Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91 results about "Zinc atom" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

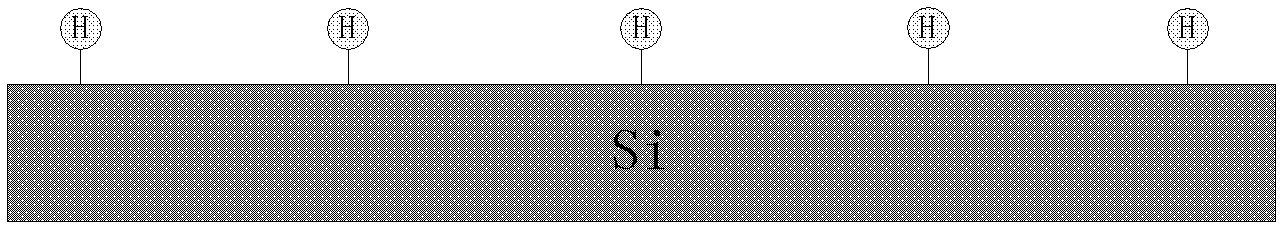

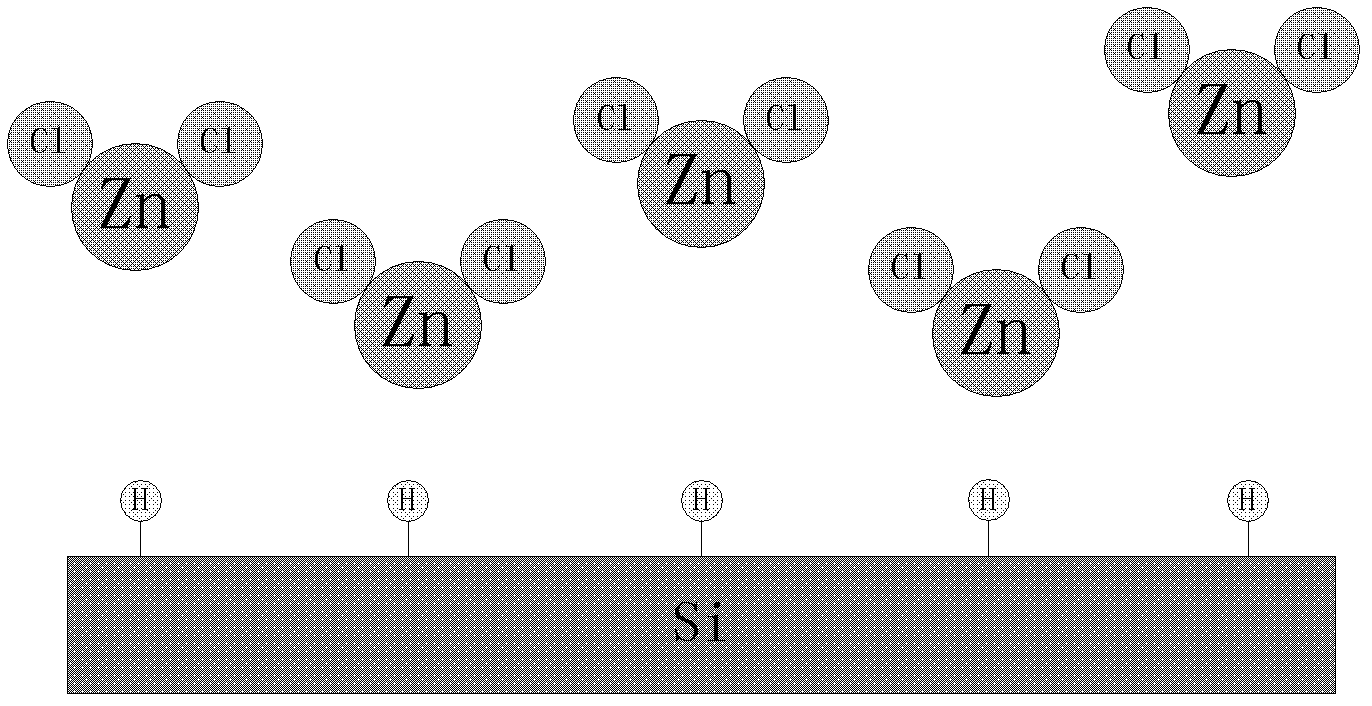

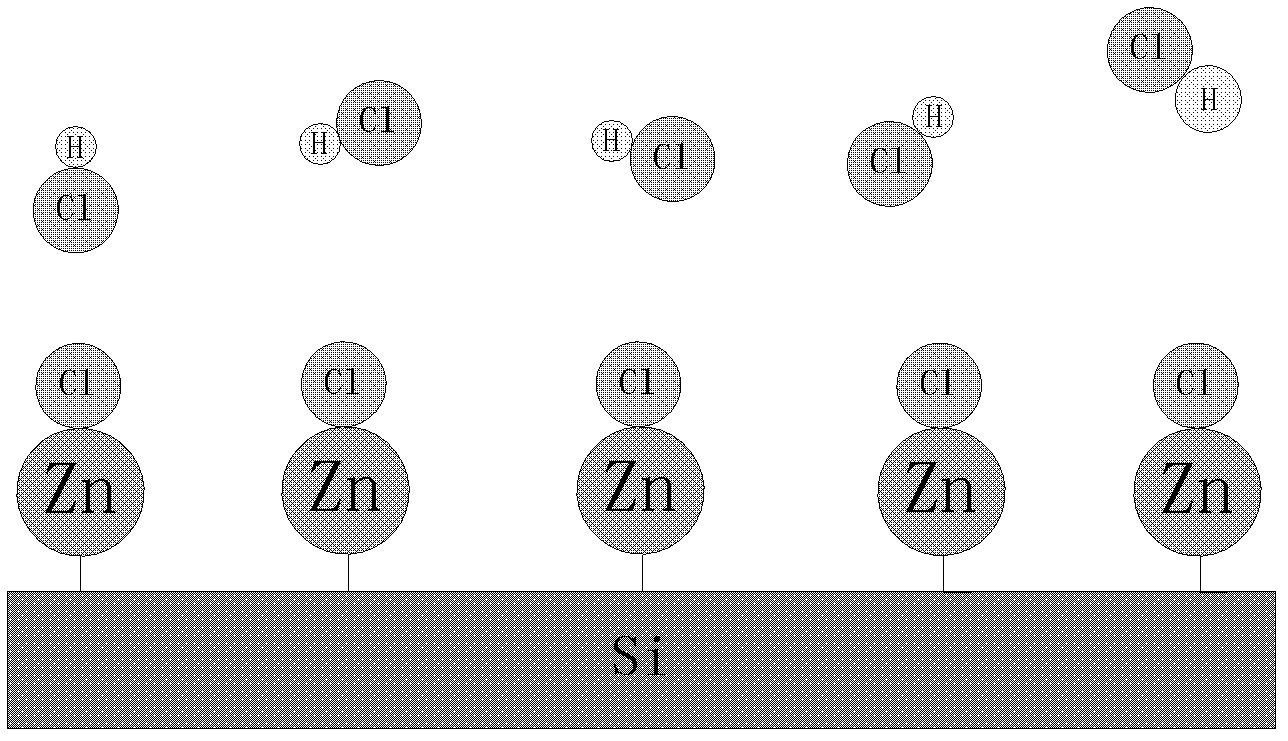

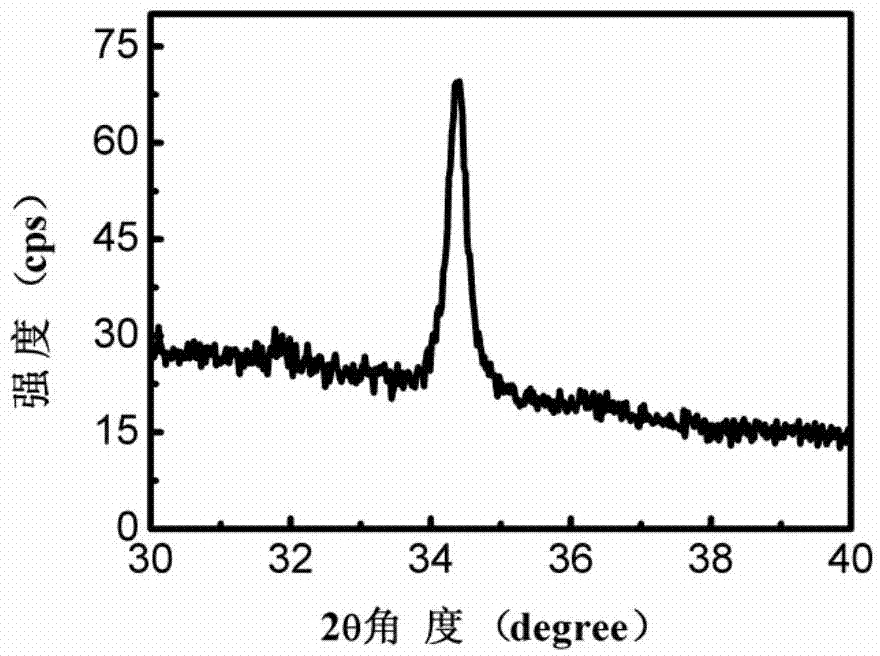

Preparation method of nitrogen-doped zinc oxide film

ActiveCN102304700AImprove performanceSimple methodFinal product manufactureSemiconductor/solid-state device manufacturingOxygenNitrogen gas

The invention relates to the technical field of zinc oxide preparation, and in particular relates to a preparation method of a nitrogen-doped zinc oxide film. The preparation method comprises: placing a silicon substrate in the reaction cavity of atomic layer deposition (ALD) equipment; introducing gas containing a zinc source into the reaction cavity of the ALD equipment, wherein the zinc atoms in the gas containing the zinc source are adsorbed to the silicon substrate; conveying hydrogen to the reaction cavity of the ALD equipment based on nitrogen as a carrier gas, and simultaneously carrying out plasma discharge; introducing an oxygen-containing source to the reaction cavity of the ALD equipment, wherein the zinc atoms which do not react with nitrogen atoms form zinc-oxygen bonds withthe oxygen atoms in the oxygen-containing source; and repeating the steps, so as to grow the zinc oxide film containing the nitrogen atoms layer by layer. In the preparation method provided by the invention, nitrogen doping is carried out on the zinc oxide film by utilizing the ALD equipment; the method is simple and practicable; by utilizing the characteristic of atomic layer deposition and single-layer cycle growth, the uniform nitrogen doping in the whole film structure can be achieved in the process of zinc oxide film growth so that the doped film is complete in structure and excellent inproperty.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

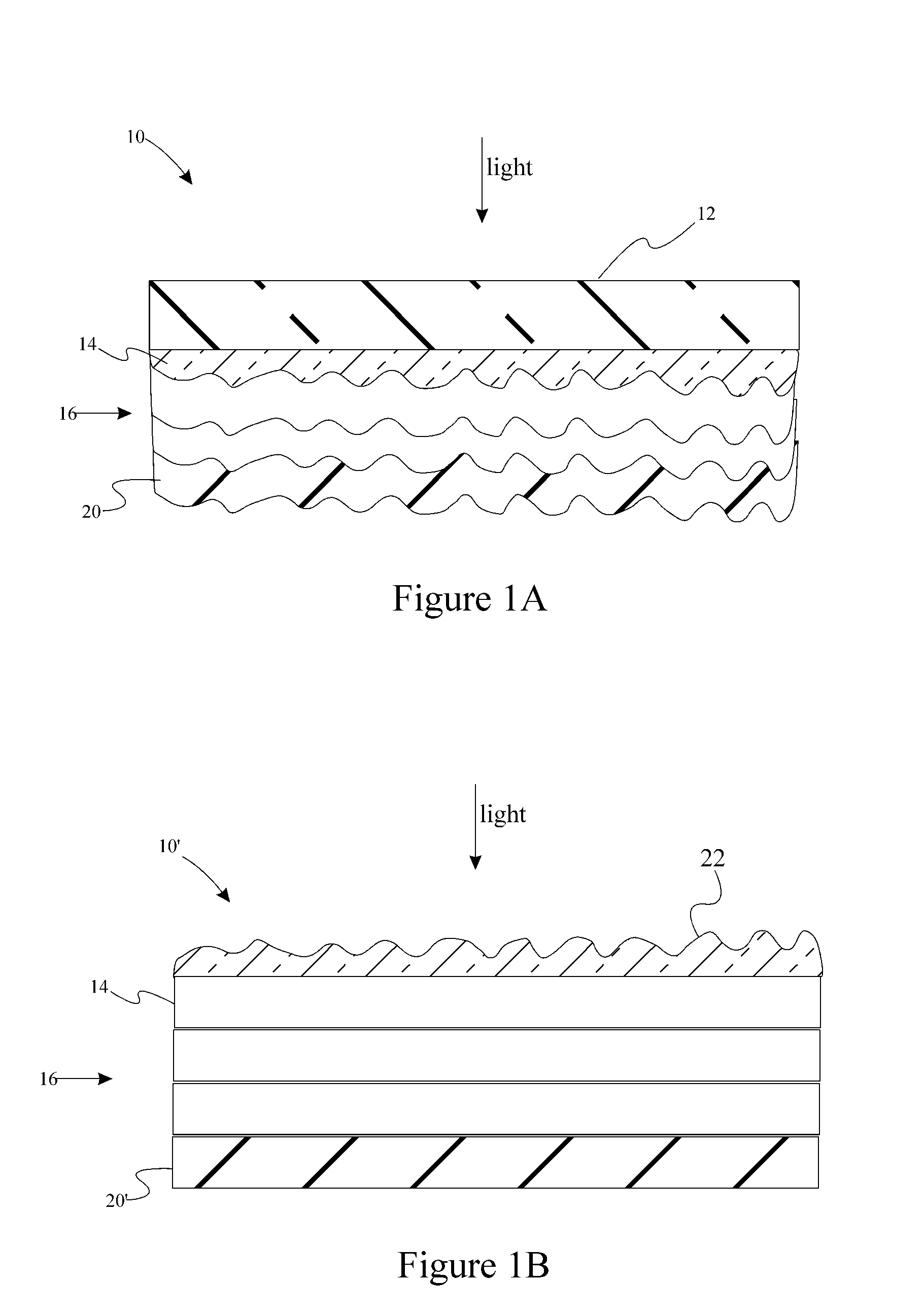

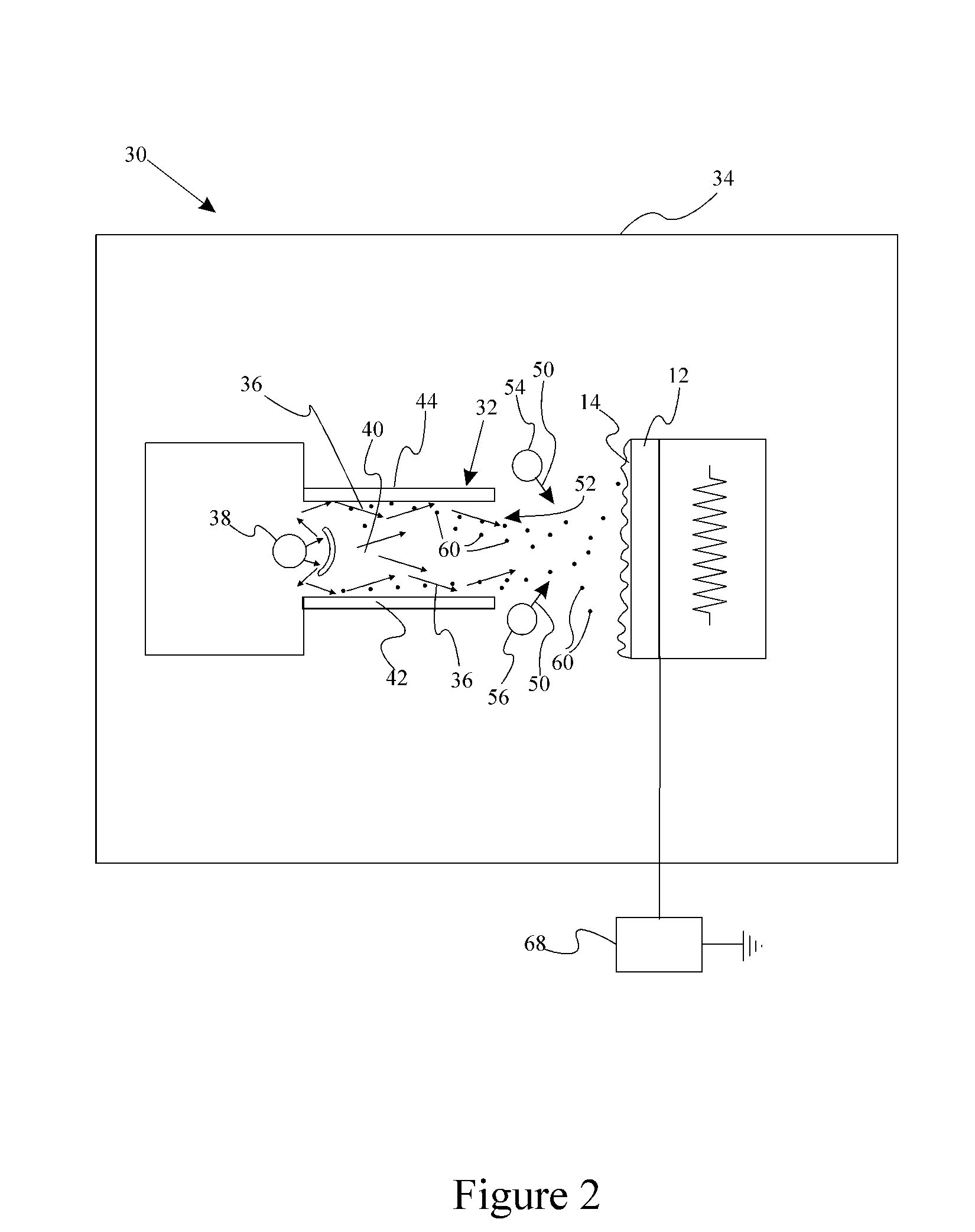

Method and process for deposition of textured zinc oxide thin films

InactiveUS20080308411A1Large widthLow costVacuum evaporation coatingSputtering coatingReactive gasZinc atom

A method for sputtering a textured zinc oxide coating onto a substrate by reactive-environment hollow cathode sputtering comprises providing a sputter reactor that has a cathode channel and a flow exit end. The cathode channel allows a gas stream to flow therein. This cathode channel is at least partially defined by a channel-defining surface that includes at least one zinc-containing target. A gas is flowed through the channel, such that the gas emerges from the flow exit. A plasma is then generated such that material is sputtered off the channel-defining surface to form a gaseous mixture containing zinc atoms that is transported to the substrate. A reactive gas is then introduced into the sputter reactor so that the reactive gas reacts with the zinc-containing gaseous mixture to form the textured zinc oxide coating.

Owner:NEW MILLENNIUM SOLAR EQUIP CORP

Bimetallic zinc complex and process of producing polycarbonate using the same as polymerization catalyst

ActiveUS7244805B2Reduce the amount requiredEconomically beneficialCosmetic preparationsMake-upPolycarbonatePolymerization catalysts

Provided are a bimetallic zinc complex and a method of producing polycarbonate, including polymerizing an epoxy compound and carbon dioxide using the bimetallic zinc complex. The bimetallic zinc complex according to the present invention has a distance between zinc-zinc atoms, which is maintained in a limited range regardless of its concentration in a reaction medium for the polymerization. Thus, the bimetallic zinc complex can have a polymerization activity even at a high ratio of monomer / catalyst, thereby reducing a catalyst amount to be used, which is economically advantageous. Further, the bimetallic zinc complex can produce a high molecular weight polycarbonate.

Owner:LG CHEM LTD

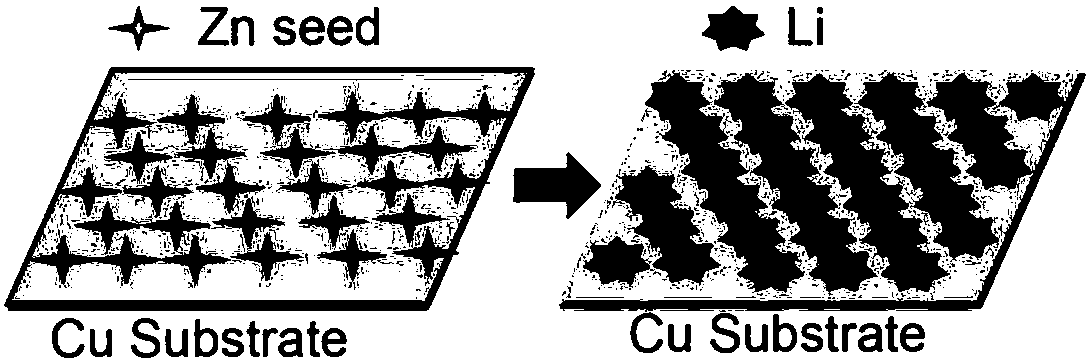

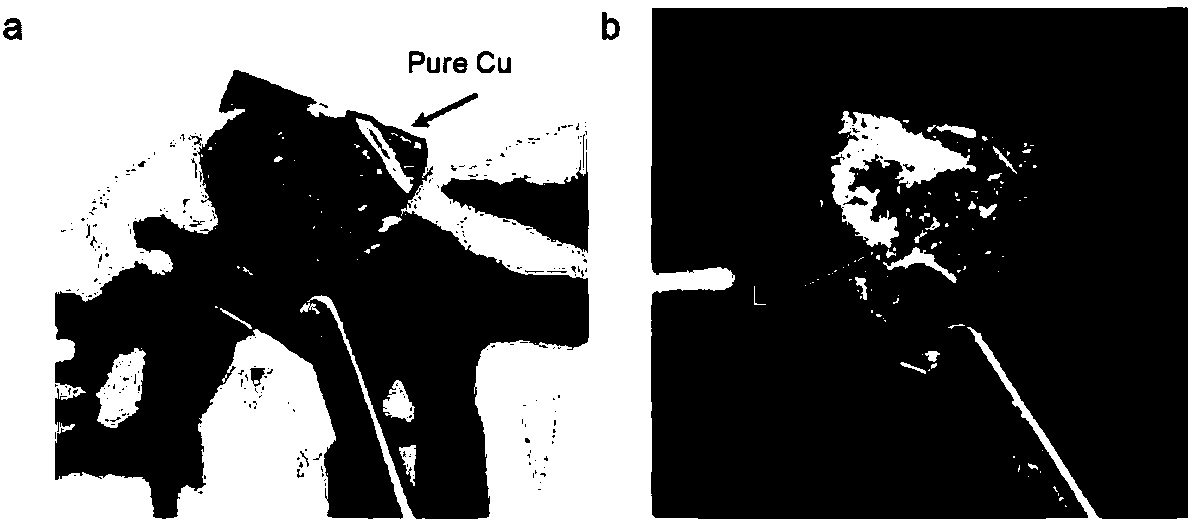

Copper-zinc alloy current collector for inhibiting lithium dendrites

InactiveCN108550858AEvenly distributedUniform deposition and growthElectrode carriers/collectorsMetallic lithiumButton battery

The invention relates to a copper-zinc alloy current collector for inhibiting lithium dendrites. A conventional current collector is covered with a layer of copper-zinc alloy, the thickness of the copper-zinc alloy is 10 nm to 1 [mu]m, and the zinc atom content of the copper-zinc alloy is 1-5%. The copper-zinc alloy current collector provides more active sites for lithium metal deposition than theconventional current collector, and a button battery is assembled in a glove box full of argon by using a metal lithium-loaded alloy current collector or a common copper foil as a negative electrodeand adopting a Celgard 2325 diaphragm and metallic lithium as a reference electrode and a counter electrode. Deposition / dissolution experiments are carried out with blue electricity. The current density is 0.5 mA cm<-2>, the voltage lag is significantly increased after the copper foil electrode only circulates for 520 h, and a copper-zinc alloy negative electrode still maintains a small voltage lag after 1000 h circulation. The current collector in the invention is applied to a lithium-lithium iron phosphate a battery, and the electrochemical performances of the battery are obviously better than those of a battery using a metallic lithium negative electrode adopting the common current collector.

