A kind of iron-zinc coated steel plate with a yield strength of 250mpa and its production method

A technology of yield strength and zinc coating, applied in coating, hot-dip coating process, metal material coating process, etc., can solve the problems of complex equipment, high maintenance cost, high investment, etc., and achieve a dense surface structure, not easy to pulverize and The effect of falling off and bonding firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below:

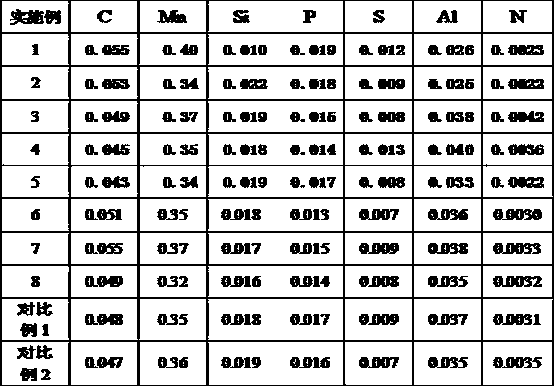

[0027] Table 1 is the value list of the chemical components of each embodiment of the present invention and comparative examples;

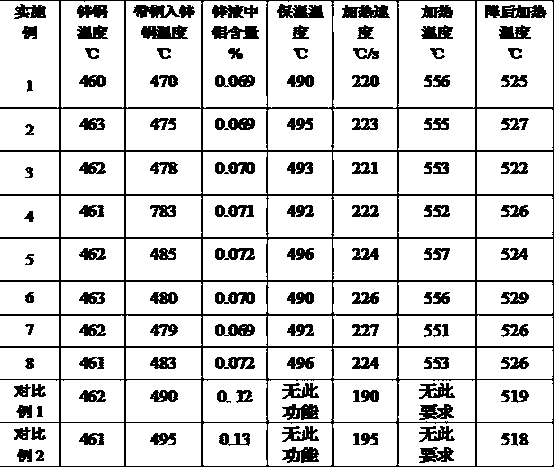

[0028] Table 2 is the value list of the main process parameters of each embodiment of the present invention and comparative examples;

[0029] Table 3 is a list of tensile properties and coating quality of each embodiment of the present invention and comparative examples.

[0030] Each embodiment of the present invention is all produced by following process:

[0031] 1) Carry out continuous hot-dip galvanizing on the cold-rolled steel plate, and control the temperature of the zinc pot at 455~465°C, and control the temperature of the strip steel into the zinc pot at 460~490°C; control the aluminum weight percentage content in the zinc solution at 0.077- 0.120%;

[0032] 2) After galvanizing, the steel plate is sent to the zinc-iron diffusion treatment heating furnace under heat preserv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com