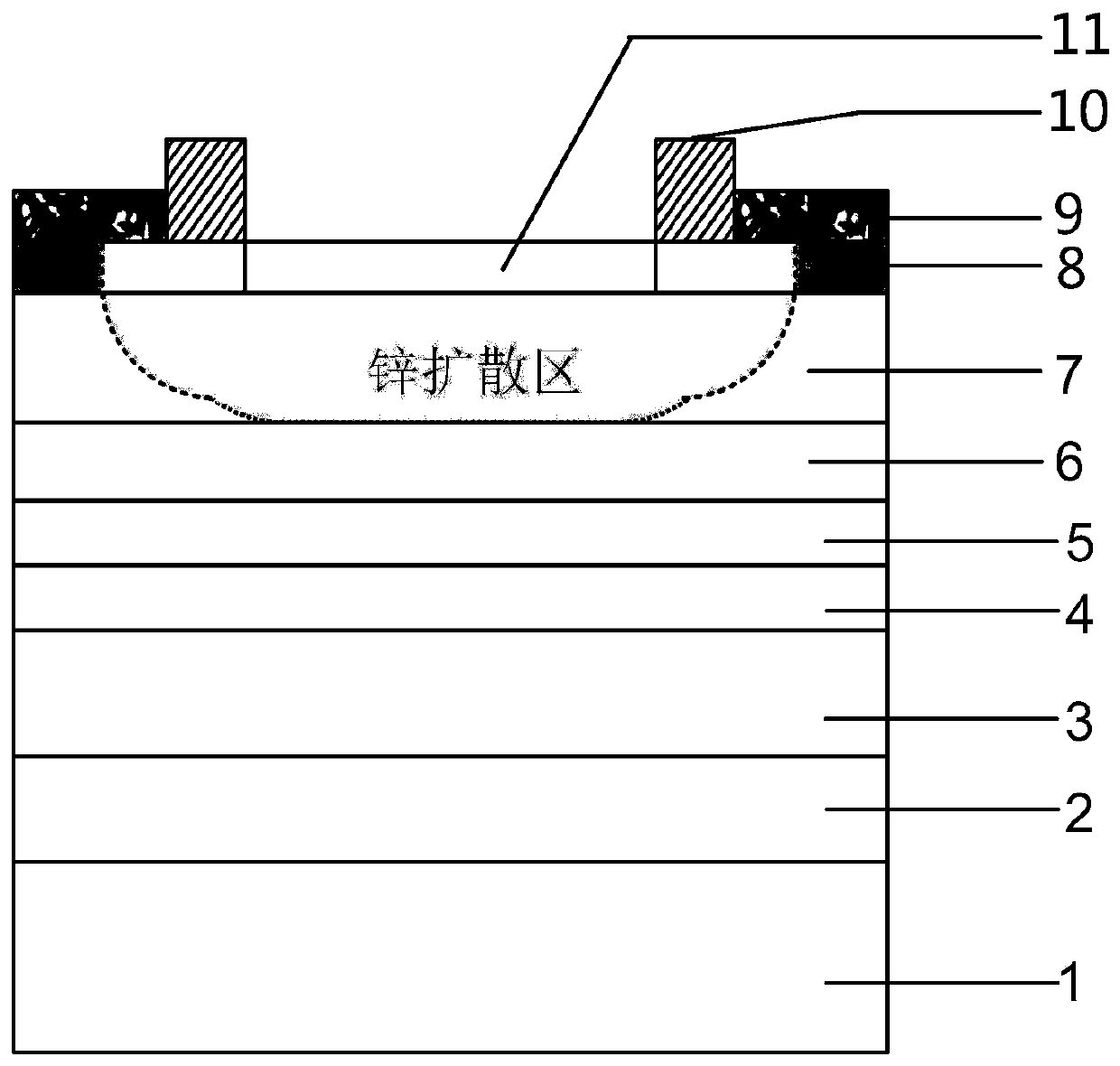

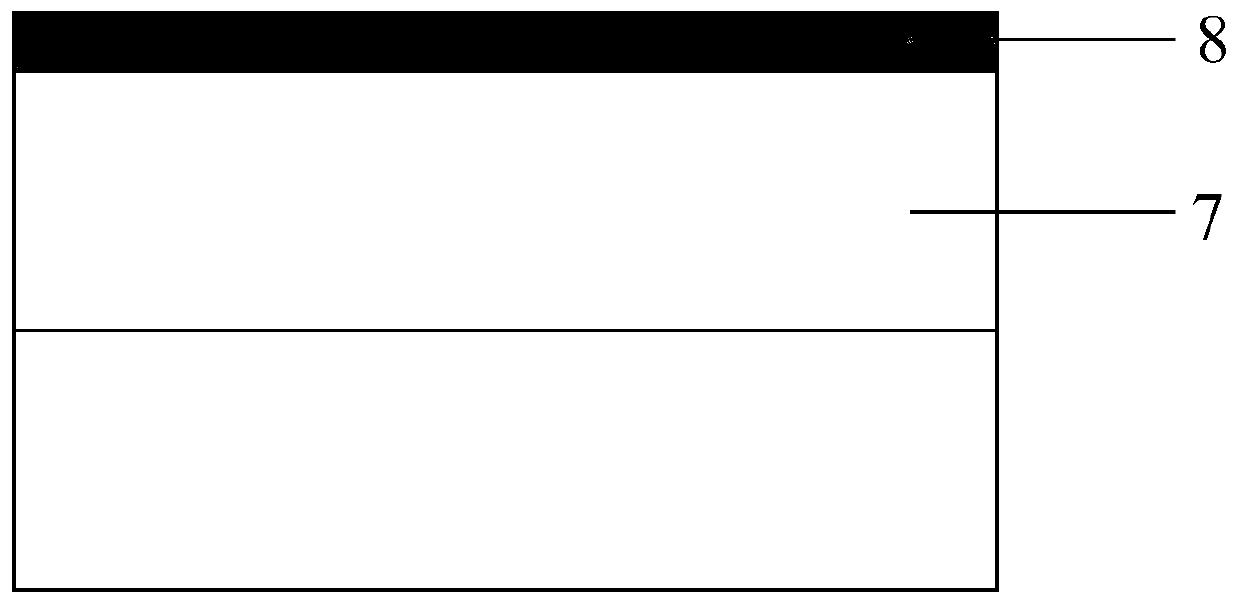

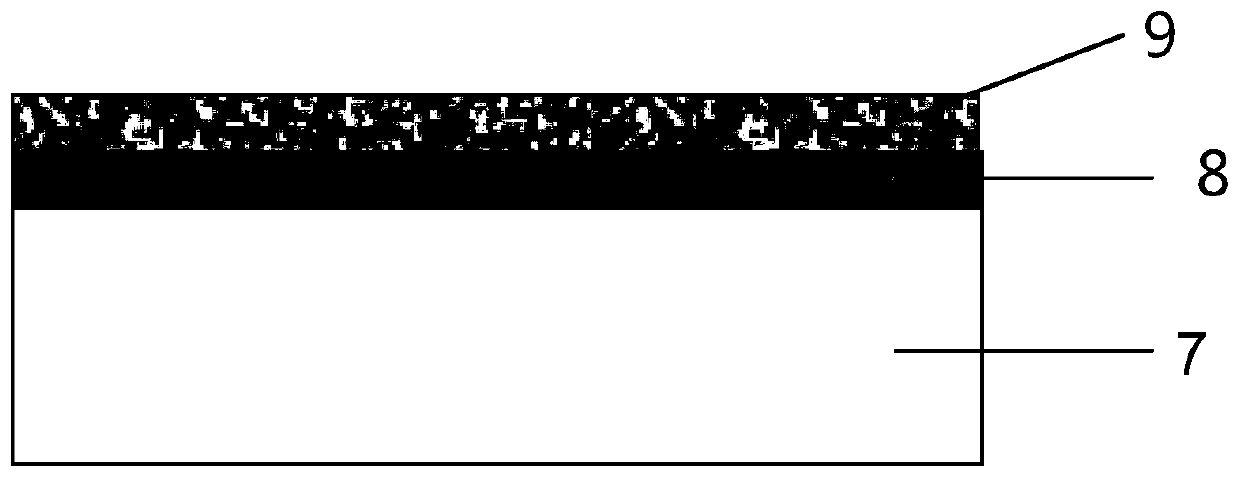

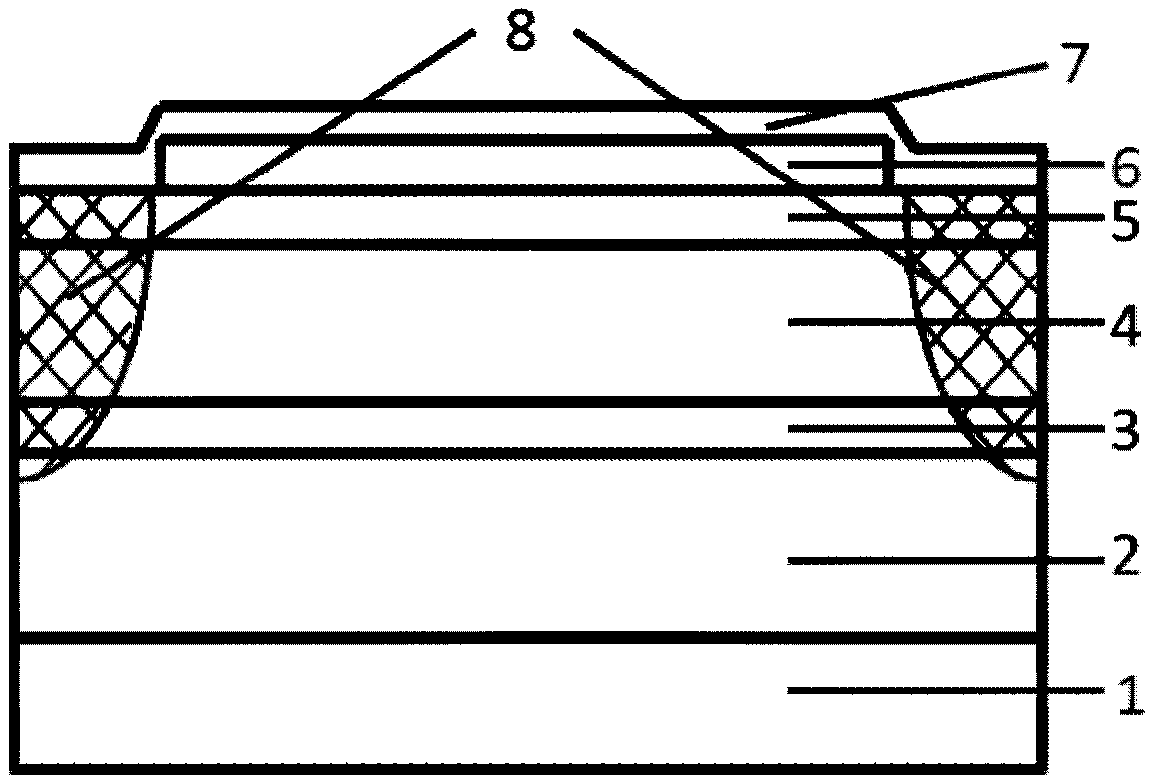

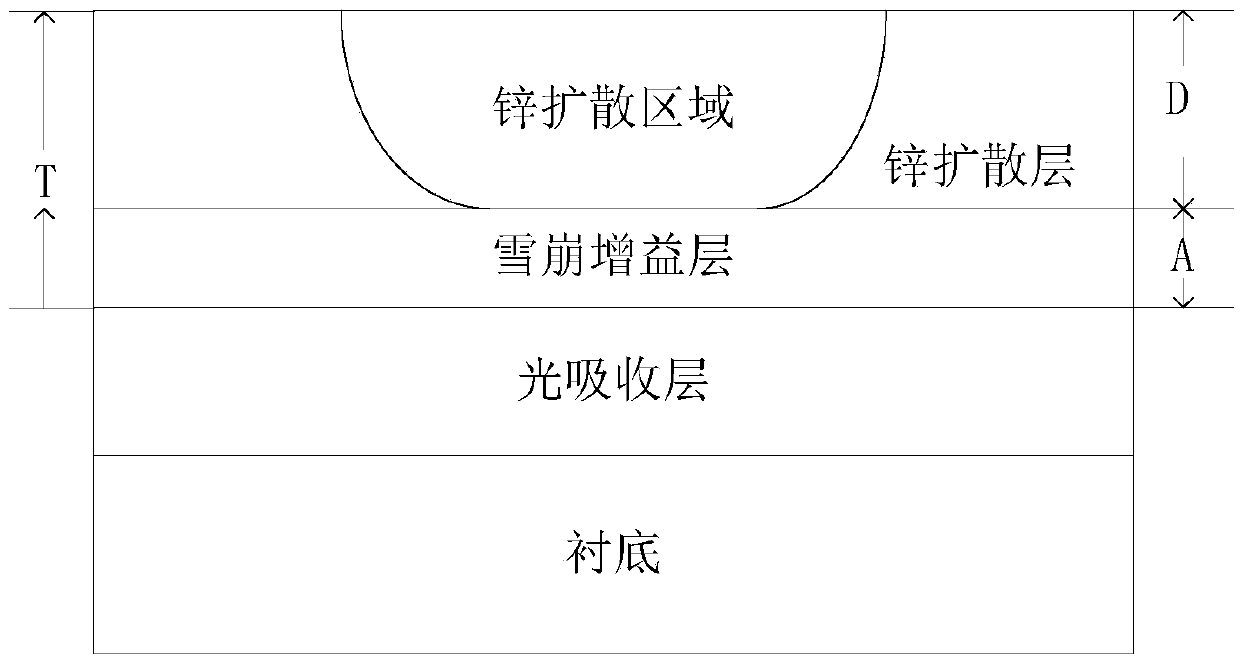

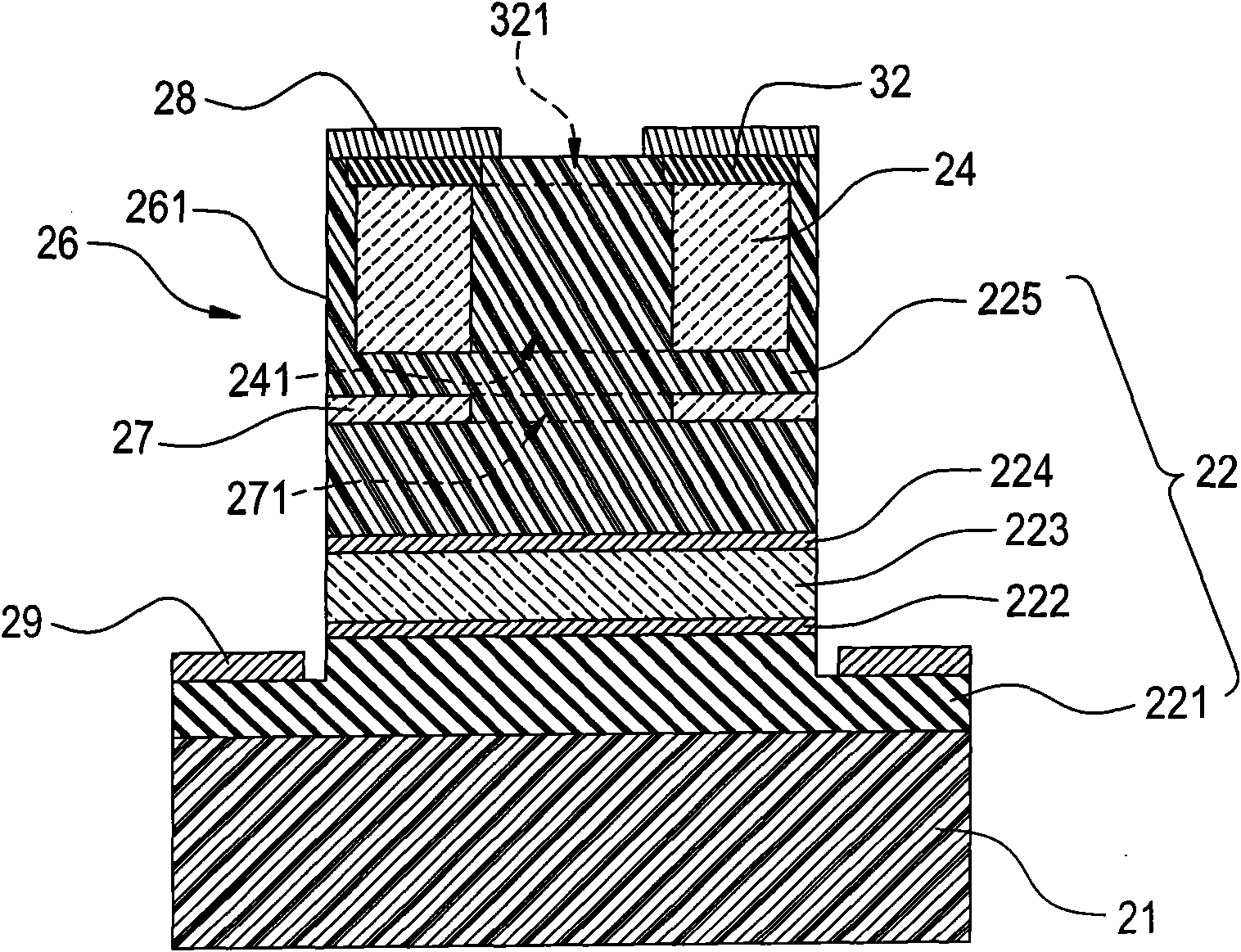

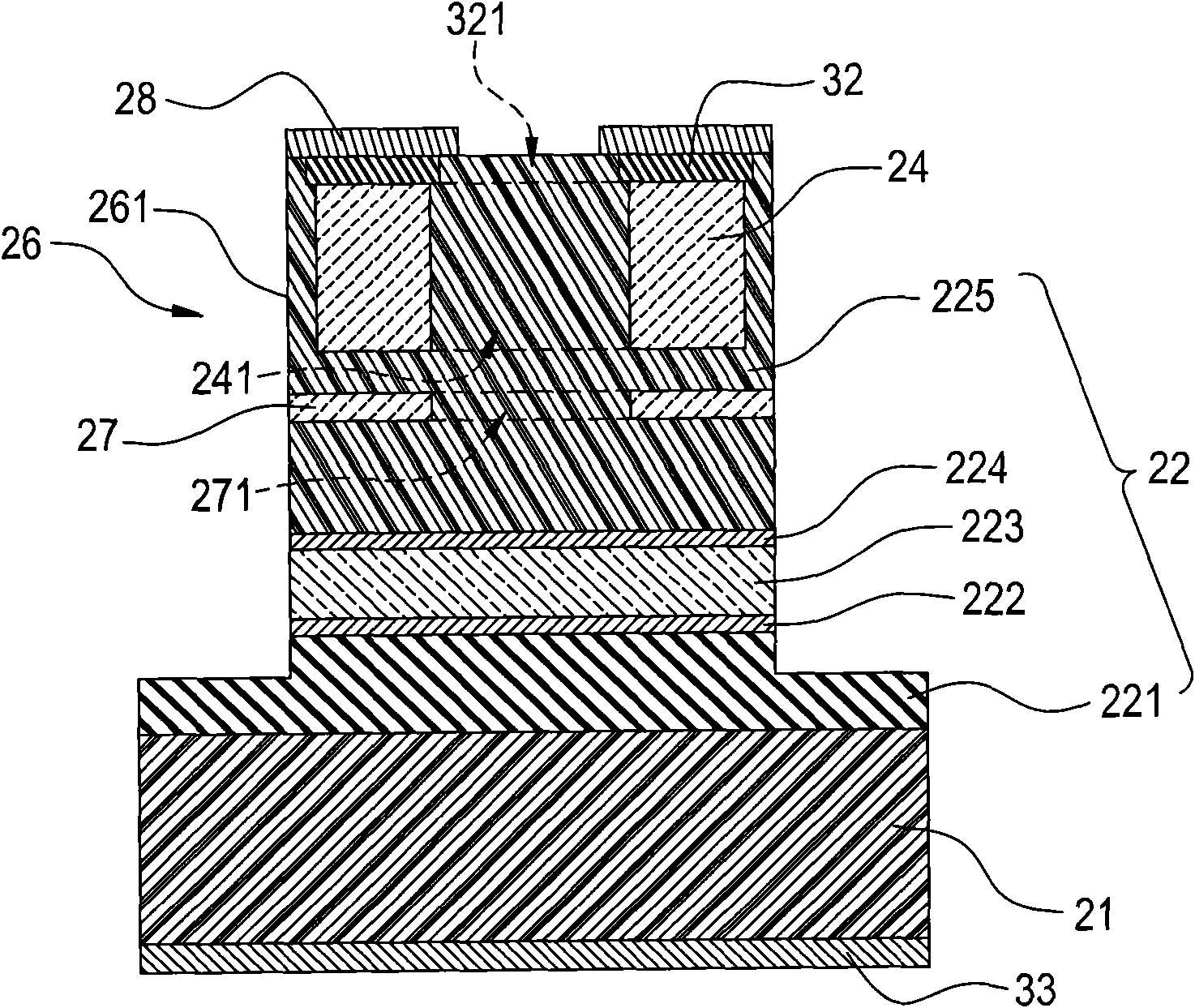

Epitaxial structure of avalanche diode and avalanche diode manufacturing method

ActiveCN106887469AControl depthPrecise thickness controlThyristorSemiconductor/solid-state device manufacturingGradient materialAvalanche diode

The present invention discloses an epitaxial structure of an avalanche diode, and relates to the technical field of semiconductor manufacturing. The epitaxial structure of the avalanche diode comprises a substrate. A light-absorbing layer is formed above the substrate. An avalanche gain layer is formed above the light-absorbing layer. A zinc diffusion layer is formed above the avalanche gain layer. The zinc diffusion layer is made of the InP material. The avalanche gain layer is made of component-gradient materials composed of the In0.52Al0.48As material, the InxGa(1-x)AsyP(1-y) material, the InxGayAl(1-x-y)As mateiral and the InxGa(1-x)AsyP(1-y) material, or component-gradient materials composed of InxGayAl(1-x-y)As. In the InxGa(1-x)AsyP(1-y) material or the component-gradient material of InxGa(1-x)AsyP(1-y), x is larger than 0 and smaller than 1, and y is larger than 0 and smaller than 1. In the InxGayAl(1-x-y)As material or the component-gradient material of InxGayAl(1-x-y)As, x is larger than 0 and smaller than 1, y is larger than 0 and smaller than 1 and the sum of x+y is larger than 0 and smaller than 1. According to the technical scheme of the invention, the depth of the zinc diffusion area is effectively controlled, and the thickness of the avalanche gain layer is accurately controlled. The yield of avalanche diode devices is improved. The invention also discloses an avalanche diode manufacturing method.

Owner:武汉光谷量子技术有限公司

PIN diode structure with zinc diffusion region

InactiveUS7538403B2Improved semiconductor structureSolid-state devicesSemiconductor devicesDopantEngineering

A PIN photodiode having a substrate, a first type electrode layer disposed on the substrate, a first layer of intrinsic material disposed over a portion of the first-type electrode layer, a first type window layer disposed over said intrinsic layer. An island shaped region of intrinsic material is disposed over the window layer and a dielectric layer disposed over the island region and at least the peripheral portion of said island shaped region whereby an opening is formed in the island shaped region. A dopant is diffused through the opening so as to form a PN junction that extends into the first layer of intrinsic material.

Owner:EMCORE INC

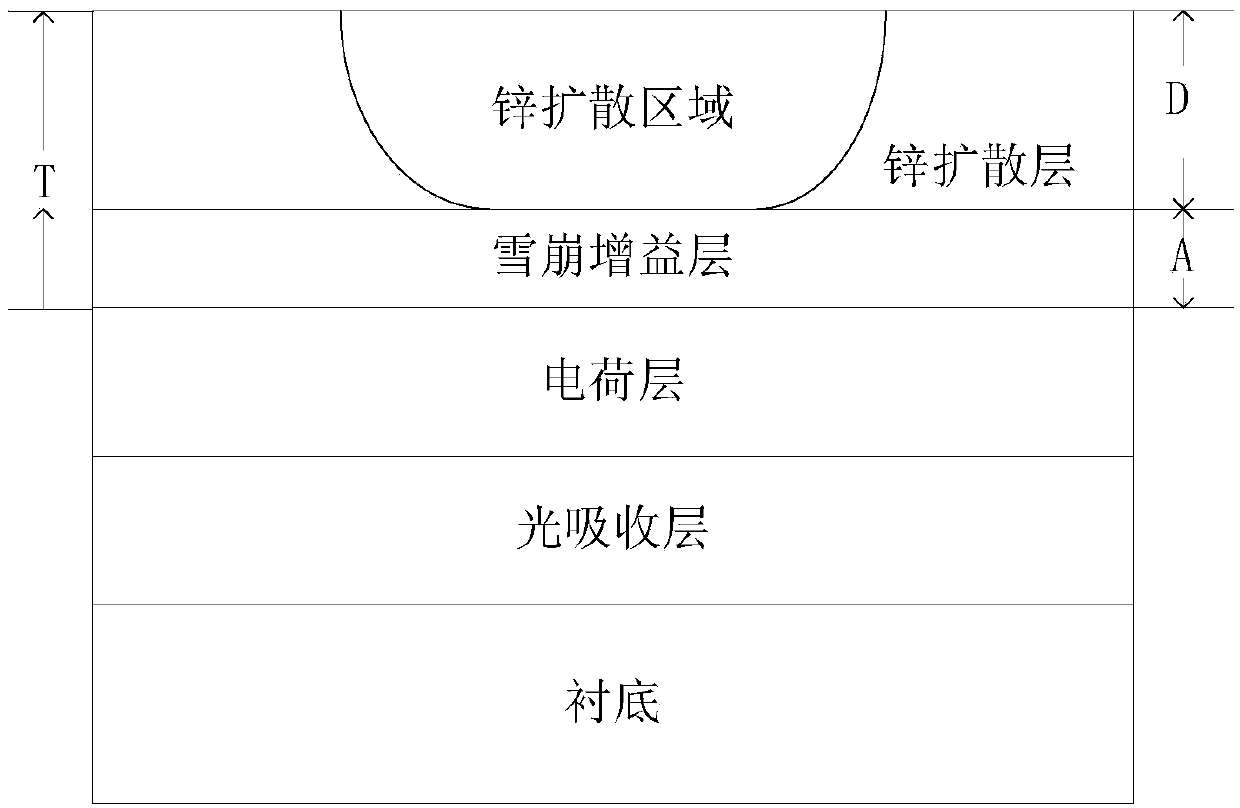

Avalanche photodiode and preparation method thereof

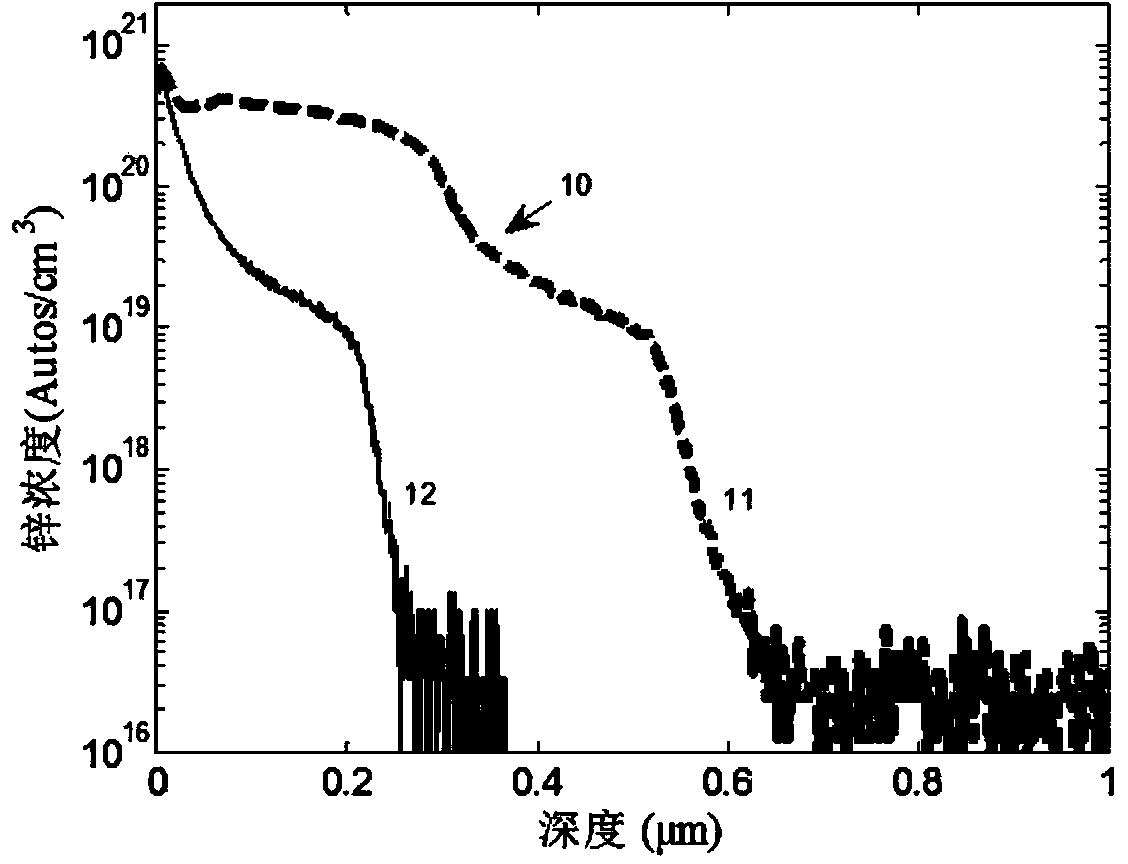

