Iron-zinc coated steel plate with yield strength being 210 MPa and production method thereof

A technology with a yield strength of 210mpa, which is applied in the field of iron-zinc coated steel sheets and production, can solve the problems of high maintenance cost, complicated equipment, high investment, etc., and achieve the effect of dense surface structure, firm bonding, and not easy to pulverize and fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

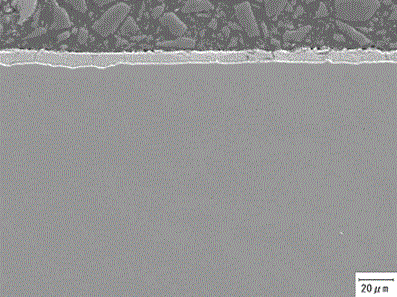

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below:

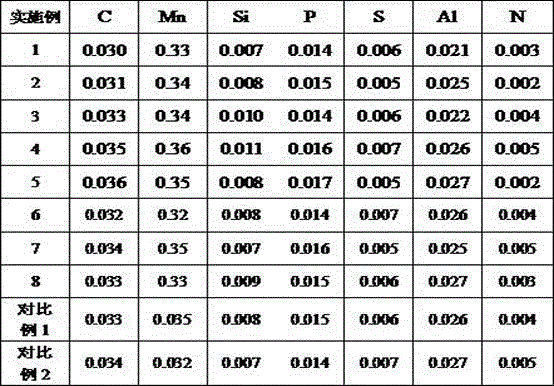

[0027] Table 1 is the value list of the chemical components of each embodiment of the present invention and comparative examples;

[0028] Table 2 is the value list of the main process parameters of each embodiment of the present invention and comparative example;

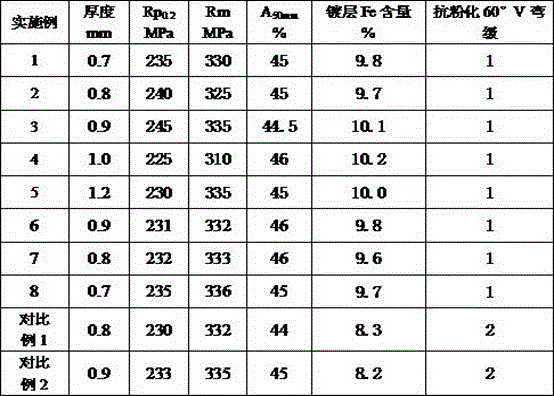

[0029] Table 3 is a list of tensile properties and coating quality of each embodiment of the present invention and comparative examples.

[0030] Each embodiment of the present invention is all produced by the following process:

[0031] 1) Carry out continuous hot-dip galvanizing on the cold-rolled steel plate, and control the temperature of the zinc pot at 455~465°C, and control the temperature of the strip steel into the zinc pot at 460~490°C; control the aluminum weight percentage content in the zinc solution at 0.08- 0.12%;

[0032] 2) After galvanizing, the steel plate is sent to the zinc-iron diffusion treatment heating furnace under the heat pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com