A method for detecting the degree of zn diffusion in the window region of a diffused zn semiconductor laser and its realization device

A diffusion degree, laser technology, applied in the structure of the active area and other directions, can solve the problems of reducing the gain area, narrow window area, high precision requirements, etc., to ensure stability and repeatability, improve long-term reliability, Simple detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

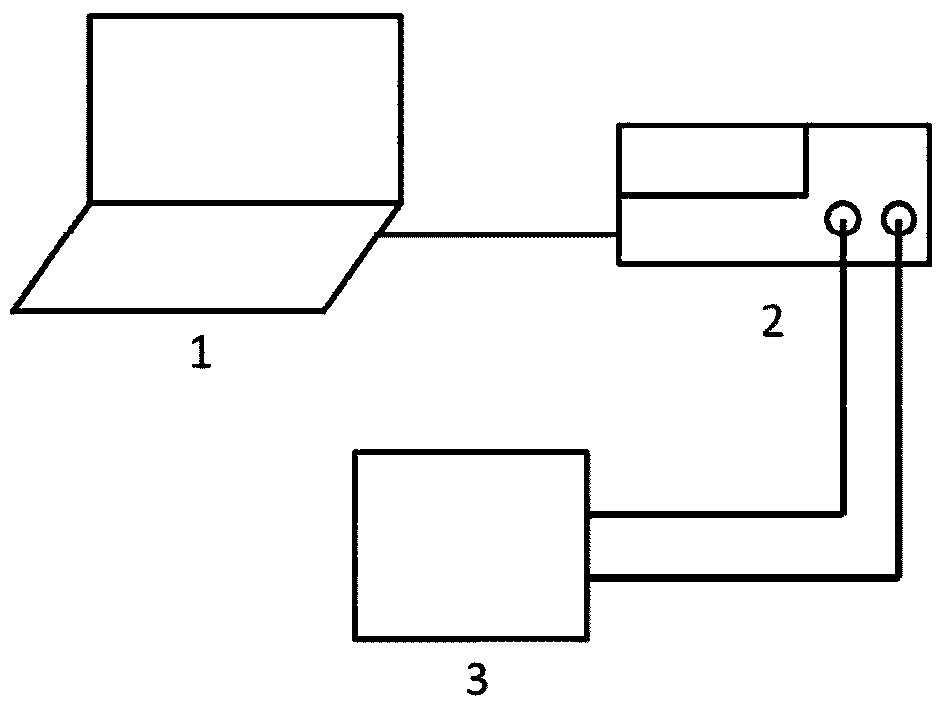

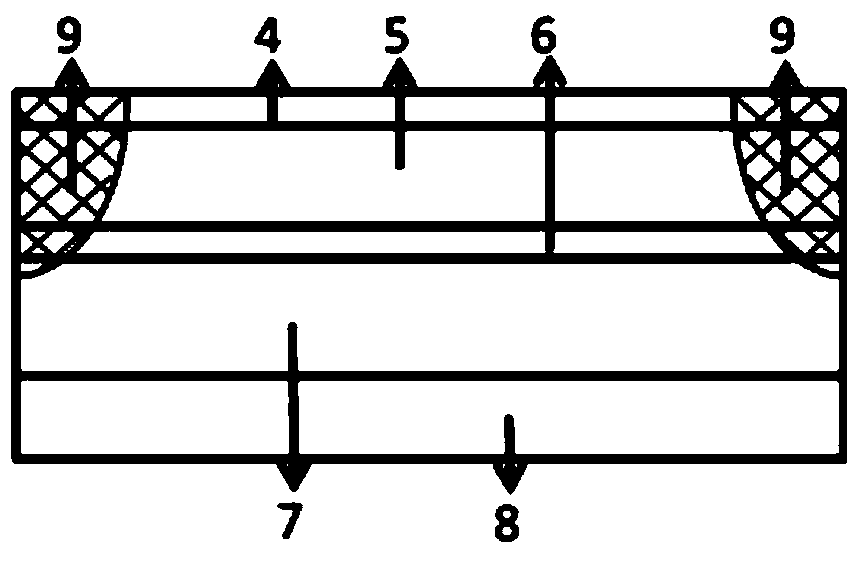

[0046] A method for detecting the diffusion degree of Zn in the window region of a diffused Zn semiconductor laser, the diffused Zn semiconductor laser comprising an ohmic contact layer 4, an upper confinement layer 5, an active region 6, a lower confinement layer 7, a substrate 8, and an expanded Zn window region 9. The exposed area near the cavity surface of the diffused Zn semiconductor laser is the expanded Zn window area 9, and the specific steps include:

[0047] A, measure the voltage V corresponding to the current value in the IV curve of the diffused Zn semiconductor laser, and the specific steps include:

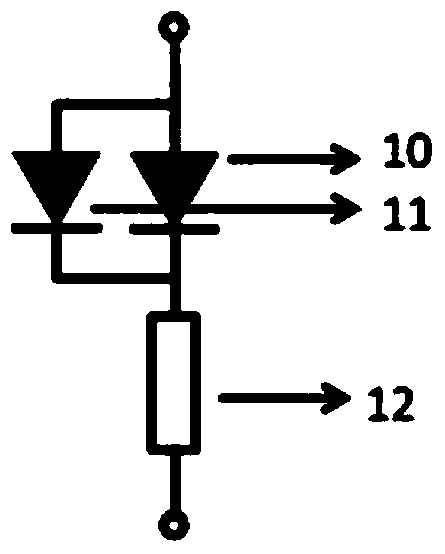

[0048] (1) Set the temperature of the test substrate to be 25° C.; the test fixture clamps the diffused Zn semiconductor laser, that is: the forward current port of the test fixture is in contact with the anode of the diffused Zn semiconductor laser, and the reverse current port of the test fixture is in contact with the diffused Zn semiconductor laser. Diffused Zn...

Embodiment 2

[0060] According to a method for detecting the degree of Zn diffusion in the window region of a diffused Zn semiconductor laser described in embodiment 1, the difference is that in embodiment 2, the Zn diffusion temperature is 580° C., and the Zn diffusion time is 20 minutes. Figure 5 The IV curve of the diffused Zn semiconductor laser under this diffusion condition.

[0061] The value of the current value is 0.1mA, and the voltage V corresponding to the current value obtained in the IV curve is 1.47V;

[0062] At this time, Von-0.15≤V

Embodiment 3

[0064] According to a kind of method for detecting the diffusion degree of Zn in the window region of the diffused Zn semiconductor laser described in embodiment 1, the difference is that the Zn diffusion temperature becomes 580° C., and the diffusion time becomes 40 minutes. Figure 6 The IV curve of the diffused Zn semiconductor laser under this diffusion condition.

[0065] The value of the current value is 0.1mA, and the voltage V corresponding to the current value obtained in the IV curve is 1.05V;

[0066] At this time, if V

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com