InactiveCN110112249AImprove adhesionImprove toughnessSemiconductor devicesHigh concentrationPhotodetector

The invention provides an avalanche photodiode applied to the technical field of photodetectors. A buffer layer, an absorption layer, a transition layer, a charge layer, a cap layer and an electrode contact layer are epitaxially grown on a substrate in order, the material of the electrode contact layer is InGaAsP, the electrode contact layer is an intrinsic gradual component material of epitaxialgrowth, the high concentration doping can be achieved by a P-type dopant diffusion doping process such as zinc diffusion, the upper surface doping concentration is 1019Atoms / cm3, and a P-type electrode is made of a non-alloy contact Ti-Pt-Au. The invention also discloses a preparation method of the avalanche photodiode, the high adhesion of Ti, the high toughness of Pt and the good electrical conductivity and corrosion resistance of Au are used, the ohmic contact characteristics of a device are effectively improved without affecting the dark current and frequency response of the device, the contact resistance is reduced, and the probability of fall is little.

Owner:UNIV OF SCI & TECH OF CHINA

Diffusion device and method for zinc in photodetector fabrication

ActiveCN103151248BDiffusion temperature fluctuations are smallSuitable for diffusion process requirementsSemiconductor/solid-state device manufacturingDiffusion methodsSlag

The invention discloses a zinc diffusion device and a diffusion method thereof in manufacturing of a photoelectric detector. The device comprises a heating furnace, a quartz tube, a gas control system, a vacuum system, a quartz boat and a vacuum pushing device, wherein both ends of the quartz tube are sealed, the quartz boat is used for accommodating a diffusion source and an epitaxial wafer to be diffused, the vacuum pushing device is used for pushing the quartz boat into the quartz tube, one end of the quartz tube is positioned in a hearth of the heating furnace and is used as a constant-temperature area, the other end of the quartz tube is positioned on the outside of the hearth of the heating furnace, is used as a cooling area and is maintained in a room temperature state, the gas control system is used for filling nitrogen into the quartz tube, and the vacuum system is used for vacuumizing the quartz tube by a vacuum pipeline. The method has the advantages that the risk of using an oxy-hydrogen flame to seal the quartz tube in the traditional tube-closing diffusion process is avoided, the pollution at the epitaxial wafer by sucking residual slag into the quartz tube at the negative pressure in the quartz tube when the quartz tube is opened is avoided, and the problems of nonuniform temperature, difficult control of diffusion depth and overlong cooling time in the traditional tube-opening diffusion process are solved. The method is favorable for batch diffusion.

