Member for slide fasteners or buttons, which is formed from plated aluminum or aluminum alloy

An aluminum alloy and zipper technology, which is applied in the field of zipper elements, can solve the problems of difficult-to-plate materials and insufficient gloss, and achieve the effect of both crack resistance and gloss, and low sliding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

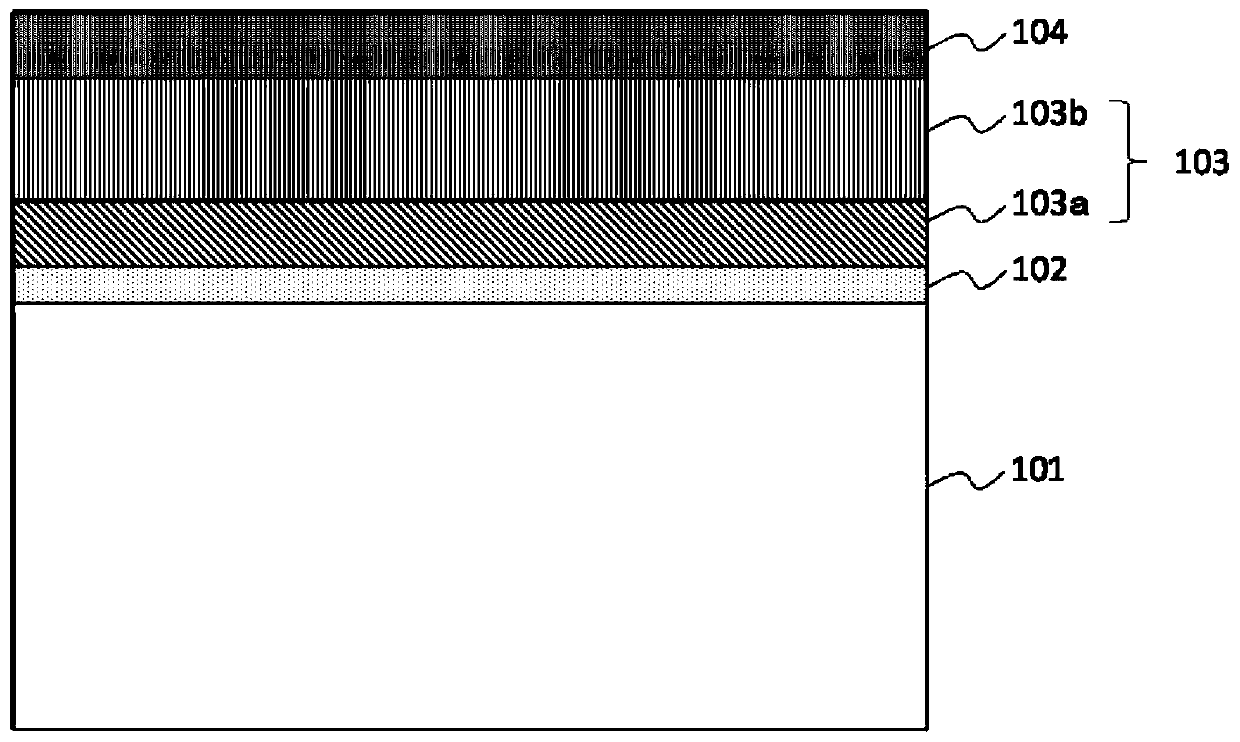

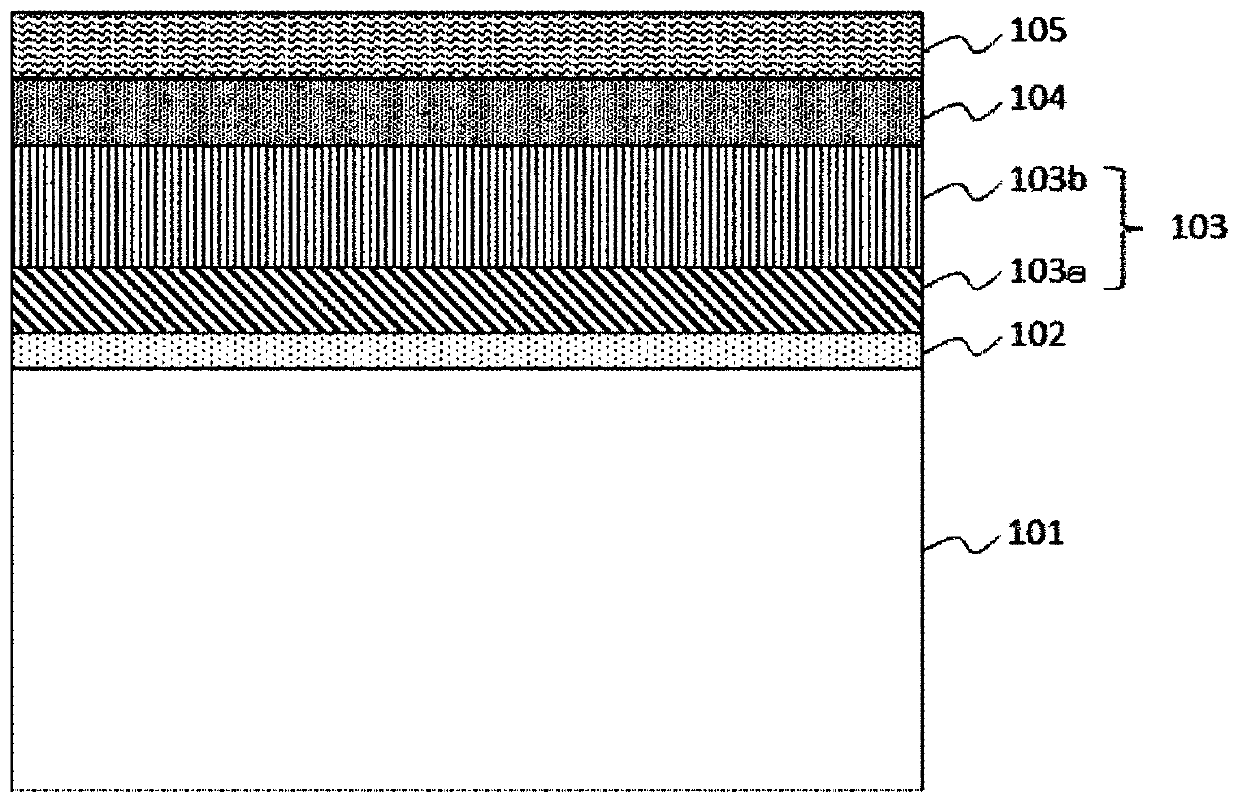

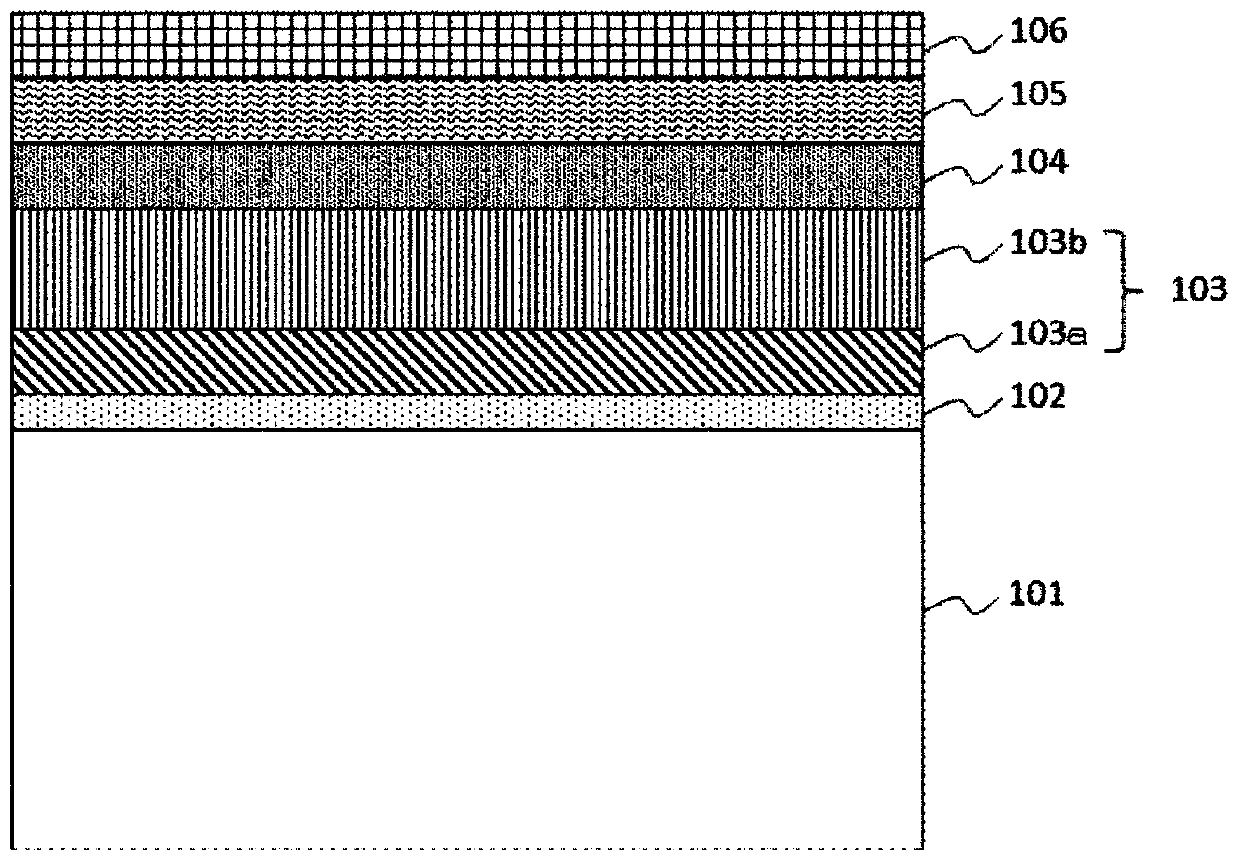

Method used

Image

Examples

Embodiment 1~5

[0094] Under the same conditions as in Comparative Example 1, pretreatment and zincate treatment were performed on a plurality of elements for slide fasteners produced by press-punching an aluminum rectangular wire rod. Next, a copper pyrophosphate plating layer (strike plating layer→main plating layer) and a copper sulfate plating layer having an average thickness described in Table 1 were sequentially formed by barrel plating. Thereafter, in Examples 2 to 4, a finishing plating layer (Cu—Sn—Zn alloy plating layer) having an average thickness described in Table 1 was formed by barrel plating. In Example 5, a Cu—Sn black plating layer (color tone adjustment plating layer) having an average thickness described in Table 1 was formed on the finishing plating layer by barrel plating. In Example 1, no finishing plating layer was formed.

[0095]

[0096] (1) Zinc diffusion layer

[0097] For each of the plated elements of the examples and comparative examples obtained under the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com