Owner:TIANJIN UNIV

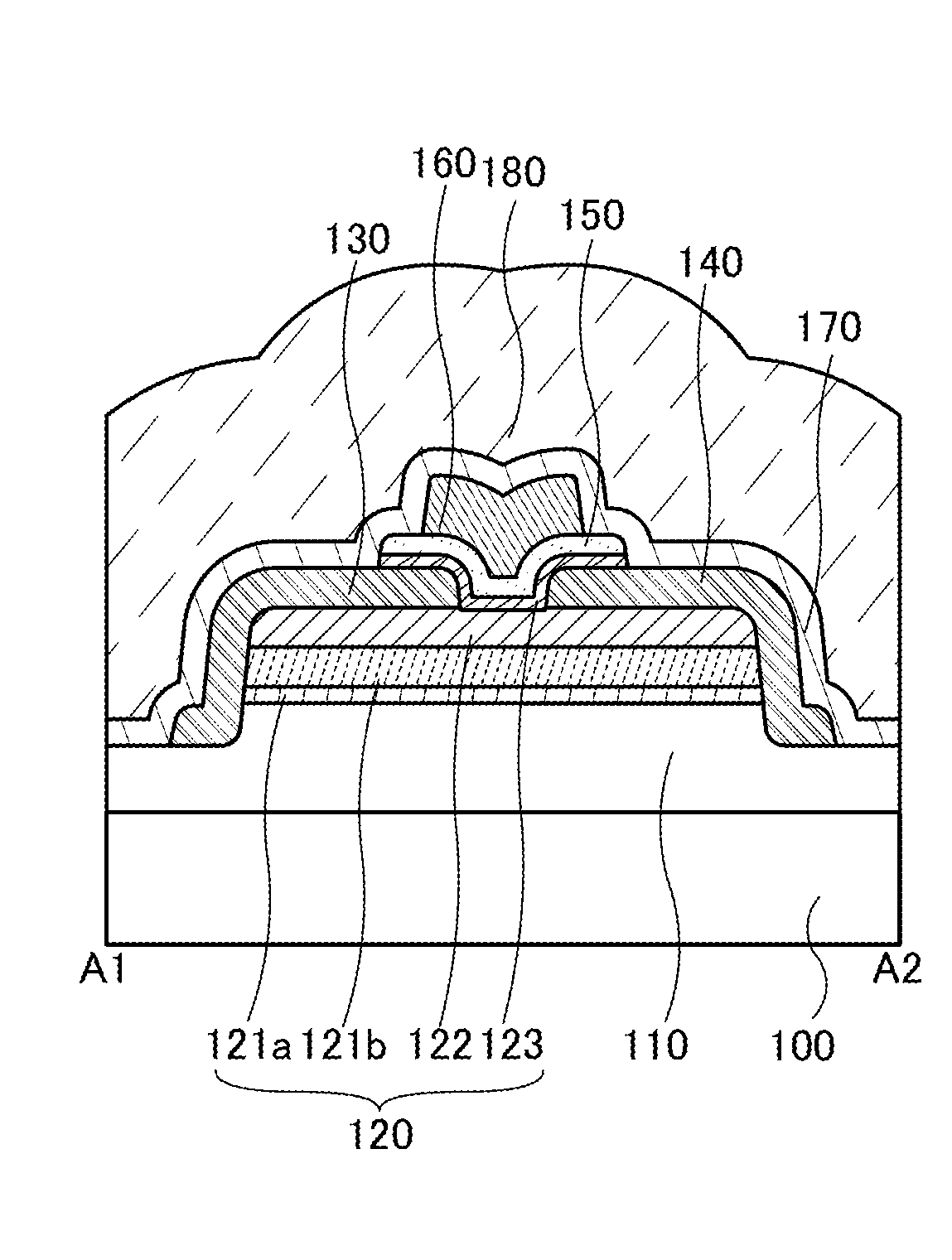

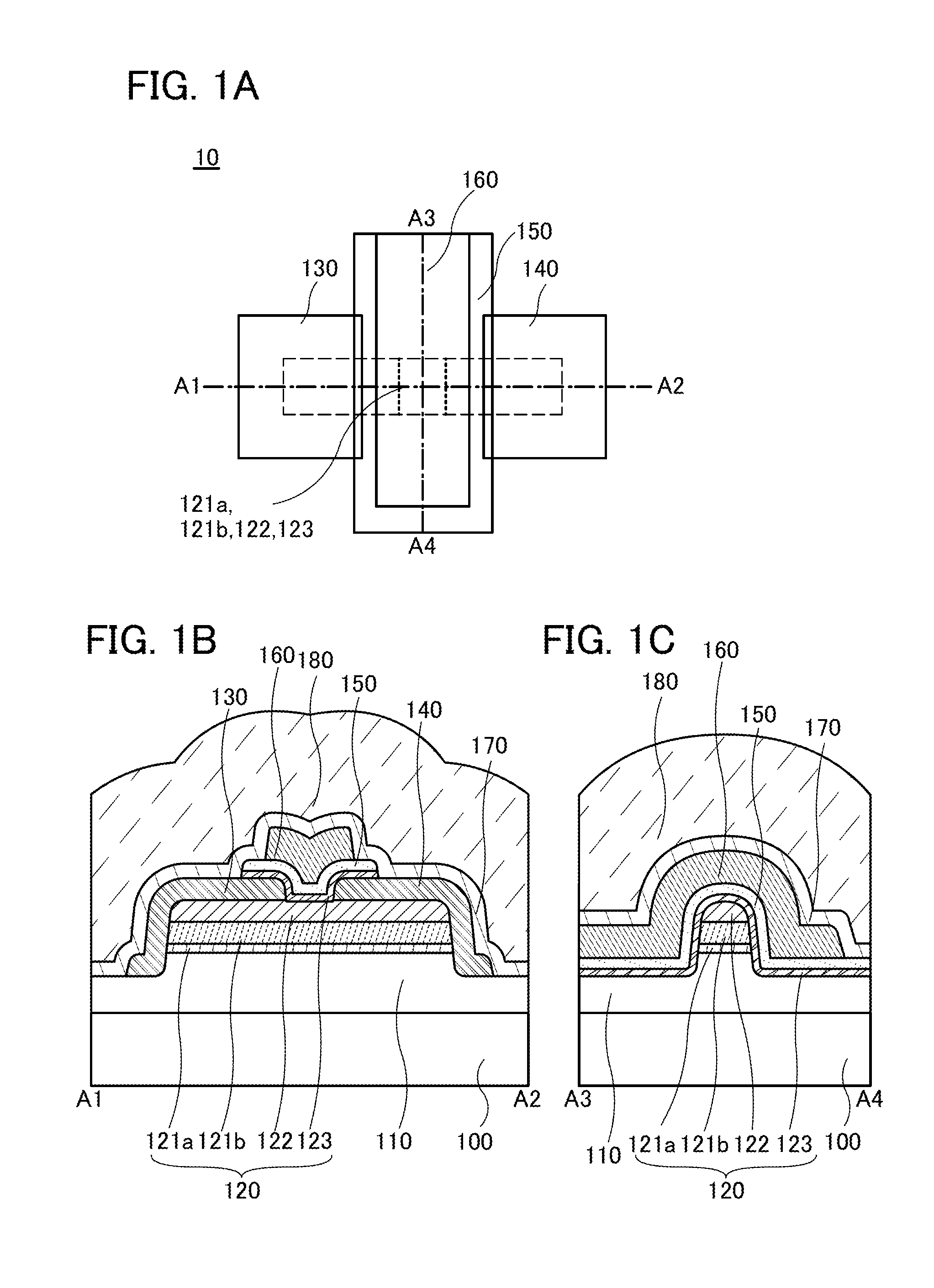

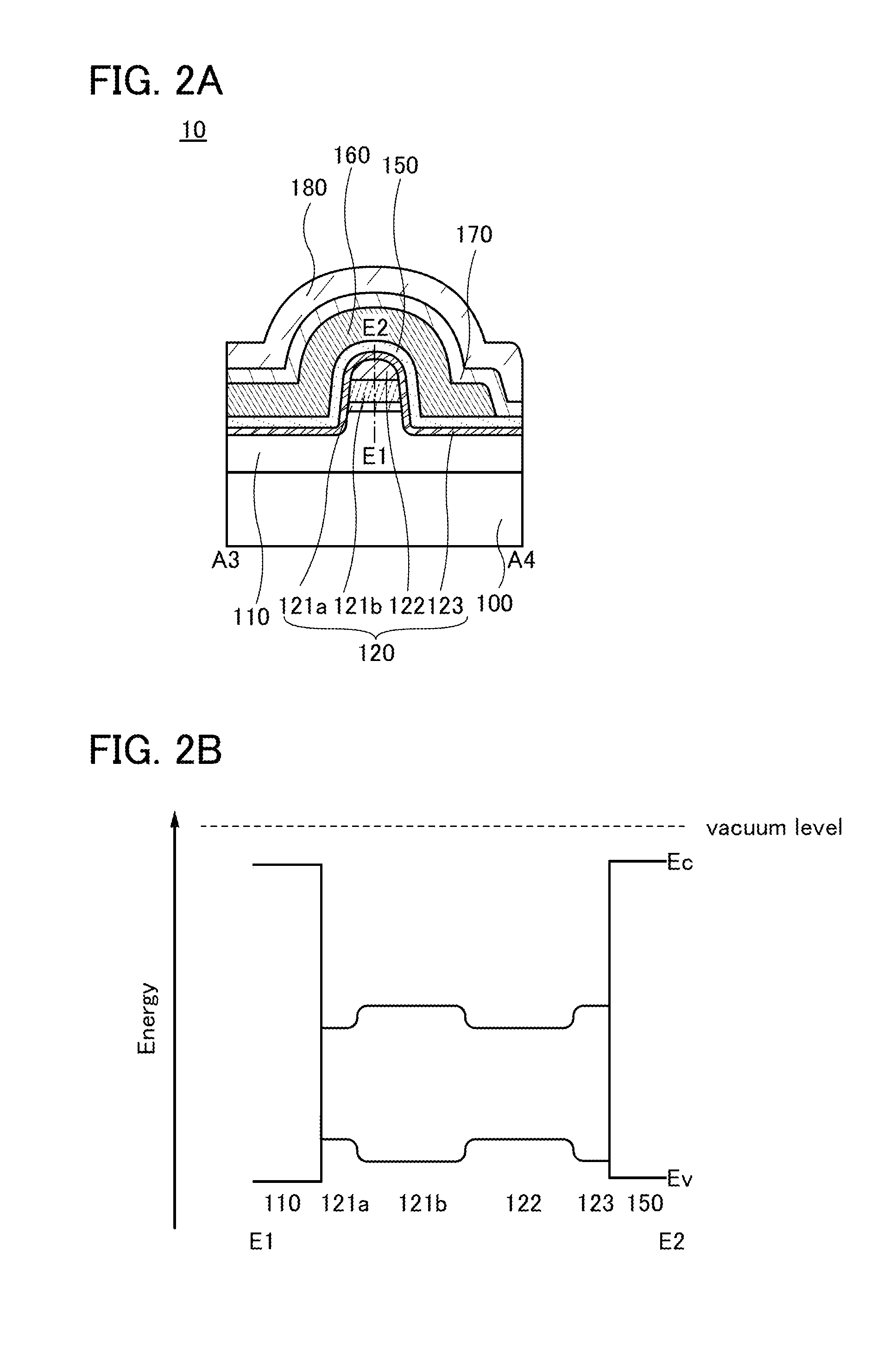

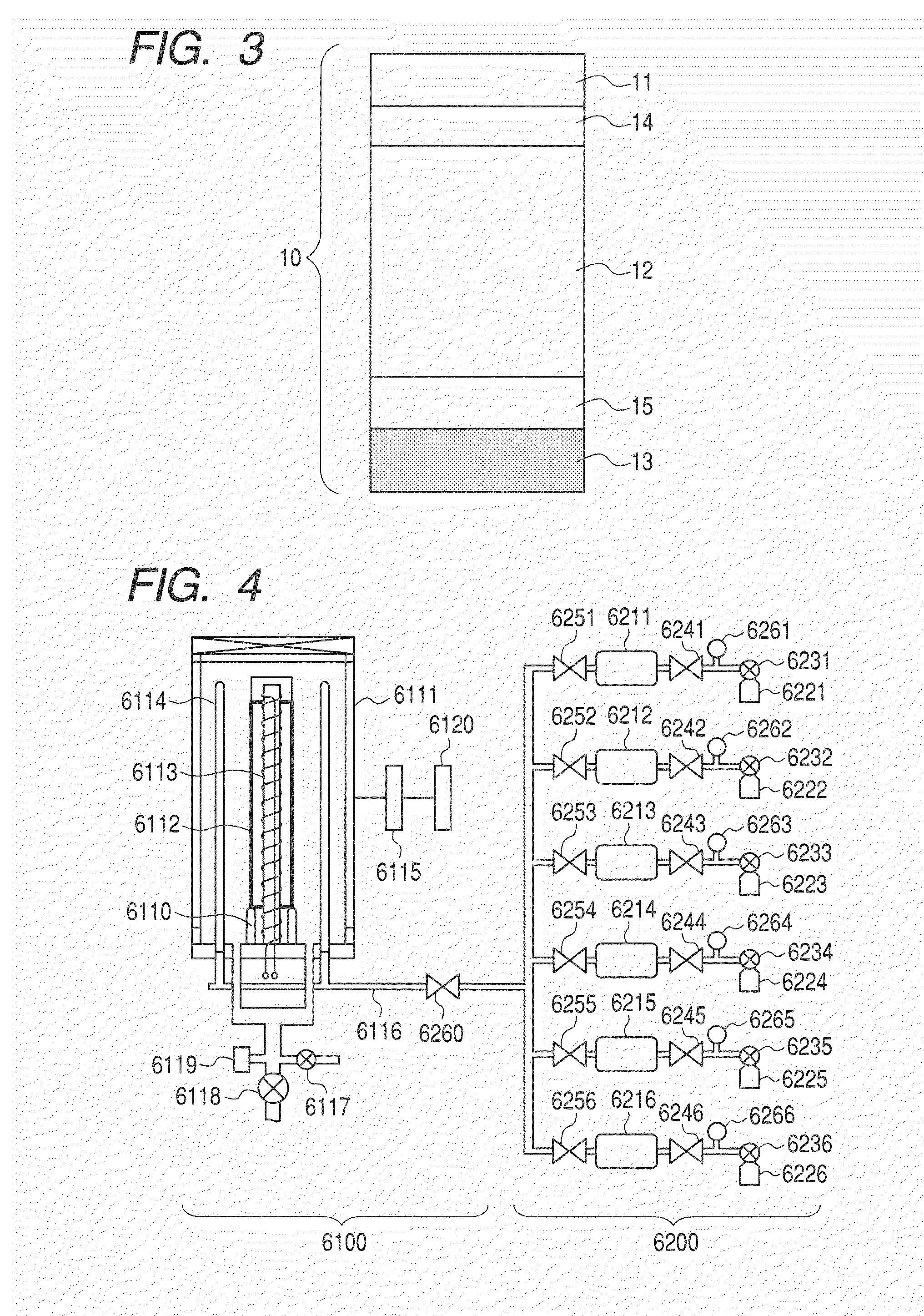

Semiconductor device, method for manufacturing the same, and electronic device

The semiconductor device includes a first insulating layer; a first oxide semiconductor; a first insulator containing indium, an element M (M is gallium, aluminum, titanium, yttrium, or tin), and zinc; a second oxide semiconductor; a source electrode layer; a drain electrode layer; a second insulator containing indium, the element M, and zinc; a gate insulating layer; and a gate electrode layer. The first and second oxide semiconductors each include a region with c-axis alignment. In the first and second oxide semiconductors, the number of indium atoms divided by sum of numbers of the indium atoms, element M atoms, and zinc atoms is ⅓ or more. In the first insulator, the number of zinc atoms divided by sum of the numbers of indium atoms, element M atoms, and zinc atoms is ⅓ or less.

Owner:SEMICON ENERGY LAB CO LTD

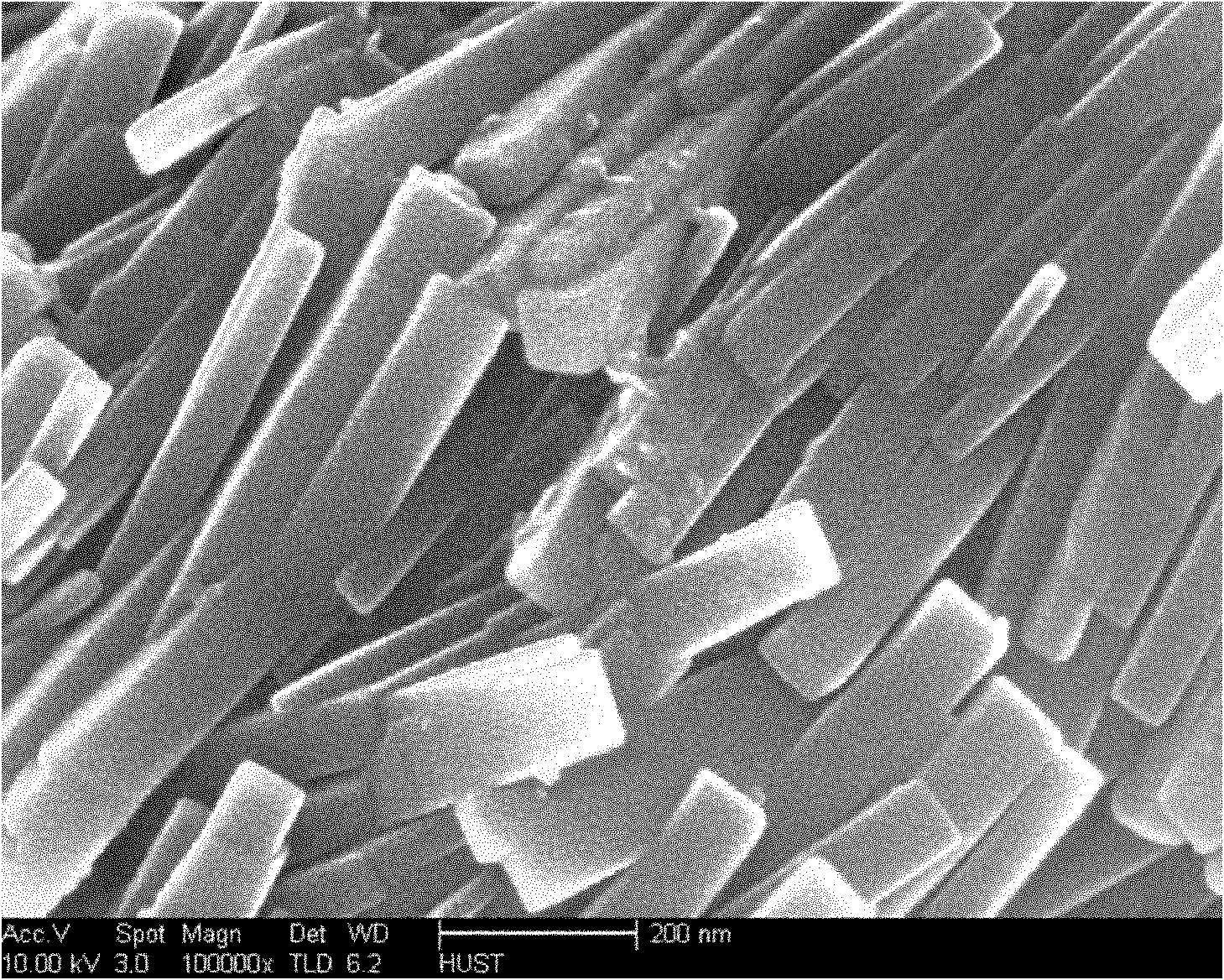

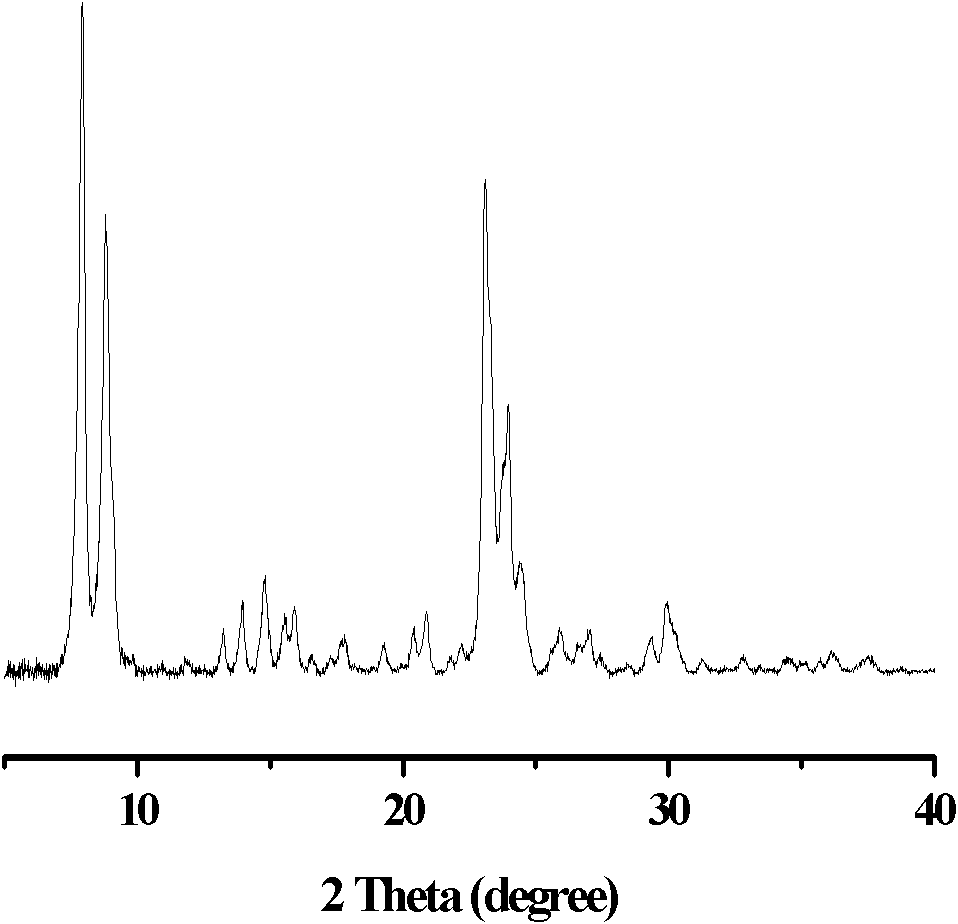

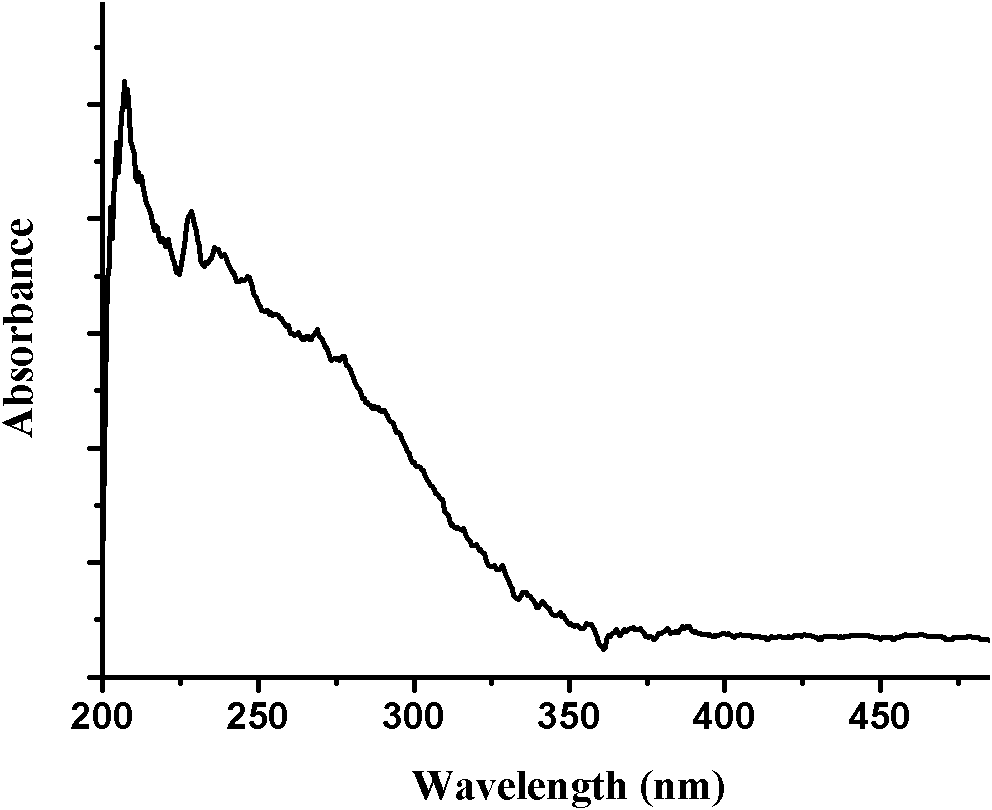

Zinc isomorphism-substituted nano molecular sieve catalyst and preparation method and application thereof

InactiveCN101954291AImprove catalytic performanceHigh yieldMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationMolecular sieveAromatization

The invention provides a zinc isomorphism-substituted nano ZSM-5 molecular sieve catalyst and a preparation method thereof. In the method, solution of zinc amine or solution of zinc ammonia is taken as a zinc source, a one-pot method is adopted to directly make zinc atoms enter a framework of a molecular sieve, the prepared molecular sieve is a nano plate crystal with the dimension of 250nm*50nm*25nm, and the molecular sieve has the advantages of high yield, easy product separation, short preparation time and simple preparation method. When the molecular sieve serving as a catalyst is applied to methanol and ethanol aromatization reaction, the molecular sieve has the characteristics of high aromatic selectivity, high BTX proportion, long service life of the catalyst, stable catalytic performance, flexible technical operation, and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

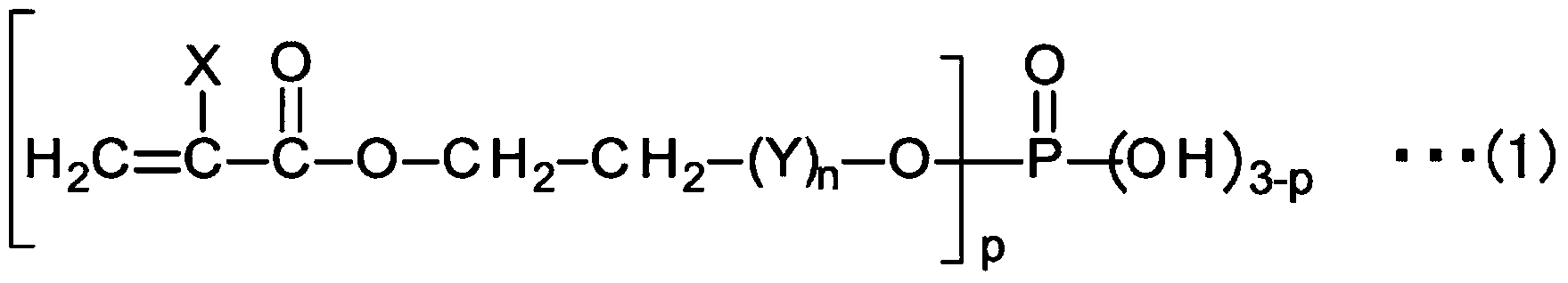

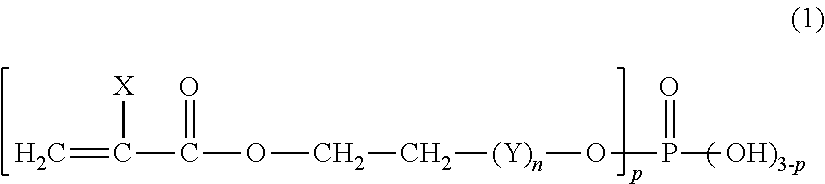

Electrophotographic photosensitive member and electrophotographic apparatus

InactiveUS20100021835A1Superior in abrasionGood adhesivenessElectrographic process apparatusCorona dischargeSurface layerMedicine

The present invention provides an electrophotographic photosensitive member in which a photoconductive layer is an amorphous layer that contains a silicon atom as a main component, and a surface layer contains an aluminum atom, a zinc atom and an oxygen atom so as to satisfy Expression (1) and Expression (2):3.0≦100 {y / (x+y)}≦7.0 (1), and1.05≦z / (1.50x+y)≦1.20 (2),in Expression (1) and Expression (2), x represents atom % of the aluminum atom contained in the surface layer, y represents atom % of the zinc atom contained in the surface layer, and z represents atom % of the oxygen atom contained in the surface layer.

