Diffusion device and method for zinc in photodetector fabrication

A technology of photodetector and diffusion method, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of large temperature fluctuation range, complicated operation, dangerous use, etc., achieve precise control of diffusion depth, diffusion temperature fluctuation Small, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

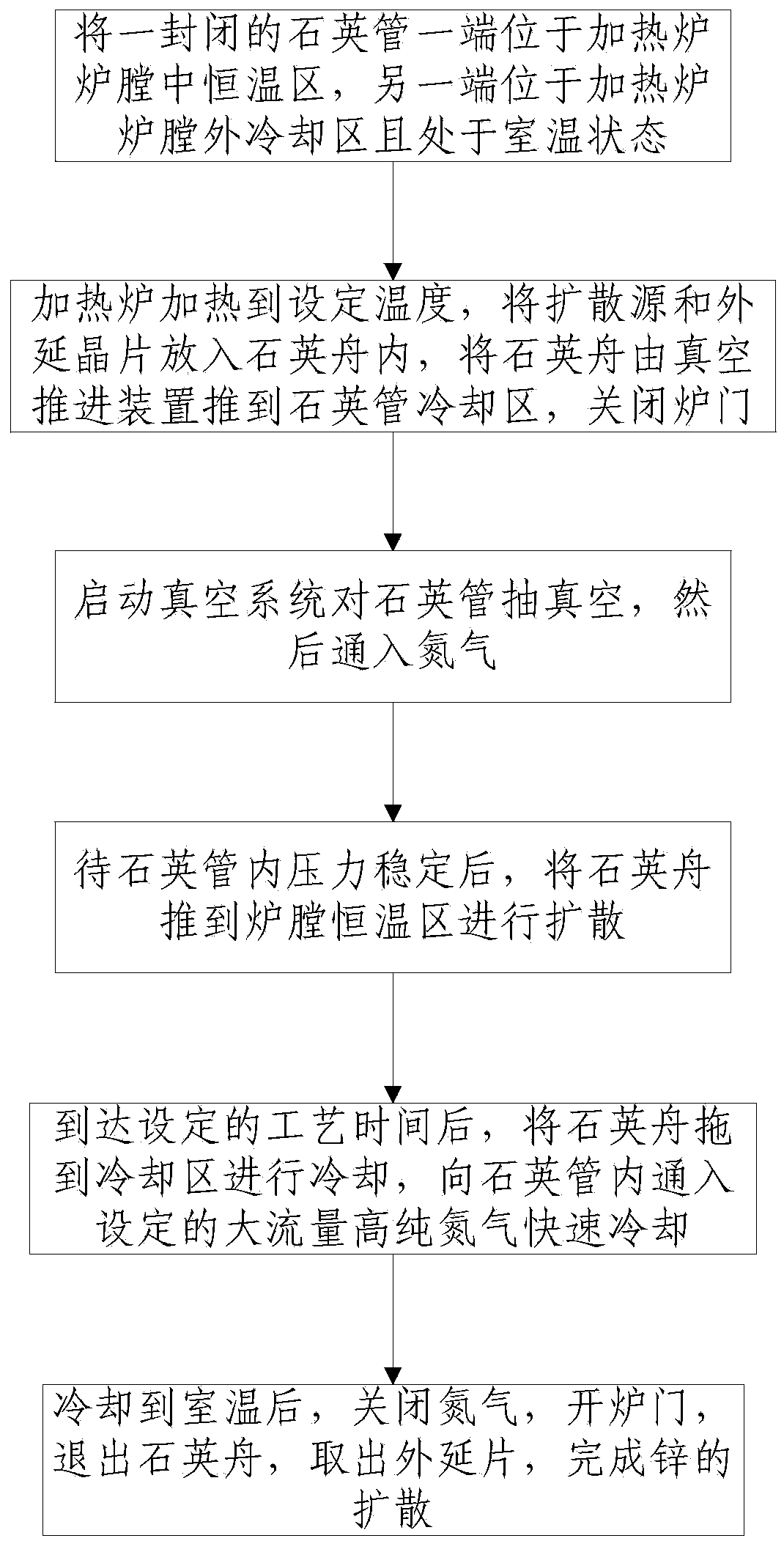

[0024] In order to facilitate a further understanding of the structure and method of the invention and the effects achieved, the preferred embodiments are described in detail below in conjunction with the accompanying drawings.