Owner:WUHAN TELECOMM DEVICES

Methods of preparing thin polymetal diffusion coatings

ActiveUS8398788B2Increased formationHot-dipping/immersion processesPretreated surfacesMetalZinc diffusion

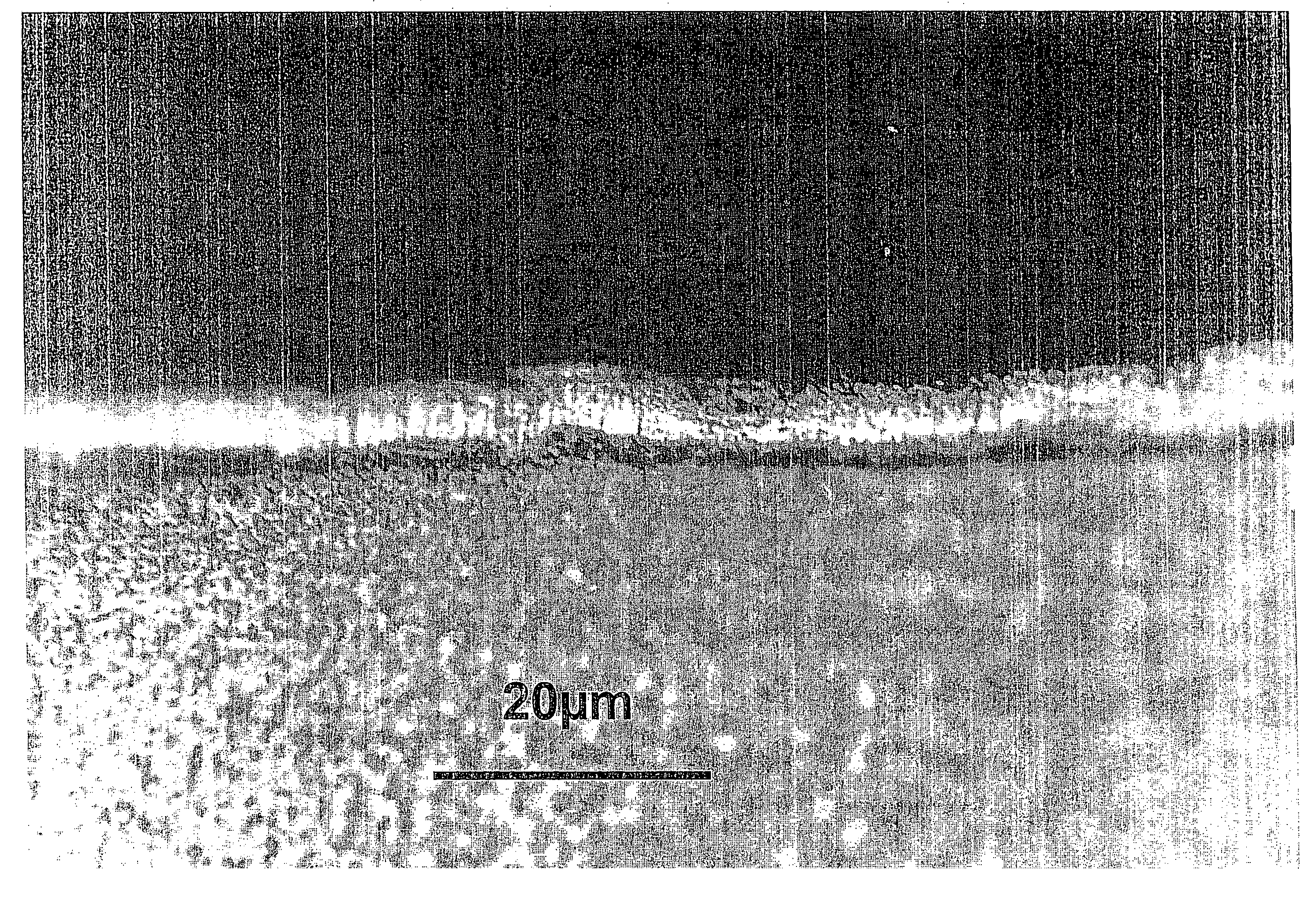

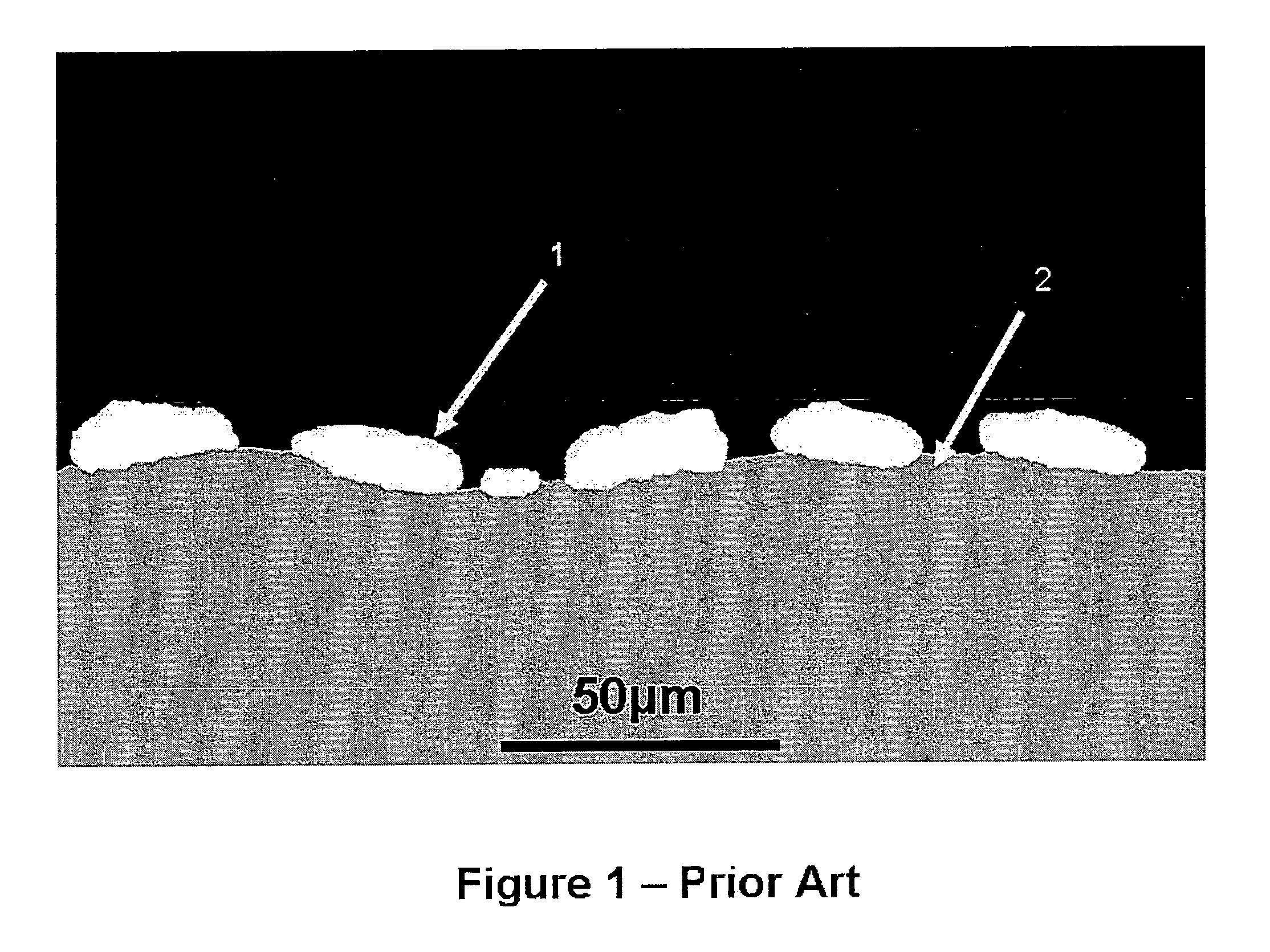

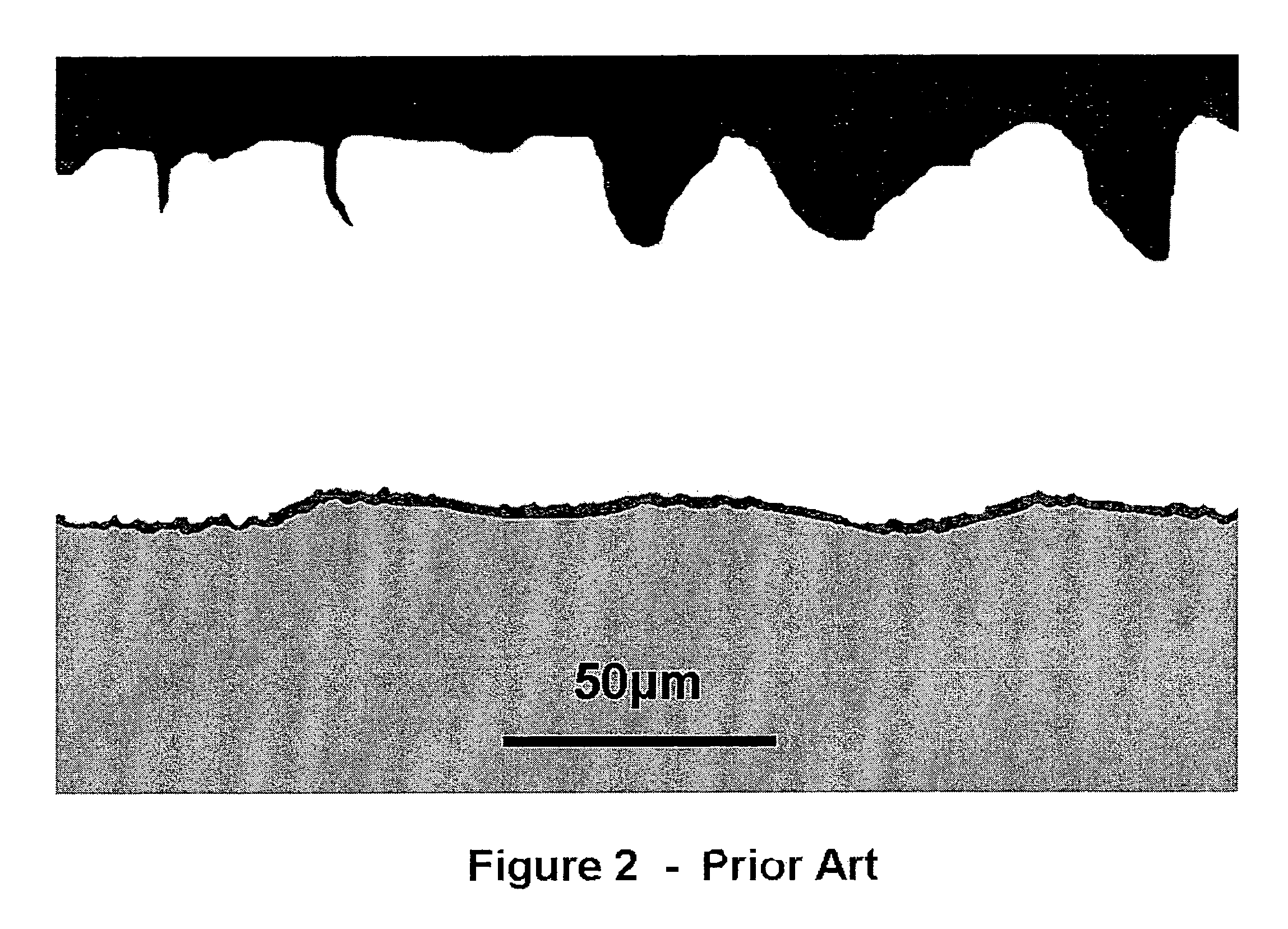

A thin zinc diffusion coating, the diffusion coating including: (a) an iron-based substrate, and (b) a zinc-iron intermetallic layer coating the iron-based substrate, the intermetallic layer having a first average thickness of less than 15 μm, as measured by a magnetic thickness gage, the intermetallic layer having a second average thickness as measured by an X-Ray fluorescence thickness measurement, and wherein a difference between the first average thickness and the second average is less than 4 μm.

Owner:GREENKOTE (ISRAEL) LTD

Selective emitter gallium antimonide infrared battery and manufacturing method thereof

InactiveCN103474501AImprove electrical performanceReduce manufacturing costFinal product manufactureSolid-state devicesHigh concentrationGallium antimonide

The invention discloses a selective emitter gallium antimonide infrared battery and a manufacturing method thereof. The method comprises the steps of p-n junction preparing in a zinc diffusion mode, electrode preparing, surface passivating, antireflection layer preparing and the like. The method is characterized in that zinc-gallium alloy is utilized as a diffusion source to conduct seal type zinc diffusion so that a zinc concentration curve only having a single diffusion front edge can be formed in an N-type gallium antimonide chip. According to the method, a high-concentration diffusion layer on the surface of the gallium antimonide chip after diffusion can be effectively restrained, and the problem that accurate corrosion is difficult to control in a traditional diffusion process is solved. According to the method, no protective gas needs to be added in a p-n junction preparing process, and cost of the gallium antimonide infrared battery is lowered. According to the selective emitter gallium antimonide infrared battery made in the method, the zinc concentration curve only having the single diffusion front edge in the selective emitter gallium antimonide infrared battery is directly formed through diffusion, and a corrosion process is not needed. Therefore, electrical output properties of the selective emitter gallium antimonide infrared battery are stable, and the selective emitter gallium antimonide infrared battery can be used as an electricity converting element in an infrared photovoltaic conversion system.

