Tin-copper carbon nanotube composite coating, electroplating solution and electroplating method for automobile terminal

A carbon nanotube composite and carbon nanotube technology, which is applied in the field of preparation of tin-copper carbon nanotube composite coatings for automotive terminals, can solve problems such as assembly difficulties and increased insertion and extraction forces, and achieve reduced procedures, lower insertion and extraction forces, and lower cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

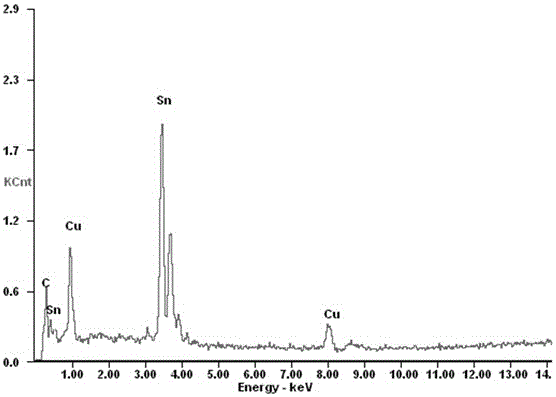

Image

Examples

Embodiment 1

[0019] A kind of electroplating solution that the tin-copper carbon nanotube composite coating of automobile terminal adopts, formula is as follows: stannous sulfate 25g / L, copper sulfate 5g / L, citric acid 45g / L, tartaric acid 40g / L, 98% sulfuric acid 95mL / L, 2-mercaptobenzimidazole 0.6mg / L, sodium dodecylsulfonate 0.05g / L, carbon nanotube 1.5g / L.

[0020] A kind of electroplating method of tin-copper carbon nanotube composite coating of automobile terminal, the steps are as follows:

[0021] (1) Add deionized water to the cleaned plating tank, slowly add 98% sulfuric acid, add stannous sulfate, copper sulfate, citric acid, tartaric acid and 2-mercaptobenzimidazole after the solution is cooled to 25°C, and Stir continuously to dissolve and form solution A;

[0022] (2) Add sodium dodecylsulfonate and carbon nanotubes into deionized water, and disperse them by ultrasonic waves for 8 minutes to form solution B;

[0023] (3) Add solution B to solution A, hang the tin anode and ...

Embodiment 2

[0026] A kind of electroplating solution that tin-copper carbon nanotube composite coating of automobile terminal adopts, formula is as follows: tin protosulfate 35g / L, copper sulfate 1g / L, citric acid 55g / L, tartaric acid 30g / L, 98% sulfuric acid 105mL / L, 2-mercaptobenzimidazole 0.1mg / L, sodium dodecylsulfonate 0.2g / L, carbon nanotube 0.5g / L.

[0027] A kind of electroplating method of tin-copper carbon nanotube composite coating of automobile terminal, the steps are as follows:

[0028] (1) Add deionized water to the cleaned plating tank, slowly add 98% sulfuric acid, add stannous sulfate, copper sulfate, citric acid, tartaric acid and 2-mercaptobenzimidazole after the solution is cooled to 35°C, and Stir continuously to dissolve and form solution A;

[0029] (2) Add sodium dodecylsulfonate and carbon nanotubes into deionized water, and disperse them by ultrasonic waves for 15 minutes to form solution B;

[0030] (3) Add solution B to solution A. At this time, if the total...

Embodiment 3

[0033] A kind of electroplating solution that the tin-copper carbon nanotube composite coating of automobile terminal adopts, formula is as follows: tin protosulfate 30g / L, copper sulfate 3g / L, citric acid 50g / L, tartaric acid 35g / L, 98% sulfuric acid 100mL / L, 2-mercaptobenzimidazole 0.4mg / L, sodium dodecylsulfonate 0.1 g / L, carbon nanotube 1g / L.

[0034] A kind of electroplating method of tin-copper carbon nanotube composite coating of automobile terminal, the steps are as follows:

[0035] (1) Add 60L of deionized water to the cleaned plating tank, slowly add 98% sulfuric acid, add 30g stannous sulfate, 3g / copper sulfate, 50g citric acid, 35g tartaric acid and 0.4mg 2-mercaptobenzimidazole, and constantly stirring to make the solution A;

[0036] (2) Add 0.1 g of sodium dodecylsulfonate and 1 g of carbon nanotubes into 5 L of deionized water, and disperse them by ultrasonic waves for 10 minutes to form solution B;

[0037] (3) Add solution B to solution A, then add 35L of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com