[0025] In order to obtain good photoelectric characteristics in the InGaAs detector process, a good PN junction must be obtained through diffusion, and the purpose of the present invention is to perform zinc diffusion in intrinsic indium phosphide.

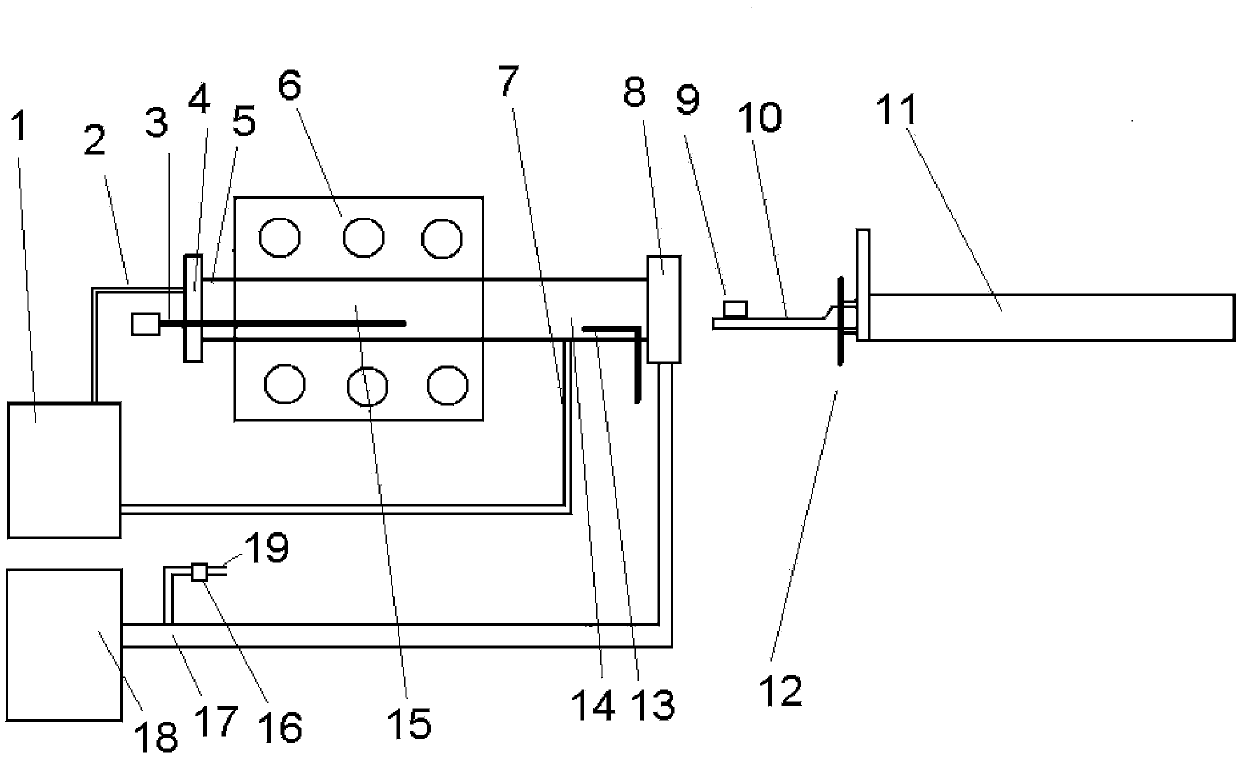

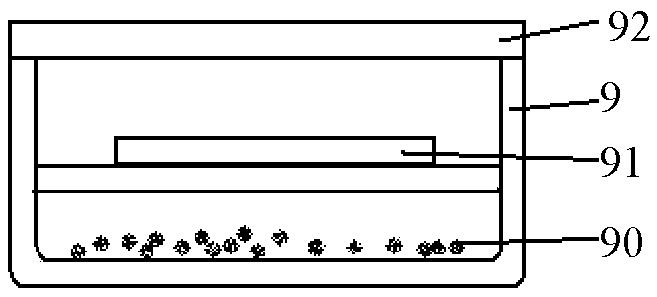

[0026] Such as figure 1 As shown, the zinc diffusion device in the photodetector production of the present invention includes a heating furnace 6, a quartz tube 5 with both ends closed, a gas control system 1, a vacuum system 18, a quartz boat 9, and is used to push the quartz boat 9 into the quartz tube 5 The vacuum propulsion device 11 and the boat board 10 connected with the vacuum propulsion device 11 are provided with a furnace door 12 near the end of the vacuum propulsion device 11 on the boat board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com