Solid-state zinc-expanding method of GaAs-based epitaxial wafer

An epitaxial wafer, solid-state technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as batch repeatability cannot be fully guaranteed, difficult to grow ZnO at low temperature, etc., to achieve uniformity and consistency of diffusion , good repeatability and consistency, good temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The invention relates to a solid-state zinc expansion method for GaAs-based epitaxial wafers, in which a ZnO thin film is set on the GaAs epitaxial wafers as a zinc source for zinc diffusion.

[0036] The ZnO thin film is arranged on the GaAs epitaxial wafer by sputtering.

[0037] The temperature at which the zinc is diffused is 450-550° C., and the atmosphere of the zinc diffusion is an inert gas, and the inert gas is nitrogen.

Embodiment 2

[0039] A solid-state zinc expansion method for a GaAs-based epitaxial wafer as described in Example 1, the difference is that when ZnO film is used as a zinc source to perform zinc diffusion on a GaAs epitaxial wafer, the GaAs epitaxial wafer is placed on a graphite tray.

Embodiment 3

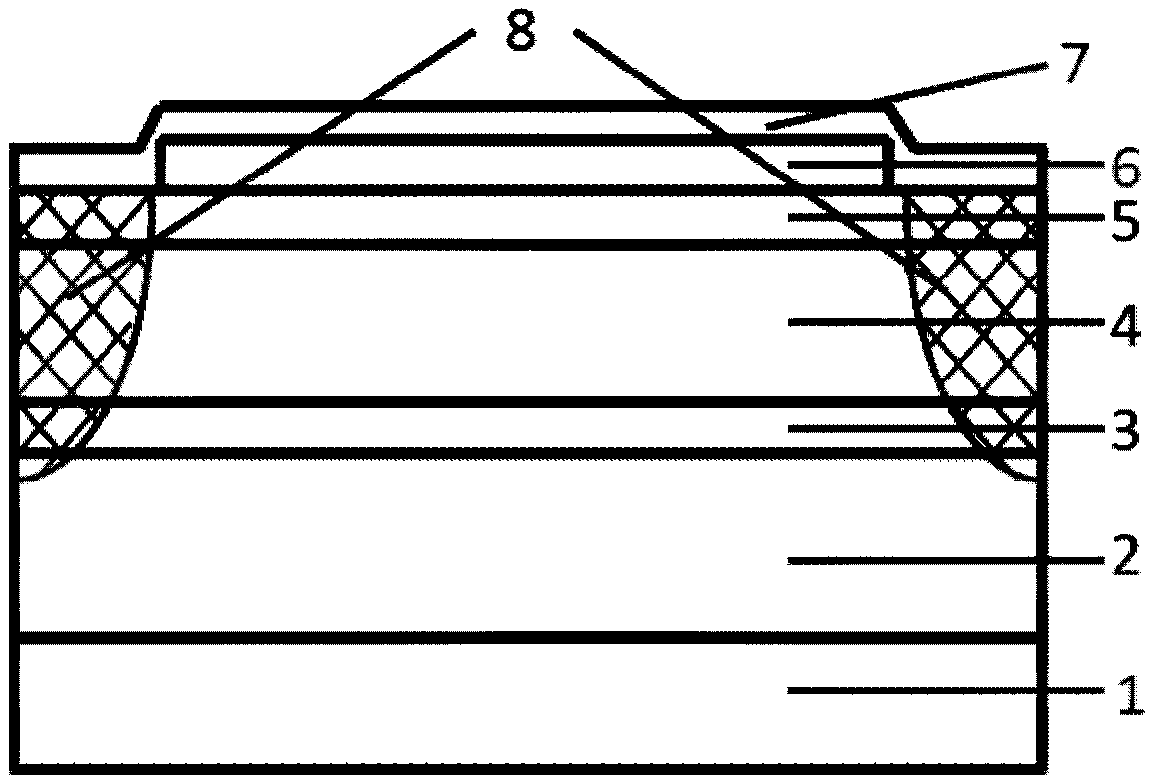

[0041] The GaAs-based epitaxial wafer described in this embodiment is a red semiconductor laser epitaxial wafer, and its structure is as attached figure 1 As shown, from bottom to top are substrate 1 , lower cladding layer 2 , active layer 3 , upper cladding layer 4 and contact layer 5 . Substrate 1 is N-type GaAs substrate; lower cladding layer 2 is N-type AlInP; active layer 3 is AlGaInP / GaInP quantum well structure; upper cladding layer 4 is P-type AlInP; contact layer 5 is P-type GaAs. This structure is a standard red semiconductor laser epitaxial structure. Because the cavity surface of the red semiconductor laser is more prone to defect absorption and COD occurs, it is necessary to make a non-absorbing window at the cavity surface. Generally, the diffusion of Zn impurities induces the interdiffusion of Al and Ga atoms in the quantum well to form a high bandgap window.

[0042] The solid-state zinc expansion method of a kind of GaAs base epitaxial wafer as described in e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com