High-gain bandwidth product optical detector and manufacturing method thereof

A technology of photodetector and manufacturing method, applied in the direction of final product manufacturing, sustainable manufacturing/processing, semiconductor devices, etc., can solve problems such as low gain, and achieve the effect of high gain bandwidth product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

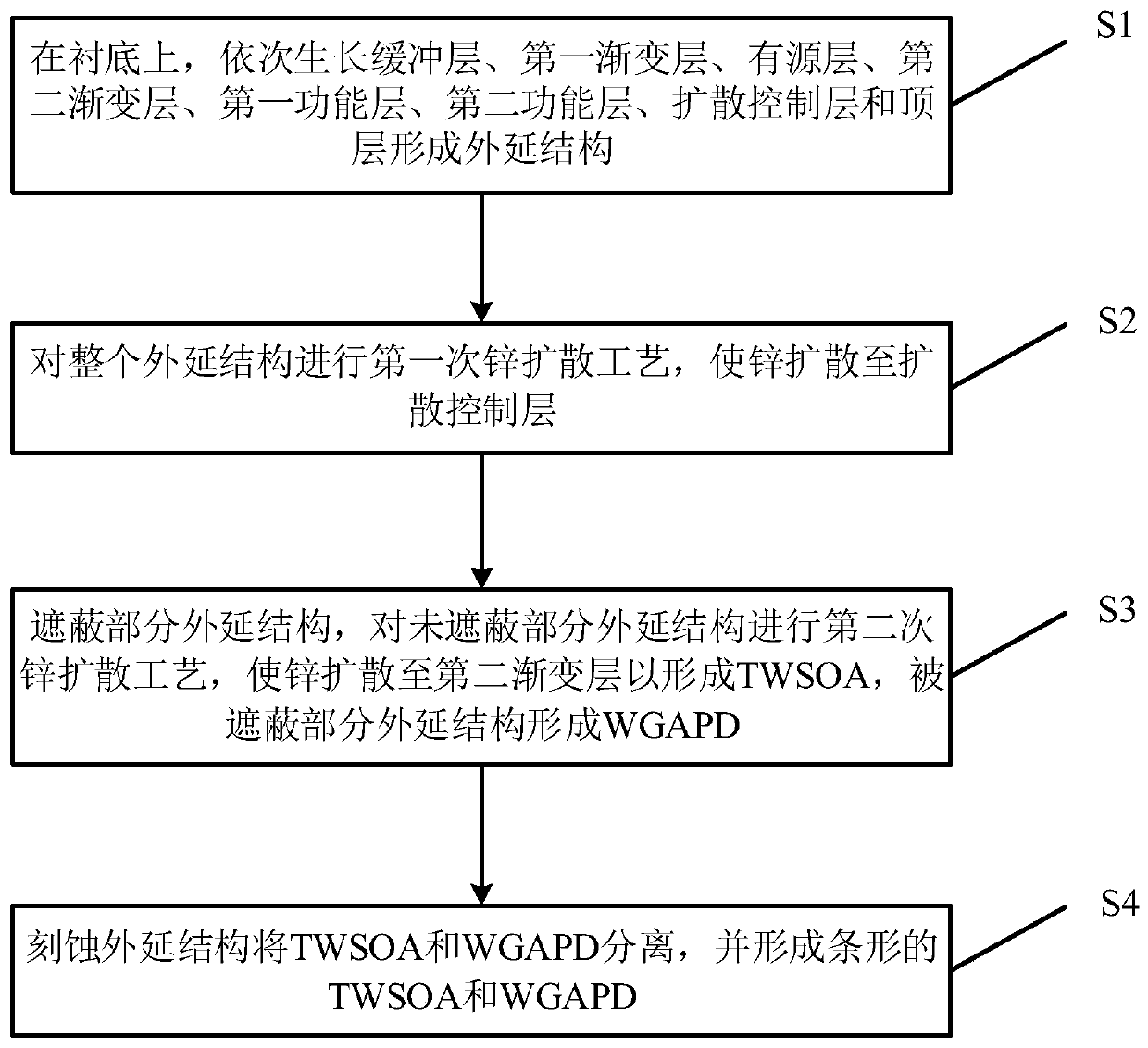

[0030] see figure 1 As shown, an embodiment of the present invention provides a method for manufacturing a photodetector with a high gain-bandwidth product, comprising the following steps:

