Selective emitter gallium antimonide infrared battery and manufacturing method thereof

A gallium antimonide and emitter technology, which is applied in the field of selective emitter gallium antimonide infrared batteries and its preparation, can solve the problems of rising battery manufacturing costs, achieve stable electrical performance and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

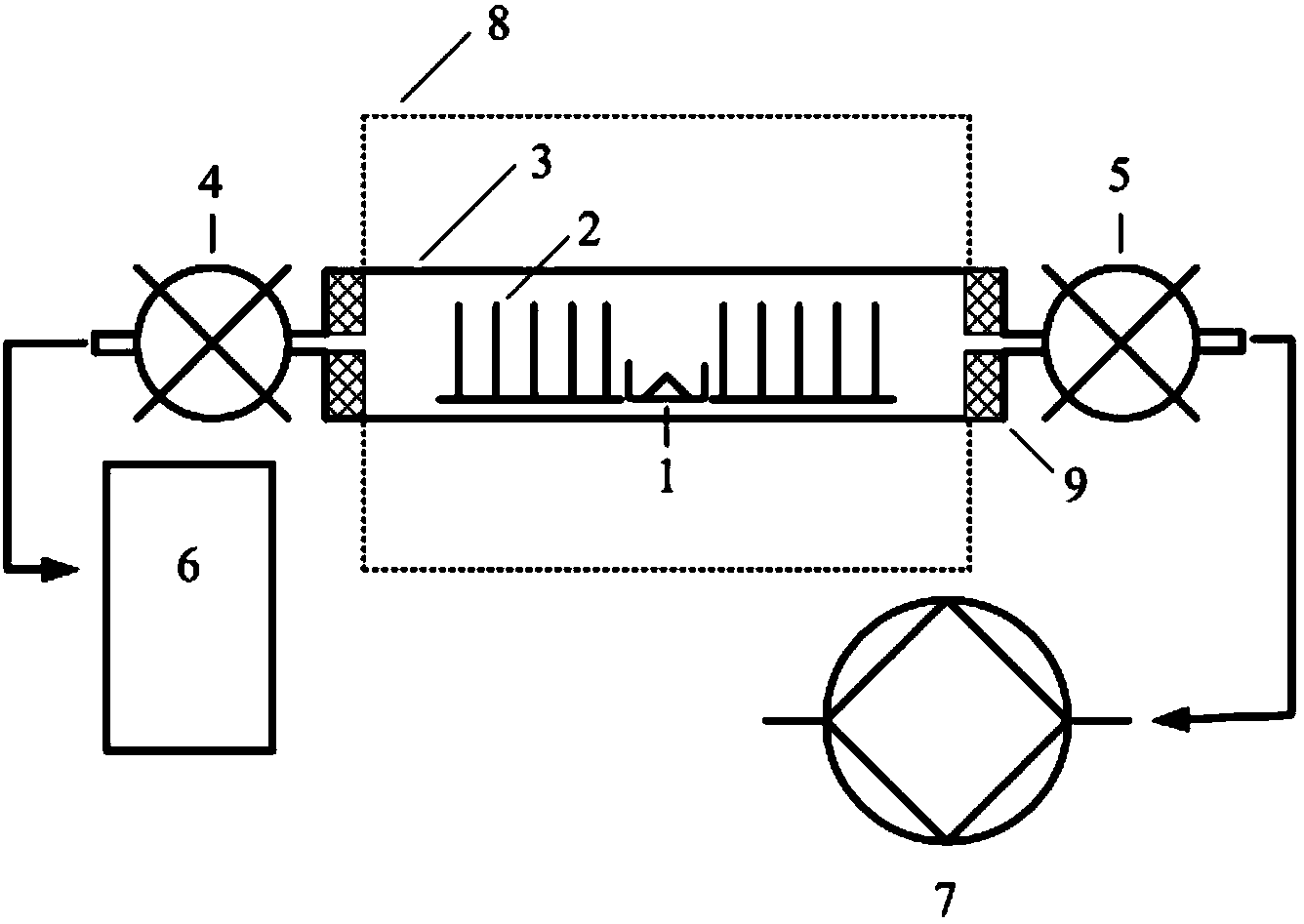

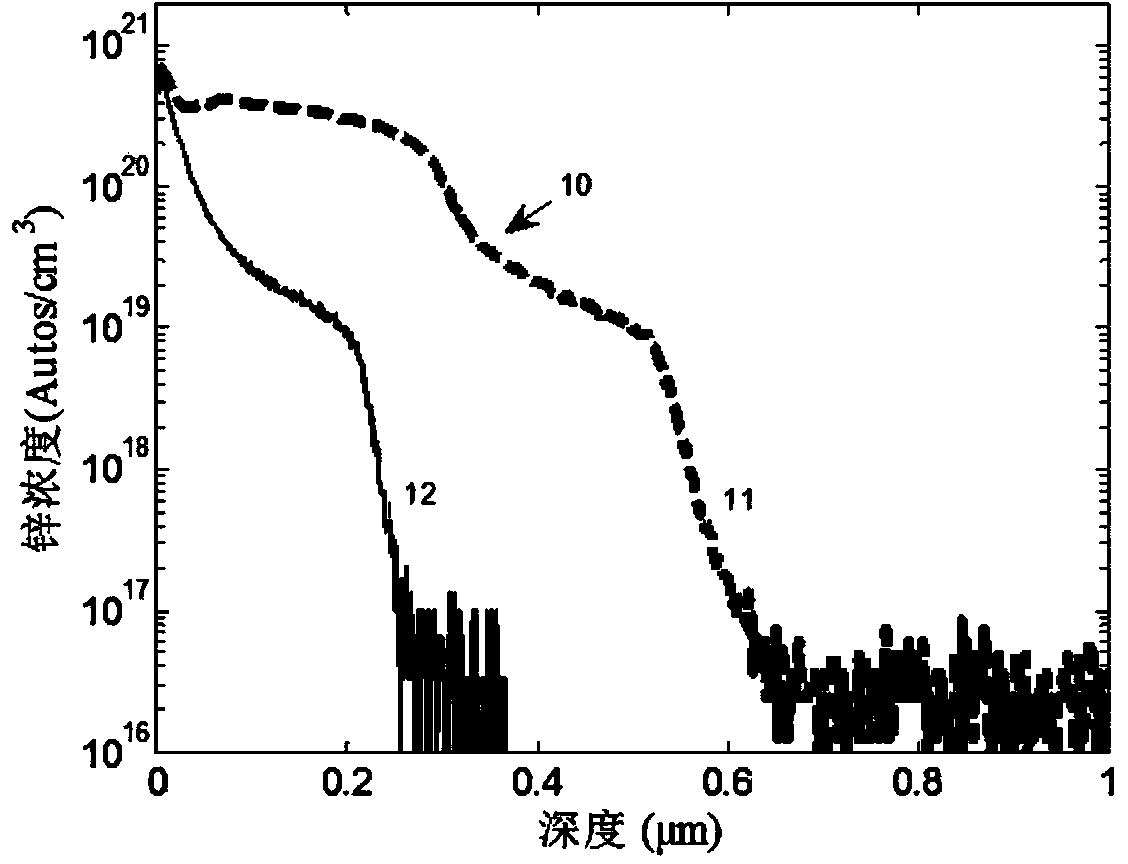

[0025] figure 1 A schematic diagram of the diffusion system required by the sealed diffusion method using zinc-gallium alloy in the present invention is given. The following describes the zinc diffusion preparation method of the selective emitter gallium antimonide infrared battery in this embodiment in conjunction with the accompanying drawings, which specifically includes the following steps:

[0026] In the first step, the concentration of Te containing tellurium is 2~7×10 17 cm -3 , The N-type gallium antimonide wafer with crystal orientation is successively placed in xylene, acetone and ethanol for cleaning, and then the surface oxide of the wafer is removed with dilute hydrochloric acid with a concentration of 5-20%, and finally cleaned in deionized water Blow dry with nitrogen gas;

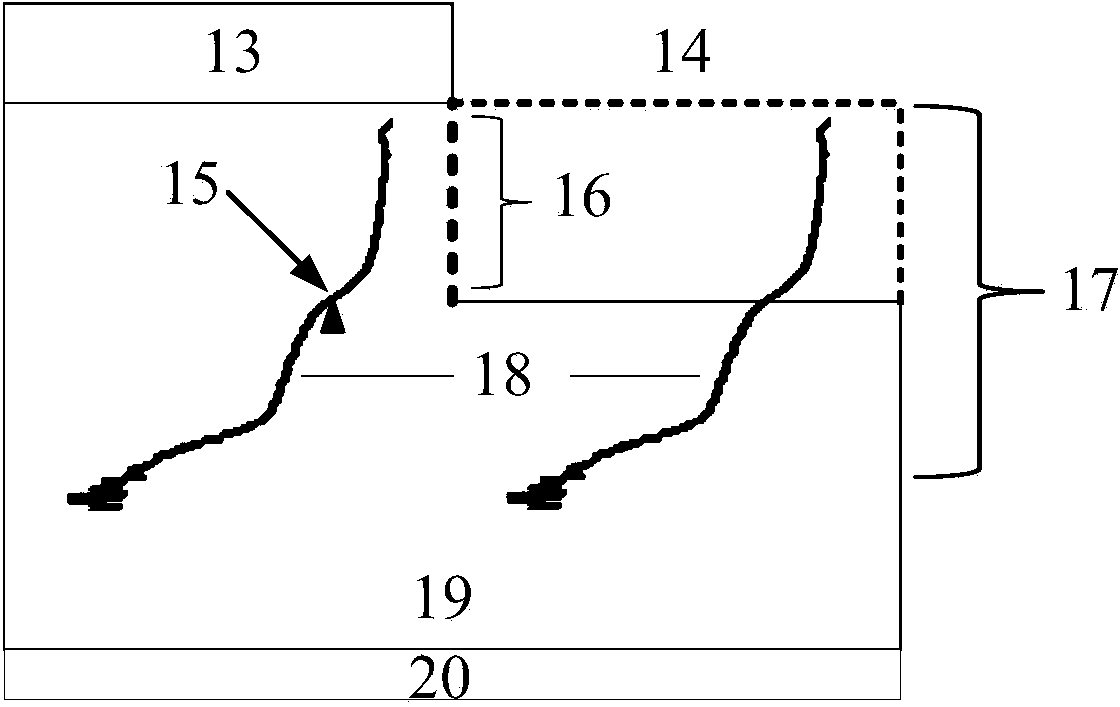

[0027] In the second step, a silicon dioxide layer with a thickness of 0.11 μm is deposited on the wafer by plasma chemical vapor deposition, and then the diffusion area in the center o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com