Avalanche photodiode and manufacturing method thereof

An avalanche optoelectronics and manufacturing method technology, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of increased manufacturing cost of diodes, decreased device yield, and reduced device consistency, so as to suppress pre-breakdown and reduce edge Curvature, the effect of improving device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

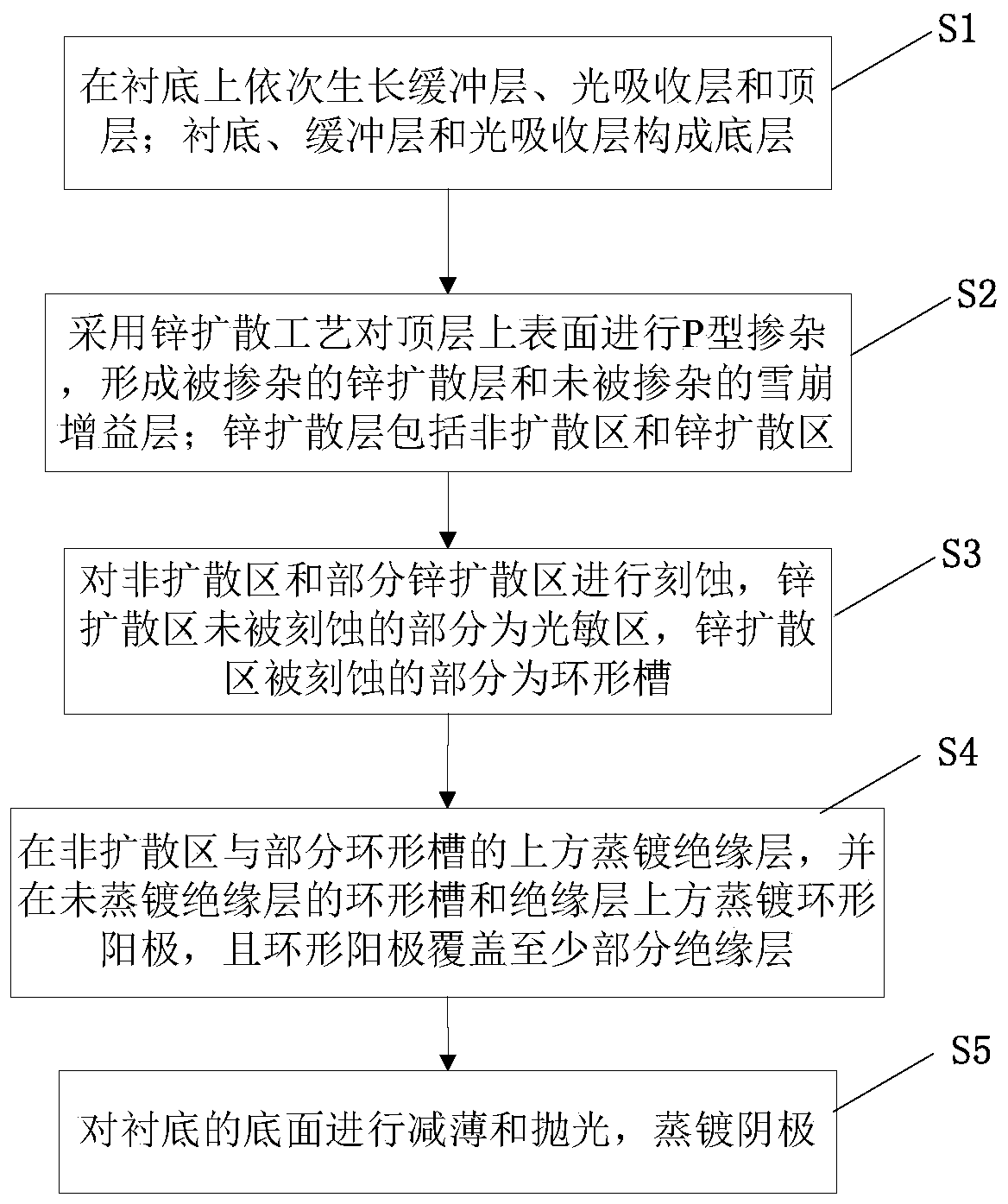

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

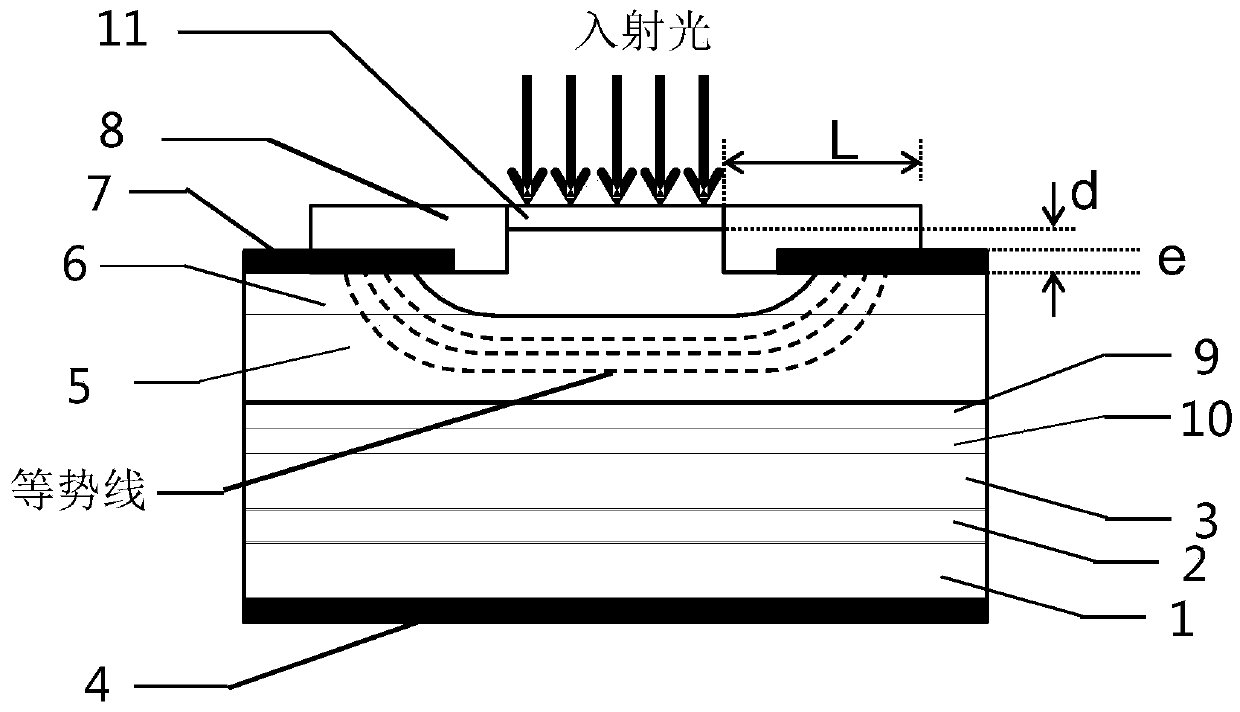

[0043] see figure 1 As shown, the embodiment of the present invention provides an avalanche photodiode, which includes a bottom layer and a top layer. A cathode 4 made of semiconductor material is