Owner:CANON KK

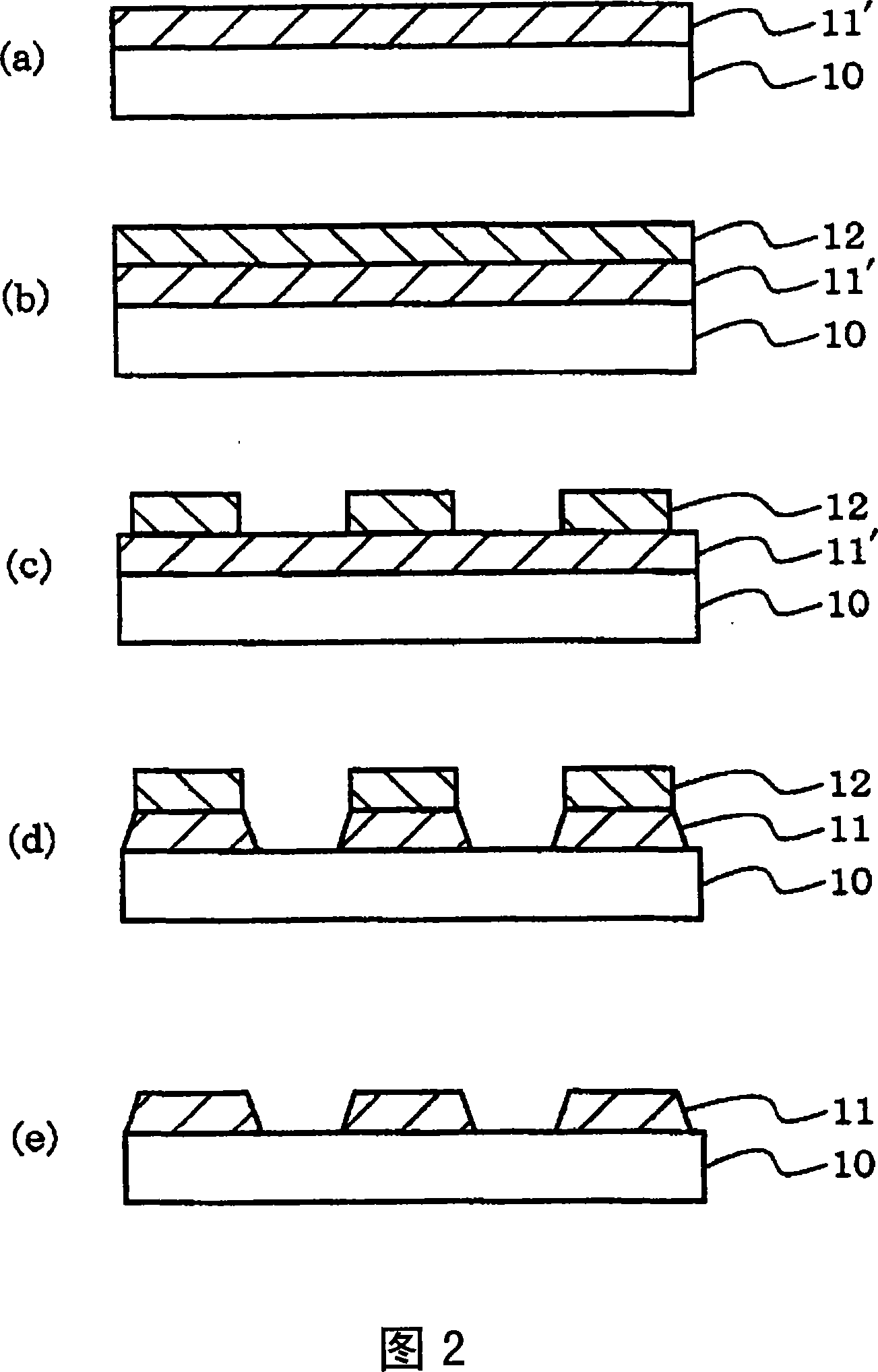

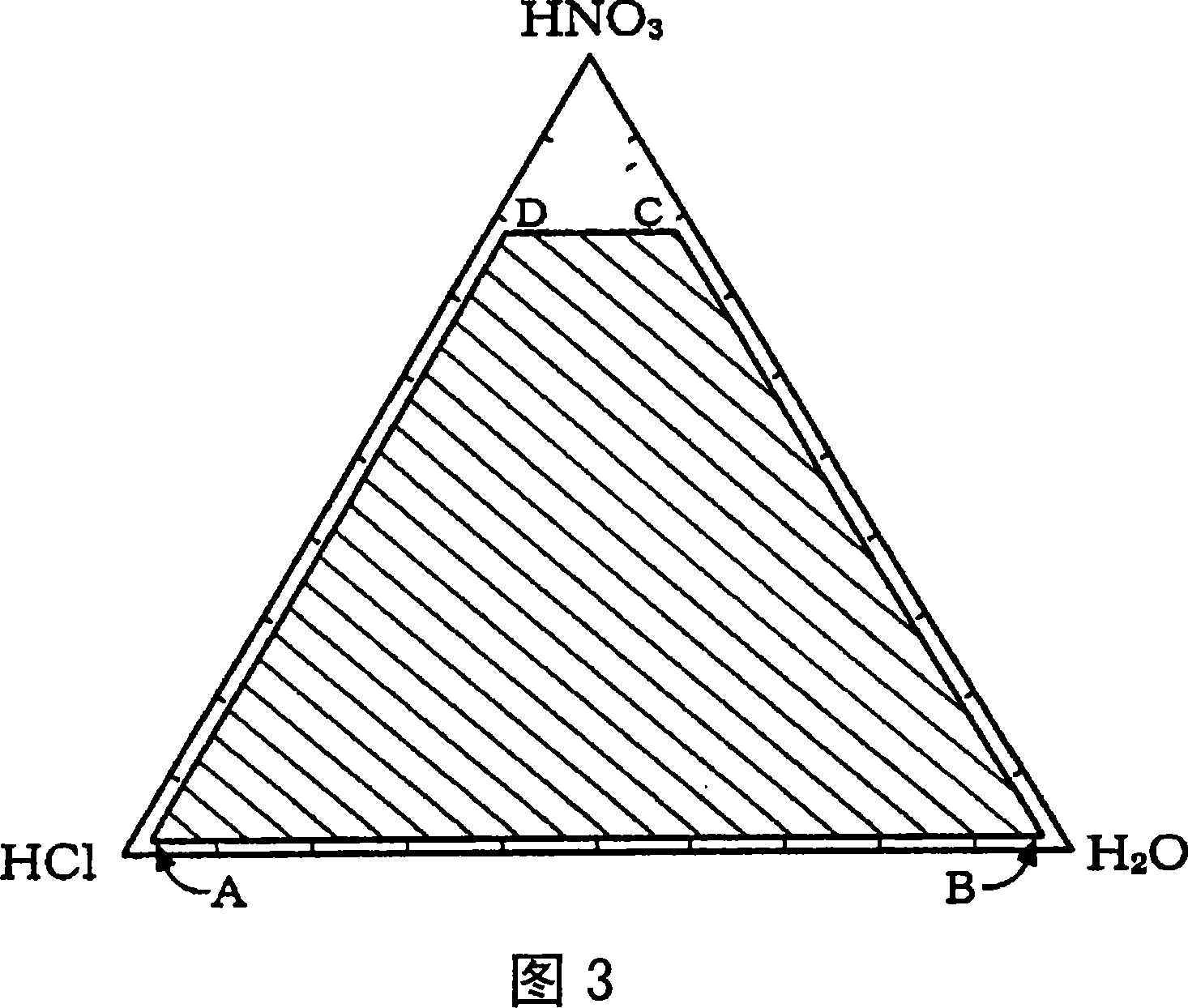

Transparent electrode and its manufacturing method

InactiveCN101076869ALow priceGood alkali resistanceConductive layers on insulating-supportsGas discharge electrodesIndiumHeat stability

Disclosed is an indium-free transparent electrode which is excellent in alkali resistance, wet heat stability and etching properties. Specifically disclosed is a transparent electrode mainly containing zinc oxide and tin oxide wherein the taper angle at the edge portion of the electrode is 30-89 DEG . The ratio of zinc atoms to the total of zinc atoms and tin atoms in the transparent electrode (Zn / (Zn + Sn) atomic ratio) is preferably within the range of 0.5-0.9.

Owner:IDEMITSU KOSAN CO LTD

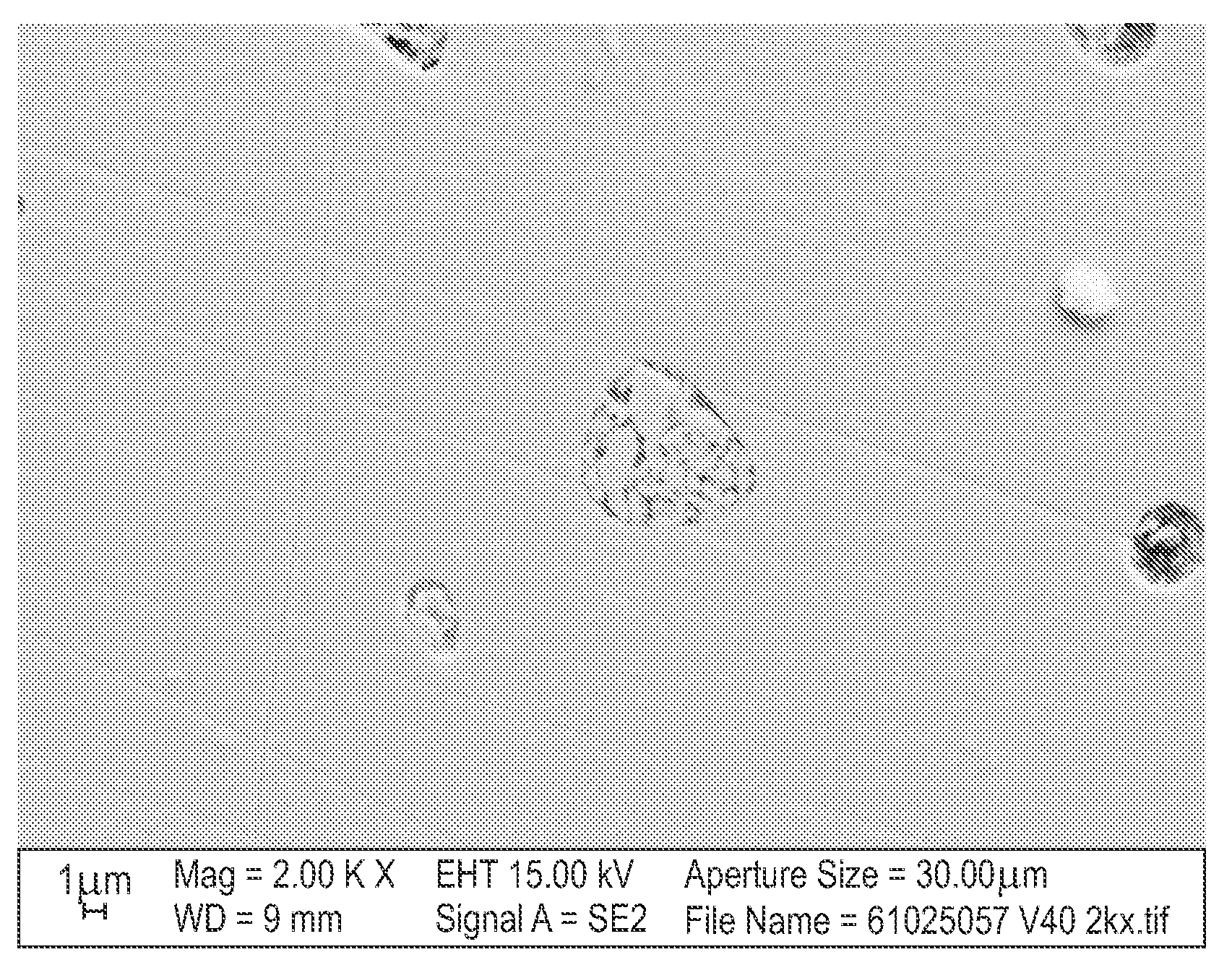

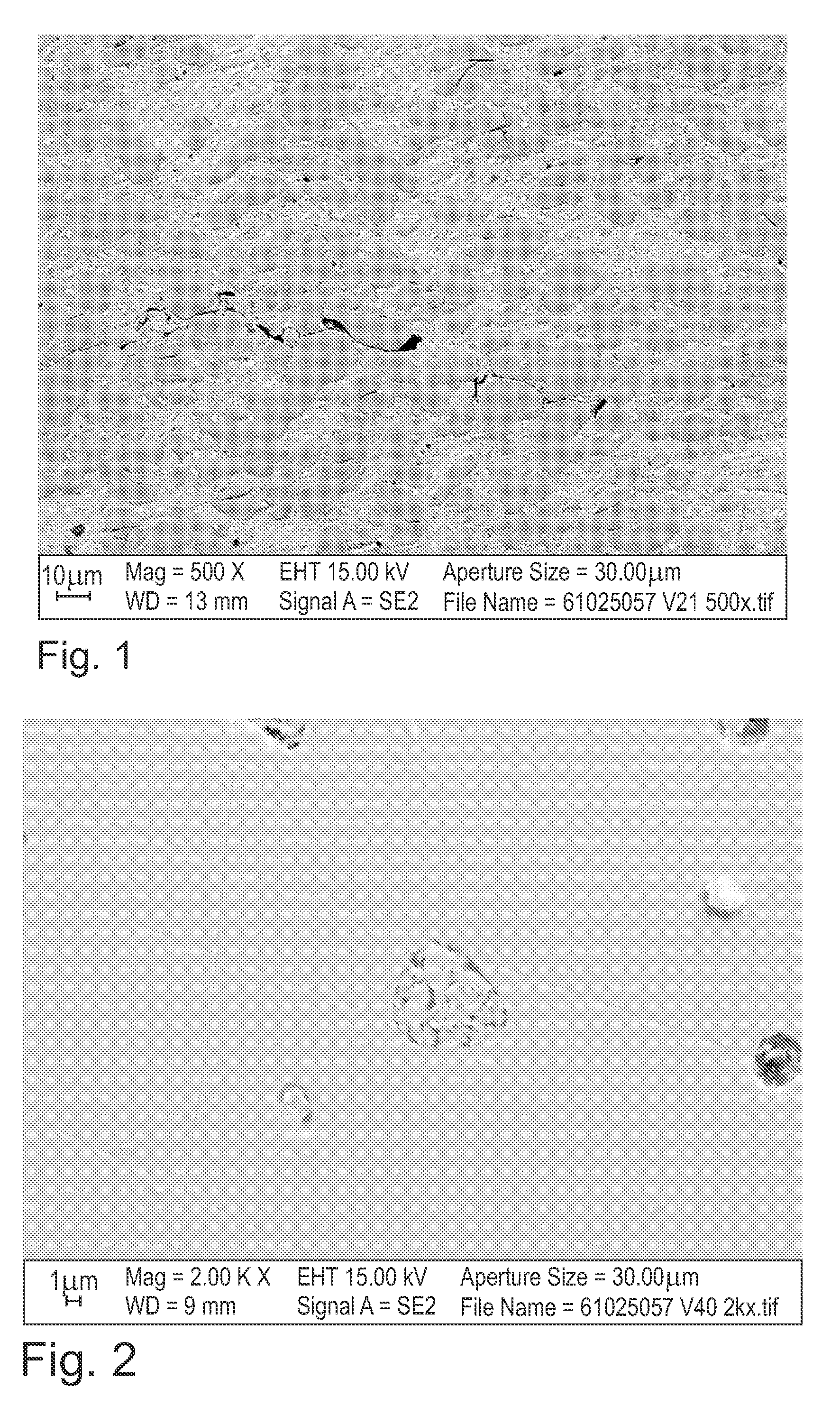

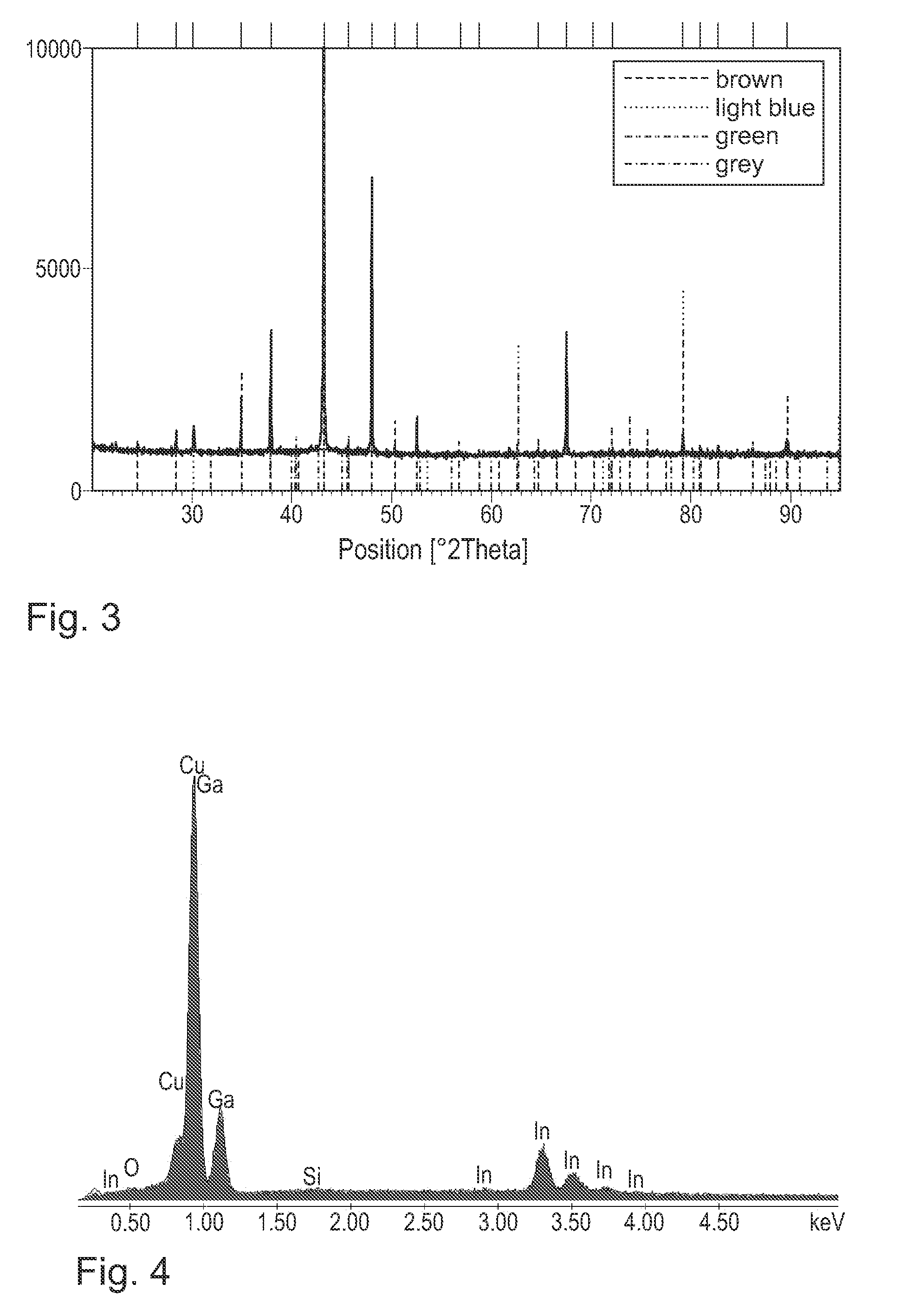

Coating material based on a copper-indium-gallium alloy, in particular for the production of sputter targets, tubular cathodes and the like

InactiveUS20080121137A1High melting temperatureImprove conductivityVacuum evaporation coatingSputtering coatingIndiumCopper

The copper-indium-gallium (CuInGa) alloy is in particular to be used for the production of sputter targets, tubular cathodes and similar coating material sources. It has a phase corresponding to a Cu5Zn8 prototype phase in which the lattice sites of the zinc atoms (Zn) are occupied by gallium atoms (gallium-substituted Cu5Zn8 phase) and in which indium is simultaneously introduced into the elementary cell or phase, making up a proportion of up to 26 wt %.