Owner:UNIV OF SCI & TECH OF CHINA

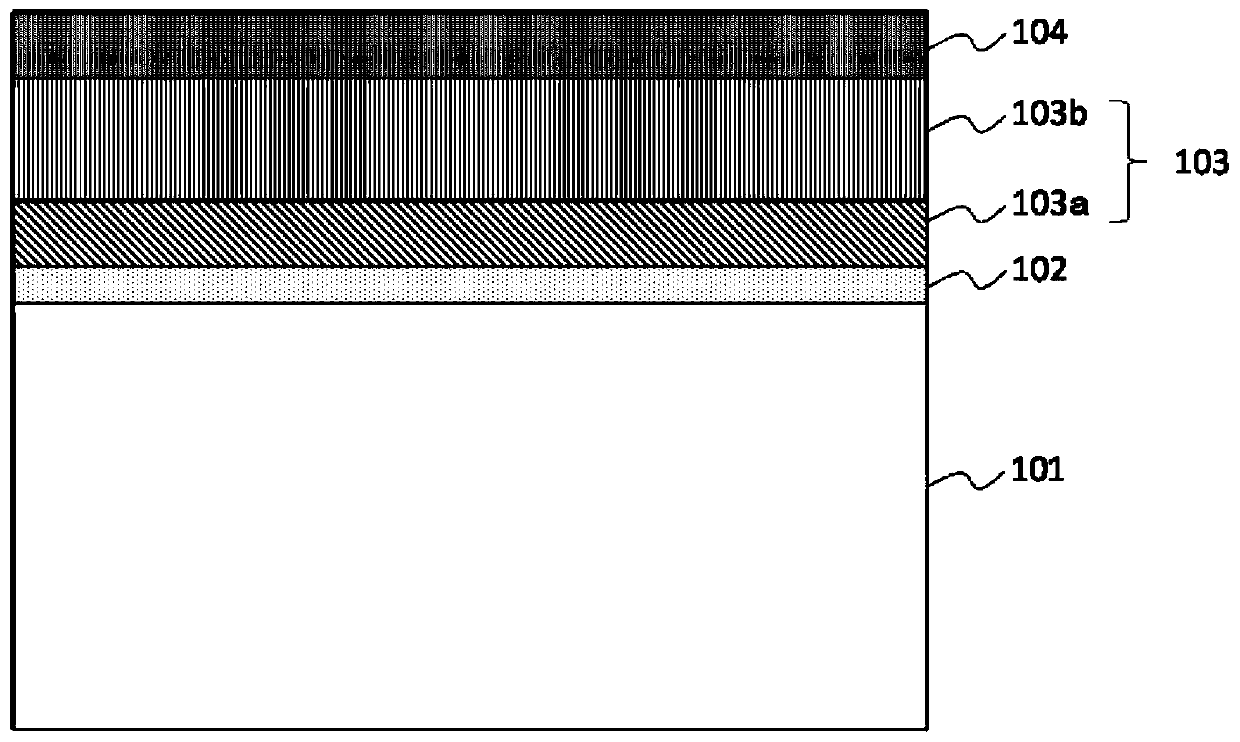

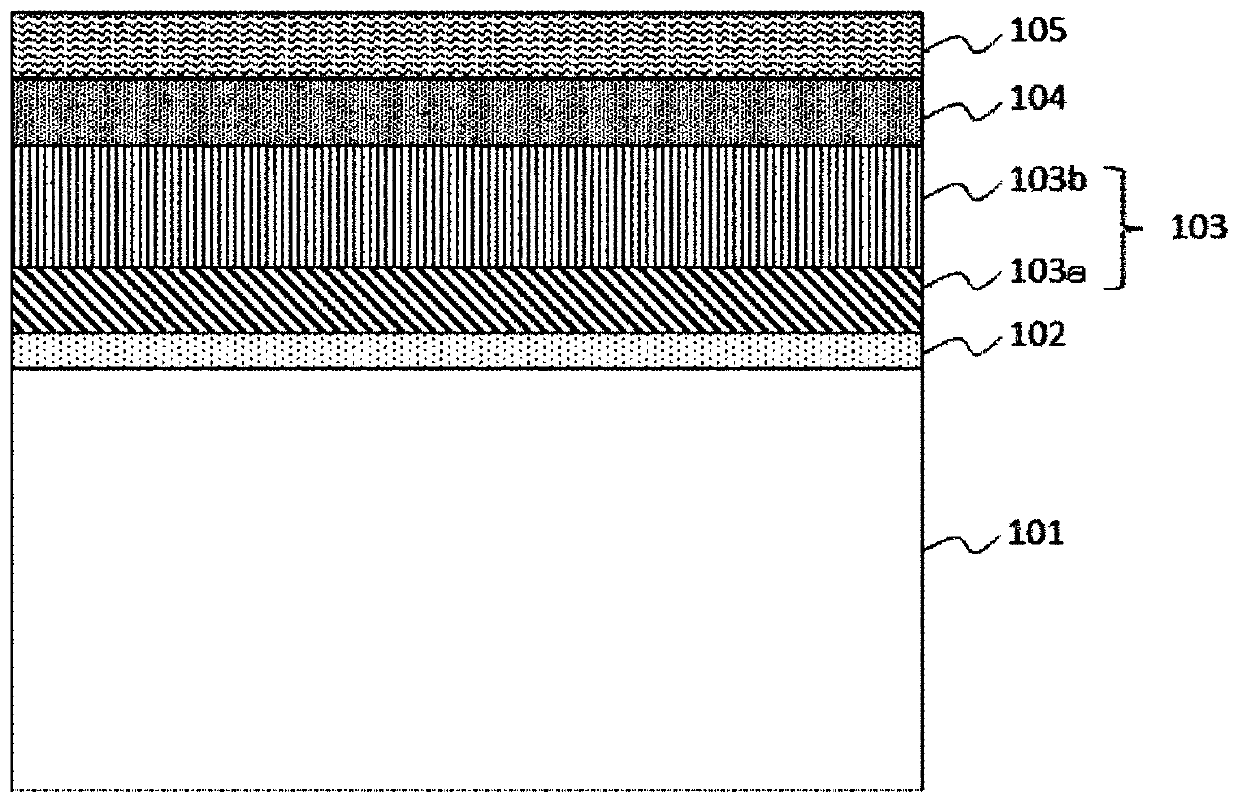

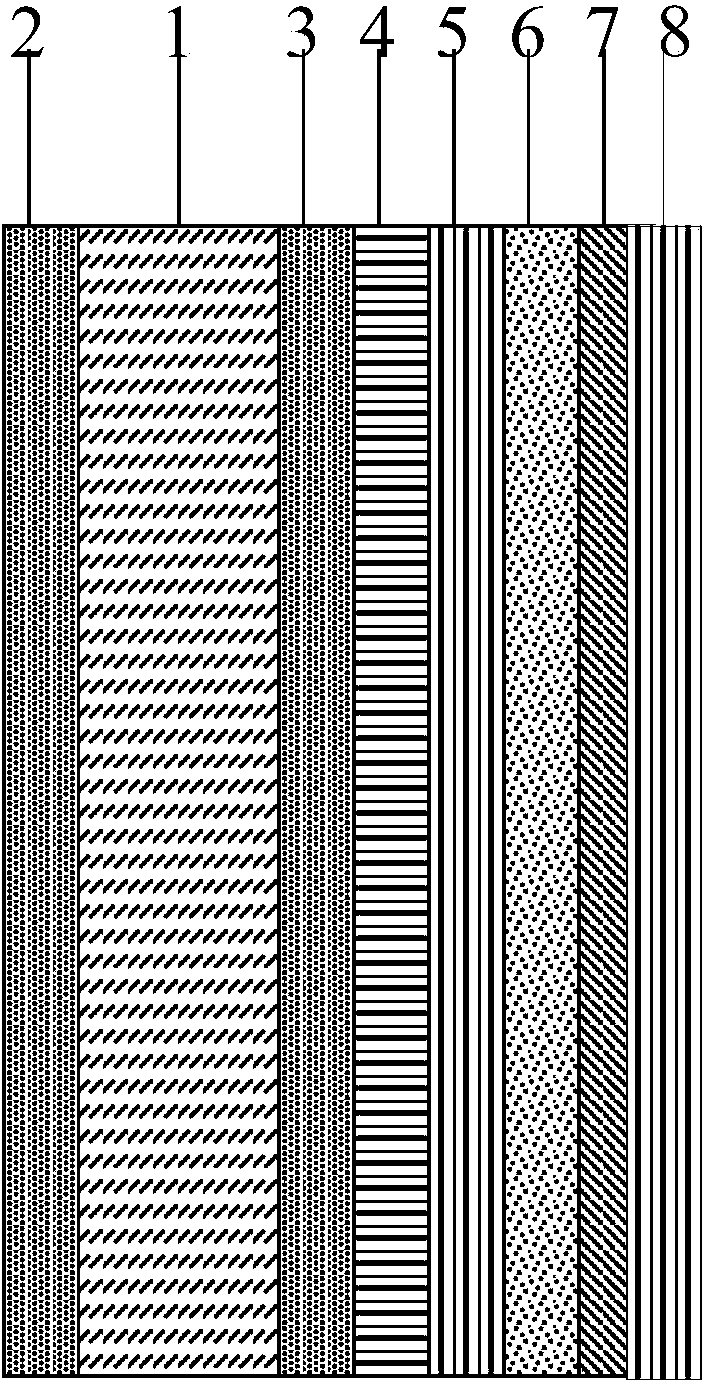

Member for slide fasteners or buttons, which is formed from plated aluminum or aluminum alloy

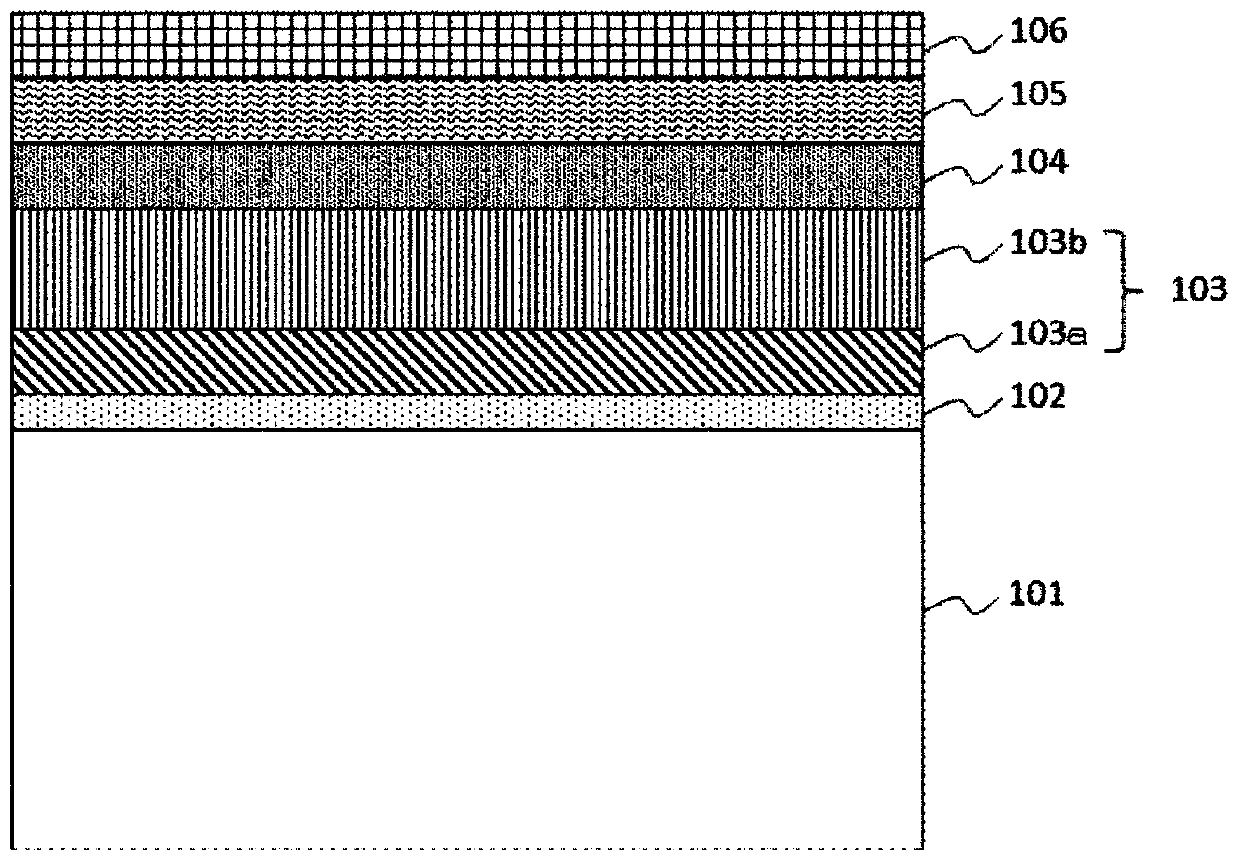

Provided is a member for slide fasteners or buttons, which is formed from a plated aluminum or aluminum alloy, and which has both cracking resistance and gloss at the same time. A member for slide fasteners or buttons, which comprises: a base material (101) that is formed from aluminum or an aluminum alloy; a zinc diffusion layer (102) that is obtained by diffusing zinc inside the surface of the base material; and a plurality of plating layers that cover the zinc diffusion layer (102). The plurality of plating layers comprise a copper pyrophosphate plating layer (103) and a copper sulfate plating layer (104) sequentially from the inner side.

Owner:YKK CORP

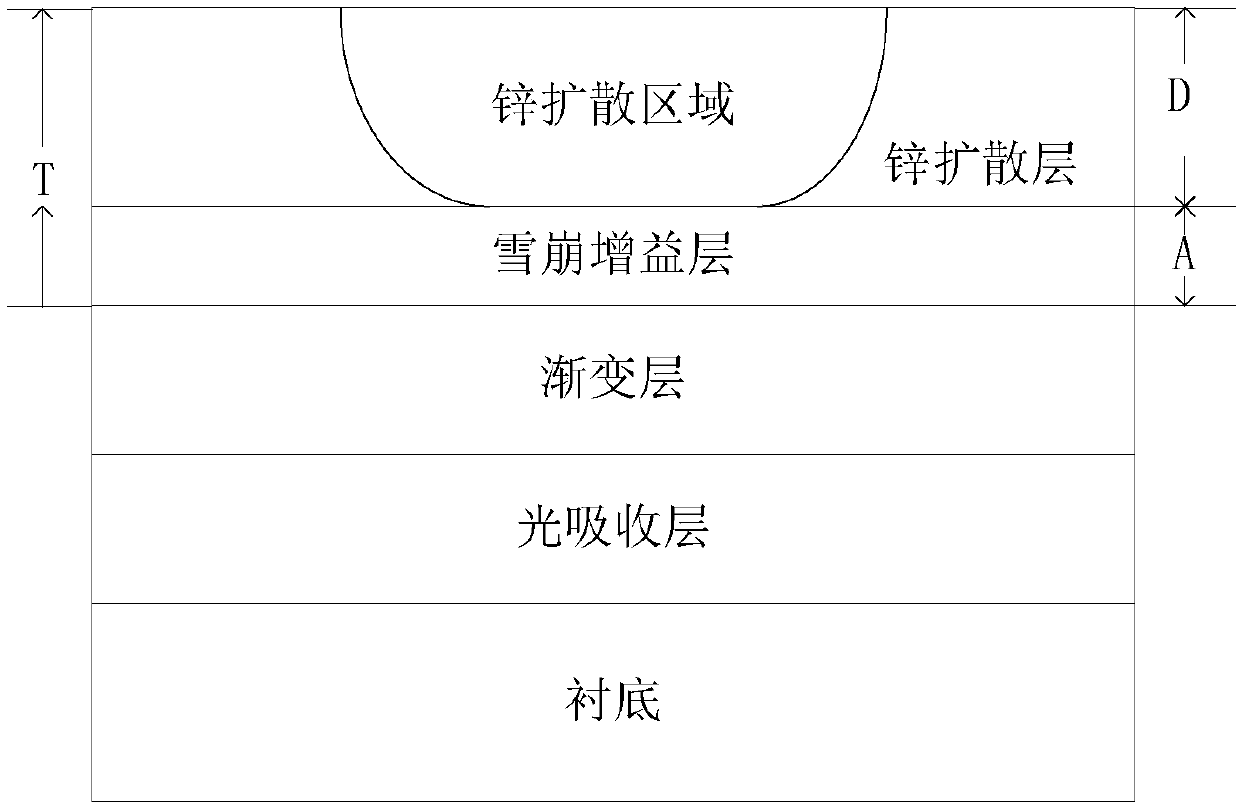

Avalanche photodiode and manufacturing method thereof

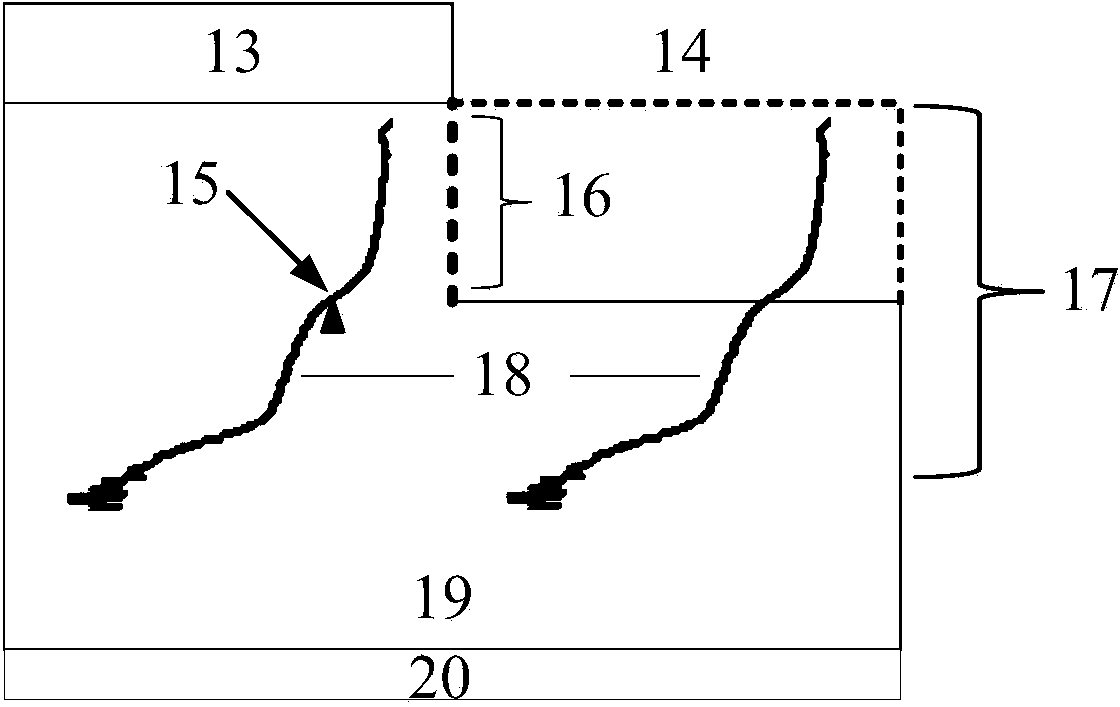

InactiveCN110323284ASolve difficultySolve the repeatabilitySemiconductor devicesContact layerComputer science

The invention discloses an avalanche photodiode and a manufacturing method thereof. The method comprises the following steps: manufacturing a substrate, a first contact layer and a second contact layer; evaporating a passivation layer on the second contact layer; etching the passivation layer and the second contact layer to form a second window and a first window, and enabling the second window and the first window to be step-shaped; performing zinc diffusion through the second window and the first window, and controlling the diffusion depth, so that a diffusion region comprising an edge region and a central region is formed in the first contact layer, and the diffusion depth of the edge region is 300-900 nanometers smaller than that of the central region. According to the invention, the problem that the edge area is difficult to control during zinc diffusion and the problem of edge pre-breakdown caused by the problem can be effectively solved.

