InGaAs/InP PIN photo electric detector and its manufacturing technology

A technology for photodetectors and manufacturing processes, applied in sustainable manufacturing/processing, photovoltaic power generation, electric solid-state devices, etc., can solve problems such as high cost, large dark current, and low responsivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

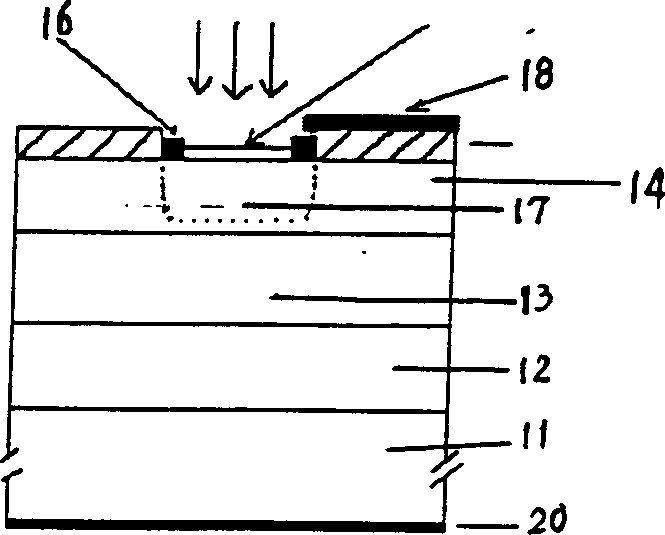

[0051] Such as figure 2 Shown, the new structure of the InGaAs / InP PIN photodetector that the present invention adopts is:

[0052] i-InP top layer 14 / i-In 0.53 Ga 0.47 As photosensitive layer 13 / i-InP buffer layer 12 / N + -InP substrate 11 four-layer double heterojunction material structure. Direct evaporation of Al on i-InP top layer 14 2 o 3 passivation film 19, and a diffusion window 16 is photoetched, and the i-InP top layer in the window is made P + Zinc expansion, so that the diffusion region 17 is close to the i-In 0.53 Ga 0.47 As photosensitive layer 13, in the diffusion window and Al 2 o 3 Evaporate Au / Zn and Ti / Al on the passivation film and photoetch the incident light window and P-type ohmic contact electrode 18 . The bottom layer is an N-type ohmic contact layer 20, which adopts an AuGeNi alloy layer.

[0053] The fabrication process flow of InP / InGaAs / InP PIN photodetector is described as follows.

[0054] Prepare epitaxial wafers grown by LP-MOCVD a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com