Owner:GFE METALLE & MATERIALIEN GMBH

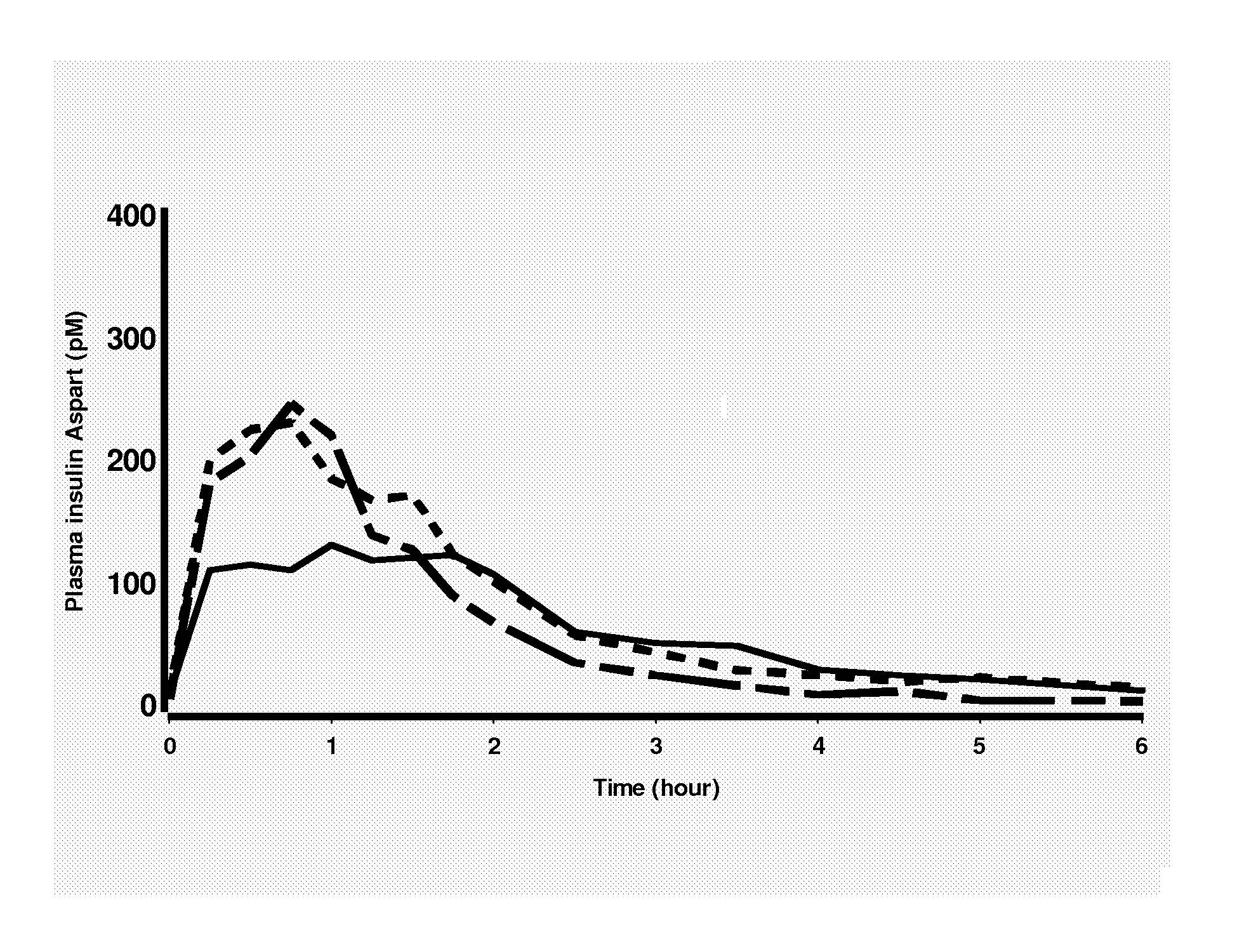

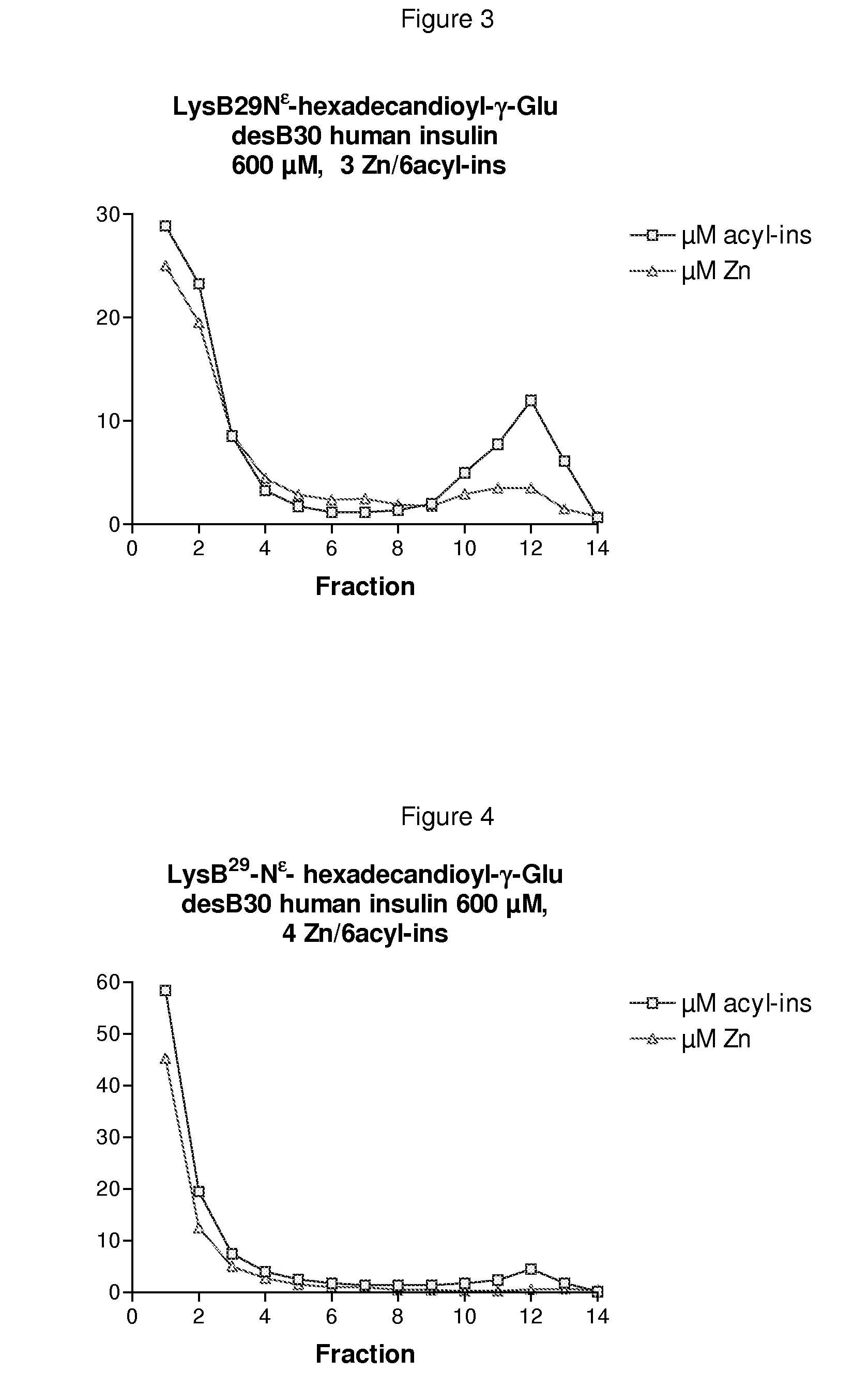

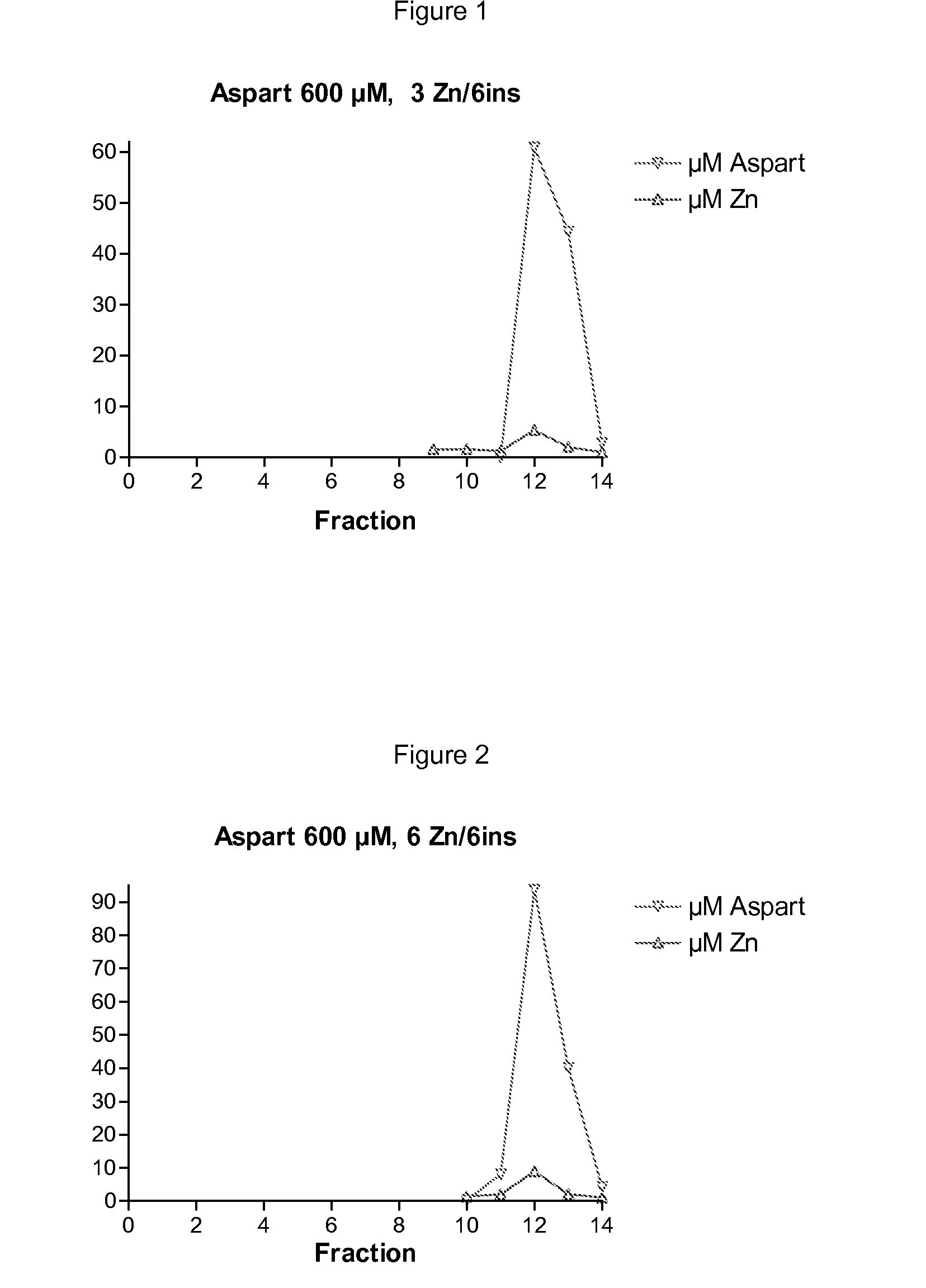

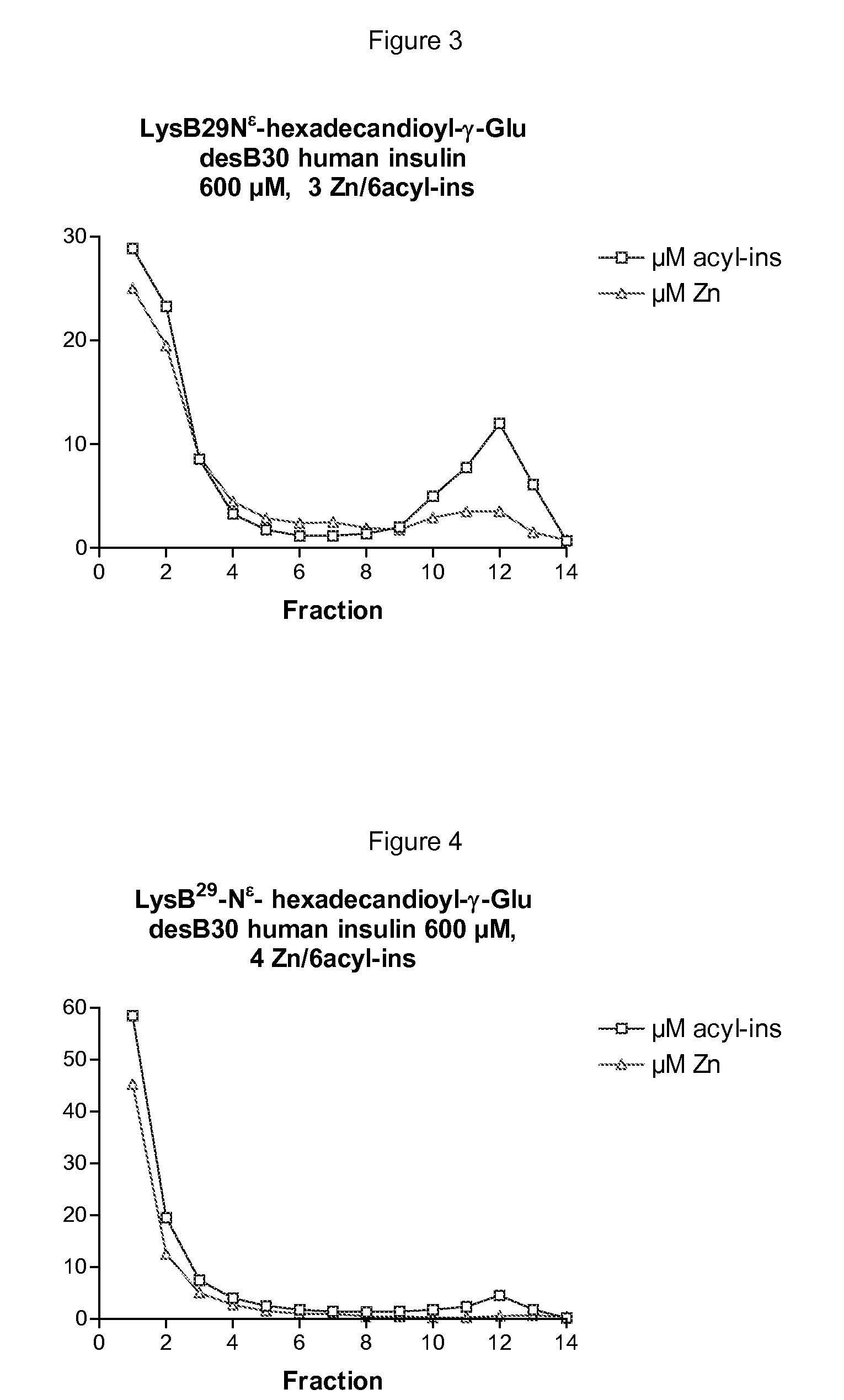

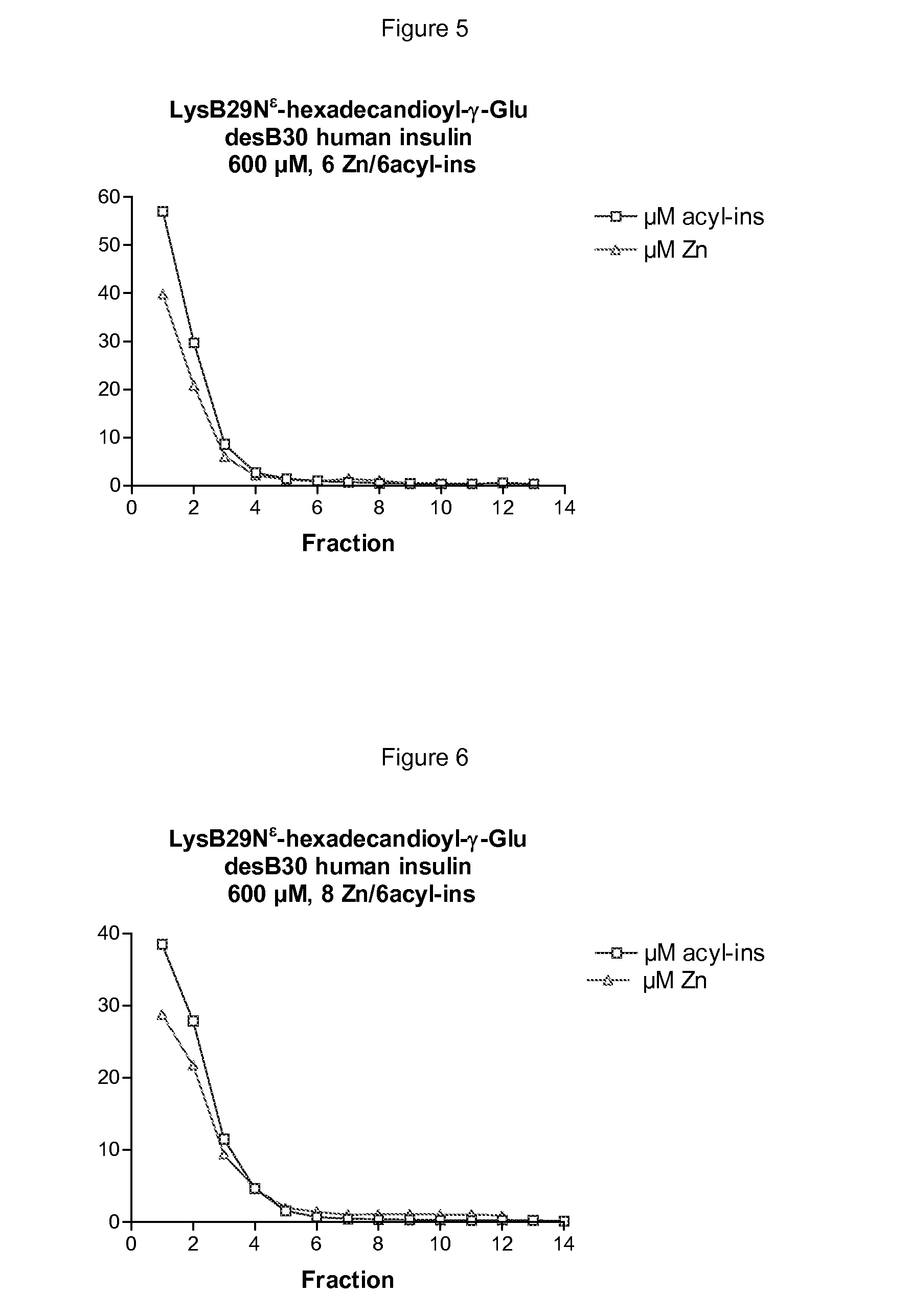

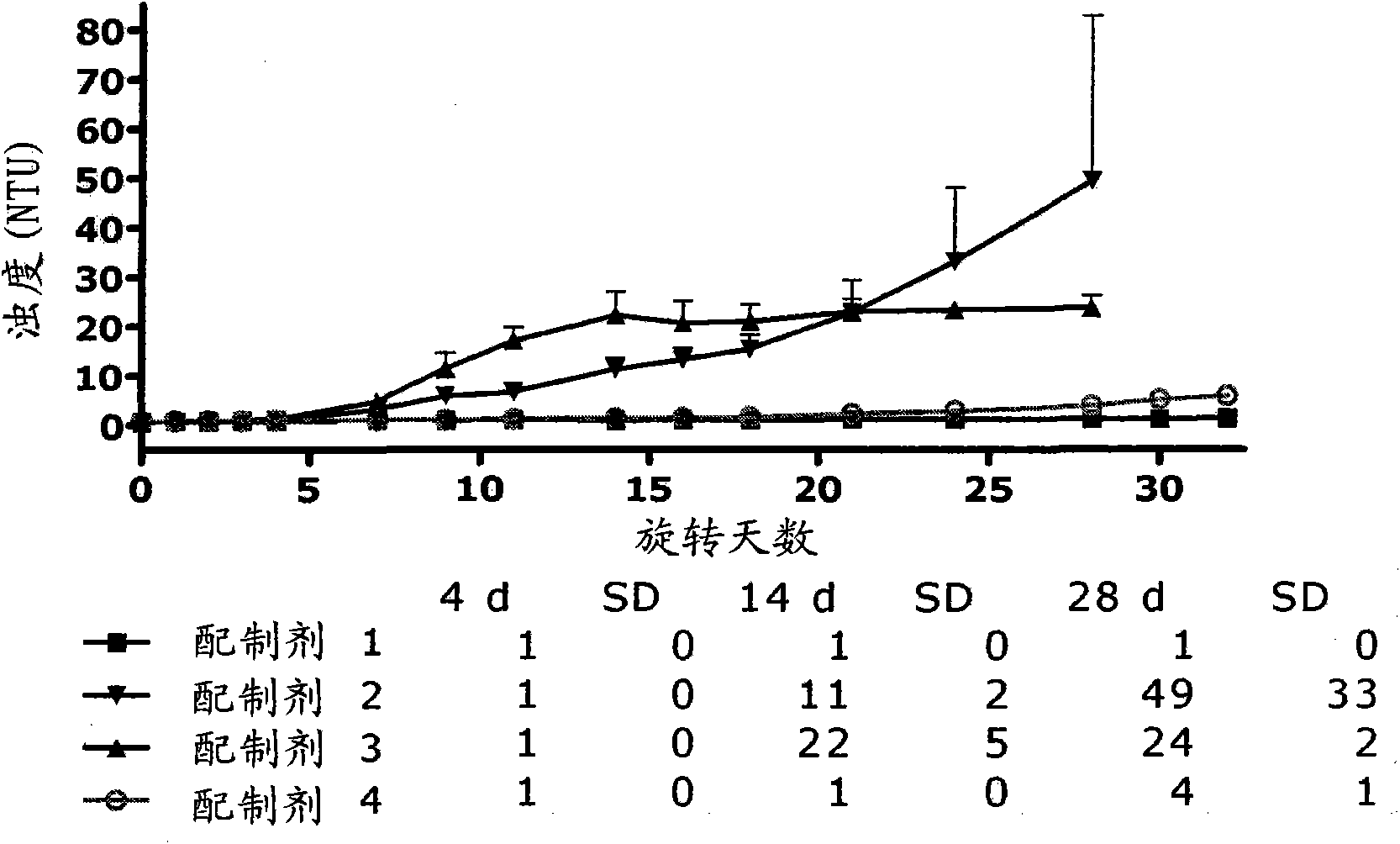

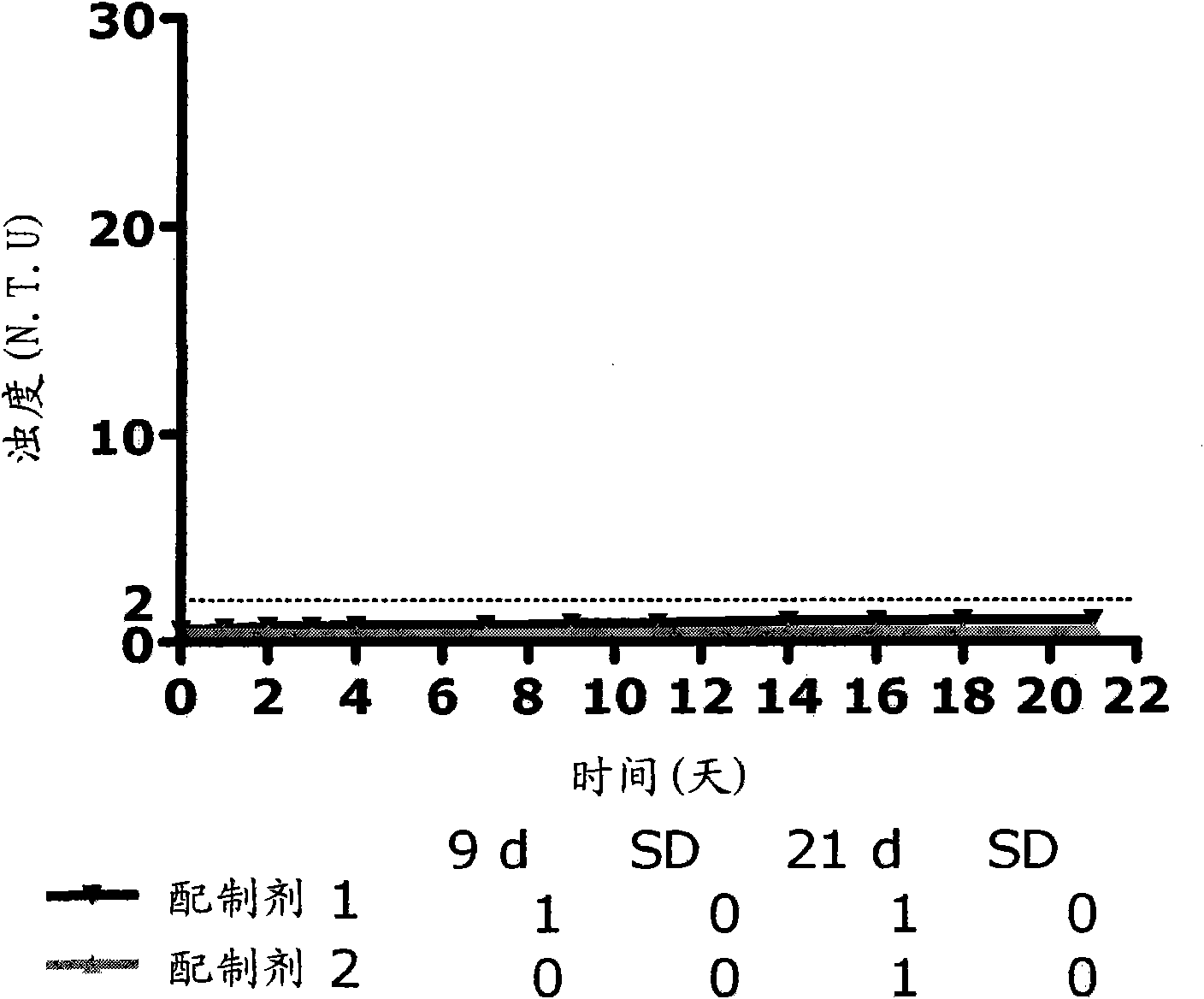

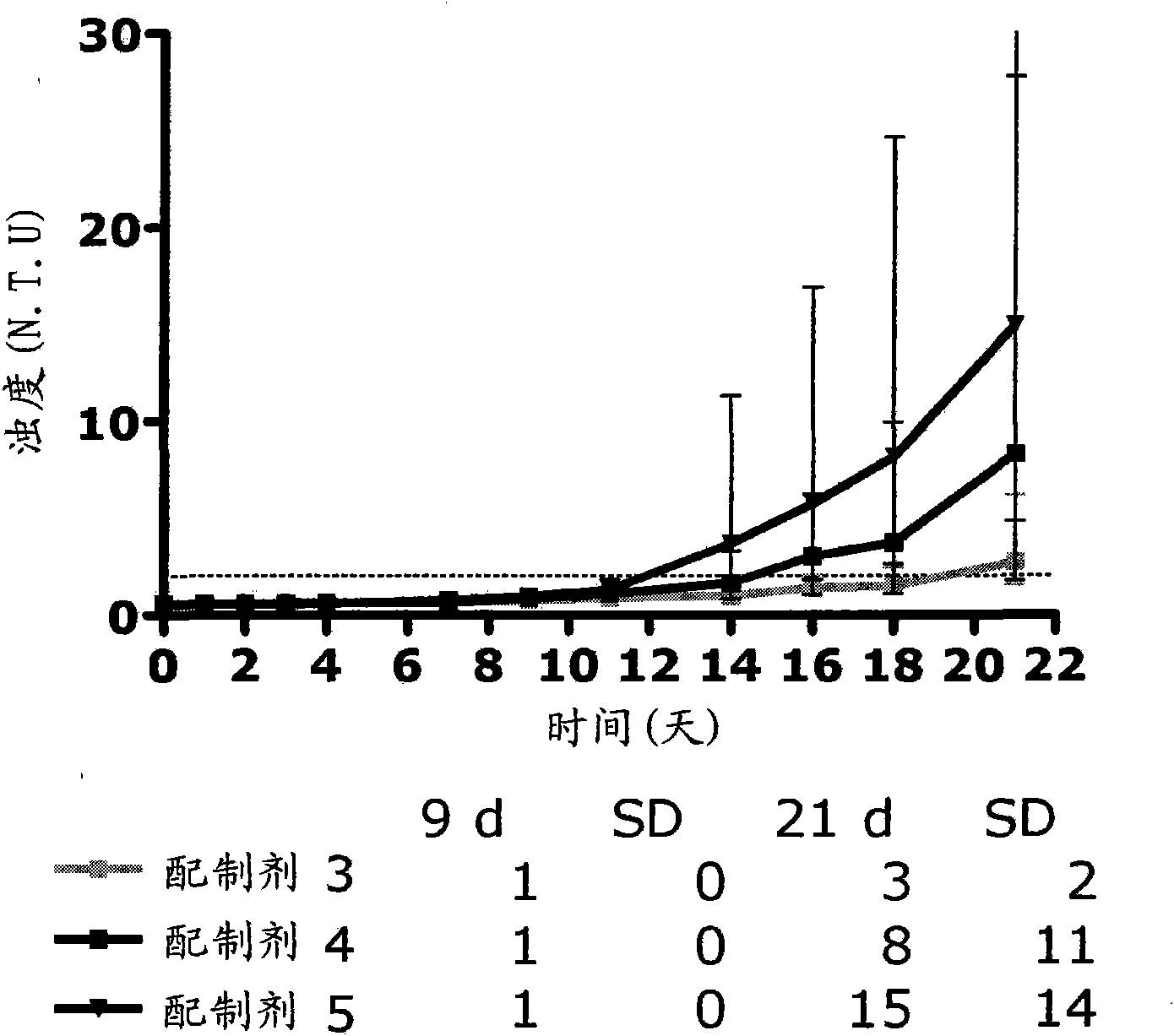

Insulin compositions and method of making a composition

InactiveUS20090074882A1High molecular weightBiocidePeptide/protein ingredientsZinc atomInsulin Analogue

The invention is related to insulin compositions with a high content of zinc atoms per six molecules of acylated insulin. The insulin is an acylated insulin and may be mixed with a further insulin analogue such as the rapid acting insulin Asp B28 human insulin.

Owner:NOVO NORDISK AS

Insulin compositions and method of making a composition

The invention is related to insulin compositions with a high content of zinc atoms per six molecules of acylated insulin. The insulin is an acylated insulin and may be mixed with a further insulin analogue such as the rapid acting insulin Asp B28 human insulin.

Owner:NOVO NORDISK AS

Pharmaceutical compositions comprising GLP-1 peptides or exendin-4 and a basal insulin peptide

Pharmaceutical composition for parenteral administration comprising a basal insulin peptide and an insulinotropic GLP-1 peptide comprising at least 6 zinc atoms per 6 insulin molecules.

Owner:NOVO NORDISK AS

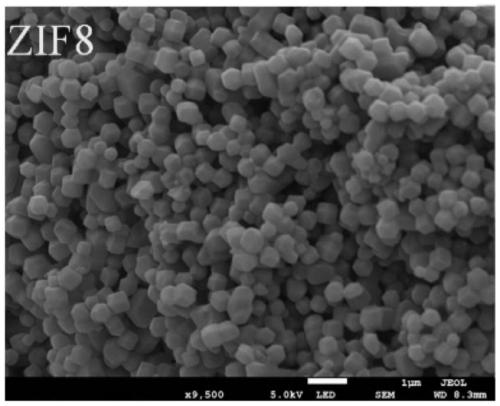

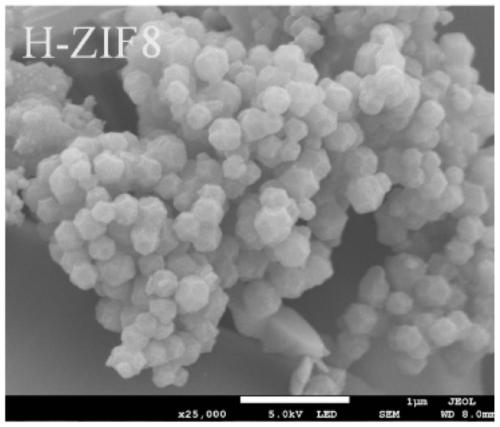

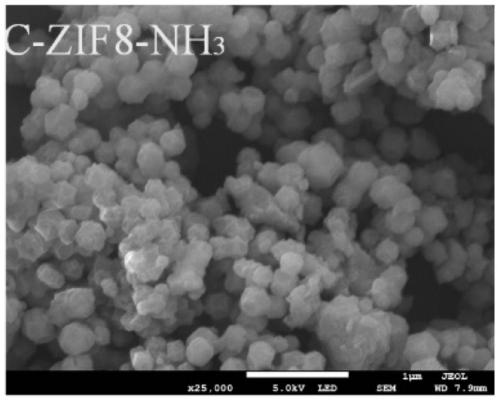

Zinc-containing monatomic catalyst as well as preparation method and application thereof

ActiveCN111584889AImprove stabilityHigh catalytic activityFuel and primary cellsCell electrodesPtru catalystPhysical chemistry

The invention discloses a zinc-containing monatomic catalyst as well as a preparation method and application thereof. According to the invention, 2-methylimidazole zinc salt (ZIF8) is used as a zinc precursor, a zinc intermediate is obtained through low-temperature calcination, then the low-zinc intermediate is etched (and loaded), and finally, high-temperature calcination is performed to preparethe zinc-containing monatomic catalyst. The method has the advantages that the process is simple and controllable, the zinc content does not need to be strictly controlled, and carrier materials do not need to be adopted; zinc atom agglomeration can be effectively prevented through low-temperature calcination and etching before high-temperature calcination; the obtained pure zinc monatomic catalyst is good in catalytic activity, high in stability and relatively good in poisoning resistance; and the obtained supported zinc-containing monatomic catalyst can further improve the catalytic activityof a pure zinc monatomic catalyst or meet the requirements of different catalytic systems.

Owner:SHENZHEN UNIV

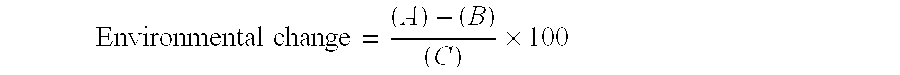

Charge control agent composition and toner utilizing the same

InactiveUS20090104554A1Excellent rising in electrostatic chargeHigh charge-imparting effectDevelopersPhotopigmentEngineering

The present invention provides a modified charge control agent composition exhibiting a high charge-imparting effect, and an electrostatic image developing toner containing such a charge control agent composition and having a high electrostatic charge amount and an environmental stability.A composition comprising a metal compound (A) of aromatic hydroxycarboxylic acid having an aromatic hydroxycarboxylic acid bonded with a metal atom selected from a zirconium atom, a calcium atom, an aluminum atom, a chromium atom, a boron atom and a zinc atom via at least any of ionic bond, covalent bond and coordinate bond; and at least one inorganic pigment (B), wherein the pigment (B) is contained in an amount of from 1 to 20 parts by mass in 100 parts by mass of the composition.