Owner:武汉光谷量子技术有限公司

Avalanche photodiode and manufacturing method thereof

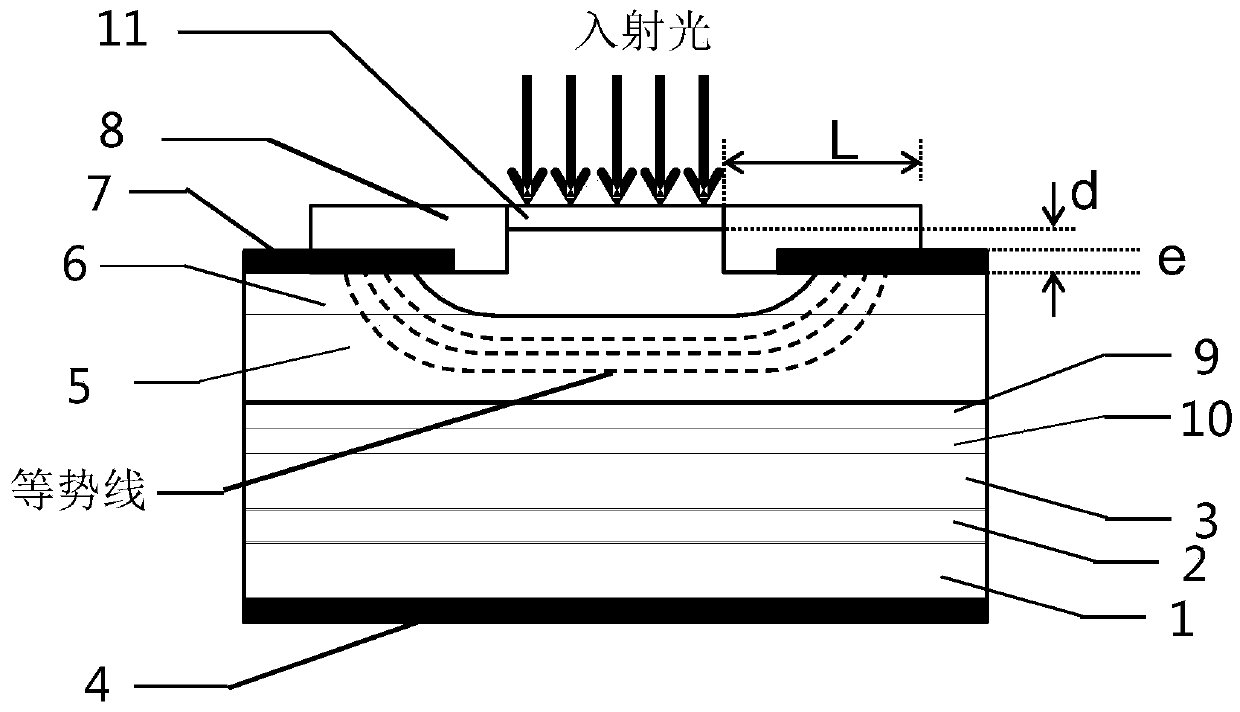

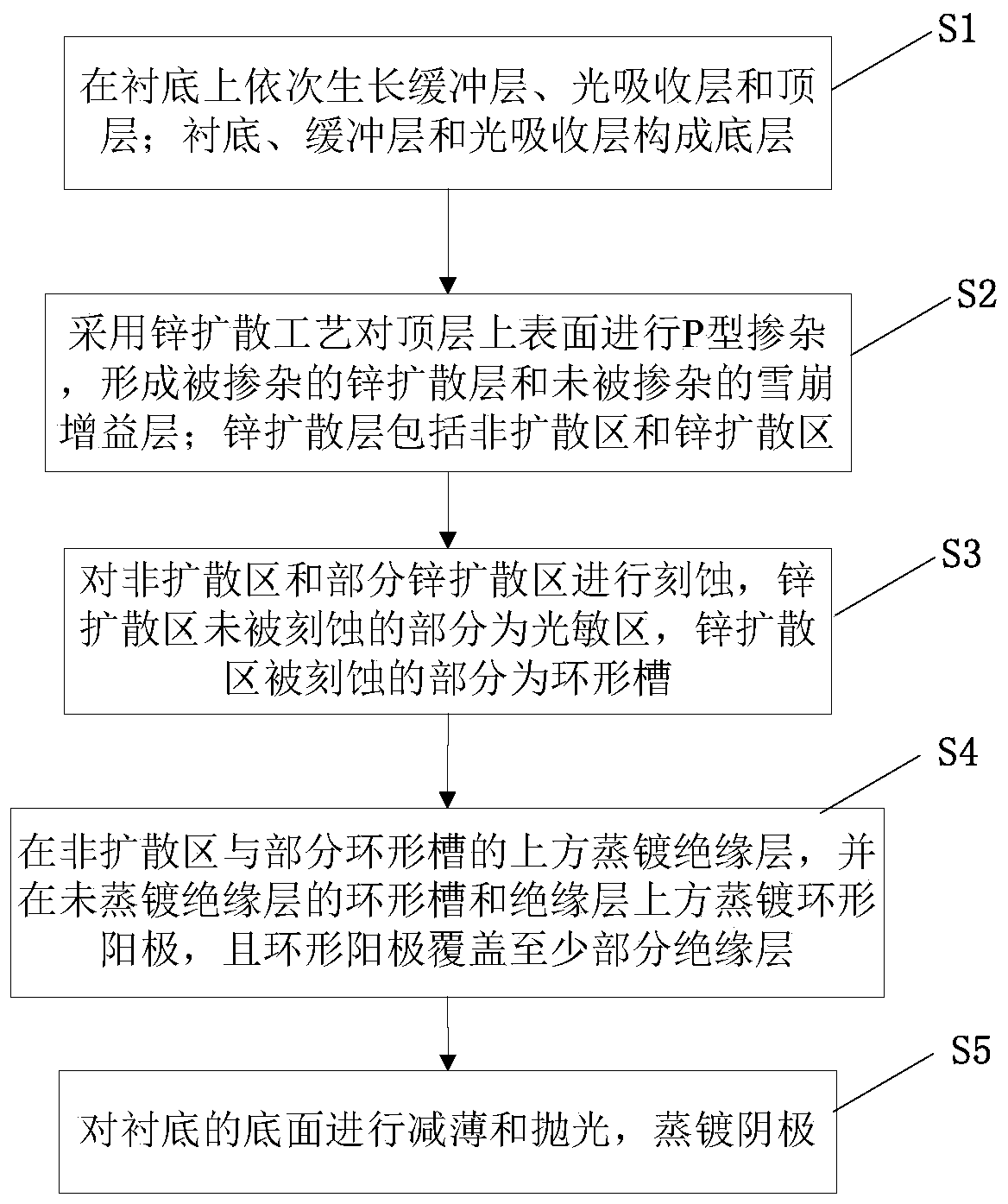

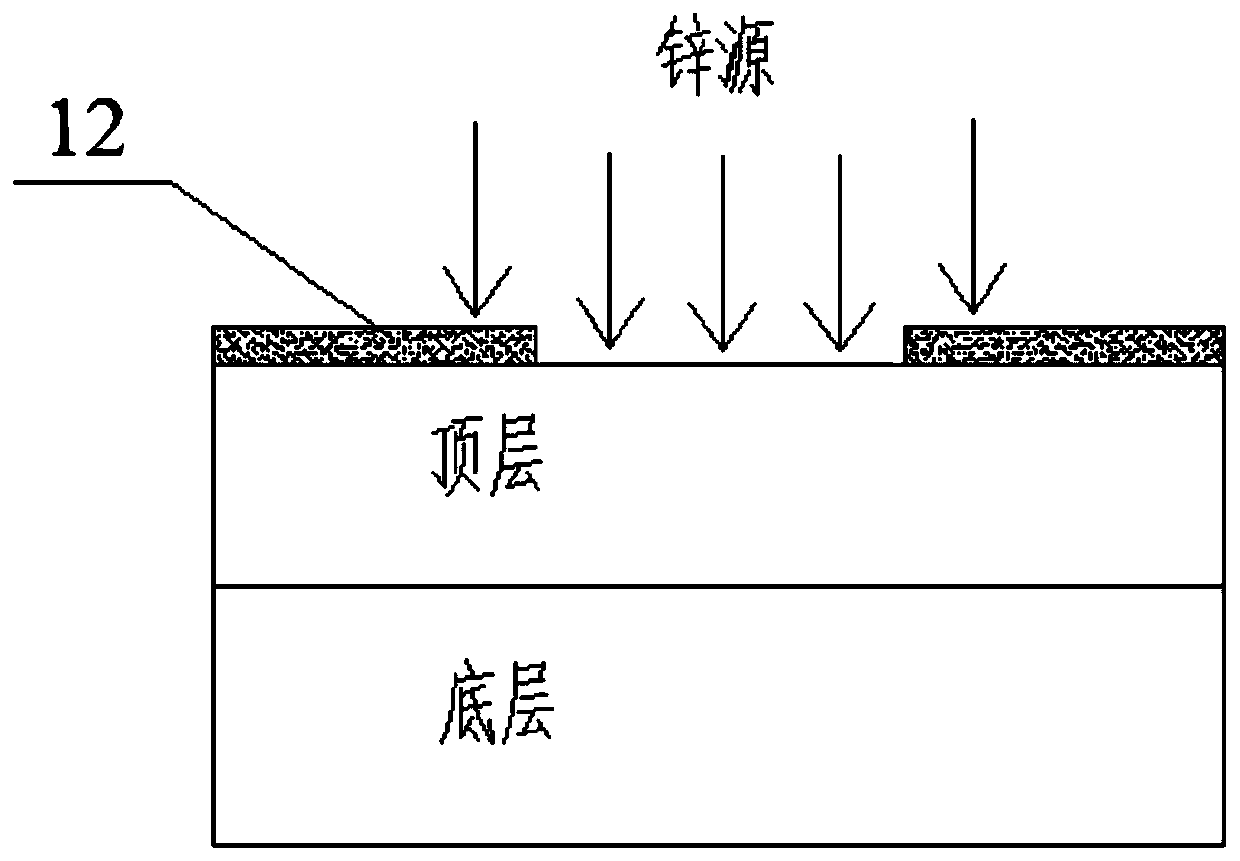

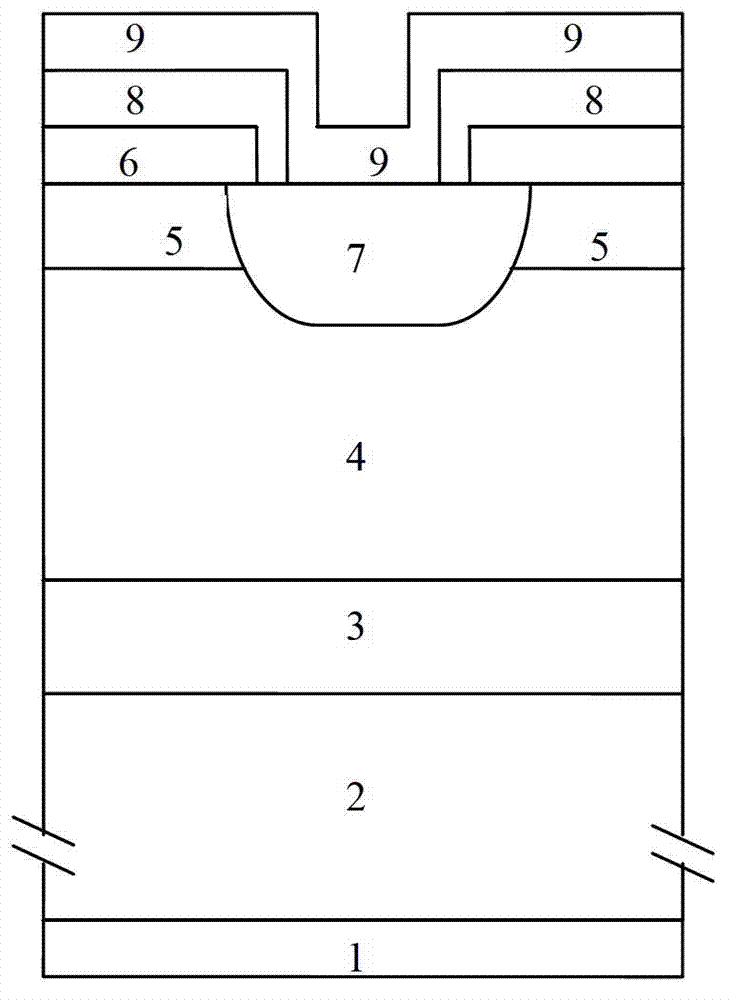

PendingCN110190148ASuppress pre-breakdownReduce edge curvatureSemiconductor devicesFinal product manufactureCapacitancePhotodiode

The invention discloses an avalanche photodiode and a manufacturing method thereof, and relates to the technical field of photodiodes. The avalanche photodiode comprises a bottom layer and a top layer, wherein the bottom layer includes a substrate, a buffer layer and a light absorption layer, and the lower surface of the substrate is provided with a cathode; the top layer is arranged above the bottom layer and includes an avalanche gain layer and a zinc diffusion layer; the zinc diffusion layer includes a non-diffusion region and a zinc diffusion region, the non-diffusion region and part of the zinc diffusion region are etched, the part, which is not etched, of the zinc diffusion region is a photosensitive region, and the etched part of the zinc diffusion region is an annular groove; an insulating layer is evaporated on the non-diffusion region and part of the annular groove, and an annular anode is evaporated on the annular groove which is not evaporated with the insulating layer andthe insulating layer; and the annular anode, the insulating layer and the cathode form an MIS structure. The avalanche photodiode of the invention can generate an anode capacitance effect, change theelectric field distribution at the edge of a p-type doping region below the anode, reduces the curvature at the edge of a depletion region, reduce the edge electric field intensity and thus suppress the edge pre-breakdown.

Owner:武汉光谷量子技术有限公司

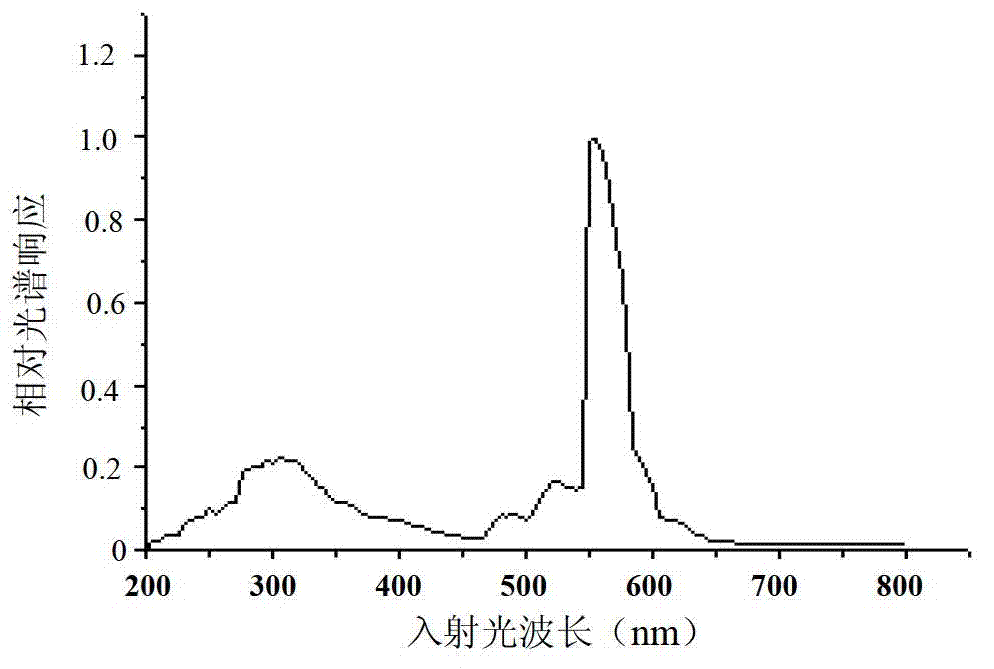

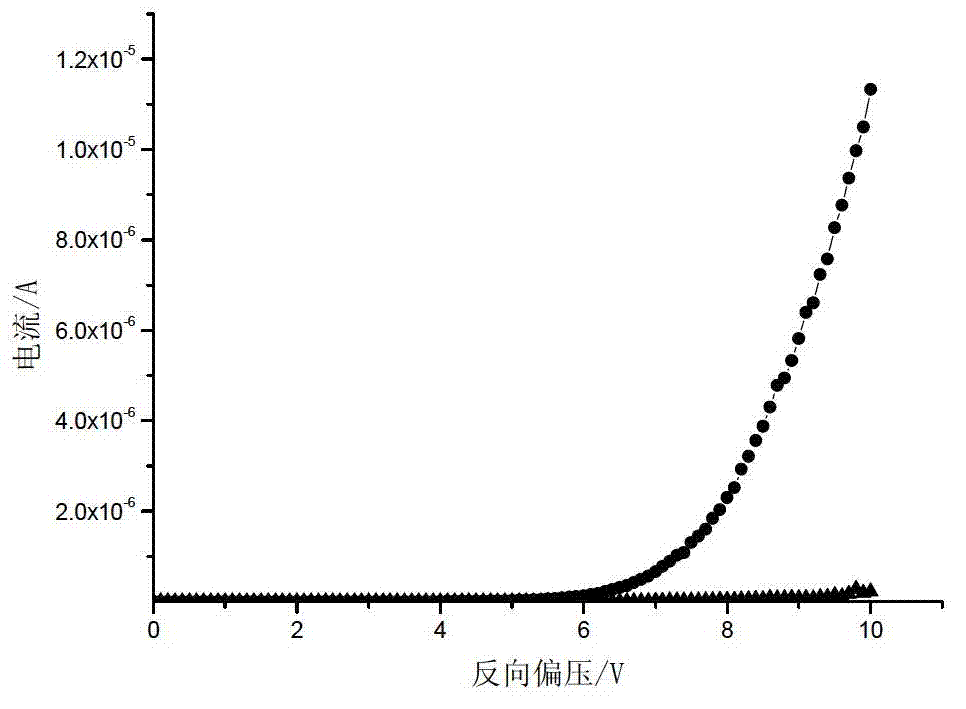

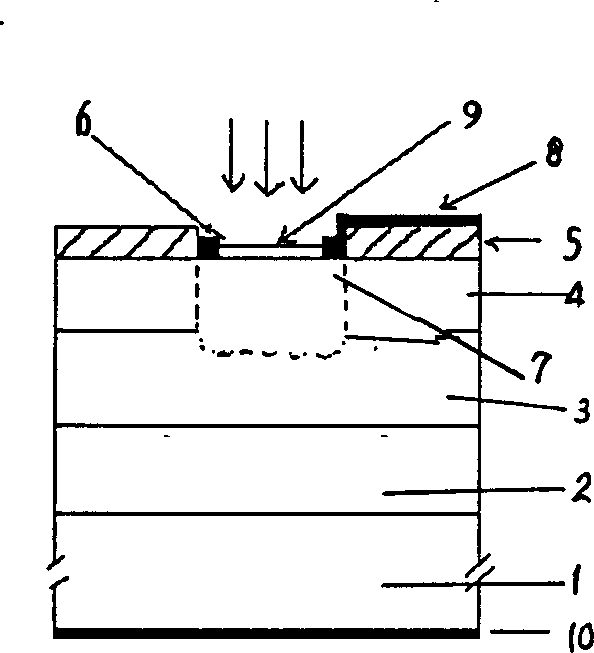

Gallium, arsenic and phosphorus/gallium phosphide yellow light narrow-band detector and manufacturing method thereof

ActiveCN102820344AImprove banknote detection abilityHigh gainFinal product manufactureSemiconductor devicesOhmic contactSingle crystal

The invention discloses a gallium, arsenic and phosphorus / gallium phosphide yellow light narrow-band detector and a manufacturing method of the gallium, arsenic and phosphorus / gallium phosphide yellow light narrow-band detector, and relates to a detector. The invention provides the gallium, arsenic and phosphorus / gallium phosphide yellow light narrow-band detector for detection of an infrared up-conversion material and the manufacturing method thereof. The detector is provided with an epitaxial wafer which is sequentially provided with an n-type high doping gallium phosphide monocrystal substrate, a non-doping gallium phosphide buffer layer, a non-doping GaAs0.15P0.85 light absorbing layer and a non-doping gallium phosphide cap layer from bottom to top. An n-type ohmic contact electrode is arranged at the bottom of the n-type high doping gallium phosphide monocrystal substrate. A silicon nitride mask, a p-type high-doping diffusing layer formed through zinc diffusion, a p-type ohmic contact electrode and a silicon nitride antireflection film grow sequentially on the non-doping gallium phosphide cap layer of the epitaxial wafer. The gallium, arsenic and phosphorus / gallium phosphide yellow light narrow-band detector has the advantages of easiness in preparation, low cost, nearly no response to infrared light and the like, and can be used to detect the infrared up-conversion material such as bill and the like, so that the bill detecting capacity of a bill detector is improved.

