Open tube zinc diffusing method for producing indium-gallium-arsenic photoelectric detector

A technology of photodetector and diffusion method, which is applied in semiconductor/solid-state device manufacturing, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of expensive equipment and materials, achieve low manufacturing cost, simple diffusion process, and launch convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

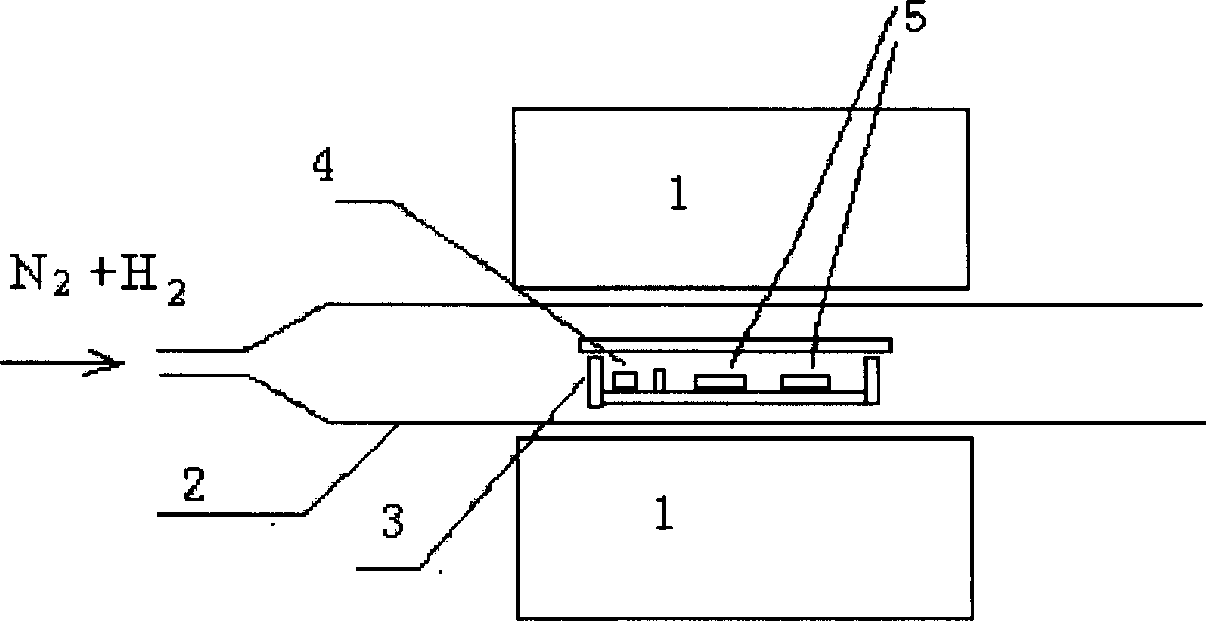

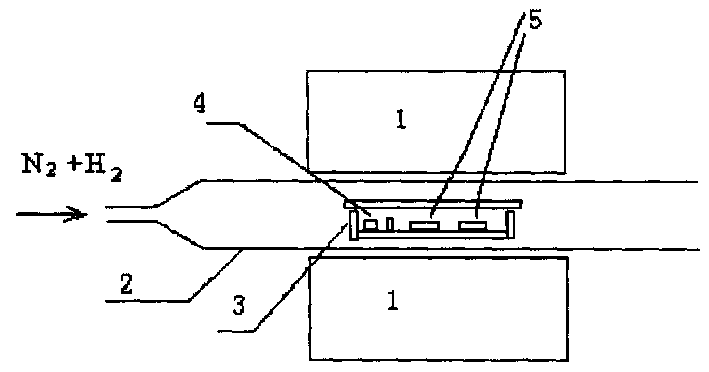

[0018] The best embodiment of the present invention is as figure 1 shown, including the following steps:

[0019] ① First raise the temperature of the diffusion furnace 1 to 400 to 600°C, and use a commercially available general-purpose semiconductor diffusion furnace to raise the temperature to 500°C in the embodiment;

[0020] ② Feed N into the diffusion quartz tube 2 in the diffusion furnace 1 2 and H 2 Mix the protective gas, and the diffusion quartz tube of the embodiment is made into an open-tube diffusion quartz tube structure, and one end of the open-tube diffusion quartz tube is designed as a thin tube structure, which is easy to pass into N 2 and H 2 gas, N 2 and H 2 The gas is a diffusion protection gas; the other end is designed as an open tube structure, which is convenient for pushing and pushing out the diffusion boat 3;

[0021] ③ Diffusion source 4 and InP / InGaAs epitaxial semiconductor wafer 5 are packed into a covered diffusion boat, and the diffusion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com