Carriage longitudinal beam tailor welding tool

A technology for longitudinal beams and welders, which is applied in the field of tailored welding tooling for longitudinal beams of carriages. It can solve problems such as poor welding consistency and stability of longitudinal beam components, influence on welding production speed, and straightness size deviation, etc., so as to shorten tooling adjustment time and reduce Cutting and scribing work, and the effects of increased welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

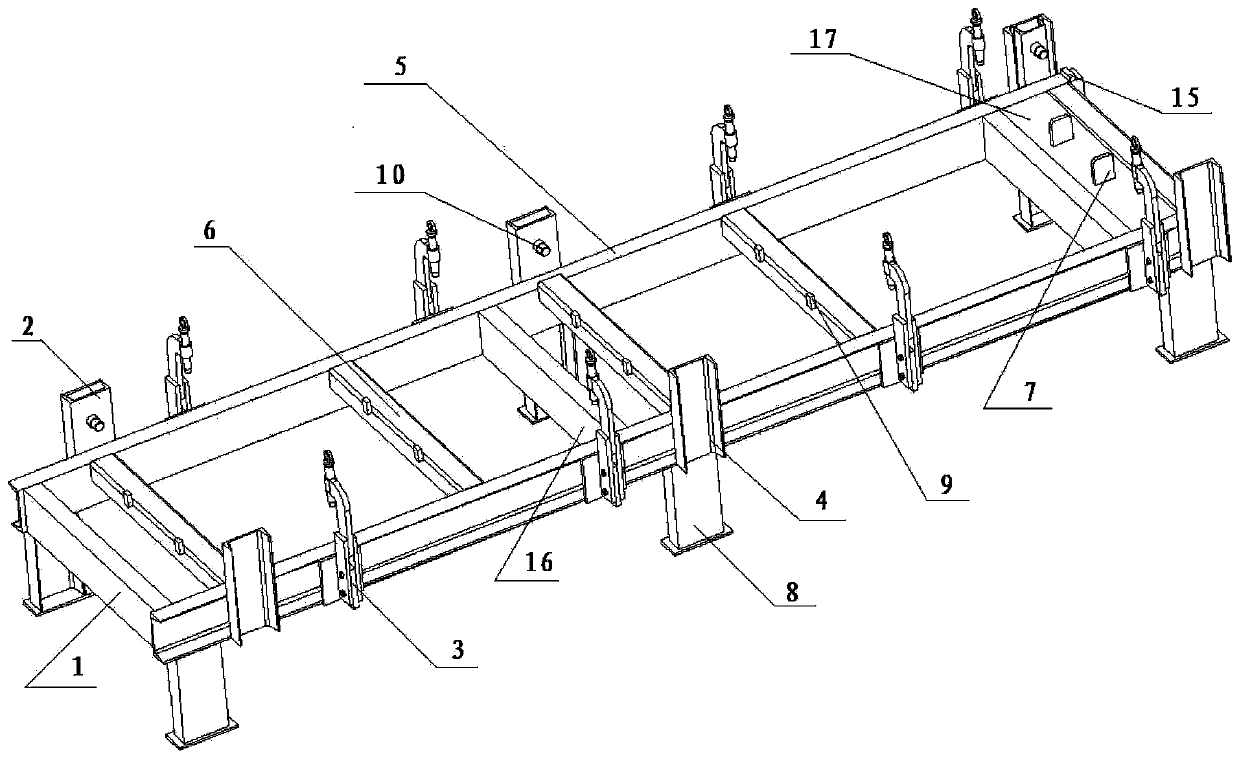

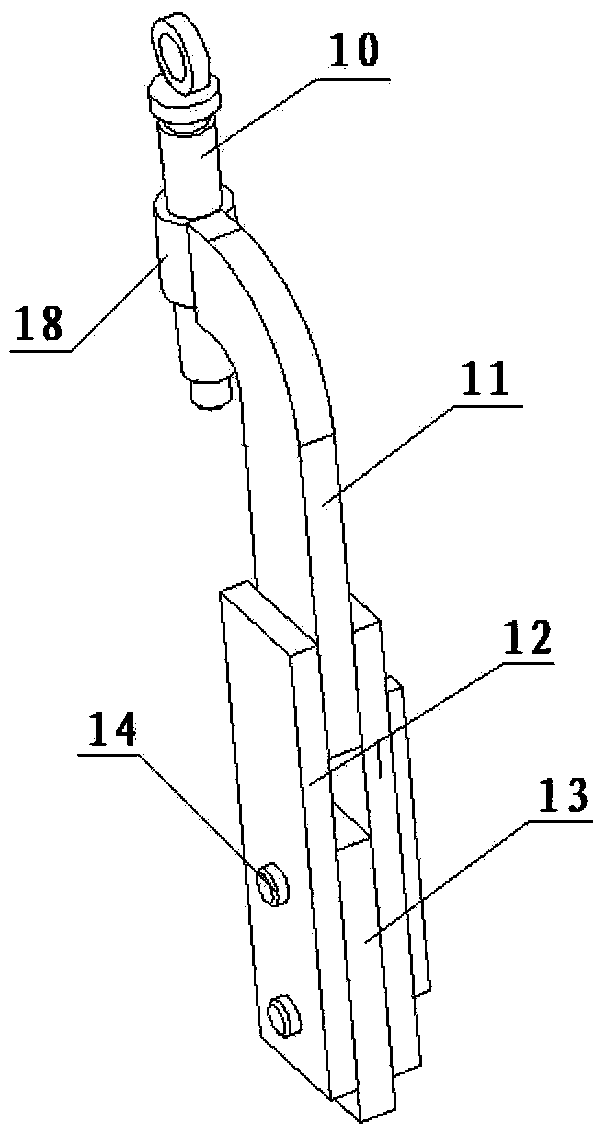

[0029] Such as figure 1 , figure 2 As shown, a tailor-welded tooling for longitudinal beams of a car box includes: a fixed frame 1, and three uprights 1 and 2 fixed on one edge of the fixed frame 1, and the uprights 1 and 2 are distributed at the upper, middle and lower positions with equal distances between them. , and the edge of the other side of the fixed frame 1 is fixedly connected to the lower part of the three columns 24, the columns 24 are distributed in the upper, middle and lower positions and the distance between the two columns is equal, and the positions of the columns 12 and 24 are symmetrical to each other, and the 8 adjusting rods 3 are fixed on the edge of the fixed frame 1 between the column one 2 and the