Avalanche photodiode and manufacturing method thereof

An avalanche photoelectric and diode technology, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problem that the edge area of zinc expansion is difficult to control, and achieve the effect of solving the difficulty of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

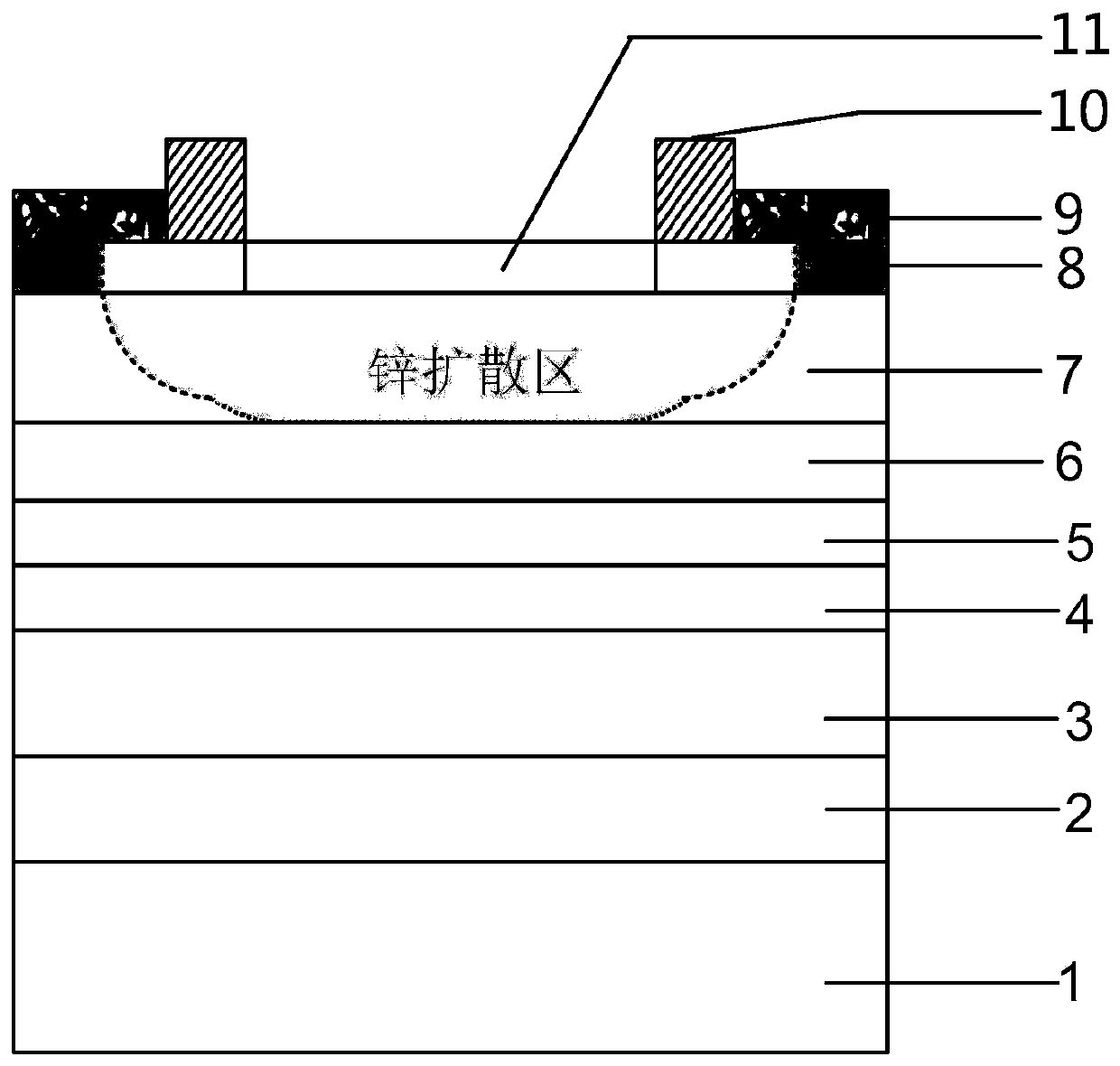

[0041] figure 1 It is a schematic structural diagram of an avalanche photodiode in an embodiment of the present invention, as figure 1 As shown, on the one hand, an embodiment of the present invention provides an avalanche photodiode, and the avalanche photodiode includes:

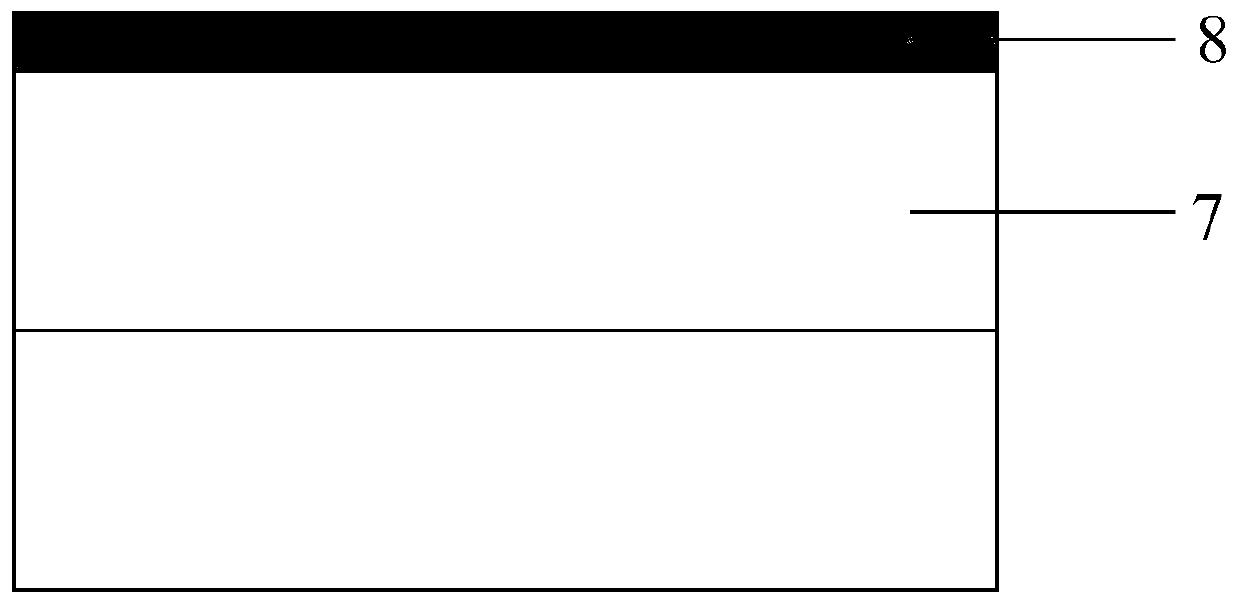

[0042] A substrate 1 on which a first contact layer 7 is provided;

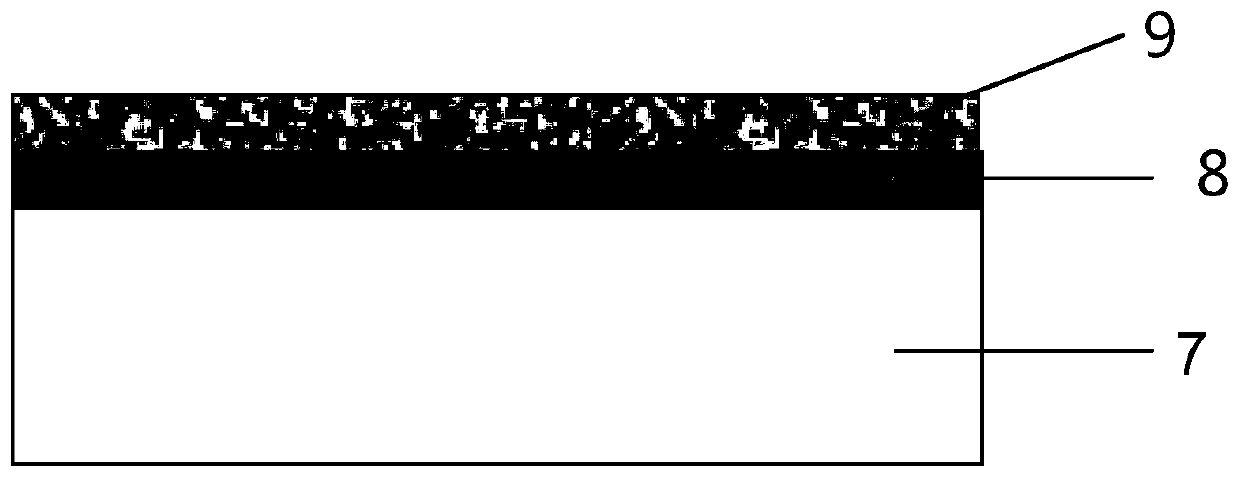

[0043] The second contact layer 8, which is plated on the first contact layer 7, and the second contact layer 8 is provided with a first window 81;

[0044] The passivation layer 9, which is plated on the second contact layer 8, and the passivation layer 9 is provided with a second window 91, the cross-sectional area of the second window 91 is larger than the cross-sectional area of the first window 81, and the second window 91 The second window 91 and the first window 81 are stepped; and

[0045]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com