Owner:HODOGOYA CHEMICAL CO LTD

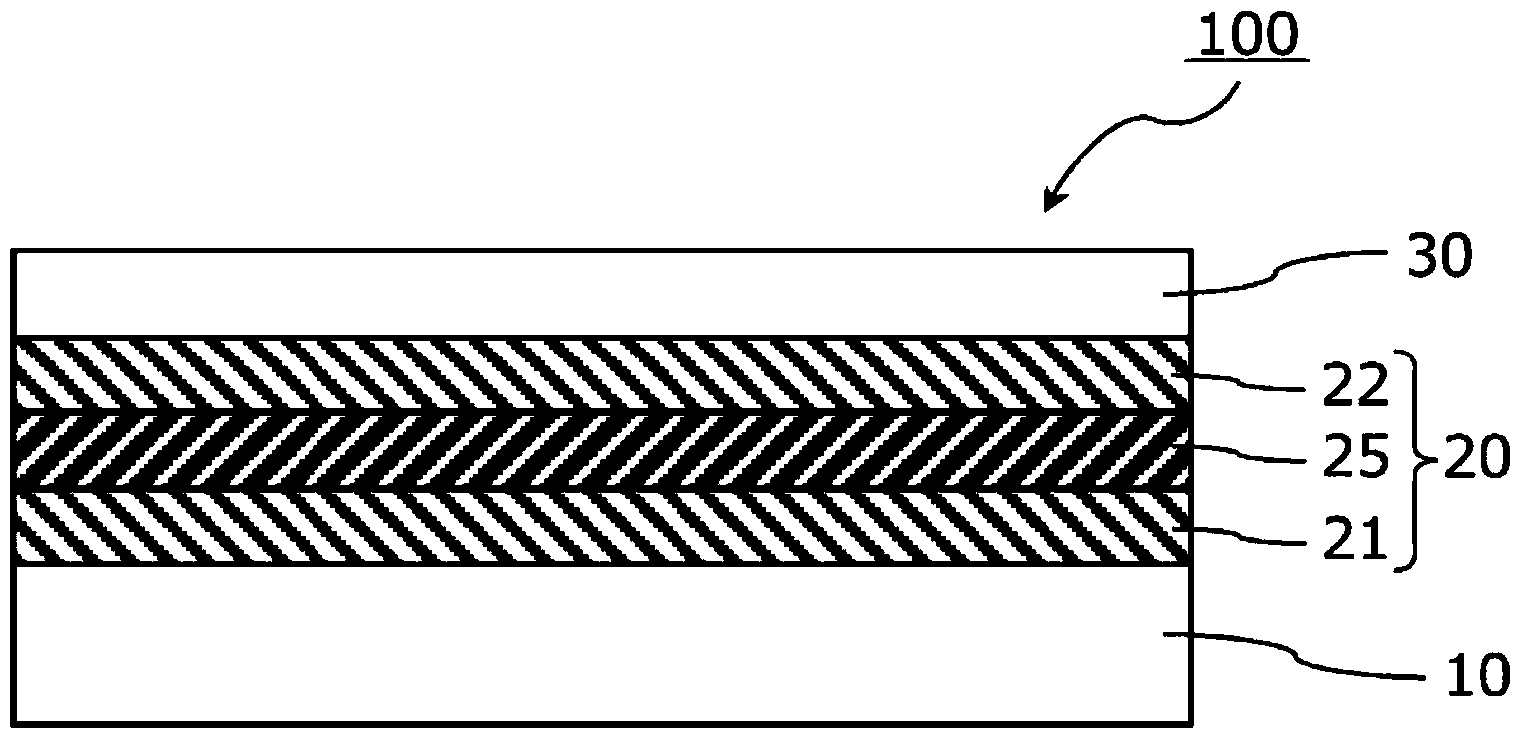

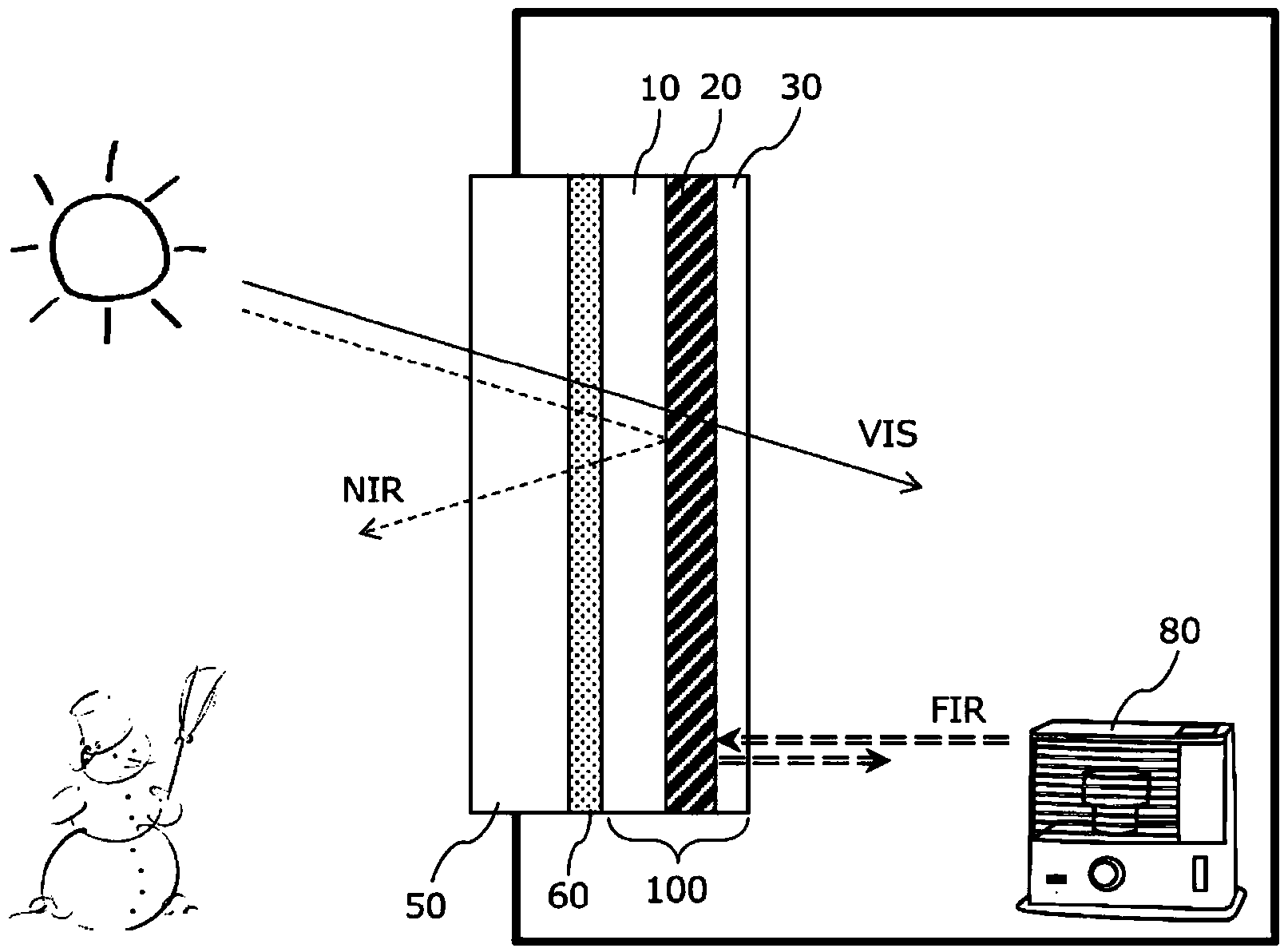

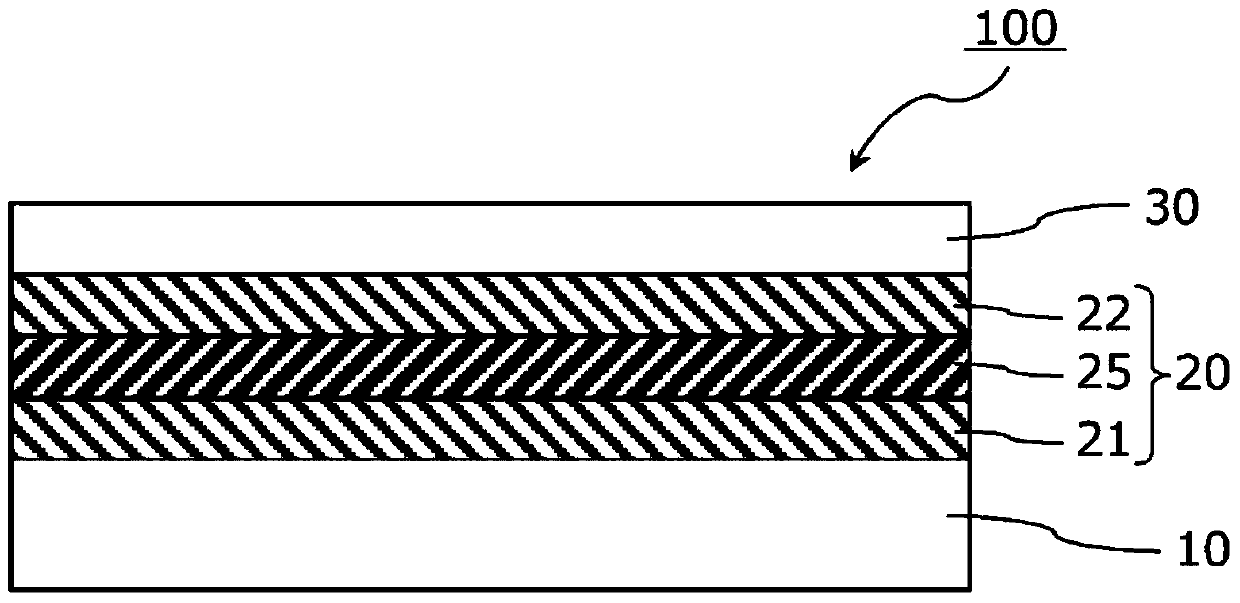

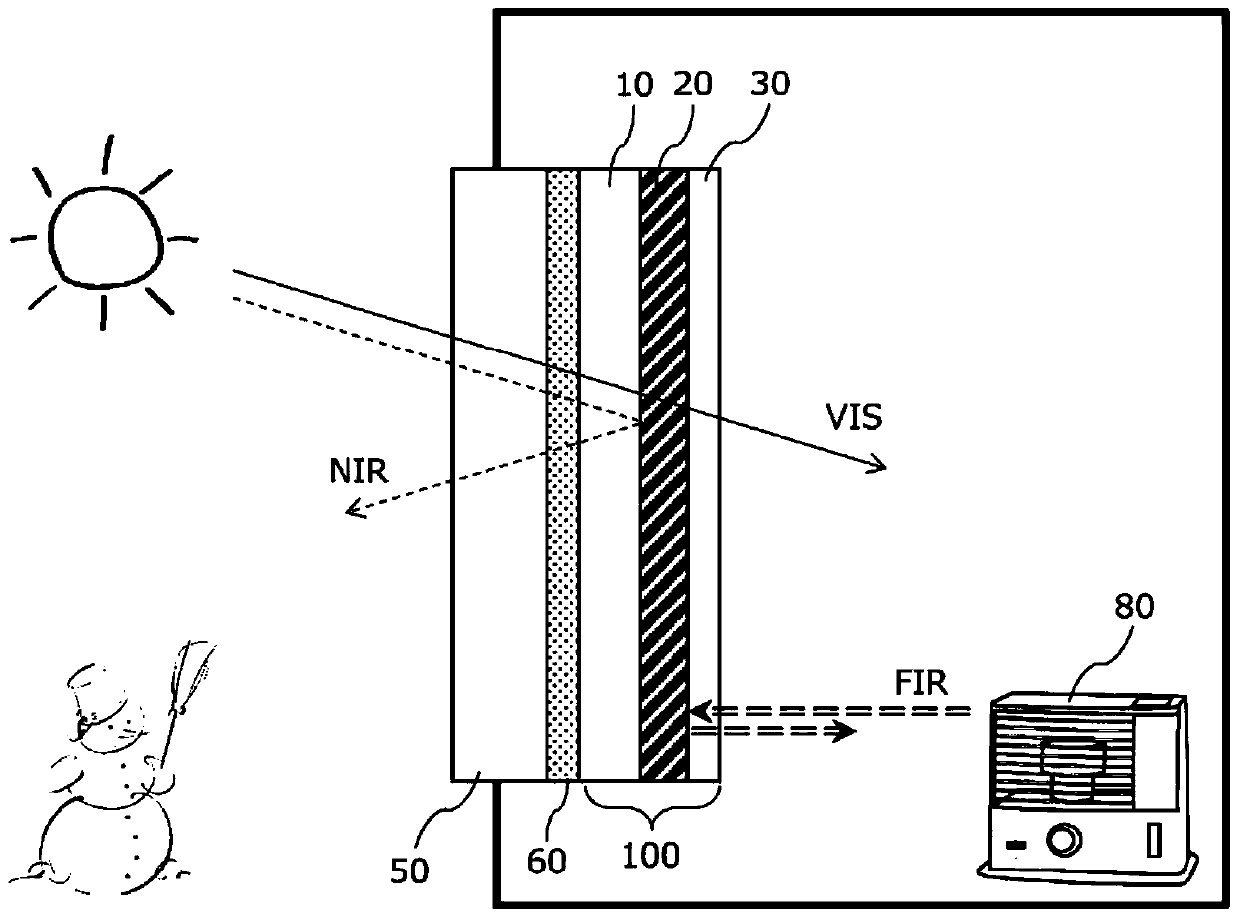

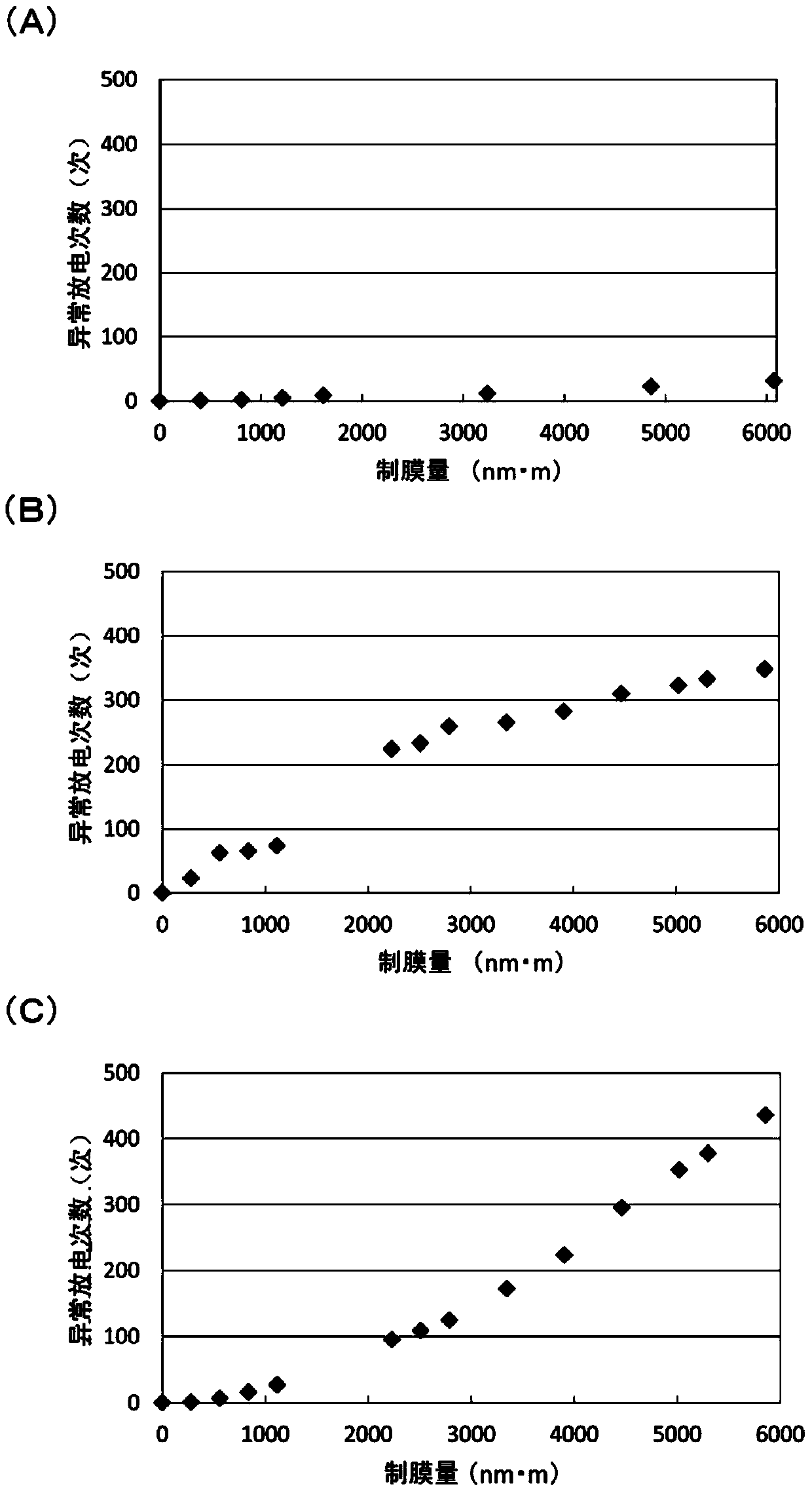

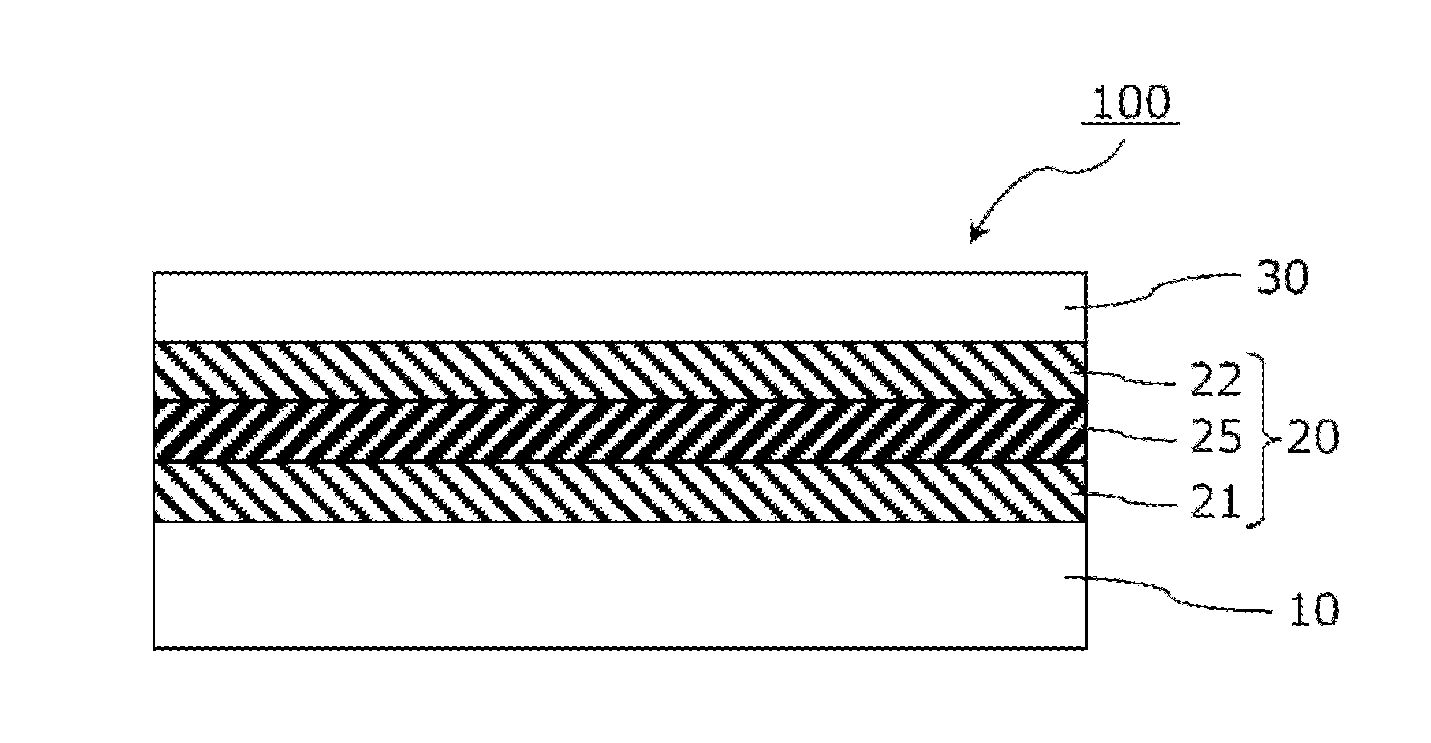

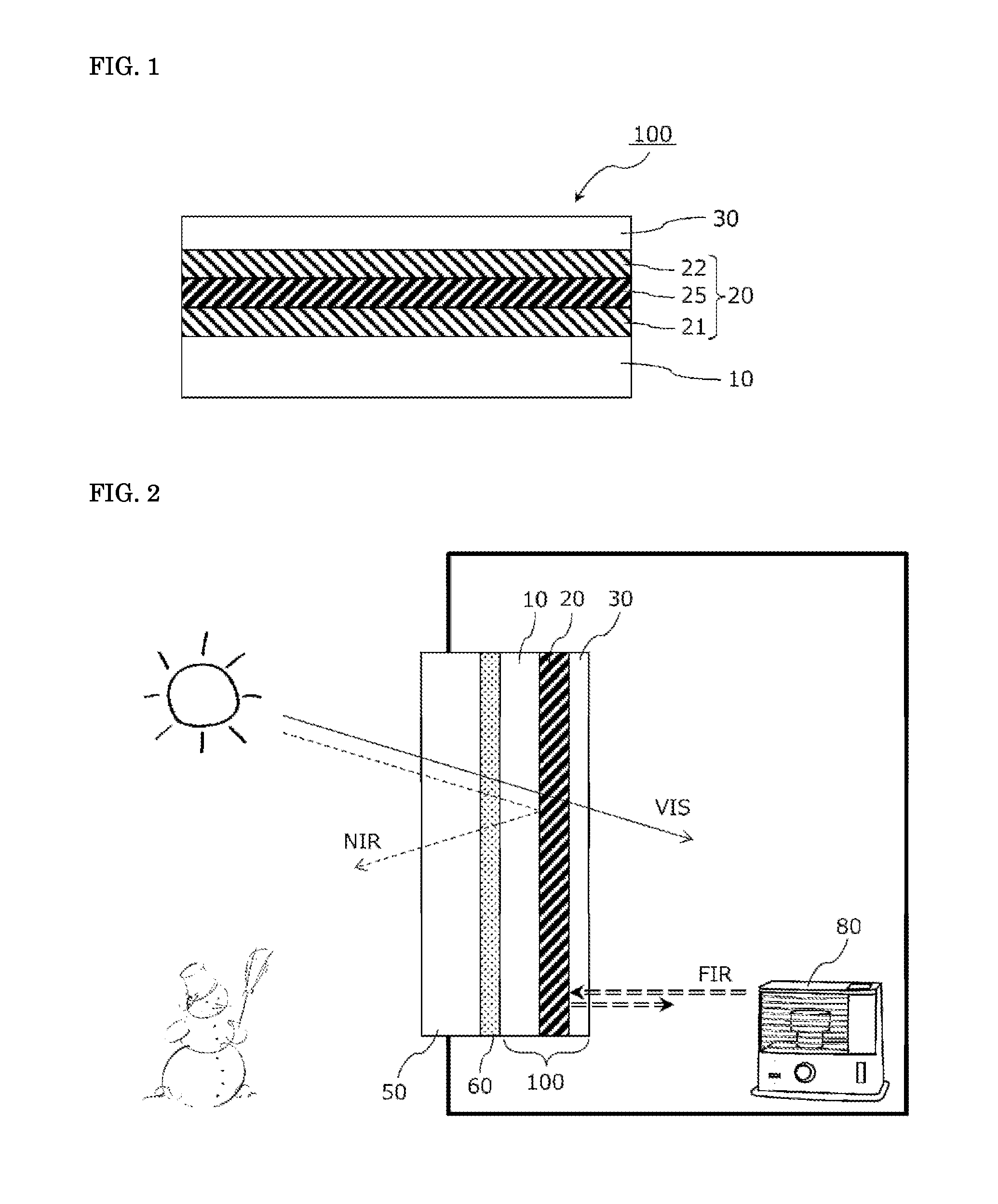

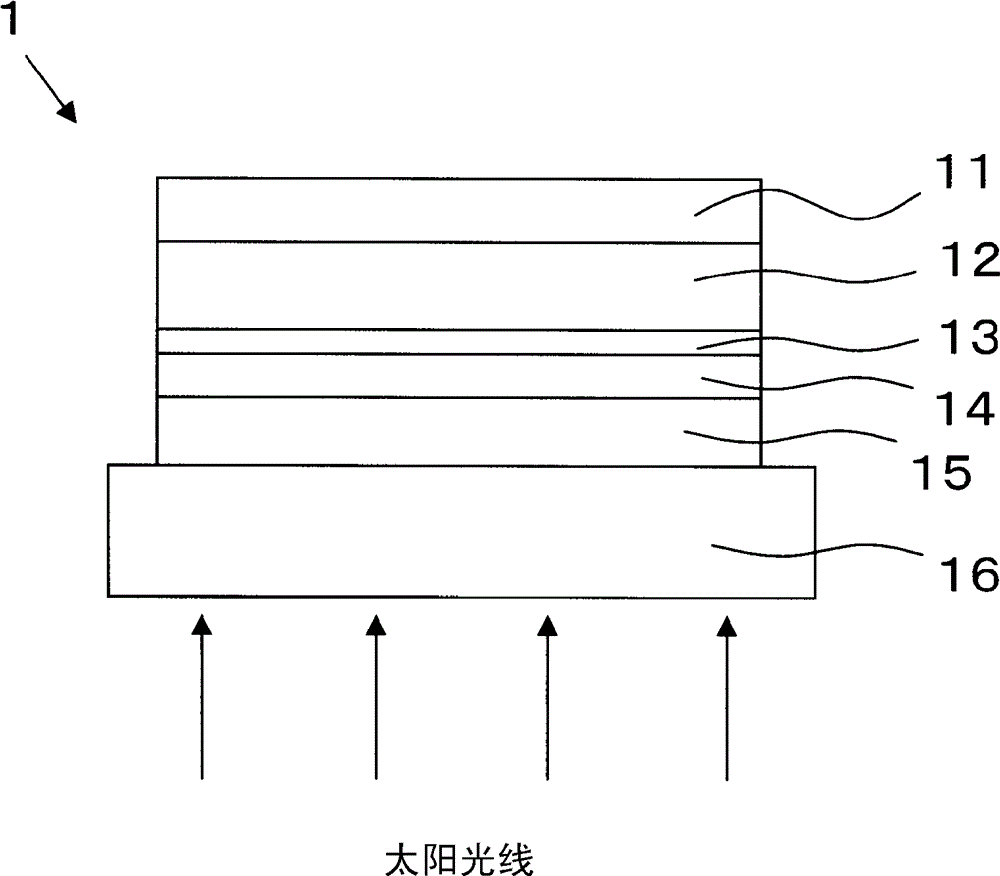

Method for producing infrared radiation reflecting film

InactiveCN103966560AImprove film production rateImprove productivityVacuum evaporation coatingSputtering coatingInfraredSputtering

The invention relates to a method for producing an infrared radiation reflecting film. This method for producing an infrared radiation reflecting film comprises, in order: a metal layer forming step in which a metal layer (25) is formed on a transparent film substrate (10); a metal oxide layer forming step in which a surface-side metal oxide layer (22) is formed by DC sputtering so as to be in direct contact with the metal layer (25); and a transparent protective layer forming step in which a transparent protective layer (30) is formed on the surface-side metal oxide layer (22). In the metal oxide layer forming step, a sputtering target used for DC sputtering contains zinc atoms and tin atoms, and is preferably formed by sintering at least one metal oxide among zinc oxide and tin oxide, and a metal powder. In the surface-side metal oxide forming step, an inert gas and an oxygen gas are introduced inside a sputtering film-forming chamber. The oxygen concentration in the gas introduced to the sputtering film-forming chamber is preferably not more than 8 vol%.