Owner:XIAMEN UNIV OF TECH

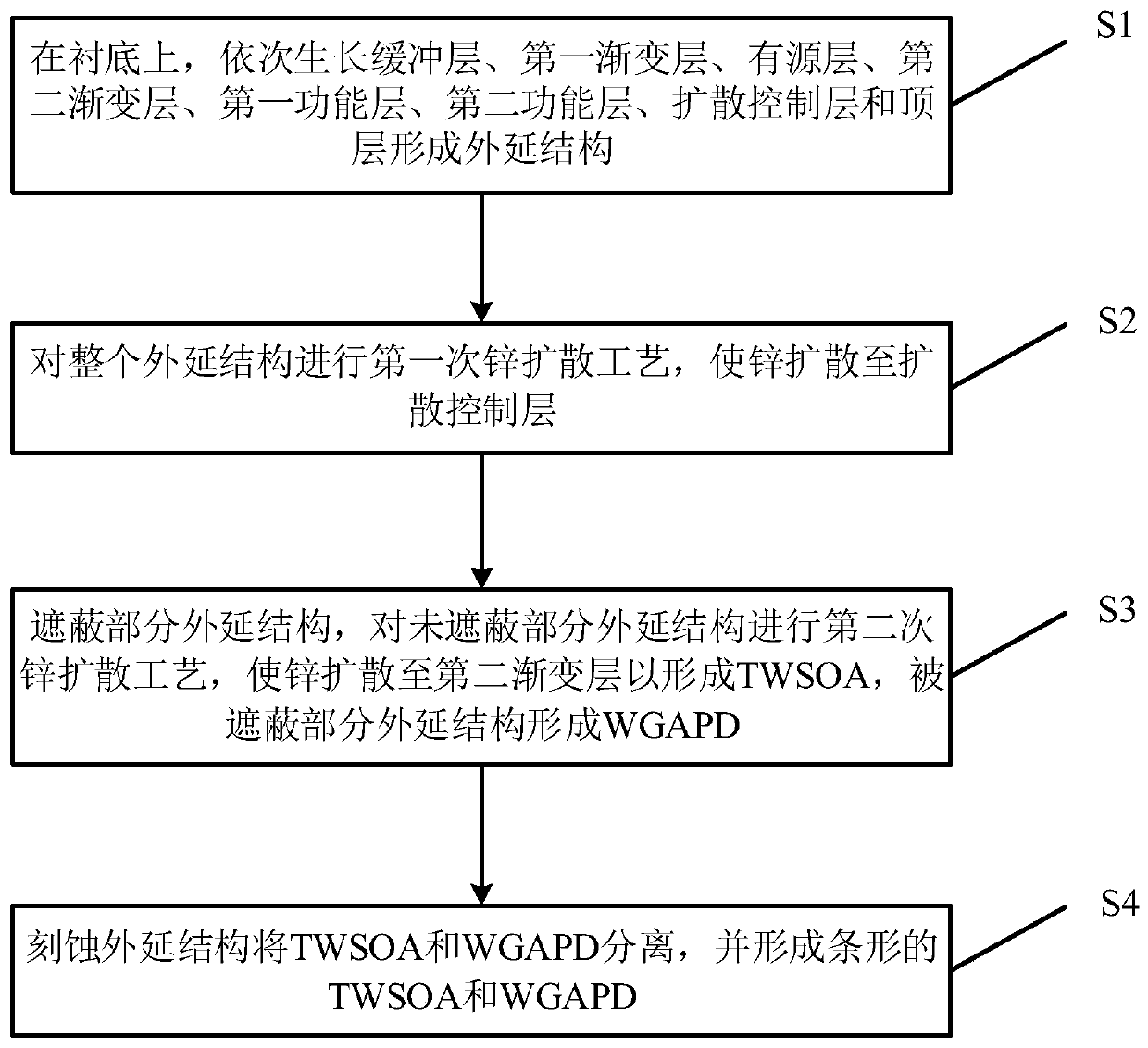

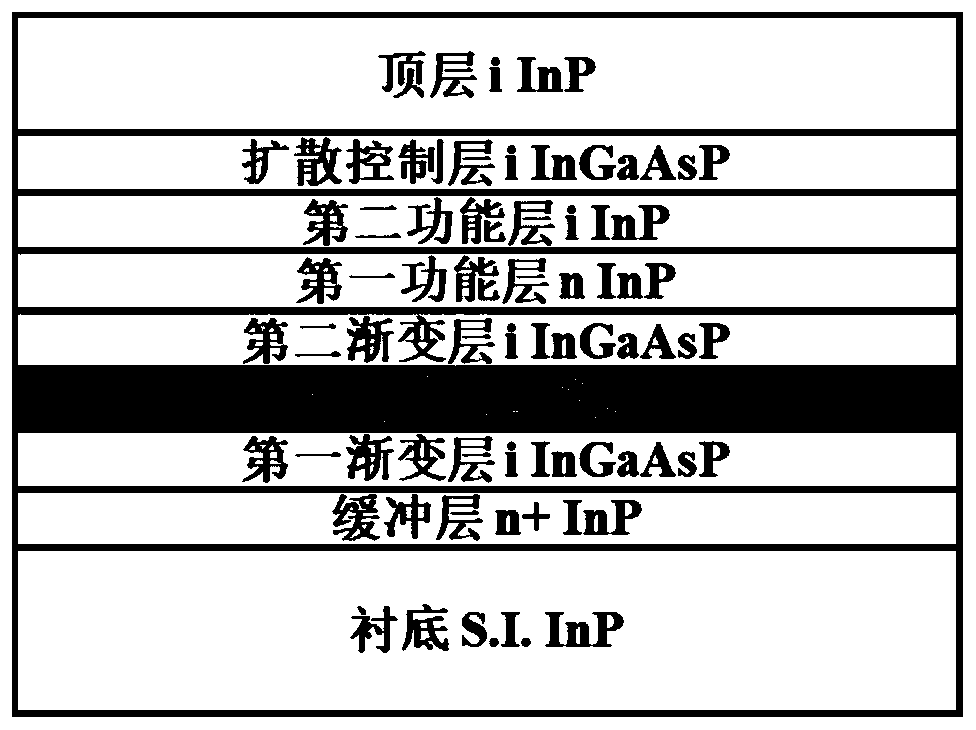

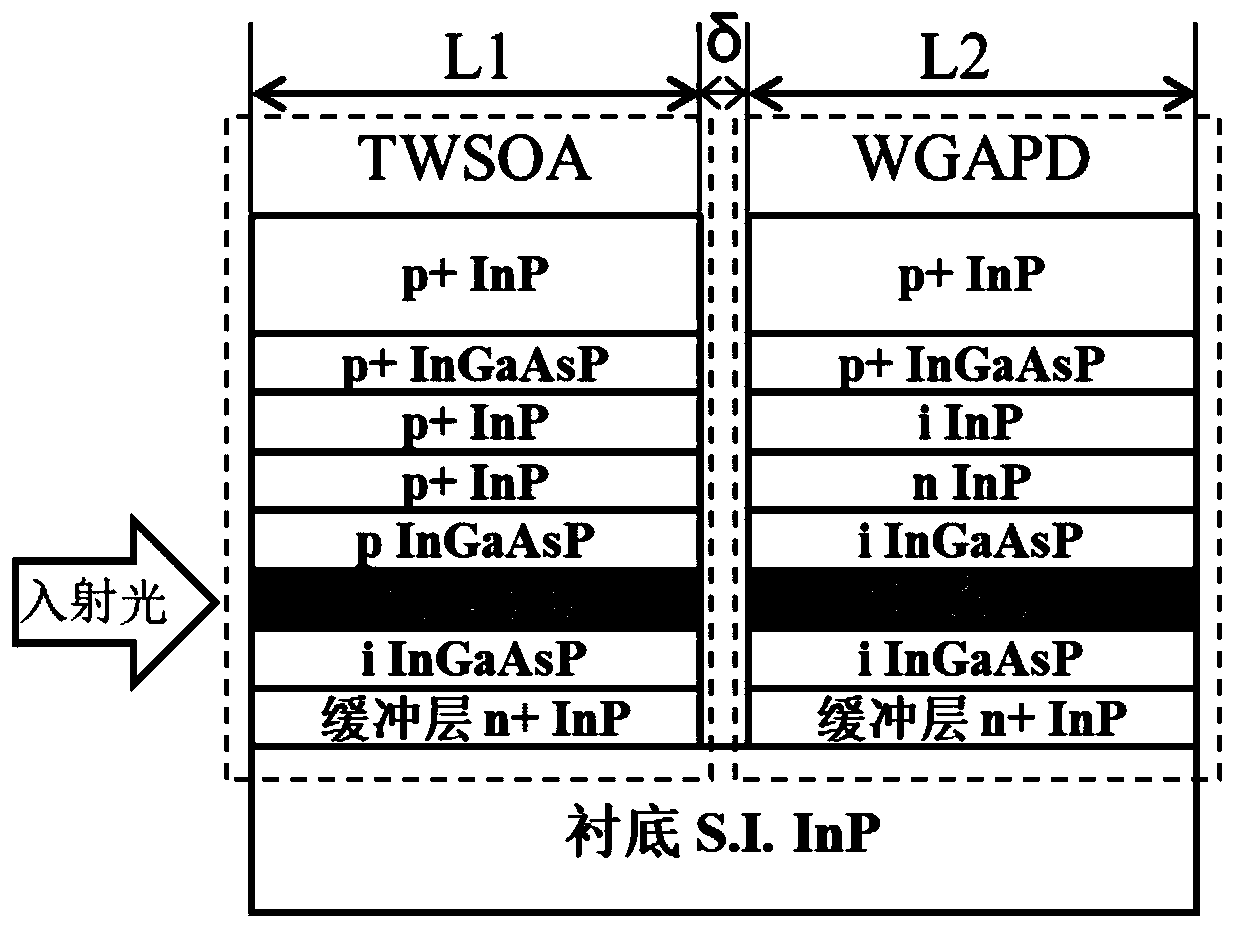

High-gain bandwidth product optical detector and manufacturing method thereof

The invention discloses a manufacturing method of a high-gain bandwidth product optical detector, and relates to the technical field of optical detectors. The optical detector comprises the followingsteps: S1, sequentially growing a buffer layer, a first gradient layer, an active layer, a second gradient layer, a first functional layer, a second functional layer, a diffusion control layer and a top layer on a substrate to form an epitaxial structure; S2, performing a first zinc diffusion process on the whole epitaxial structure to diffuse zinc to the diffusion control layer; S3, shielding part of the epitaxial structure, and performing a second zinc diffusion process on the unshielded part of the epitaxial structure so as to diffuse zinc to the second gradient layer to form TWSOA, whereinWGAPD is formed on the shielded part of the epitaxial structure; S4, etching the epitaxial structure to separate the TWSOA from the WGAPD, and forming a strip-shaped TWSOA and a strip-shaped WGAPD; and S5, respectively manufacturing electrodes of the TWSOA and the WGAPD. The invention also discloses the optical detector with high-gain bandwidth product. The gain bandwidth product of the optical detector provided by the invention can reach 1000GHz.