column two 4, and the adjusting rods 3 on both sides of the fixed frame 1 are symmetrical to each other, and the adjusting rods 3 on each side are equally spaced apart from each other. , the backing plate 15 is fixedly connected to the surface of one end ...

Embodiment 2

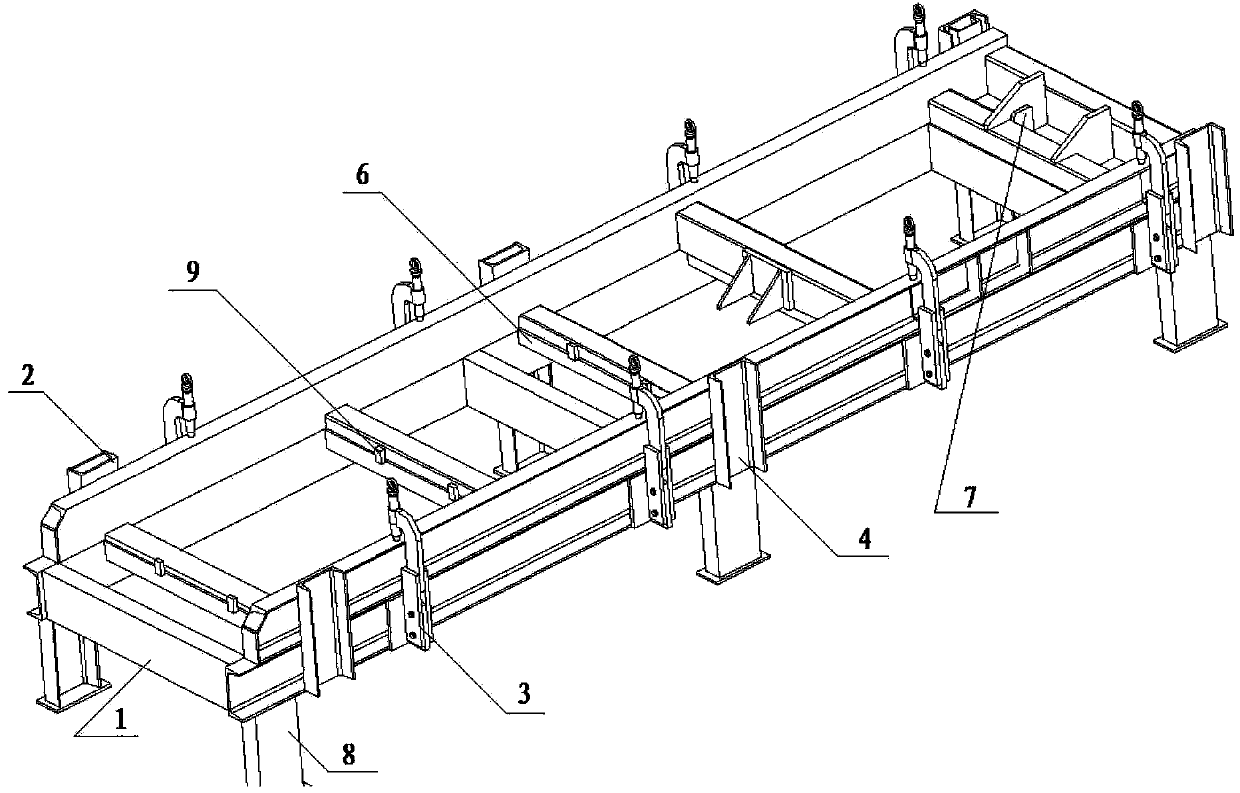

[0037] Such as image 3 As shown, the actual operation of the tailor welding of the longitudinal beam of the carriage:

[0038] Place the longitudinal beam of the carriage on the fixed frame 1, perform positioning by the cushion block 15 and perform horizontal adjustment by the adjusting screw 10 on the pillar one 5, and perform positioning of each component by the positioning block 9 and the positioning block 7 of the push plate, and adjust the position through the adjustment rod The adjustment screw rod 10 on the 3 is adjusted and fixed, and each part can be welded.

[0039] Tailored welding tooling for longitudinal beams of carriages in the present invention is positioned and clamped through the fixing frame, the first column, the second column and the adjustment rod, and has the functions of accurately positioning and reliably clamping the parts to be welded, facilitating the assembly and welding of the weldment, and improving the structure of the weldment advantages such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com