Owner:NITTO DENKO CORP

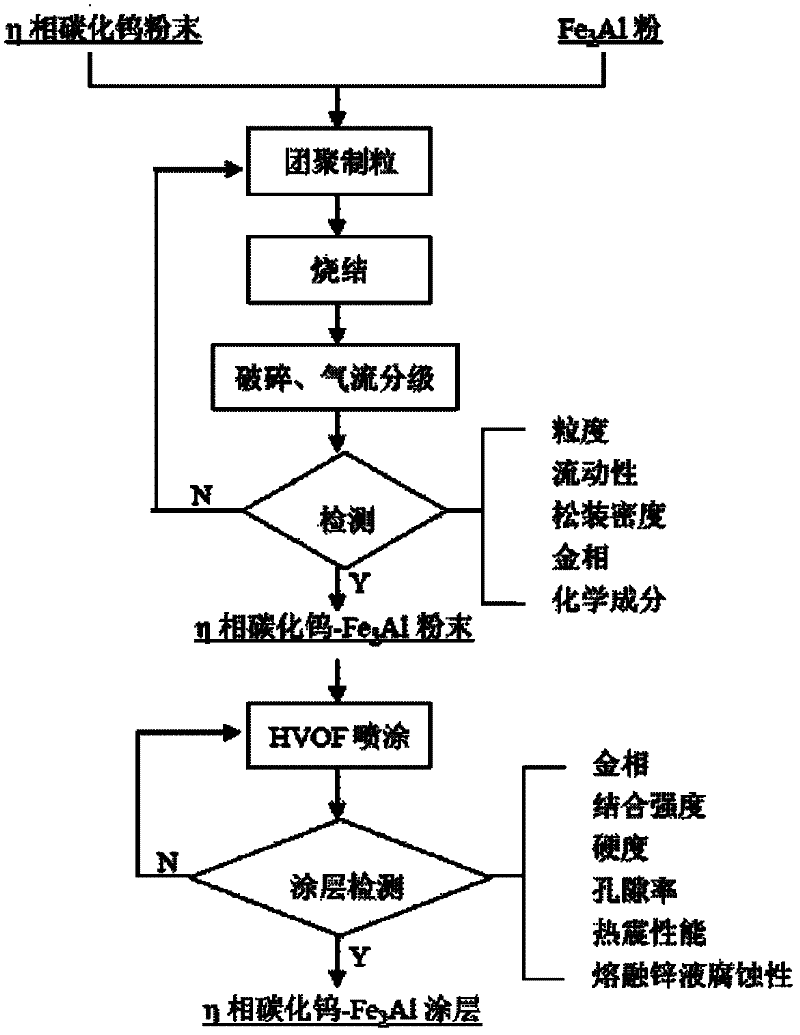

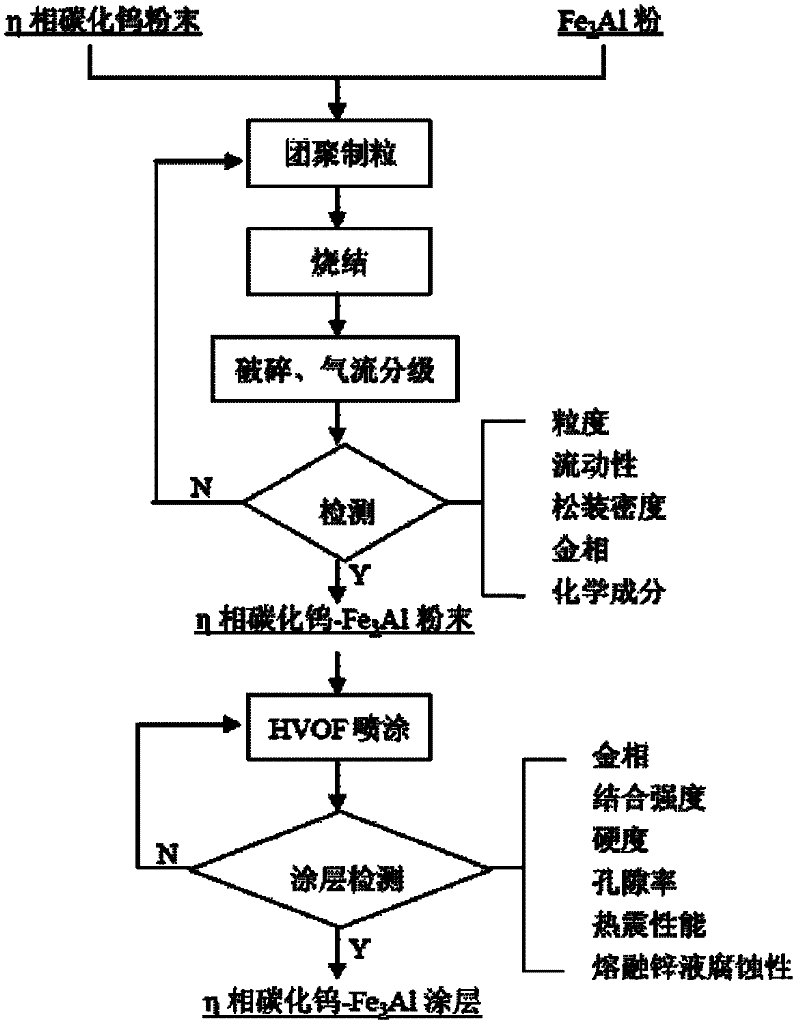

Preparation method of fused zinc erosion resistant coating material for thermal spraying and coating material prepared by the same

The invention provides a fused zinc erosion resistant coating material for thermal spraying and a preparation method of the coating material. The preparation method comprises the steps of: utilizing an eta phase tungsten carbide as a hard phase to replace the WC labile at a high temperature, and utilizing Fe3Al as an adhesion phase to replace Co, preparing an eta phase tungsten carbide-Fe3Al coating on a hot galvanized submerging roller or on the surface of a shaft sleeve of the hot galvanized submerging roller by a thermal spraying method to prepare a target product. The preparation method of the invention has the advantages that the hard phase, eta phase tungsten carbide can effectively prevent the zinc atoms from dispersing inward the alloy to resist against the fused zinc erosion, the eta phase tungsten carbide is high-temperature resistant and indecomposable to perform a good high-temperature wearing resistance function, and the adhesion phase Fe3Al and the Zn can be used for forming a fused zinc erosion resistant Fe-Al-Zn ternary phase, so that the fused zinc erosion resistance is better than that of a sintered WC-Co coating.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

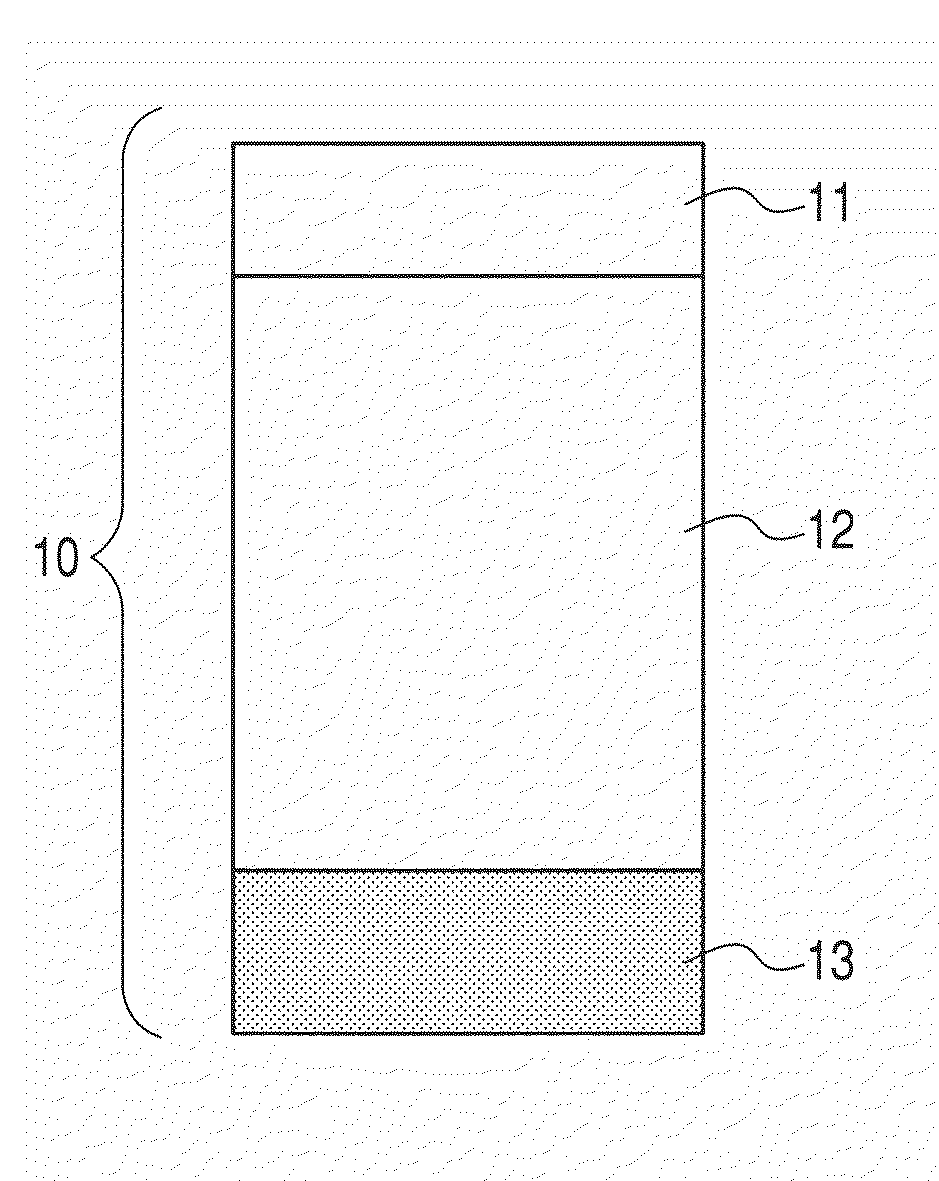

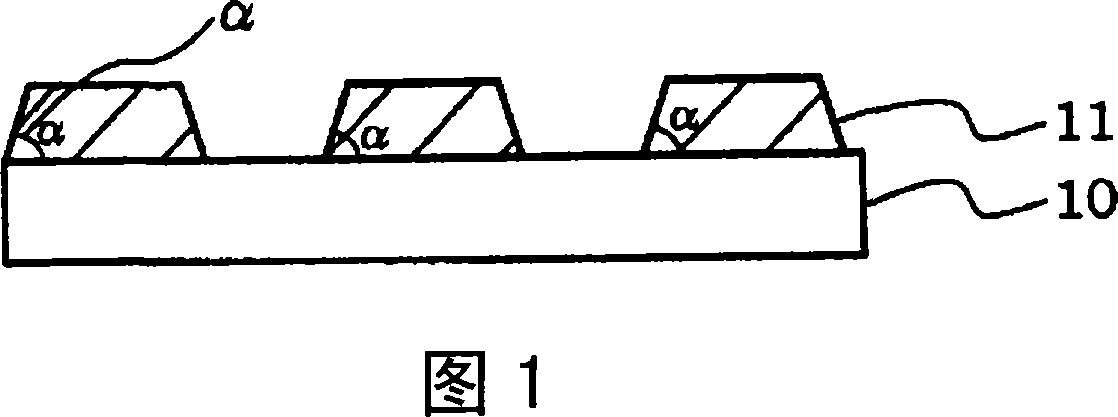

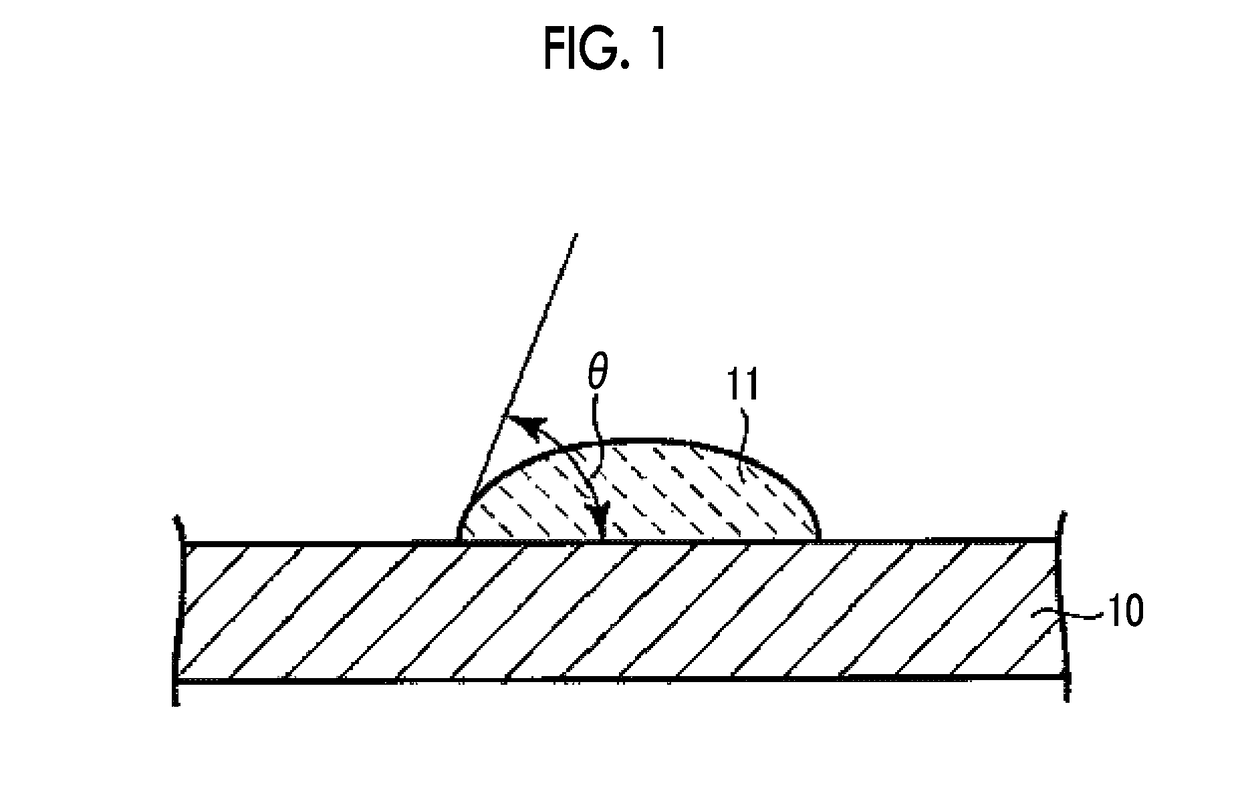

Semiconductor light-emitting device and method of manufacturing the same

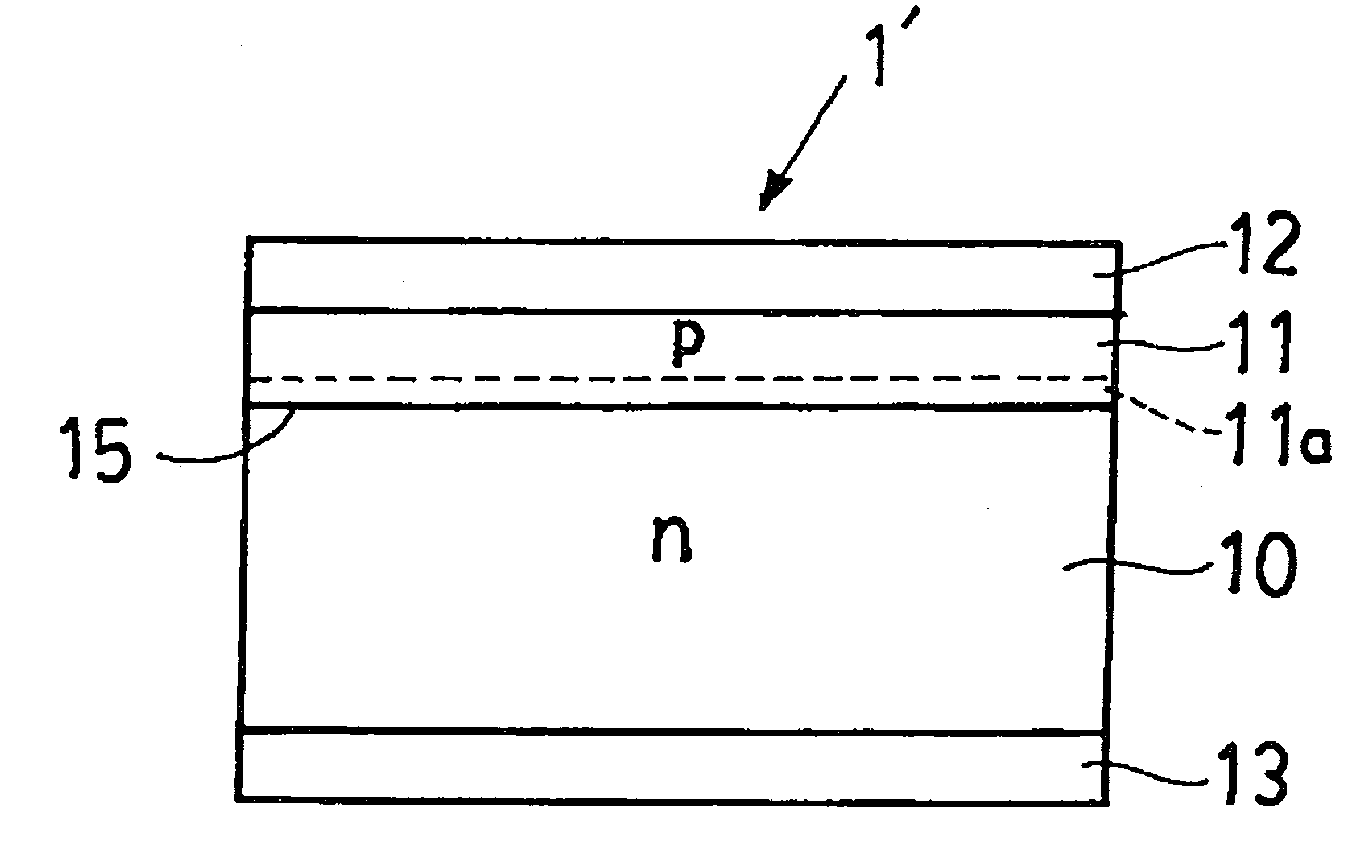

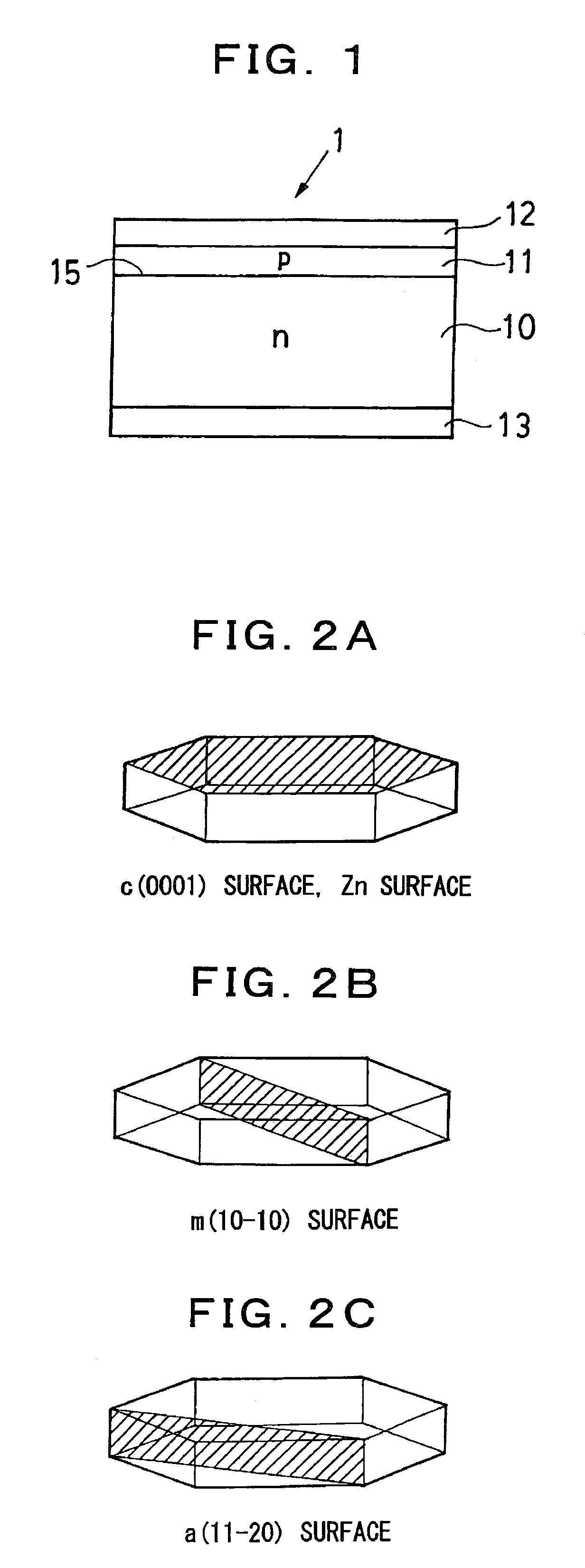

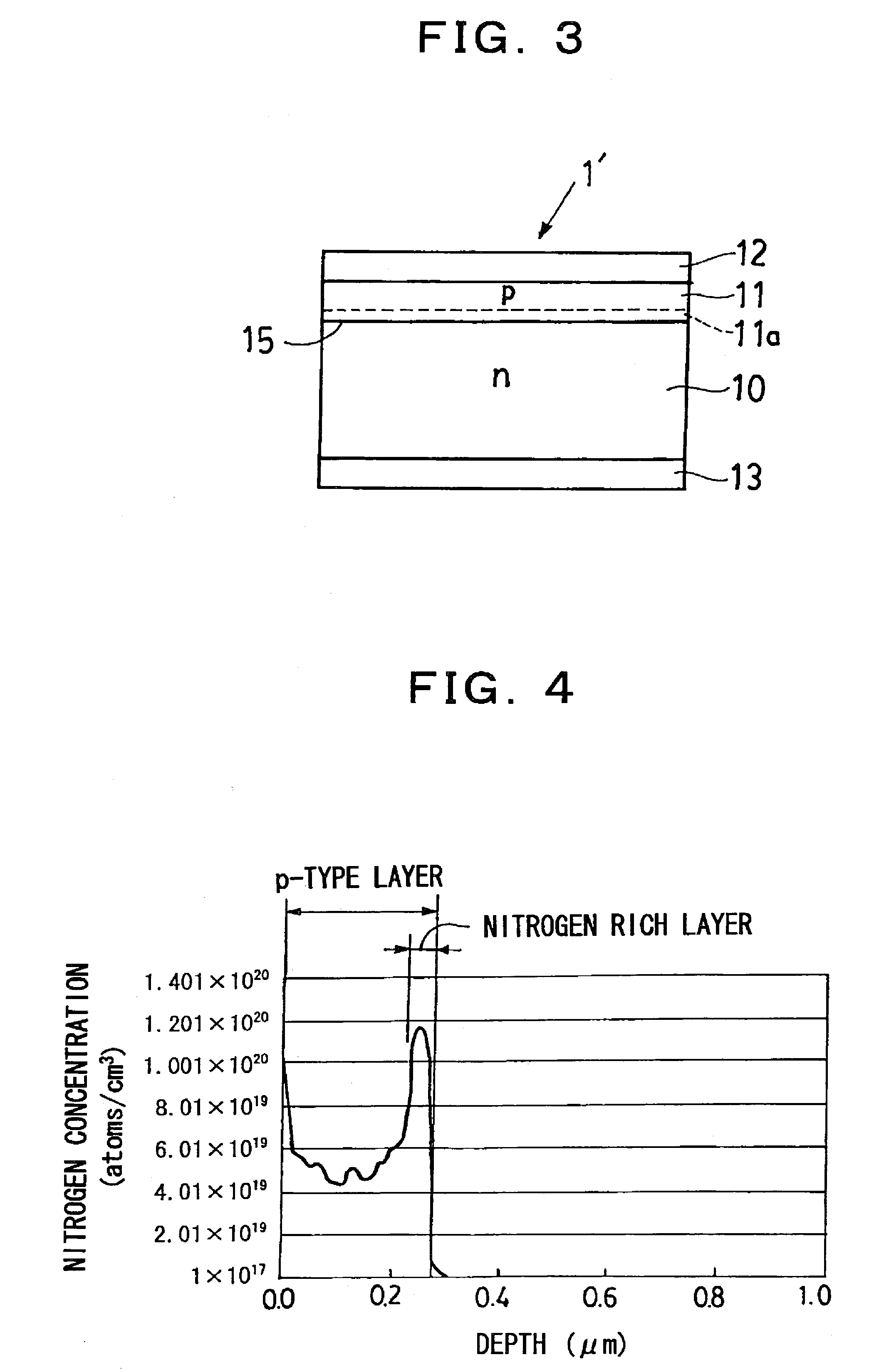

InactiveUS7964868B2Solve the lack of outputImprove batch productivityPolycrystalline material growthVacuum evaporation coatingNitrogenSingle crystal substrate

Disclosed is a semiconductor light-emitting device wherein a pn junction is formed by forming, as a p-type layer (11), a semiconductor thin film which is composed of a ZnO compound doped with nitrogen on an n-type ZnO bulk single crystal substrate (10) whose resistance is lowered by being doped with donor impurities. It is preferable to form the p-type layer (11) on a zinc atom containing surface of the n-type ZnO bulk single crystal substrate (10).