Owner:武汉光谷量子技术有限公司

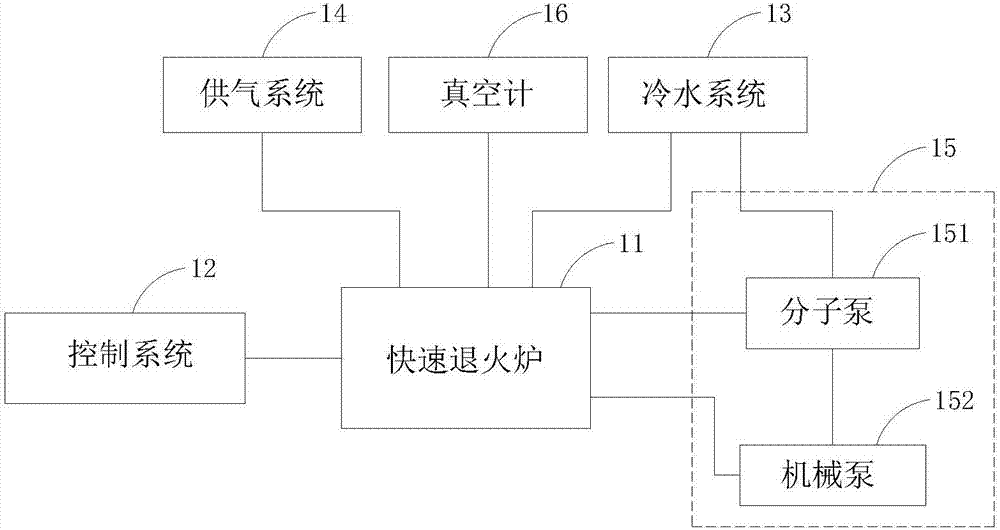

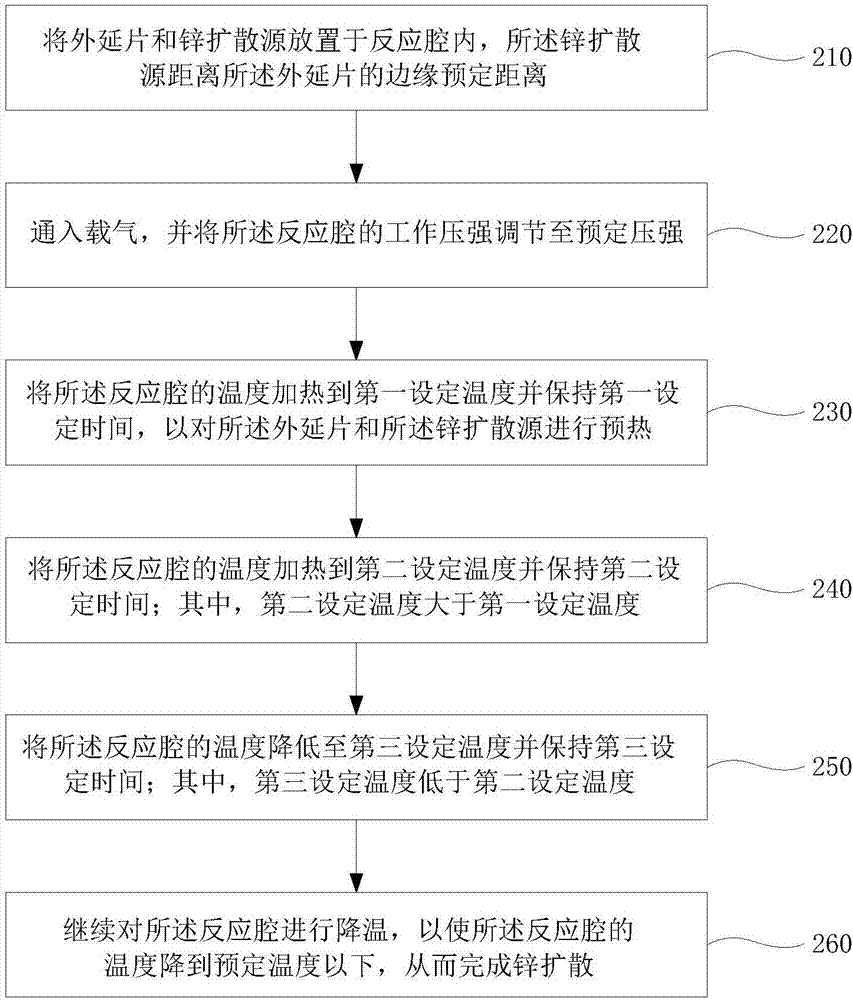

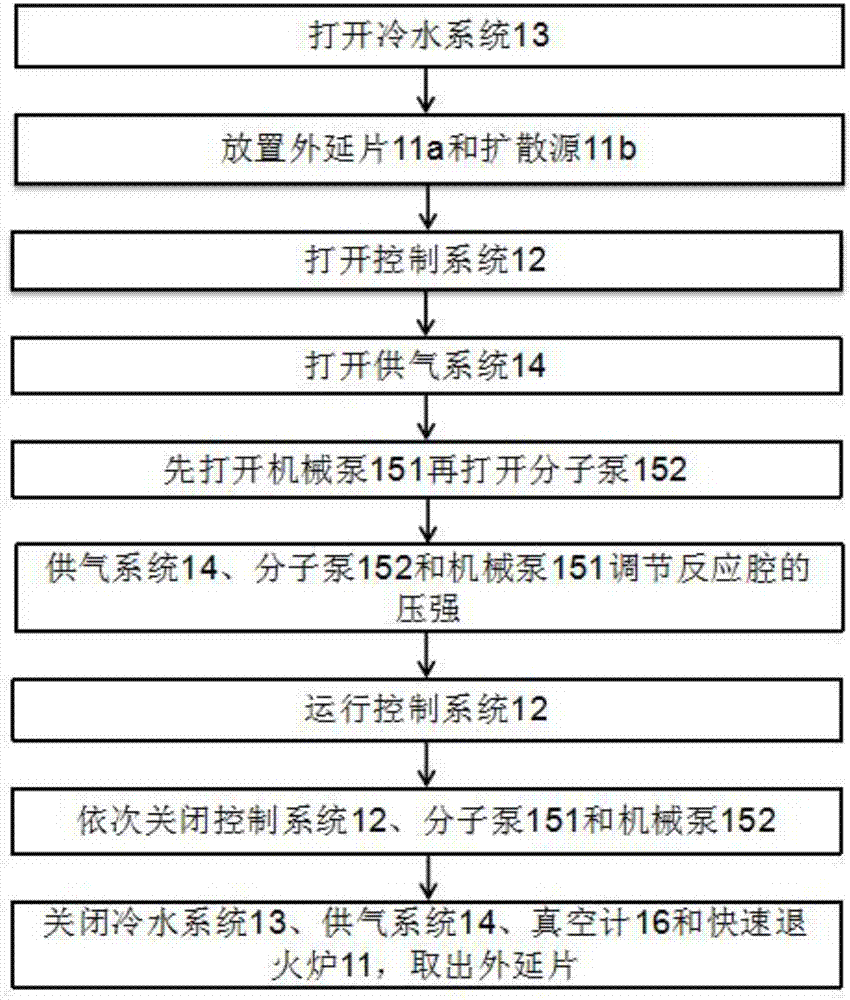

Device for zinc diffusion and zinc diffusion method

ActiveCN107887263AReduce surface damageEasy to operateFinal product manufactureSemiconductor/solid-state device manufacturingZinc diffusionMaterials science

The invention discloses a device for zinc diffusion and a zinc diffusion method. The method comprises: an epitaxial wafer and a zinc diffusion source are placed in a reaction cavity, wherein a distance between the zinc diffusion source and the edge of the epitaxial wafer is a predetermined distance; carrier gas is inputted and the working pressure of the reaction cavity is adjusted to be a predetermined pressure; the temperature of the reaction cavity is heated to be a first set temperature and the first set temperature is kept for first set time, so that the epitaxial wafer and the zinc diffusion source are preheated; the temperature of the reaction cavity is heated to be a second set temperature and the second set temperature is kept for second set time; the temperature of the reaction cavity is reduced to be a third set temperature and the third set temperature is kept for third set time; and the reaction cavity is cooled continuously and thus the temperature of the reaction cavityis reduced to be below a predetermined temperature to complete zinc diffusion. Therefore, the operation becomes simple and the cost is low; the surface of the prepared finished product is protected from being damaged; the junction depth is easy to control; and batched and continuous production of the devices can be realized conveniently.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

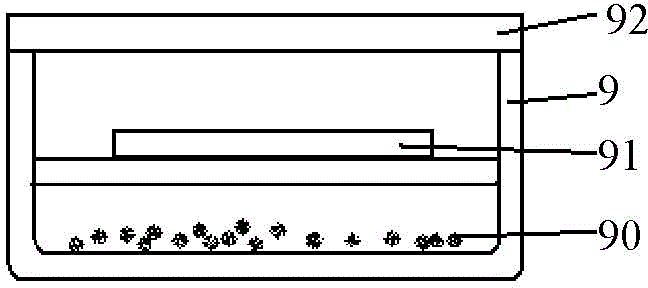

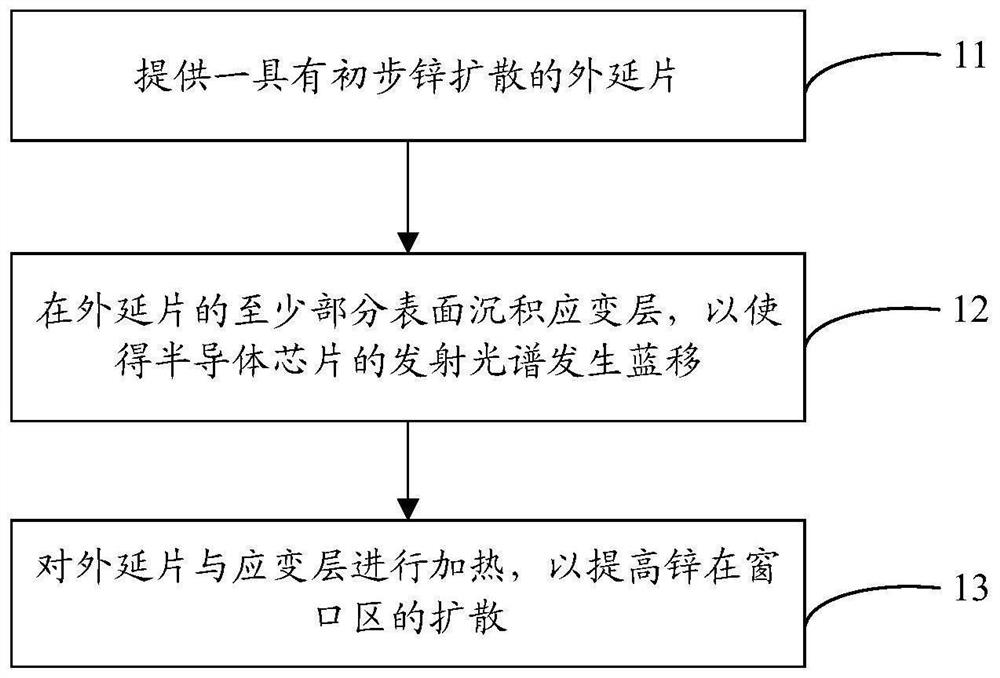

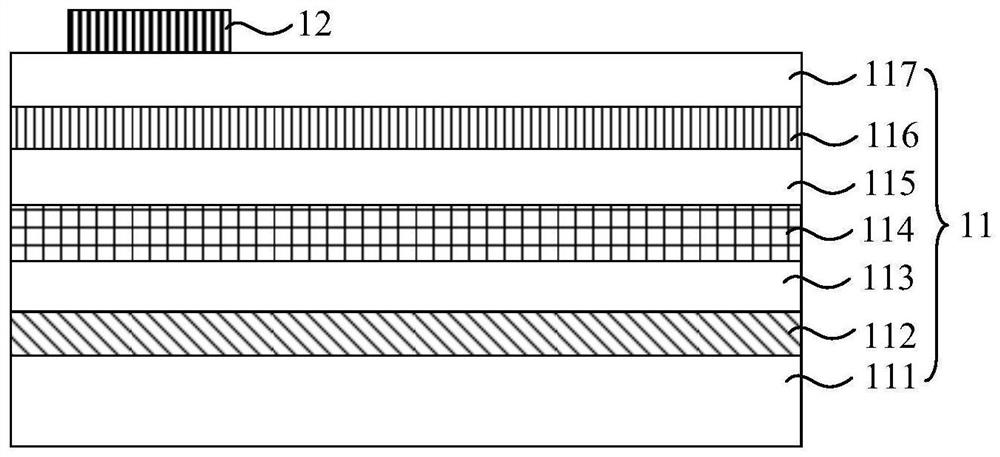

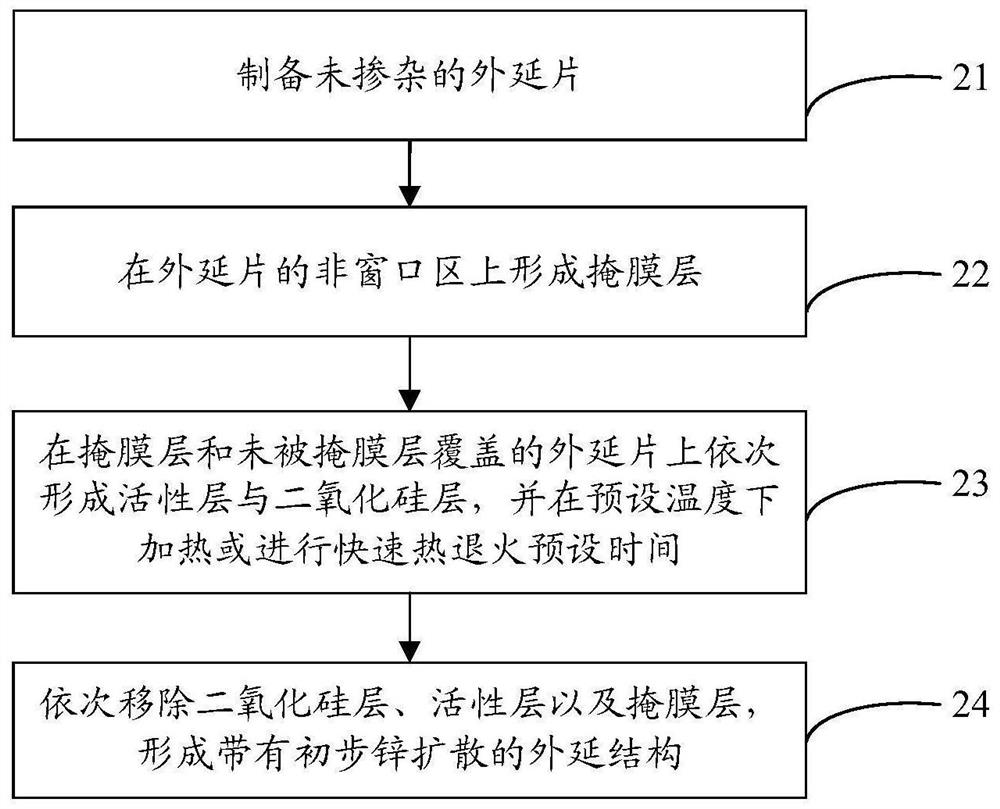

Manufacturing method of semiconductor chip and laser

PendingCN113783103AFacilitated DiffusionShorten Diffusion TimeLaser detailsSemiconductor lasersSemiconductor chipThin membrane

The invention discloses a manufacturing method of a semiconductor chip and a laser. The method comprises the steps of providing an epitaxial wafer with preliminary zinc diffusion; depositing a strain layer on at least part of the surface of the epitaxial wafer so as to enable blue shift of the emission spectrum of the semiconductor chip to occur, wherein at least part of the surface comprises a window area; and heating the epitaxial wafer and the strain layer to improve the diffusion of zinc in the window area, wherein the film strain of the strain layer after heating is greater than the film strain before heating. Through the mode, diffusion of zinc can be accelerated, the production efficiency is improved, and the capability of resisting catastrophic optical mirror surface damage is improved.

Owner:SHENZHEN LASER INST

InGaAs/InP PIN photo electric detector and its manufacturing technology

InactiveCN1188914CStable growth conditionsEasy to controlFinal product manufactureSolid-state devicesManufacturing technologySignal-to-noise ratio (imaging)

A InGaAs / InP PIN photoelectric detector relating to a semiconductor component has the structure of double hetergeneous material in four layer of i-In0.53 Ga 0.47As photosensitive layer / i-InP buffer layer / N+-Inp substrate. There is P+ zinc diffusion layer which is close to i-In 0.53 Ga0.47 As photosensitive layer but not reach the photosensitive layer at the top layer. It is prepared by the following steps, growing a passivation film of aluminium oxide on the epitaxial sheet and carrying out open-type zinc diffusion by using zinc as a diffusion source, depositing high quality film of aluminium oxide on InP material by directly using evapouration to reduce dark current, and raising the signal to noise ratio. The film obtained can be used in passivation film of InP material.

Owner:XIAMEN UNIV

Solid-state zinc-expanding method of GaAs-based epitaxial wafer

InactiveCN108878273AGood repeatabilityImprove consistencySemiconductor/solid-state device manufacturingNitrogenOptoelectronics

The invention discloses a solid-state zinc-expanding method of a GaAs-based epitaxial wafer. A ZnO thin film is arranged on the GaAs epitaxial wafer to serve as a zinc source for performing zinc diffusion. The ZnO thin film is arranged on the GaAs epitaxial wafer in a sputtering mode. The temperature of zinc diffusion is 450-550 DEG C, the atmosphere of zinc diffusion is inert gas, preferably, theinert gas is nitrogen. The zinc diffusion source is the ZnO thin film, and is a solid-state source, so that the repeatability and the consistency of the diffusion process are relatively high. When the ZnO thin film is prepared by adopting the sputtering method, a damage layer can be formed on the surface of the epitaxial layer; and zinc atoms can easily enter the epitaxial layer along the damagedefects when zinc diffusion is carried out. An MOCVD reaction chamber is used for zinc diffusion, and the heat transfer mode adopts heat conduction, so that the temperature change of the epitaxial wafer is very fast, and the temperature uniformity of the whole epitaxial wafer is very high, thereby achieving very high diffusion uniformity and consistency.

Owner:潍坊华光光电子有限公司

An epitaxial structure of an avalanche diode and a method for manufacturing the avalanche diode

ActiveCN106887469BControl depthPrecise thickness controlThyristorSemiconductor/solid-state device manufacturingGradient materialAvalanche diode

The present invention discloses an epitaxial structure of an avalanche diode, and relates to the technical field of semiconductor manufacturing. The epitaxial structure of the avalanche diode comprises a substrate. A light-absorbing layer is formed above the substrate. An avalanche gain layer is formed above the light-absorbing layer. A zinc diffusion layer is formed above the avalanche gain layer. The zinc diffusion layer is made of the InP material. The avalanche gain layer is made of component-gradient materials composed of the In0.52Al0.48As material, the InxGa(1-x)AsyP(1-y) material, the InxGayAl(1-x-y)As mateiral and the InxGa(1-x)AsyP(1-y) material, or component-gradient materials composed of InxGayAl(1-x-y)As. In the InxGa(1-x)AsyP(1-y) material or the component-gradient material of InxGa(1-x)AsyP(1-y), x is larger than 0 and smaller than 1, and y is larger than 0 and smaller than 1. In the InxGayAl(1-x-y)As material or the component-gradient material of InxGayAl(1-x-y)As, x is larger than 0 and smaller than 1, y is larger than 0 and smaller than 1 and the sum of x+y is larger than 0 and smaller than 1. According to the technical scheme of the invention, the depth of the zinc diffusion area is effectively controlled, and the thickness of the avalanche gain layer is accurately controlled. The yield of avalanche diode devices is improved. The invention also discloses an avalanche diode manufacturing method.

Owner:武汉光谷量子技术有限公司

Vertical resonant cavity surface emitting laser and manufacturing method thereof

ActiveCN102738703BModal stabilityReduce higher order modesLaser detailsSemiconductor lasersResonant cavityOxidation zone

The invention provides a vertical resonant cavity surface emitting laser and a manufacturing method thereof. The vertical resonant cavity surface emitting laser comprises a substrate and an epitaxial lamination. The epitaxial lamination is formed on the substrate and includes an annular zinc diffusion zone, an annular ion implantation zone under the zinc diffusion zone, an annular oxidation zone under the ion implantation zone, and an active zone under the annular oxidation zone, wherein the zinc diffusion zone has a zinc diffusion through hole, the ion implantation zone has an ion implantation through hole, the oxidation zone has an oxidation through hole, and the zinc diffusion through hole, the ion implantation through hole and the oxidation through hole are in mutual communication. In addition, the present invention also provides the manufacturing method of the vertical resonant cavity surface emitting laser.