also provided. In this embodiment, the substrate 1 is made of InP material, the buffer layer 2 is made of n-type low-doped InP material, and the light absorbing layer 3 is made of intrinsic InGaAs material.

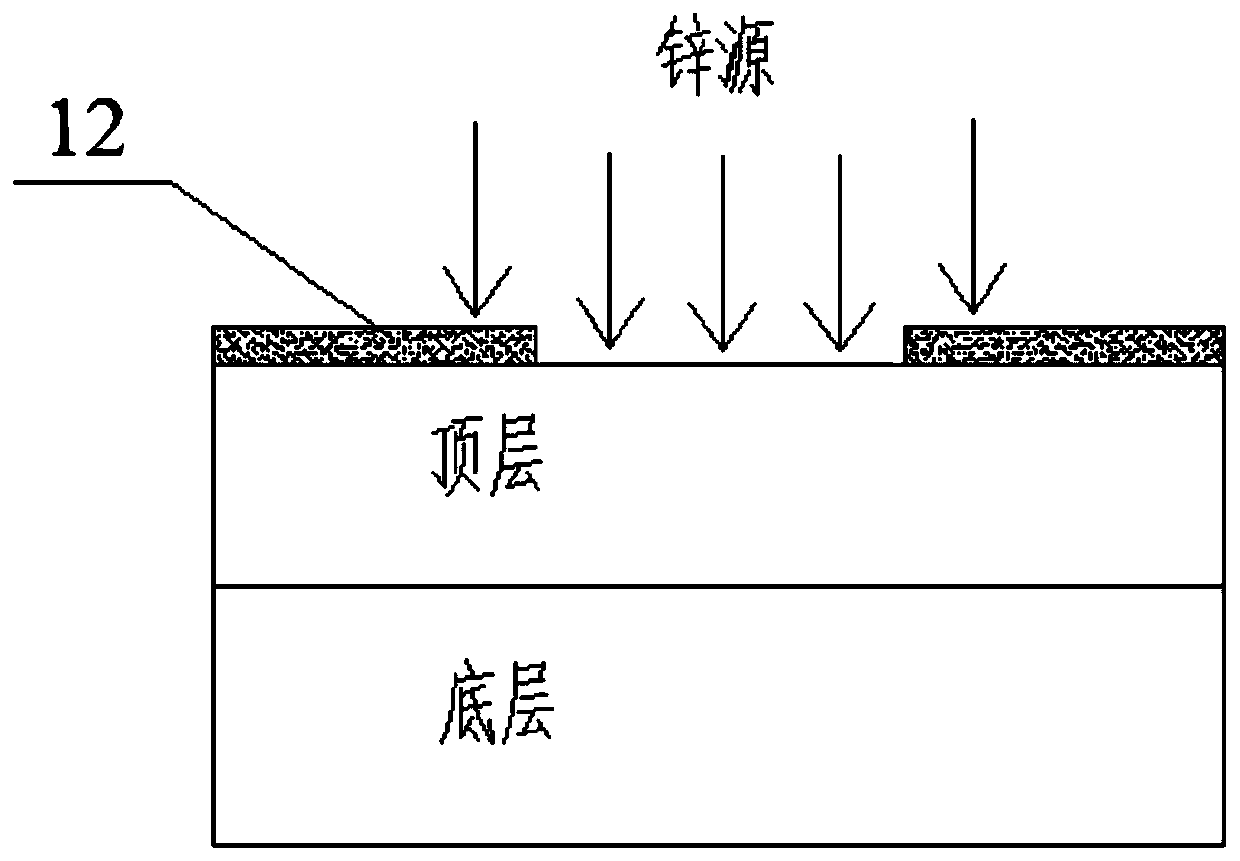

[0044] The top layer is arranged above the bottom layer, ie above the light absorbing layer 3 . Since the diffusion rate of zinc in the InP material is relatively high, it is easier to obtain a deeper diffusion morphology. Therefore, the top layer is made of n-type low doping or intrinsic InP material. The top layer includes an avalanche gain layer 5 and a zinc diffusion layer 6 disposed above the avalanche gain layer 5 , that is, the undoped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com