Owner:CITIZEN WATCH MFG +1

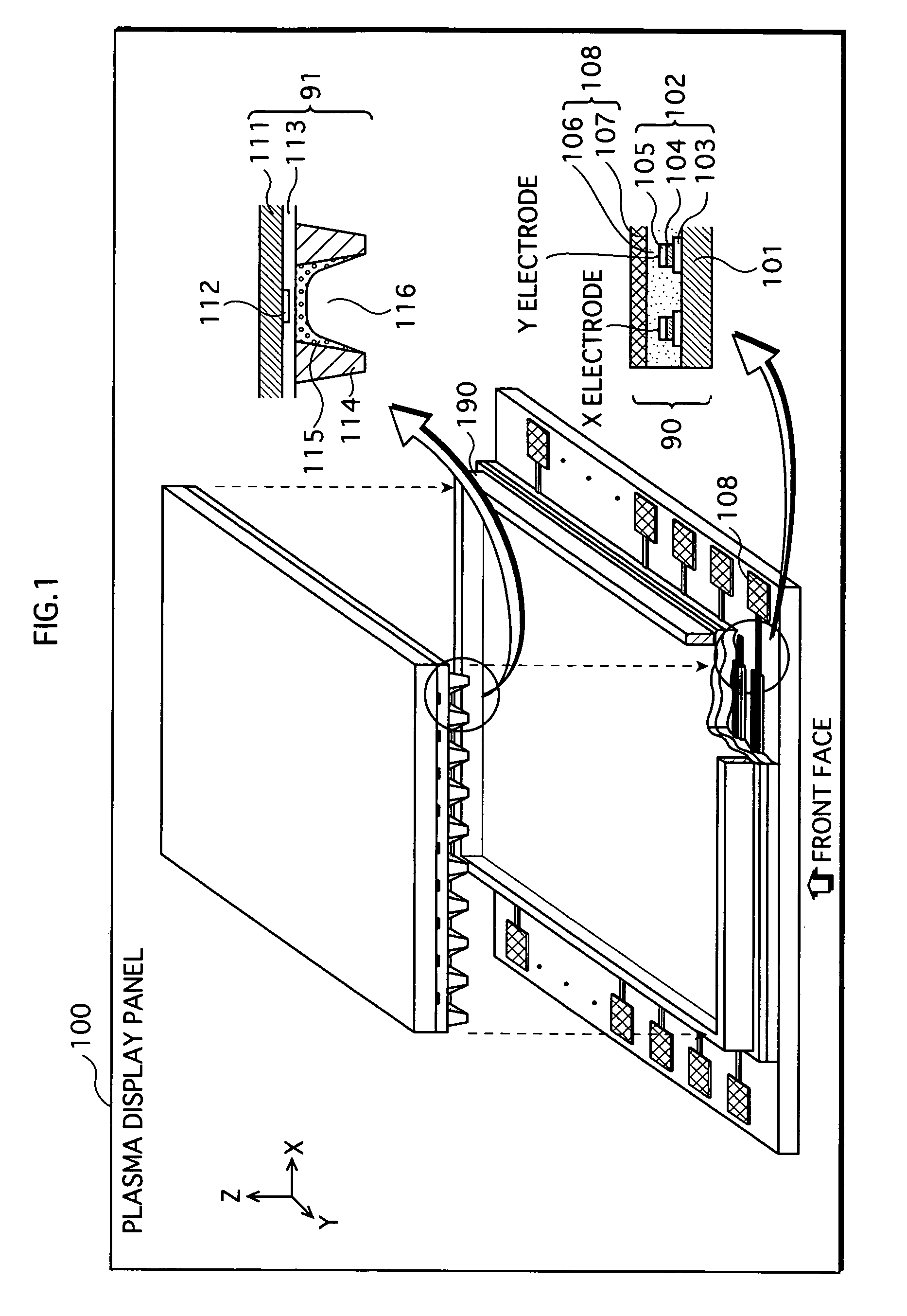

Phosphor having resistance to deterioration caused by ultraviolet rays, and gas discharge display device of which image quality is not readily deteriorated over time

InactiveUS20050263742A1Not easy to deteriorateDeteriorate with timeDischarge tube luminescnet screensLamp detailsImaging qualityPhosphor

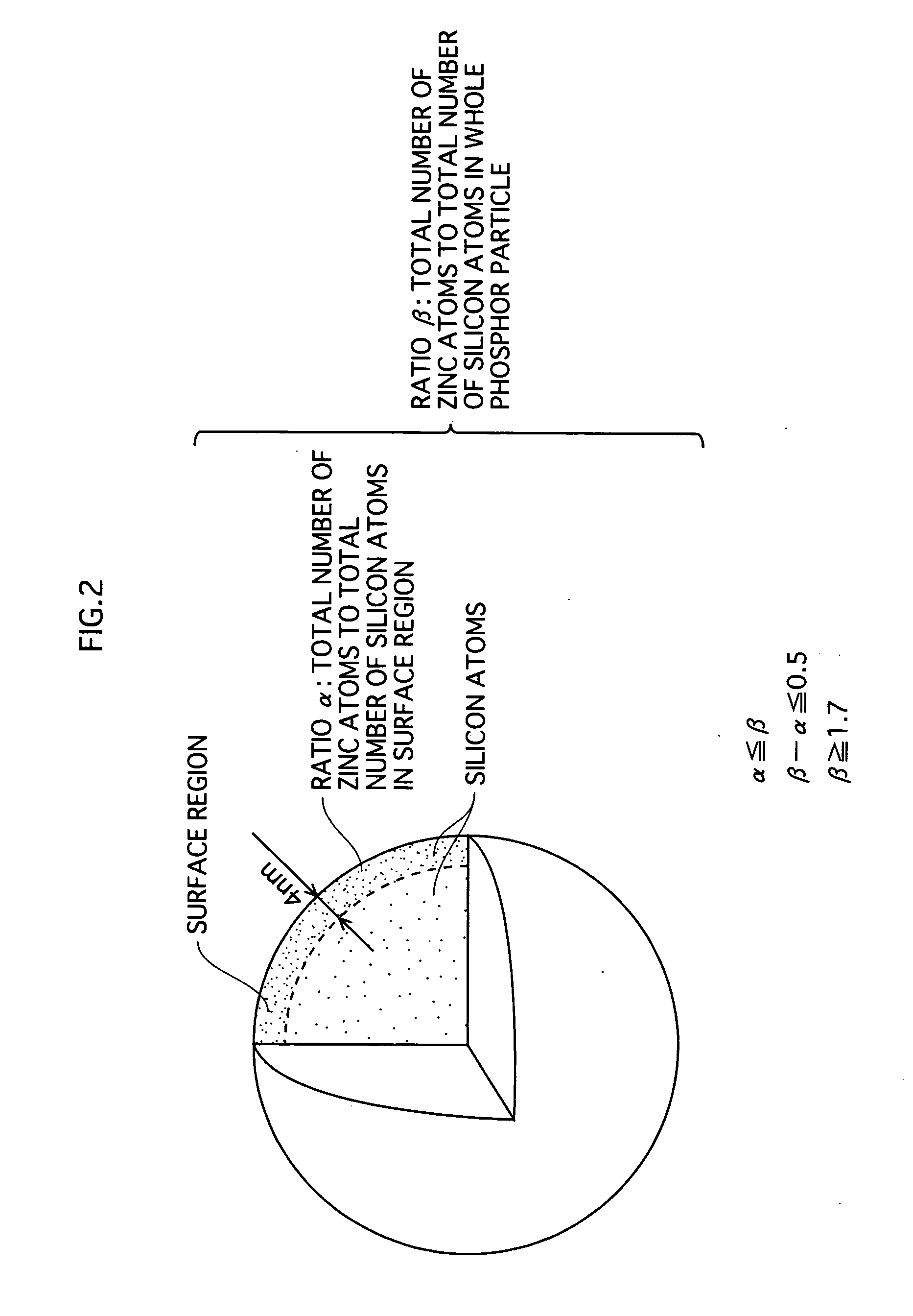

A manganese-activated zinc silicate phosphor according to the present invention satisfies 0<β-α≦0.5 and 1.7≦β, where a value α is a ratio of a number of zinc atoms to a number of silicon atoms in a surface region of a phosphor particle, including a surface of the phosphor particle and a vicinity thereof, and a value β is a ratio of a number of zinc atoms to a number of silicon atoms in a whole of the phosphor particle.

Owner:PANASONIC CORP

Production method of copper-zinc alloy foil for preventing lithium dendrite arm from being produced by lithium ions

InactiveCN108893763AImprove distributionReduce explosionElectrode carriers/collectorsElectrolysisElectrical battery

The invention discloses a production method of a copper-zinc alloy foil for preventing a lithium dendrite arm from being produced by lithium ions and belongs to the technical field of copper foil electrolysis. The method comprises the steps of carrying out acid pickling, washing, electric deposition, zinc deposition, washing and passivating, extruding and drying; a lithium dendrite arm copper-zincalloy foil of a lithium-ion battery can be prevented from being produced; zinc atom defects which are uniformly distributed in a current collector of the copper-zinc alloy foil can be used as induction crystal seeds to deposit metal lithium for nucleation, so that the distribution of the lithium ions on the surface of the current collector can be effectively improved; a zinc-layer crystal in thecopper-zinc alloy foil has tight and uniform tissue and the tissues are distributed orderly; the thickness is uniform and the deviation is less than 0.01mum; and the adhesive force is good, and the tensile strength and the elongation percentage reach utilization standards of the lithium-ion battery; and the copper-zinc alloy foil has good surface weldability and good high temperature resistance and corrosion resistance.

Owner:青岛昊月鑫电子材料有限公司

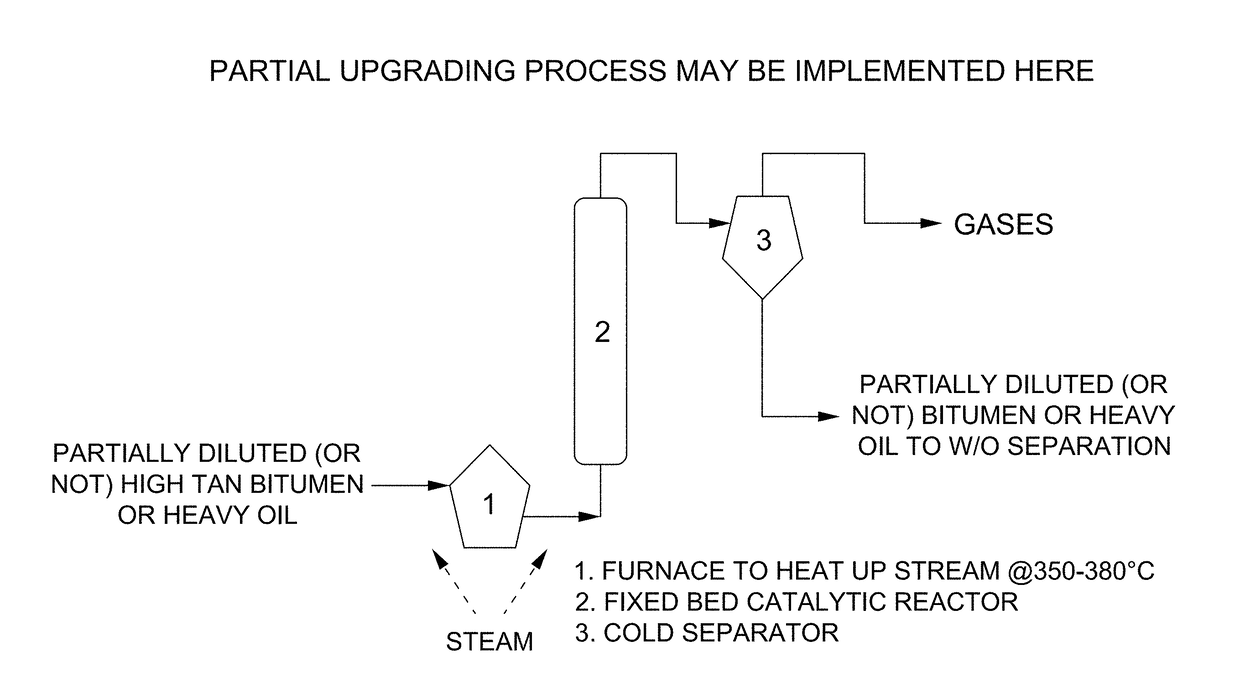

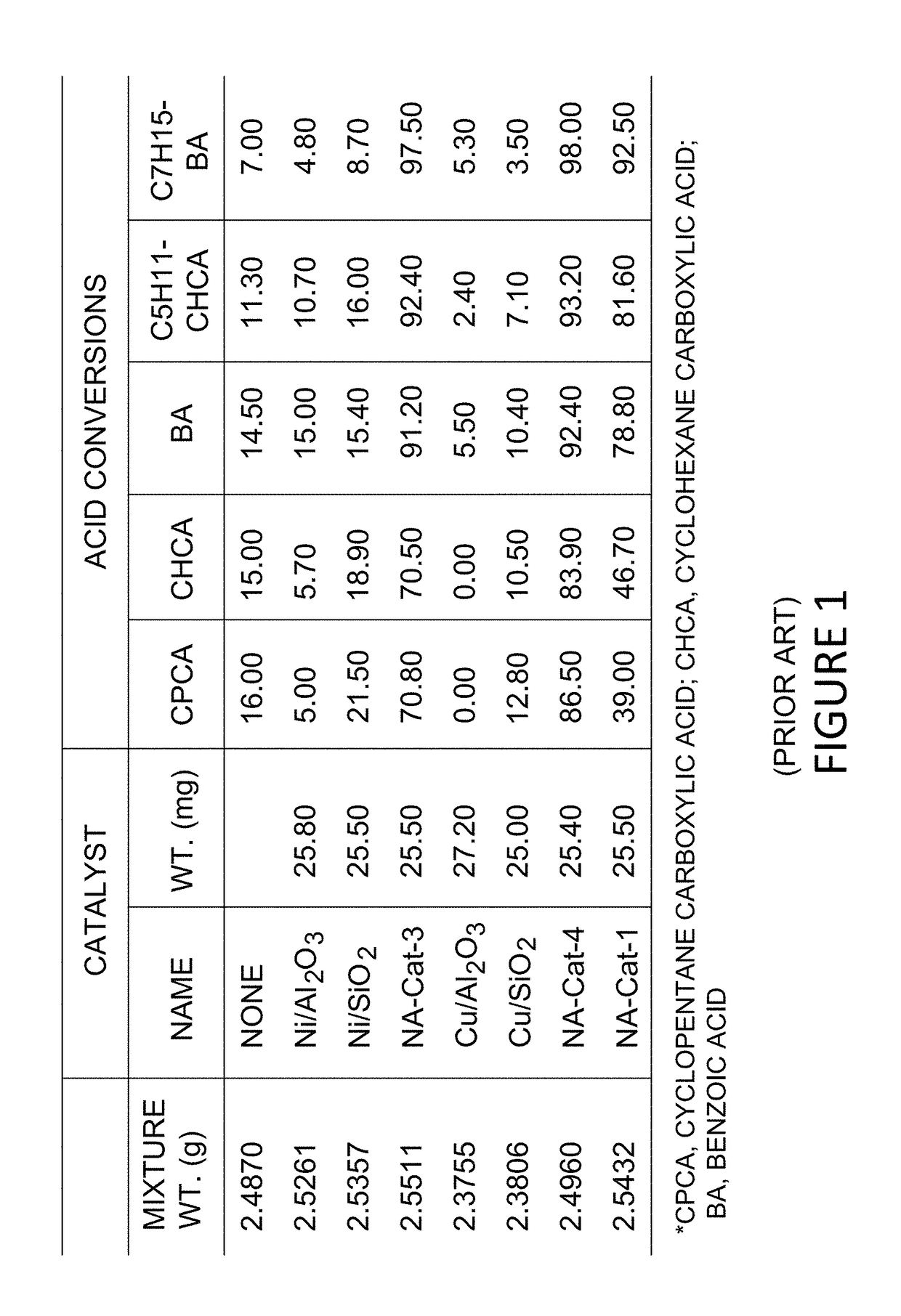

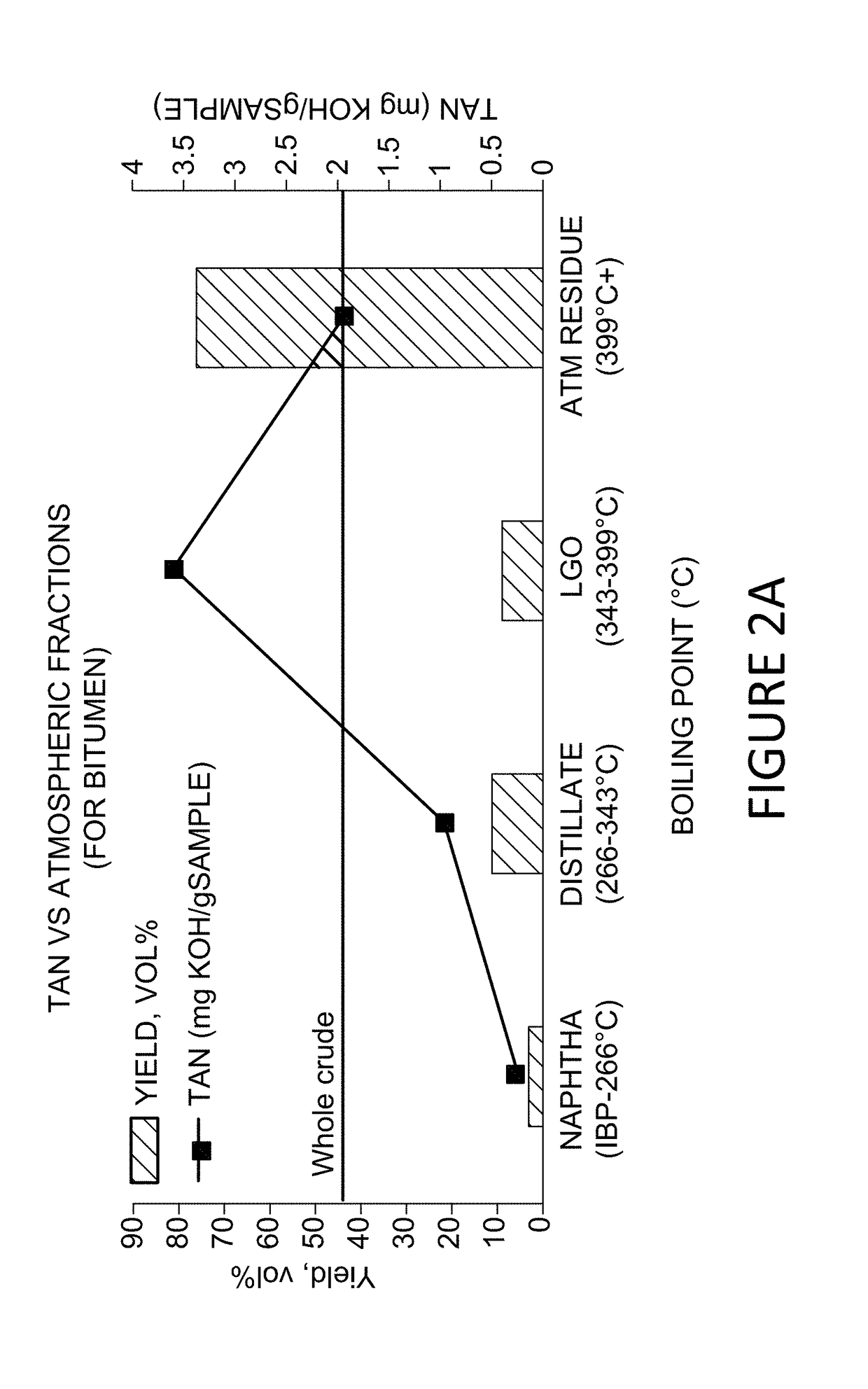

Metallo-silicate catalyst (MSC) compositions, methods of preparation and methods of use in partial upgrading of hydrocarbon feedstocks

ActiveUS20180029022A1Improve propertiesHigh strengthCatalytic crackingLiquid hydrocarbon mixture productionCeriumIon

The invention relates to the preparation of novel bi- or tri metallic silicate micro-porous and / or meso-porous materials based on cerium, nickel, copper and / or zinc on a porous silicate framework matrix to use its molecular sieve effect to target preferentially the acidic organic molecules present in hydrocarbon feedstocks like crude oil, bitumen, VGO and the like. The chosen metals are selected based on their ability to activate steam and transfer oxygen for completing the oxidation of carboxylic compounds or decarboxylating them. These composite materials can be prepared under hydrothermal synthesis conditions in order to produce suitable porous solids where the metals are well dispersed and preferentially distributed inside the channels of the silicate framework where they can interact only with the molecules that can go inside the channels. According to the invention, the metallo-silicate materials are prepared under hydrothermal synthesis conditions Modification of the physical-chemical properties of the porous silicate materials can be accomplished by partial replacement of the silicon atoms by cerium, nickel, copper and / or zinc atoms in the material by isomorphous substitutions of these elements in a synthesis gel or by post-synthesis modifications like ion-exchange or impregnation / deposition. The materials can be used as prepared catalysts for the steam catalytic reduction of the total acid number (TAN) in acidic crude oil feedstocks and in the presence of steam and / or CO2 as oxidizing agent to complete decarboxylation and to keep the metal oxide active sites from reducing and deactivating as well as other partial upgrading reactions.

Owner:PC CUPS LTD +1

Production method for infrared radiation reflecting film

InactiveCN103966559AInhibitionImprove productivityLamination ancillary operationsMirrorsInfraredSputtering

The invention relates to a production method for an infrared radiation reflecting film. The infrared radiation reflecting film (100) is provided with, in order, an infrared radiation reflecting layer (20) having a metal layer (25) and metal oxide layers (21, 22), and a transparent protective layer (30) on a transparent film substrate (10). In this production method, the metal oxide layers are formed by DC sputtering using a winding sputtering apparatus. The sputtering target used in DC sputtering contains zinc atoms and tin atoms. The sputtering target is preferably obtained by sintering a metal powder, and at least one metal oxide among zinc oxide and tin oxide.

Owner:NITTO DENKO CORP

Method for producing infrared radiation reflecting film

InactiveUS20160145736A1Increased durabilityImprove adhesionVacuum evaporation coatingSputtering coatingInfraredSputtering

The method for manufacturing an infrared reflecting film comprises, in order: a metal layer forming step of depositing a metal layer on a transparent film substrate; a metal oxide layer forming step of depositing a surface-side metal oxide layer by DC sputtering on the metal layer so as to be in direct contact with the metal layer; and a transparent protective layer forming step of depositing a transparent protective layer on the surface-side metal oxide layer. In the metal oxide layer forming step, a sputtering target used for DC sputtering contains zinc atoms and tin atoms, and is preferably formed by sintering a metal powder and at least one metal oxide among zinc oxide and tin oxide. In the surface-side metal oxide layer forming step, an inert gas and an oxygen gas are introduced into a sputtering chamber. The oxygen concentration in the gas introduced to the sputtering chamber is preferably not more than 8 vol %.

Owner:NITTO DENKO CORP

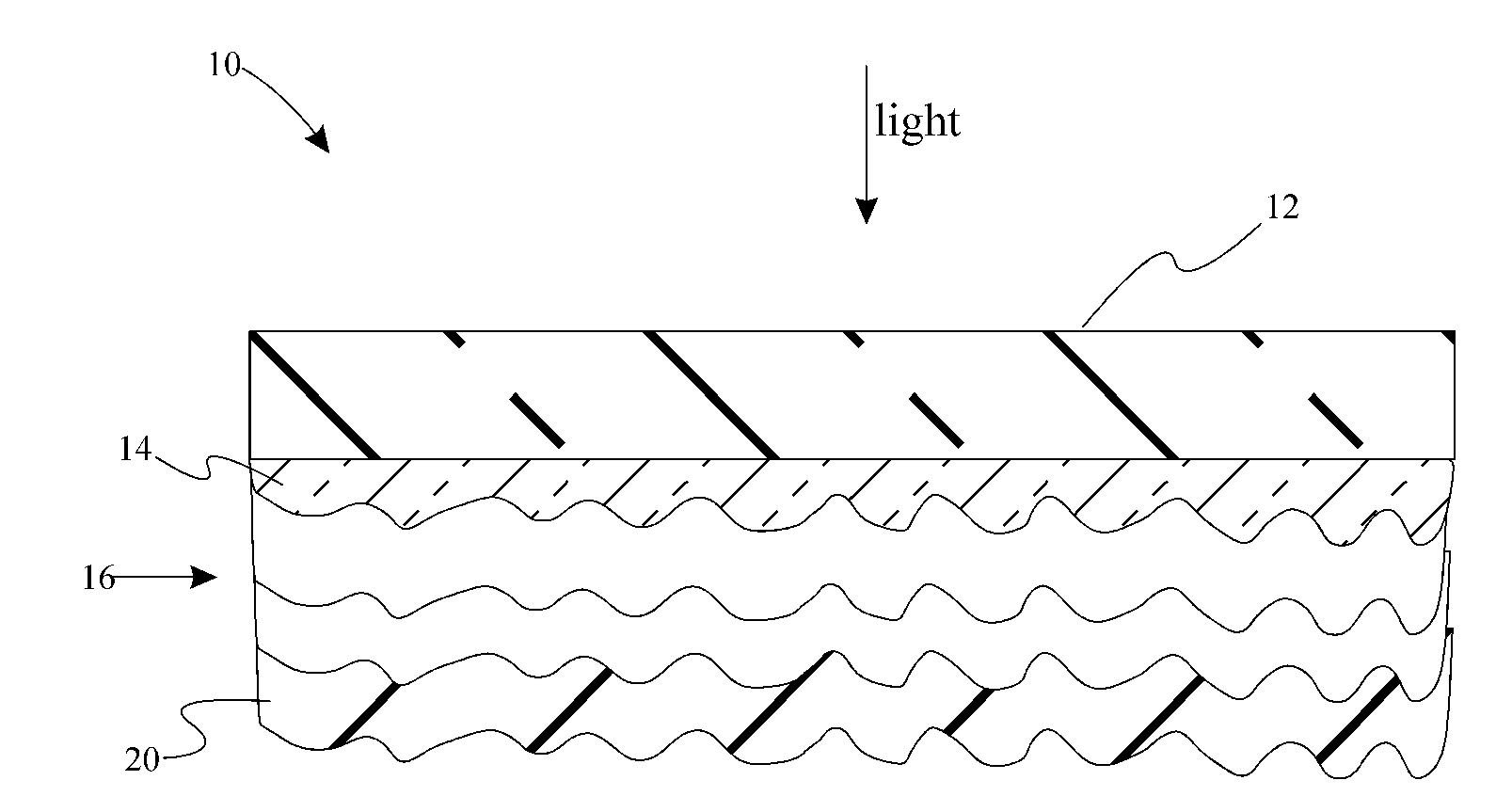

Perovskite solar cell and preparation method thereof

ActiveCN105932162AImprove photoelectric conversion efficiencyInject easySolid-state devicesSemiconductor/solid-state device manufacturingMetal electrodesZinc atom

The invention discloses a perovskite solar cell and a preparation method thereof. The perovskite solar cell comprises a conductive glass layer, a compact titanium dioxide film, a porous titanium dioxide film, a methylamine lead iodine polycrystalline film, a hole-transport material layer and a metal electrode layer in sequence. The perovskite solar cell is characterized in that the porous titanium dioxide film is Zn-doped, and after doping, mole ratio between zinc atoms and titanium atoms is 0.1%-0.4%:1. The perovskite solar cell has the advantages that the Zn-doped porous titanium dioxide is utilized as a photo anode of the perovskite solar cell; a titanium dioxide conduction band can be changed through Zn-doping, and the titanium dioxide conduction band is allowed to move down, so that a gap between a methylamine lead iodine conduction band serving as a perovskite light absorption layer and Zn-doped porous titanium dioxide conduction band is enlarged, electrons are allowed to be easier to inject and pass, and photoelectric conversion efficiency of the perovskite solar cell can be improved.

