An epitaxial structure of an avalanche diode and a method for manufacturing the avalanche diode

An avalanche diode and epitaxial structure technology, which is applied in semiconductor/solid-state device manufacturing, thyristors, semiconductor devices, etc., can solve the problems of difficulty in improving the yield rate of avalanche diode devices, poor uniformity of epitaxial thickness, and increasing the difficulty of control circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

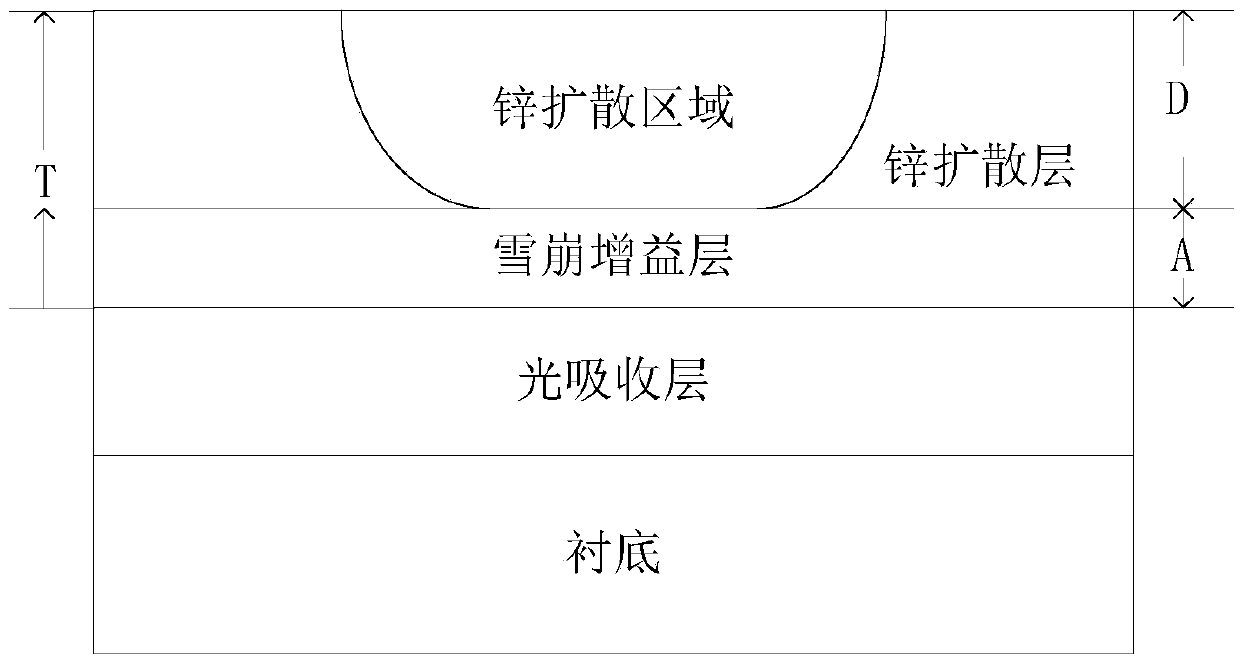

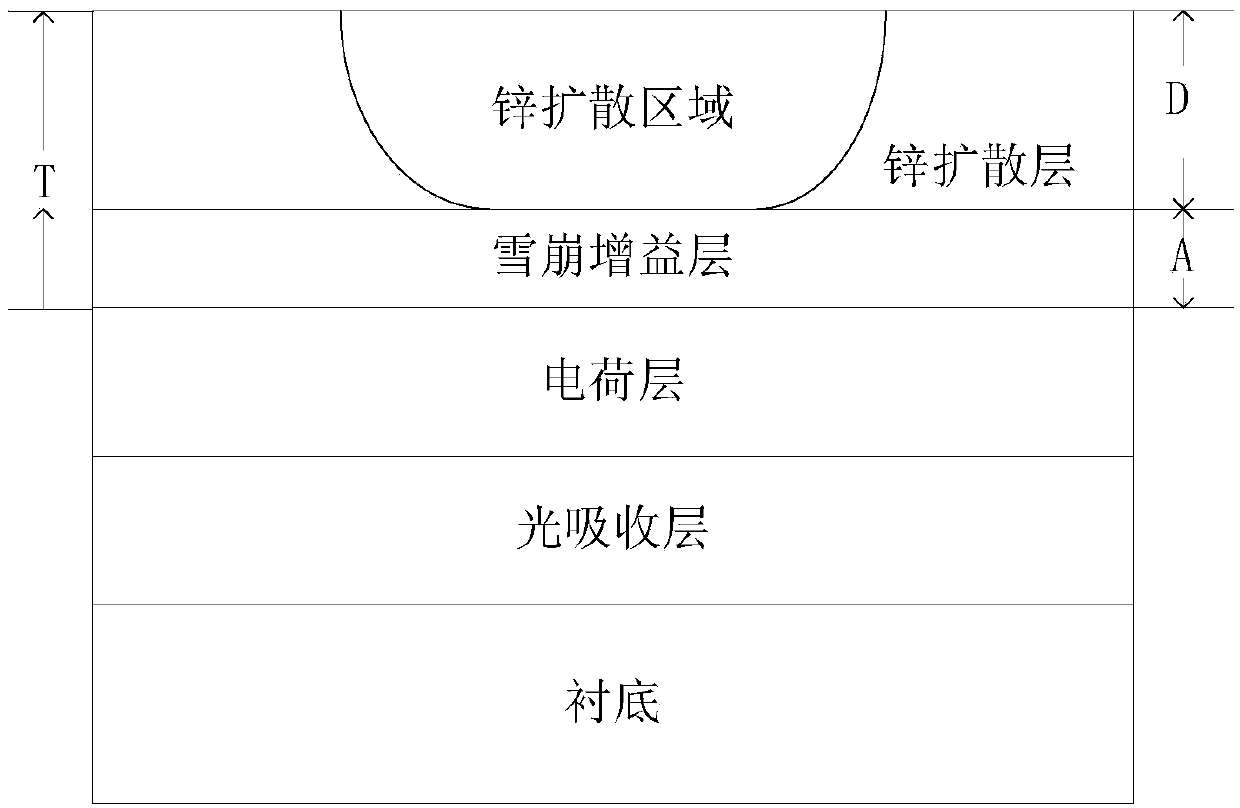

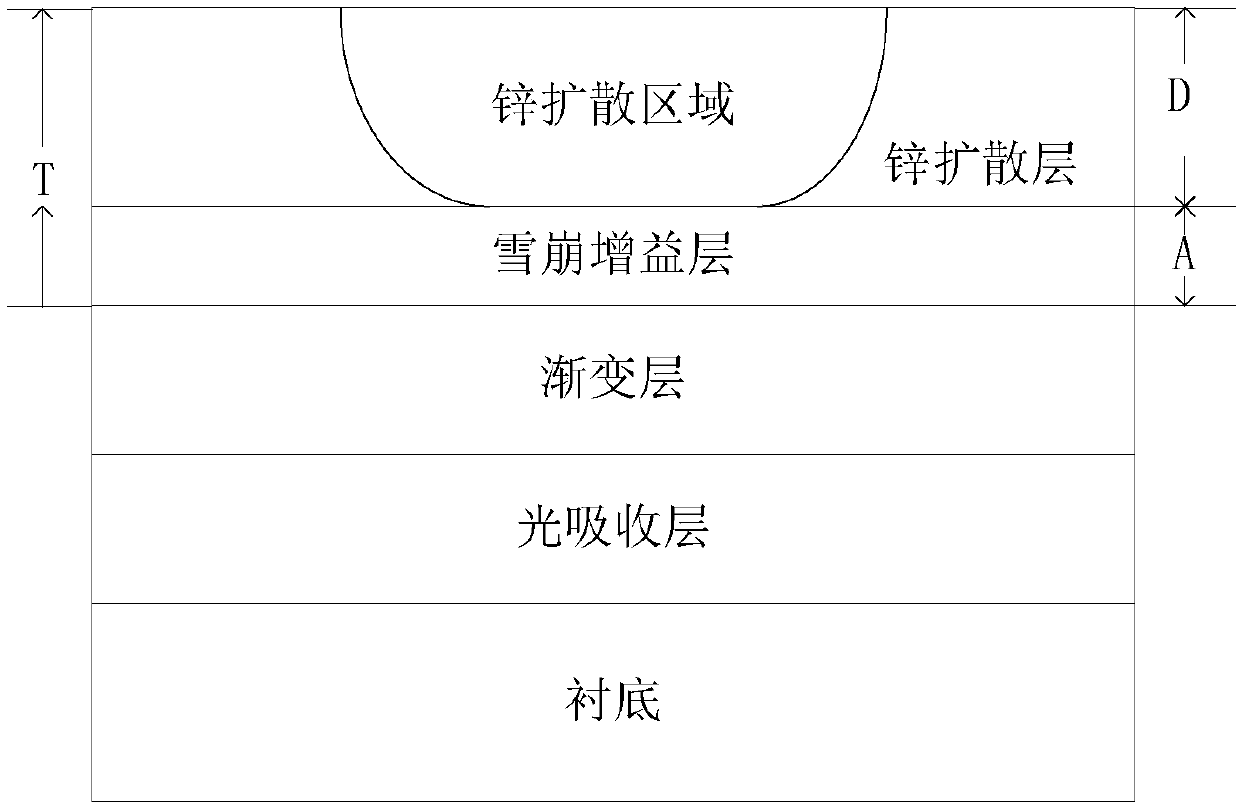

[0022] see figure 1 As shown, the embodiment of the present invention provides an epitaxial structure of an avalanche diode, including a substrate, a light absorbing layer is formed above the substrate, an avalanche gain layer is formed above the light absorbing layer, and a zinc diffusion layer is formed above the avalanche gain layer. Floor. The zinc diffusion layer is made of InP material, and the avalanche gain layer is made of In 0.52 Al 0.48 As material, In x Ga (1-x) As y P (1-y) Material, In x Ga y Al (1-x-y) As material, In x Ga (1-x) As y P (1-y) Composition of Gradient Material or In x Ga y Al (1-x-y) The composition of As is composed of graded materials, where In x Ga (1-x) As y P (1-y) Material or In x Ga (1-x) As y P (1-y) 0x Ga y Al (1-x-y) As material or In x Ga y Al (1-x-y) In the composition gradi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com