Owner:TRUE LIGHT

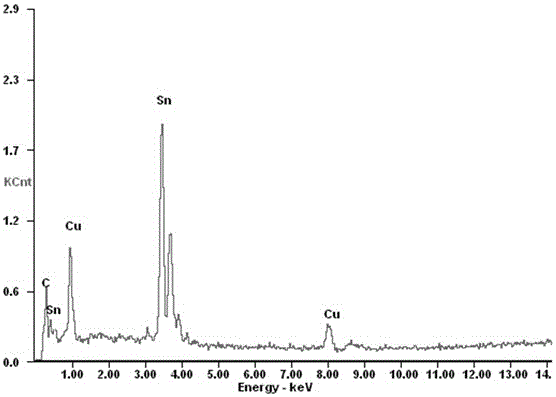

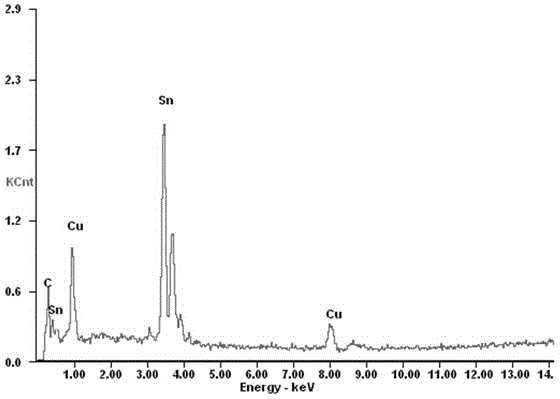

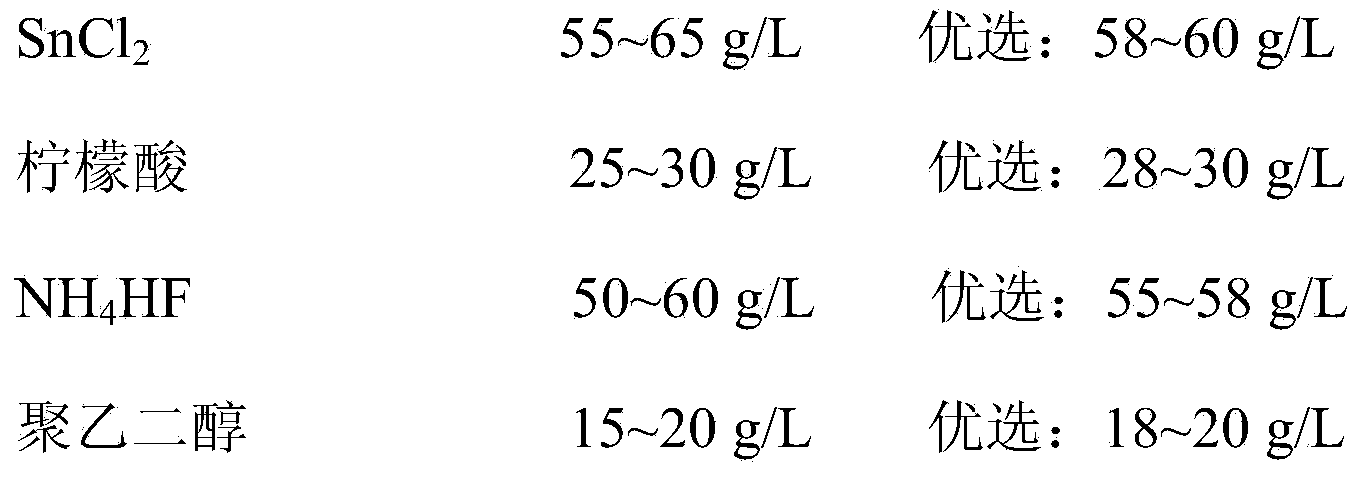

Tin-copper carbon nanotube composite coating, electroplating solution and electroplating method for automobile terminal

The invention discloses a tin and copper carbon nanotube composite coating of an automobile terminal, electroplating liquid and an electroplating method for the tin and copper carbon nanotube composite coating of the automobile terminal. The thickness of the coating is 0.5 micrometers, and the coating is prepared from, by mass, 1-3% of copper, 0.2-0.8% of carbon nanotube and the balance tin. The electroplating liquid is prepared from 30 g / L of tin sulfate, 3 g / L of copper sulfate, 50 g / L of citric acid, 35 g / L of tartaric acid, 100 mL / L of 98% sulfuric acid, 0.4 mg / L of 2-mercapto benzimidazole, 0.1g / L of sodium dodecyl sulfate and 1g / L of carbon nanotube. The treated automobile terminal is electroplated for 8-12 minutes in the electroplating liquid at 25 DEG C with the cathode-current density of 3 A / dm<2> and the rolling speed of 8 turns per minute. The problems that the plugging force of the automobile terminal obtained after tin plating is increased too much and assembling is difficult are solved, and the electroplating processes and the thickness of the coating are reduced; and while the cost is reduced, the plugging force is reduced, the protection performance of the terminal is improved, and the capability of resisting zinc diffusion which causes color changing of the coating is improved.

Owner:HENAN THB ELECTRIC

Open tube zinc diffusing method for producing indium-gallium-arsenic photoelectric detector

InactiveCN1186800CDiffusion process is simpleEasy to operateFinal product manufactureSemiconductor/solid-state device manufacturingIndiumShielding gas

This invention discloses an open tube zinc diffusion method for the production of In-Ga-As photo-electric detectors relating to the diffusion technique of semiconductor photoelectric apparatus. The method includes applying a structure of open tubew diffusion quartz tube structure to intake the protecting gases of hydrogen and nitrogen, and putting zinc and semiconductor wafers into a carbon diffusion boat to carry out high temperature diffusion under normal pressure, and finishing the zinc diffusion technique of the semiconductor wafer. This invention has uniform and repeated diffusion, result, good property of junction with simple production technique and dimenision of semiconductor wafer can be increased along with the enlarging of the diffusion furnace, and the diffusion boat and the source can be used repeatedly.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

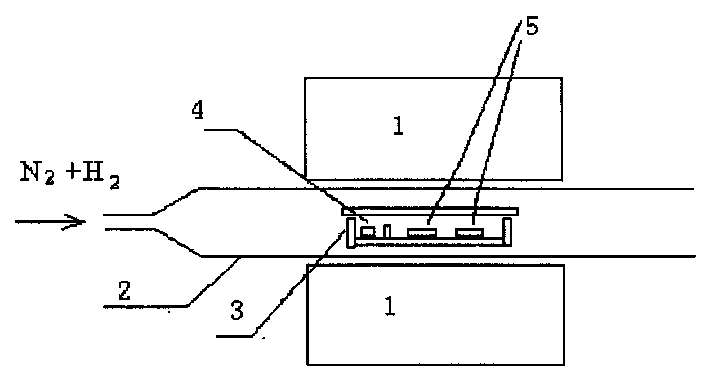

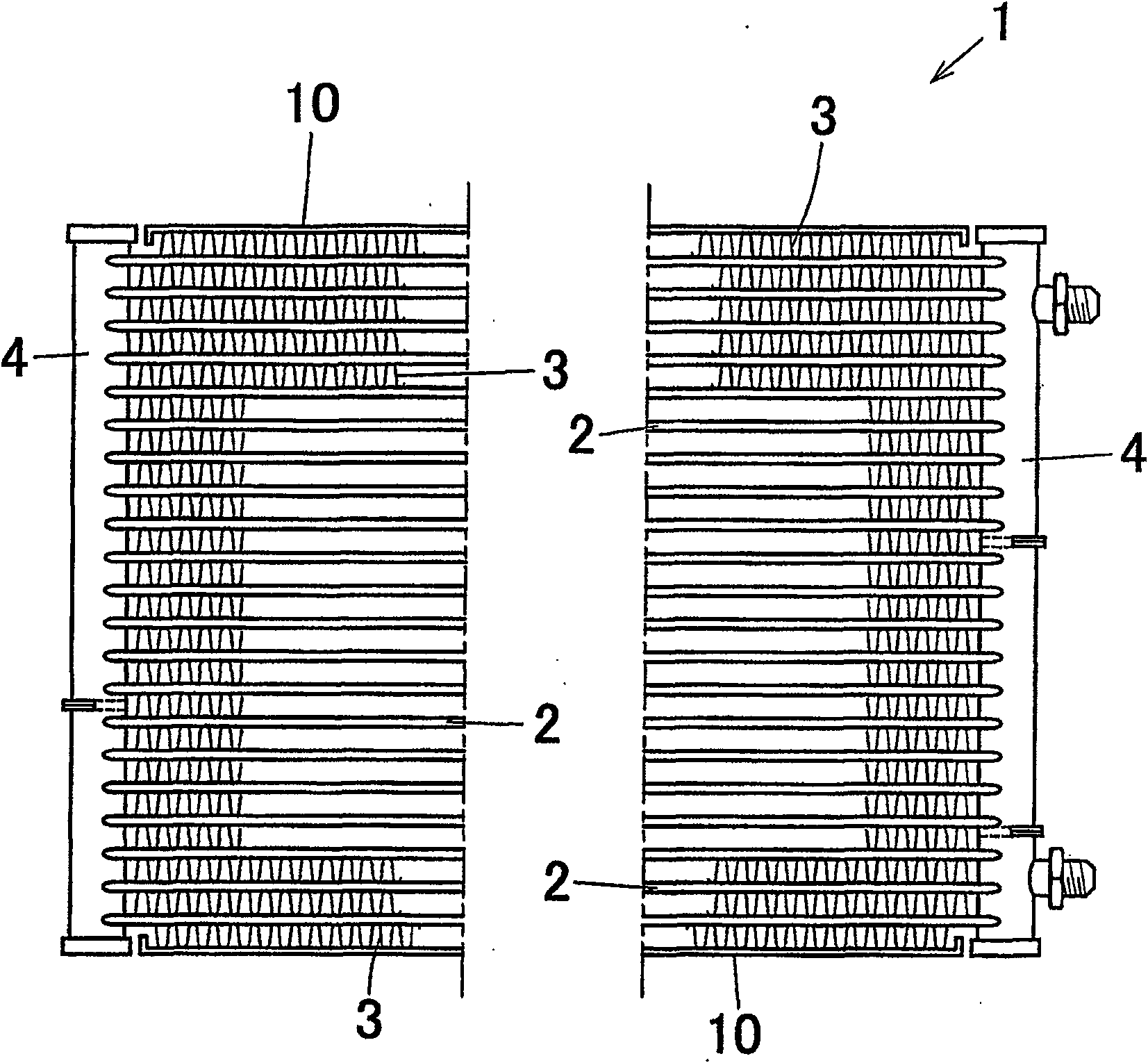

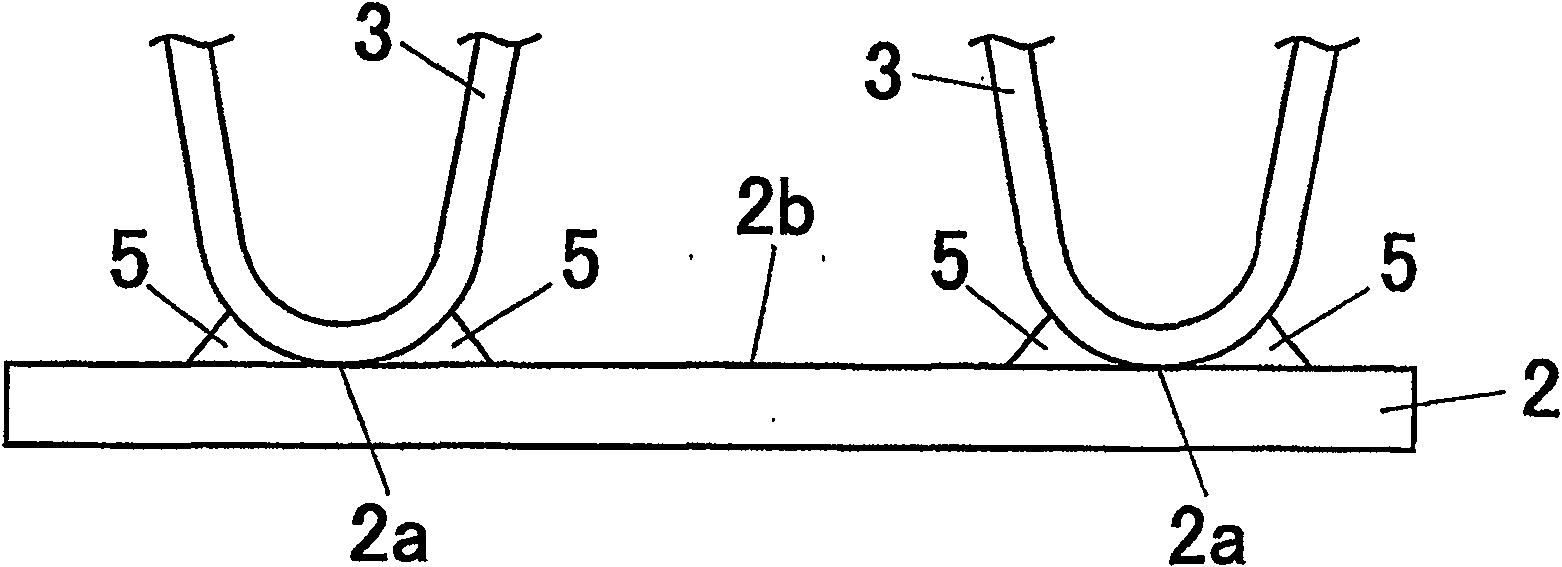

Method for manufacturing heat exchanger

InactiveCN100565082CImprove corrosion resistanceAvoid defectsStationary conduit assembliesCoatingsThermal sprayingZinc diffusion

Owner:SHOWA DENKO KK

Tin and copper carbon nanotube composite coating of automobile terminal, electroplating liquid and electroplating method for tin and copper carbon nanotube composite coating of automobile terminal

The invention discloses a tin and copper carbon nanotube composite coating of an automobile terminal, electroplating liquid and an electroplating method for the tin and copper carbon nanotube composite coating of the automobile terminal. The thickness of the coating is 0.5 micrometers, and the coating is prepared from, by mass, 1-3% of copper, 0.2-0.8% of carbon nanotube and the balance tin. The electroplating liquid is prepared from 30 g / L of tin sulfate, 3 g / L of copper sulfate, 50 g / L of citric acid, 35 g / L of tartaric acid, 100 mL / L of 98% sulfuric acid, 0.4 mg / L of 2-mercapto benzimidazole, 0.1g / L of sodium dodecyl sulfate and 1g / L of carbon nanotube. The treated automobile terminal is electroplated for 8-12 minutes in the electroplating liquid at 25 DEG C with the cathode-current density of 3 A / dm<2> and the rolling speed of 8 turns per minute. The problems that the plugging force of the automobile terminal obtained after tin plating is increased too much and assembling is difficult are solved, and the electroplating processes and the thickness of the coating are reduced; and while the cost is reduced, the plugging force is reduced, the protection performance of the terminal is improved, and the capability of resisting zinc diffusion which causes color changing of the coating is improved.

Owner:HENAN THB ELECTRIC

Mercury-free button cell cathode cap material and preparation method thereof

The invention discloses a mercury-free button cell cathode cap material and a preparation method thereof, and belongs to the field of a mercury-free alkaline zinc-manganese button cell. The preparation method comprises the following steps: by taking a steel strip as a base, arranging a nickel coating on one side of the base as the external surface of a cell cathode cap, and orderly electrically depositing the nickel coating, a copper coating, a first zinc coating, a tin coating, an indium coating and a second zinc coating on the other side of the base; and thermal treating all the metal coatings to improve the toughness of the outermost zinc coating, wherein the tin coating and the indium coating are protected by the arrangement of the inner and outer zinc coatings, and a tin diffusion layer, an indium diffusion layer and a zinc diffusion layer are formed, thus the hydrogen evolution over-potential is increased; and by mechanical rolling, the stamping resistance of a product is effectively improved. Compared with a conventional process for directly preparing an alloy, the cathode cap material prepared by the method disclosed by the invention is simpler and easier to operate, effectively prevents the problems that the tin coating falls off and is adhered with a grinding tool during the preparation of a cathode cap by use of an original pre-coating method, simultaneously realizes an aim of environmental protection by replacing mercury with indium, has good stamping performance and air expansion resistance, can completely realize no use of mercury of the alkaline zinc-manganese button cell and is applicable to industrial production.

Owner:HUNAN YONGSHENG NEW MATERIALS

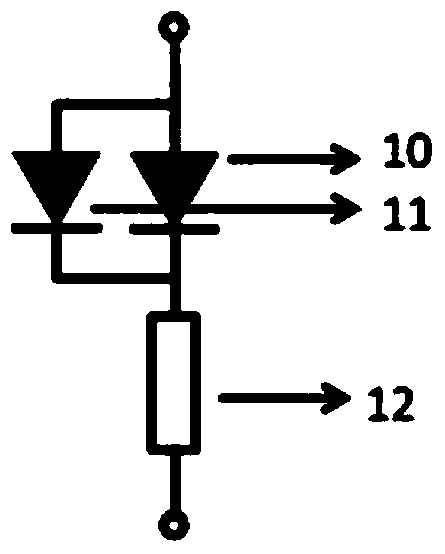

A method for detecting the degree of zn diffusion in the window region of a diffused zn semiconductor laser and its realization device

ActiveCN105720480BImprove long-term reliabilityAvoid enteringLaser active region structureDiffusionQuantum well

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com