Owner:NINGBO UNIV

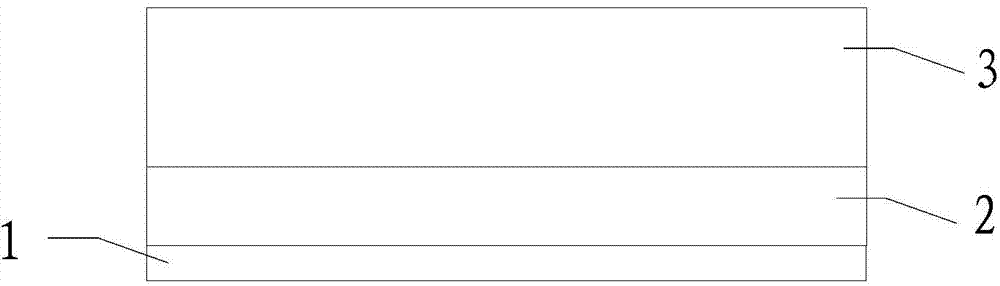

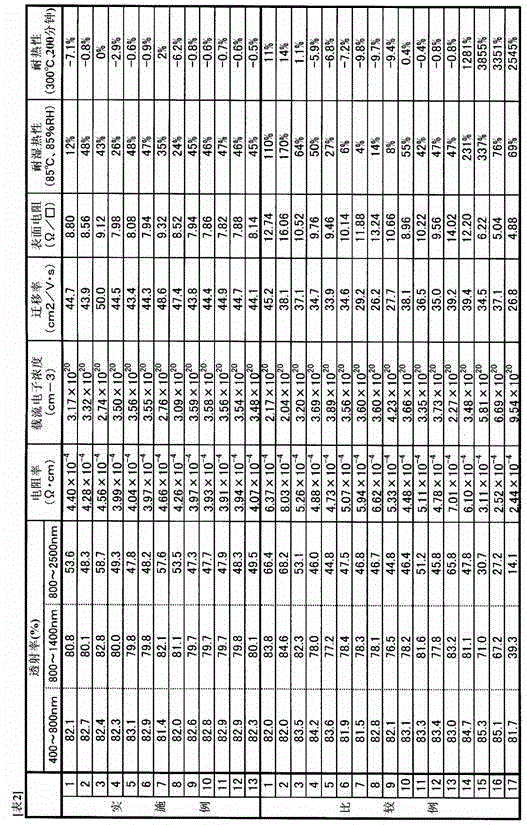

High-carrier concentration ultrathin AZO transparent conducting thin film and preparation method thereof

ActiveCN103866253AReduce absorptionCompliant with transparent electrode requirementsConductive layers on insulating-supportsVacuum evaporation coatingDeposition temperatureSputtering

The invention discloses a high-carrier concentration ultrathin AZO transparent conducting thin film and a preparation method thereof. The ultrathin AZO transparent conducting thin film comprises a substrate, a zinc layer and an AZO layer in sequence from top to bottom, wherein the total thickness of the zinc layer and the AZO layer is less than 120nm; the thickness of the zinc layer is 2-10nm; the thickness of the AZO layer is 35-100nm. According to the high-carrier concentration ultrathin AZO transparent conducting thin film and the preparation method thereof, deposition is carried out on the substrate by using magnetron sputtering to obtain the zinc layer and the AZO layer; rapid annealing is carried out on the thin film after the deposition; by virtue of setting the annealing condition, zinc atoms in the zinc layer permeate into the AZO layer and form Zni defects so as to improve the carrier concentration; the deposition temperature of the zinc layer and the AZO layer is not higher than 200 DEG C in the deposition process so that the production energy consumption is saved, the production cost is reduced and the production efficiency is improved; the high-carrier concentration ultrathin AZO transparent conducting thin film and the preparation method thereof are suitable for industrial production. The specific resistance of the high-carrier concentration ultrathin AZO transparent conducting thin film is 13-3.8*10<-4>omega.cm, the carrier concentration is 5.0-13.8*10<20>cm<-3>, and the average transmittance (including the substrate) at the wave section of 380-800nm is 70-88%.

Owner:宁波海燕新材料有限公司

A kind of transparent conductive oxide film and its production method

InactiveCN102290128AImprove adhesionHigh infrared reflectivityConductive layers on insulating-supportsThin/thick film capacitorMetallic aluminumPlastic film

A transparent conductive oxide film and a production method thereof relate to the technical field of production of transparent conductive oxide films. Firstly, a surface photografting modification method is used to modify the surface of a transparent plastic film to form a modified transparent plastic film. Under vacuum conditions, aluminum atoms and zinc atoms are sequentially sputtered on the same surface of the modified transparent plastic film, heated at 120-140°C to set the shape, and then rolled after cooling. The product of the present invention combines the performance advantages of flexible film and metal aluminum and zinc. It not only has high transparency, high gloss, can be curled, and is light in weight, but also has high electrical conductivity, is not easy to break, is easy to produce in a large area, and is convenient for transportation. unique advantages.

Owner:扬州英利新材料有限公司

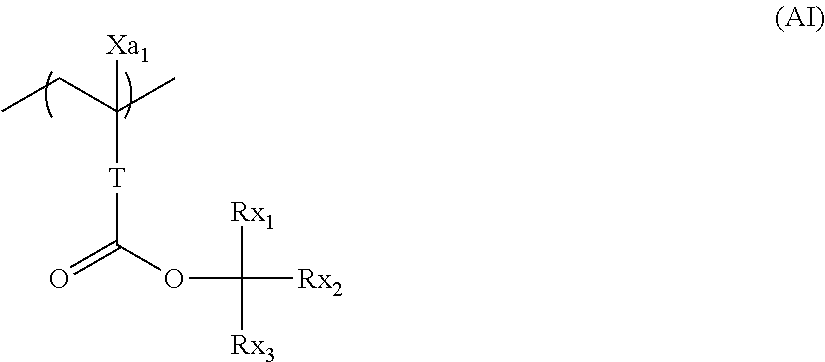

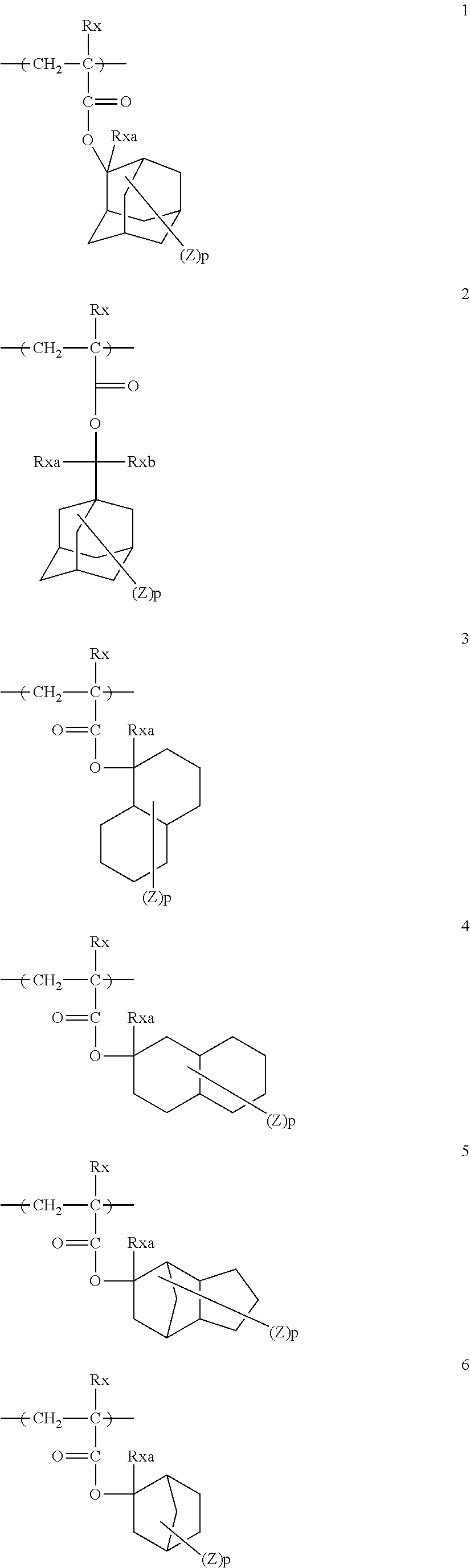

Method of manufacturing chemical fluid for manufacturing electronic material, pattern forming method, method of manufacturing semiconductor device, chemical fluid for manufacturing electronic material, container, and quality inspection method

ActiveUS20190011827A1Efficient preparationSemiconductor/solid-state device manufacturingIon sources/gunsCopper atomPower semiconductor device

In a method of manufacturing a chemical fluid for manufacturing an electronic material, a method of reducing particulate metal in the chemical fluid is selected according to a concentration of particulate metal including an iron atom, a concentration of particulate metal including a copper atom, and a concentration of particulate metal including a zinc atom which are measured by SP ICP-MS in the chemical fluid, and at least one of the concentration of particulate metal including an iron atom, the concentration of particulate metal including a copper atom, or the concentration of particulate metal including a zinc atom is reduced by using the selected reducing method.

Owner:FUJIFILM CORP

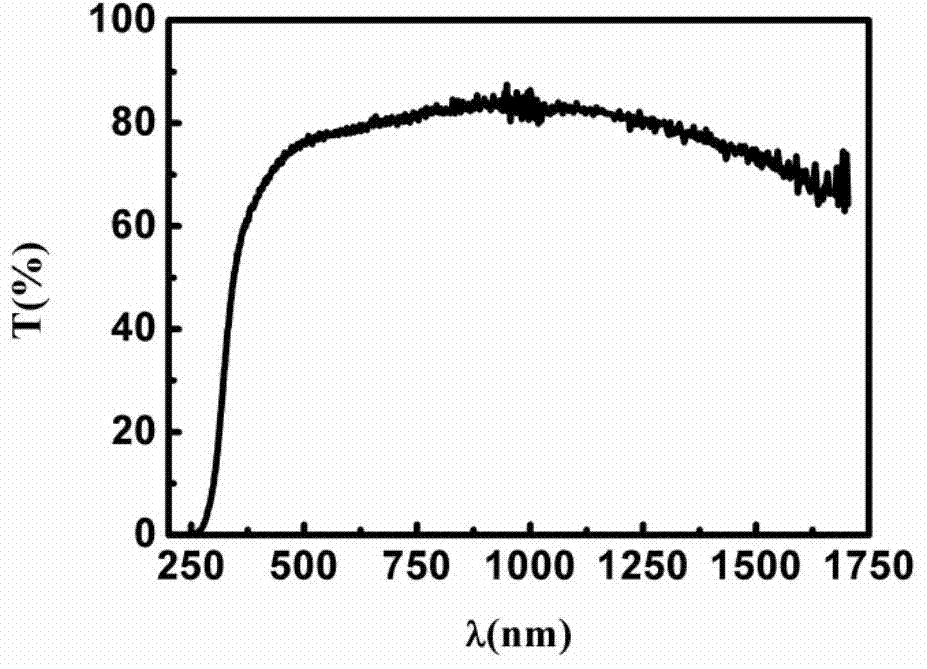

Capillaritron ion beam sputtering system and thin film production method

InactiveUS20090236217A1Reduce the impactReduce surface roughnessCellsElectric discharge tubesZinc atomRoot mean square

A capillaritron ion beam sputtering system and a thin film production method are disclosed. By utilizing reactive capillaritron ion beam sputtering deposition, argon and oxygen are passed through a capillaritron ion source simultaneously. Argon is being ionized and accelerated by a voltage to bombard a zinc target and create zinc atoms, while oxygen atoms are created at the same time. Zinc atom and oxygen atom are combined to form ZnO to deposit on a substrate. The stoichiometric properties, deposition rate, transmission properties, surface roughness and film density of the as-deposited film can be altered by adjusting capillaritron ion beam energy and oxygen partial pressure. Using preferred processing parameters, the root-mean-square surface roughness of the as-deposited film can be smaller than 1.5 nm, while the transmission coefficient at visible range can be greater than 80%.

Owner:NAT TAIWAN UNIV OF SCI & TECH

Phosphor having resistance to deterioration caused by ultraviolet rays, and gas discharge display device of which image quality is not readily deteriorated over time

InactiveUS7270774B2Not easy to deteriorateDeteriorate with timeDischarge tube luminescnet screensLamp detailsPhosphorImaging quality

A manganese-activated zinc silicate phosphor according to the present invention satisfies 0<β−α≦0.5 and 1.7≦β, where a value α is a ratio of a number of zinc atoms to a number of silicon atoms in a surface region of a phosphor particle, including a surface of the phosphor particle and a vicinity thereof, and a value β is a ratio of a number of zinc atoms to a number of silicon atoms in a whole of the phosphor particle.

Owner:PANASONIC CORP

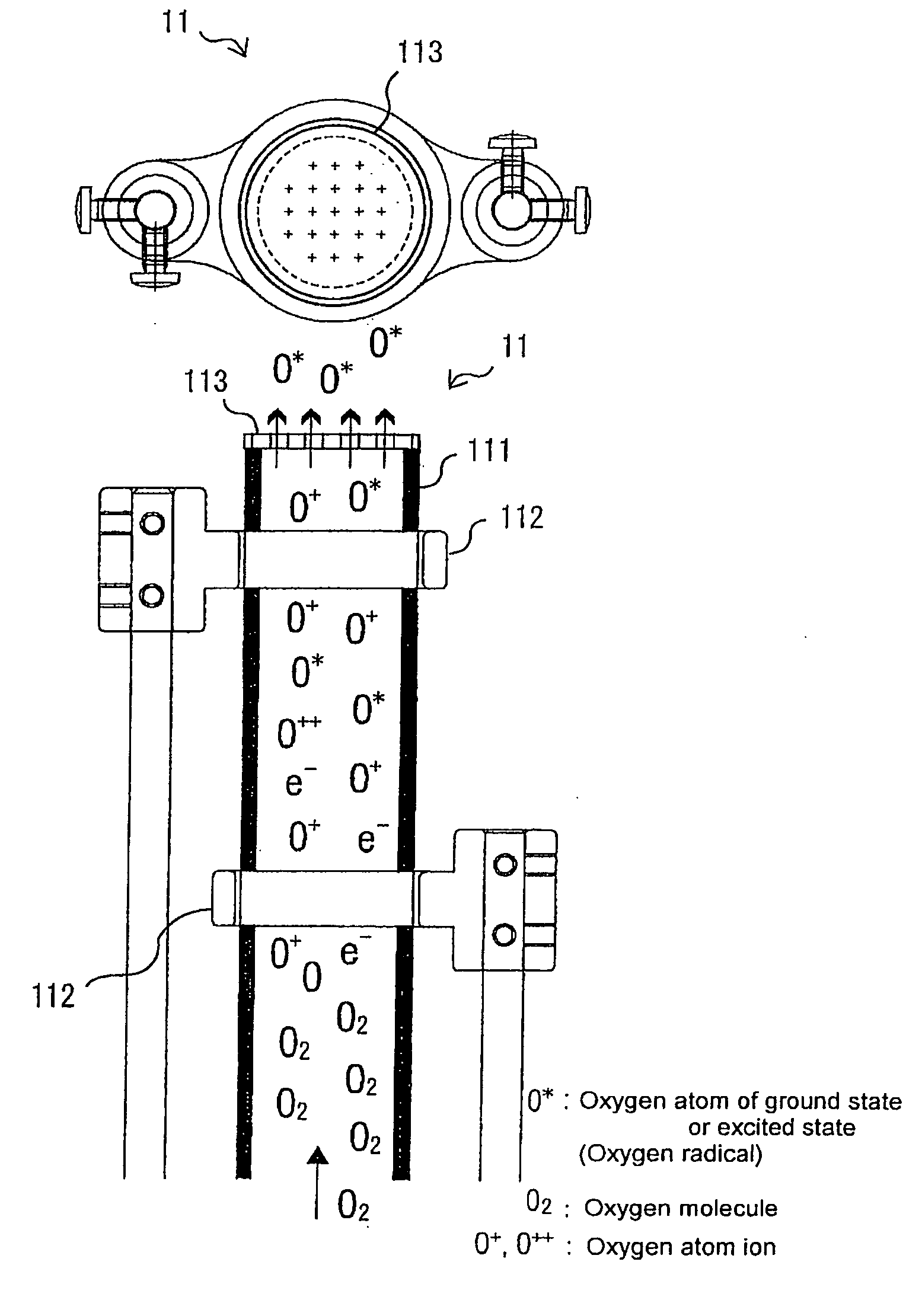

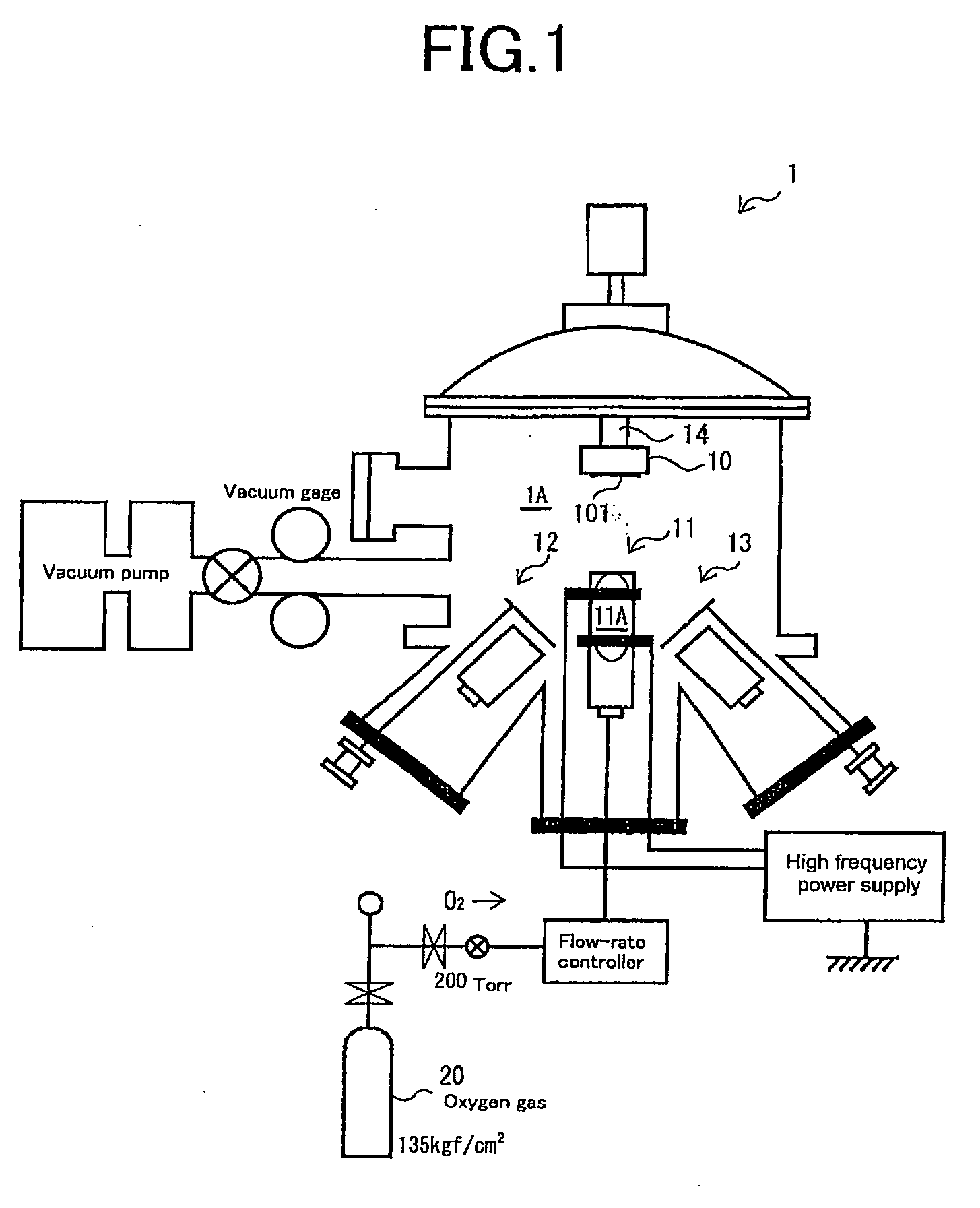

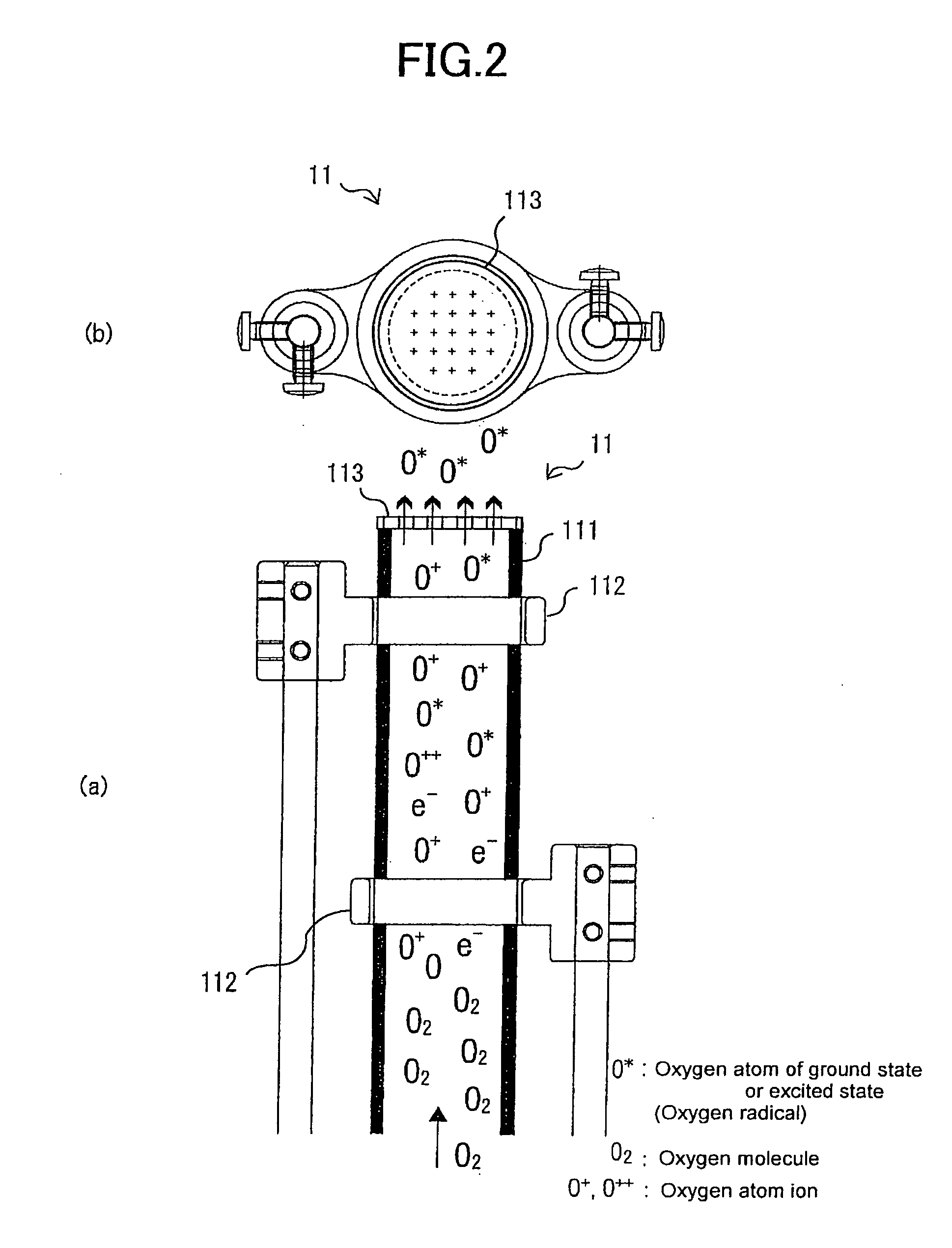

Method and apparatus for manufacturing a zinc oxide thin film at low temperatures

ActiveUS20070042216A1Easy to controlLower electrical resistivityVacuum evaporation coatingSemiconductor/solid-state device manufacturingOptoelectronicsCrystallographic defect

The present invention provides a method and apparatus for forming a zinc oxide thin film with high transparency and high conductivity on a surface of a flexible substrate such as plastic without the indispensable requirement of doping impurities. In the method of forming a zinc oxide thin film by reacting oxygen radicals and zinc atoms on a surface of a substrate placed in a film-forming chamber evacuated to a vacuum, the density of crystal defects that are defects of the atomic arrangement of the zinc oxide thin film is controlled by the temperature of the substrate, and the zinc oxide thin film is thereby formed. It is suitable to form the film while maintaining the temperature of the substrate at 400° C. or less to intentionally disturb the regularity of the atomic arrangement of the zinc oxide thin film.

Owner:UNIVERSITY OF YAMANASHI +2

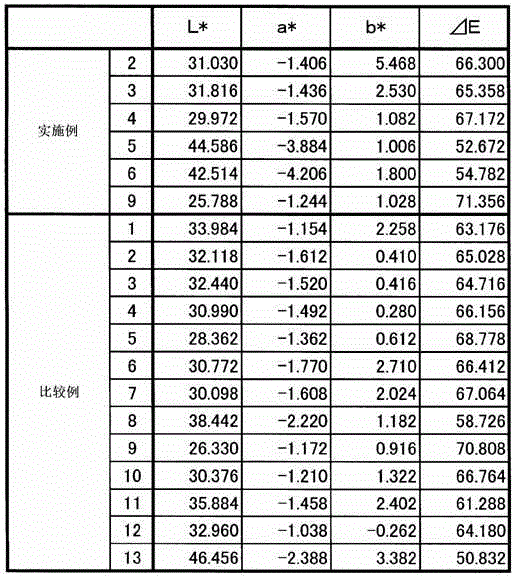

Zinc oxide-based transparent conductive film

InactiveCN104871257AImprove transmittanceLower resistanceConductive layers on insulating-supportsFinal product manufactureTransparent conducting filmOxygen

Provided is a zinc oxide-based transparent conductive film comprising zinc atoms, oxygen atoms, and M as defined below, wherein the total number of zinc atoms, oxygen atoms, titanium atoms, gallium atoms, and aluminum atoms accounts for 99% or more of the number of all atoms forming the zinc oxide-based transparent conductive film; the ratio of the total number of titanium atoms, gallium atoms, and aluminum atoms per the total number of zinc atoms, titanium atoms, gallium atoms, and aluminum atoms contained in the film ((number of titanium atoms + number of gallium atoms + number of aluminum atoms) / (number of zinc atoms + number of titanium atoms + number of gallium atoms + number of aluminum atoms) x 100)is 1.3% or greater but 2.0% or less; the number of titanium atoms accounts for at least 50% of the total number of titanium atoms, gallium atoms, and aluminum atoms contained in the film; the carrier electron concentration is 3.60 x 1020cm-3 or less, the mobility is 43.0 cm2 / Vs or greater and resistivity is 5.00 x 10-4Ω·cm or less. M represents titanium atoms; titanium atoms and gallium atoms; titanium atoms and aluminum atoms; or titanium atoms, gallium atoms, and aluminum atoms.

Owner:SUMITOMO CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com