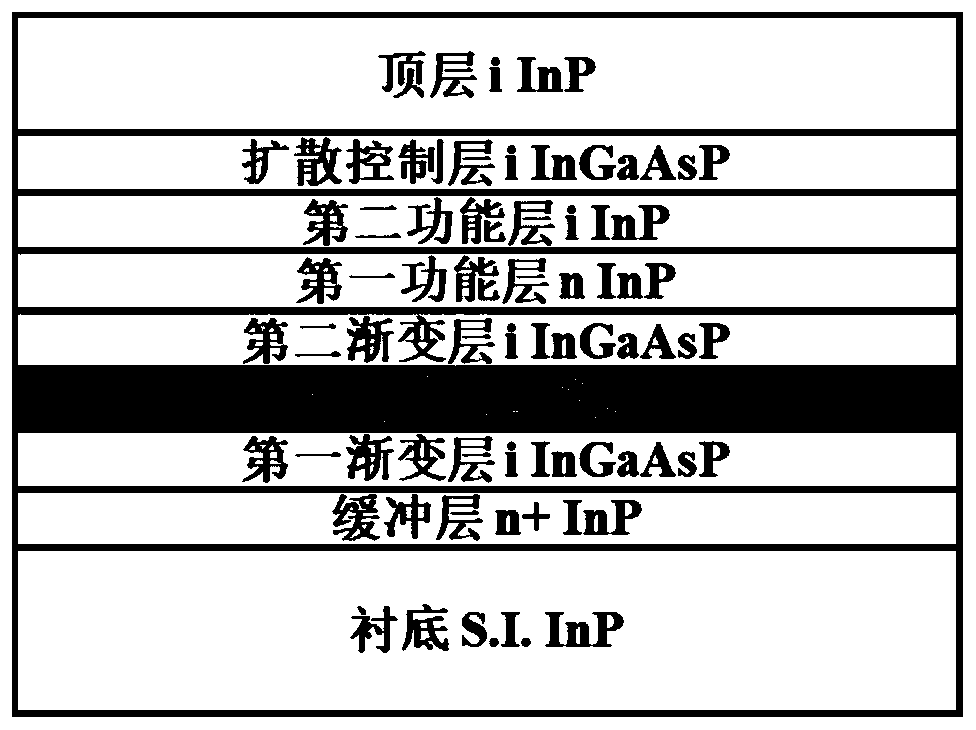

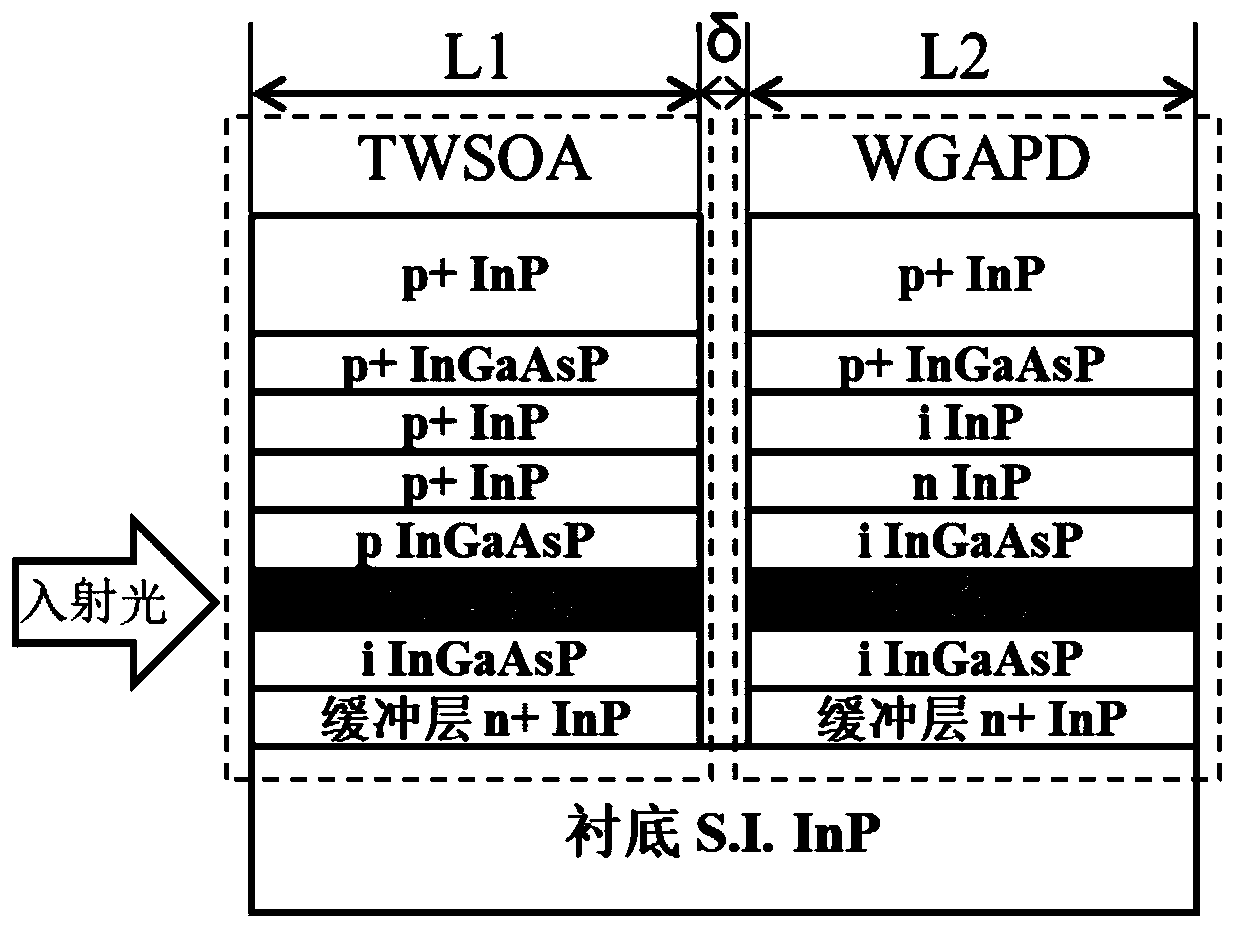

[0031] Step S1, on the substrate, sequentially grow a buffer layer, a first graded layer, an active layer, a second graded layer, a first functional layer, a second functional layer, a diffusion control layer and a top layer to form an epitaxial structure.

[0032] Specifically, see figure 2 As shown, on a semi-insulating (S.I., semi-insulating) indium phosphide InP substrate, epitaxial growth such as MBE (Molecular Beam Epitaxy) or metal-organic compound chemical vapor deposition (MOCVD (Metal-organic Chemical Vapor Deposition)) technology, growing the buffer layer, the first graded layer, the active layer, the second graded layer, the first functional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com