Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

173results about How to "Not easy to deteriorate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

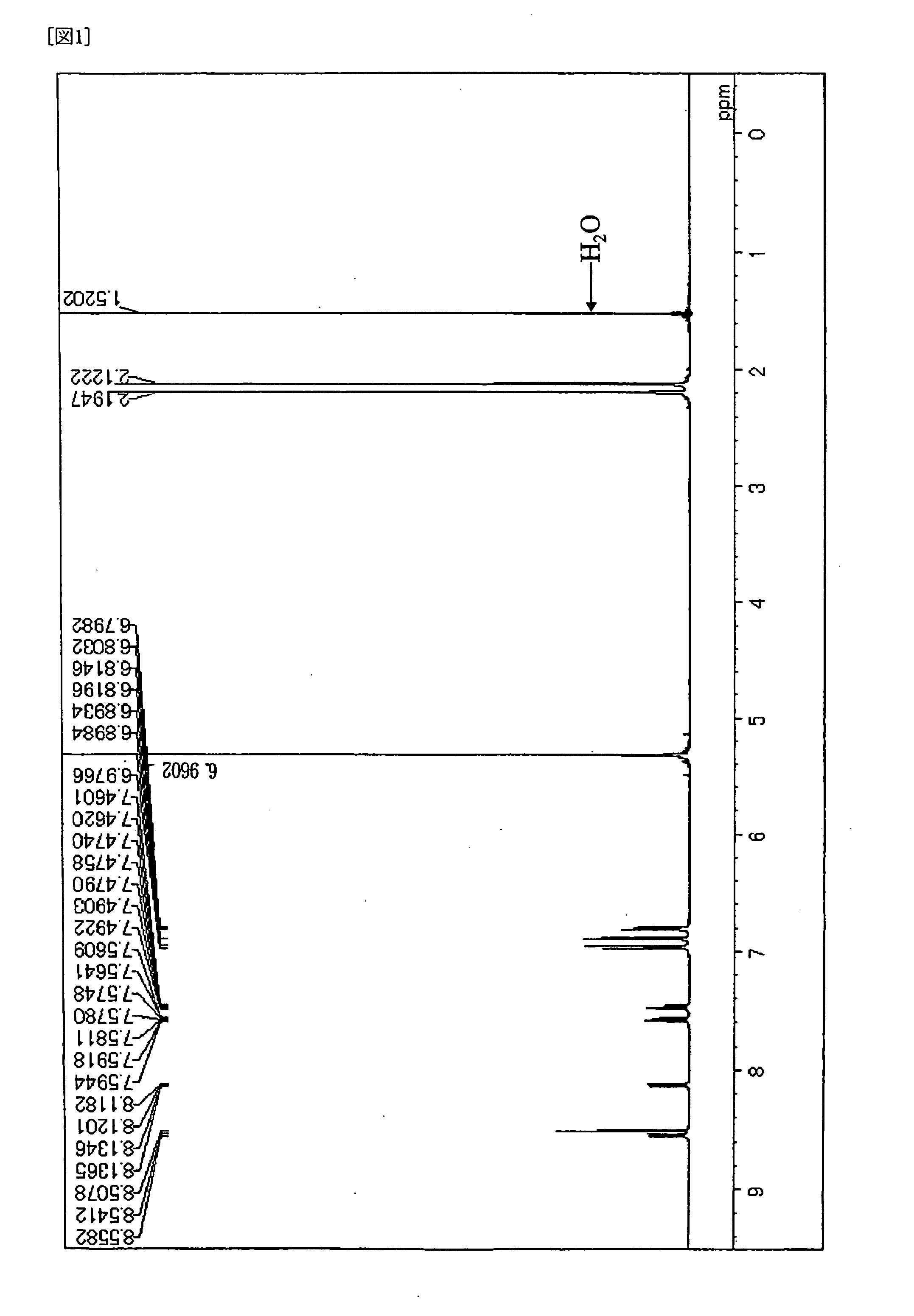

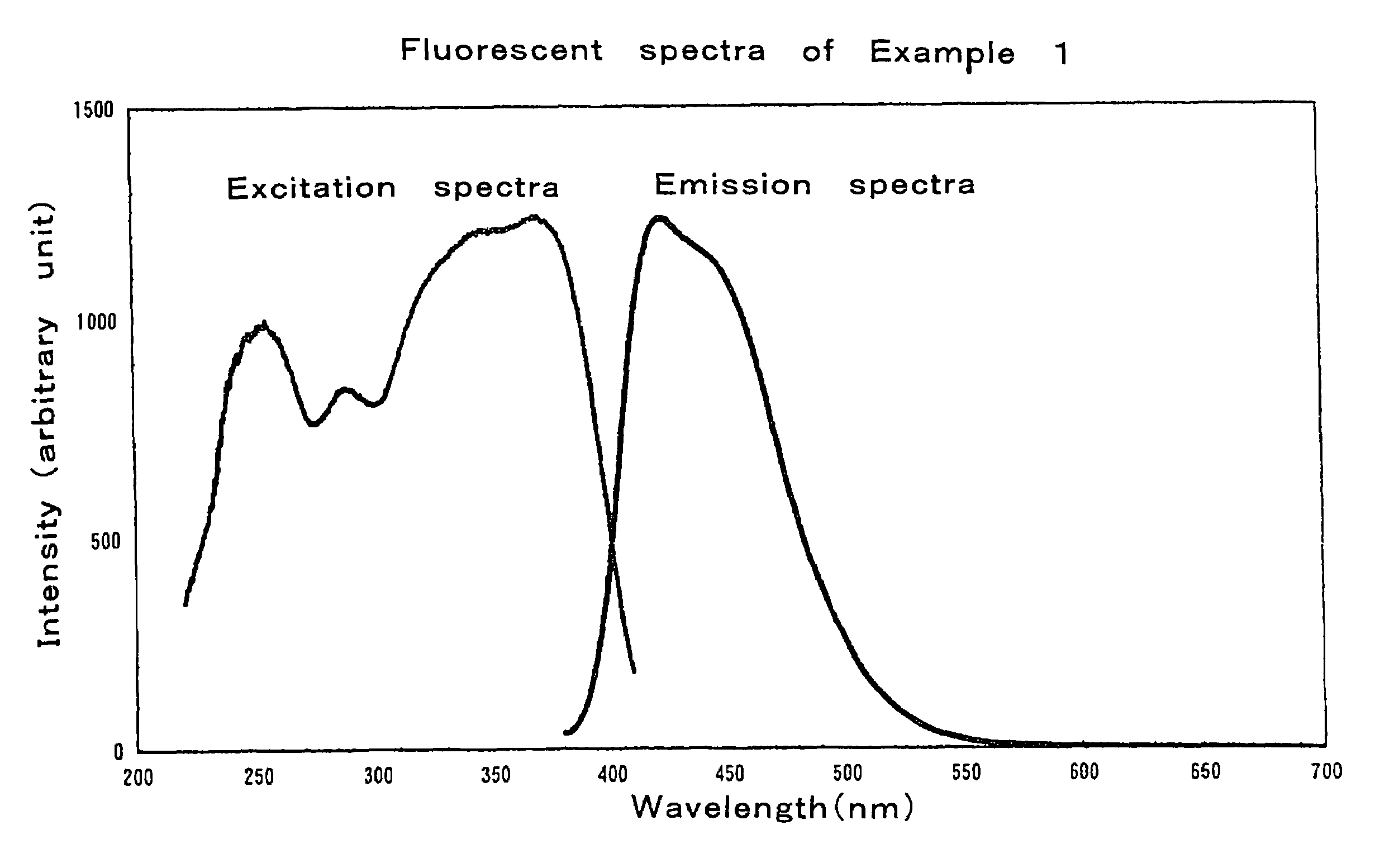

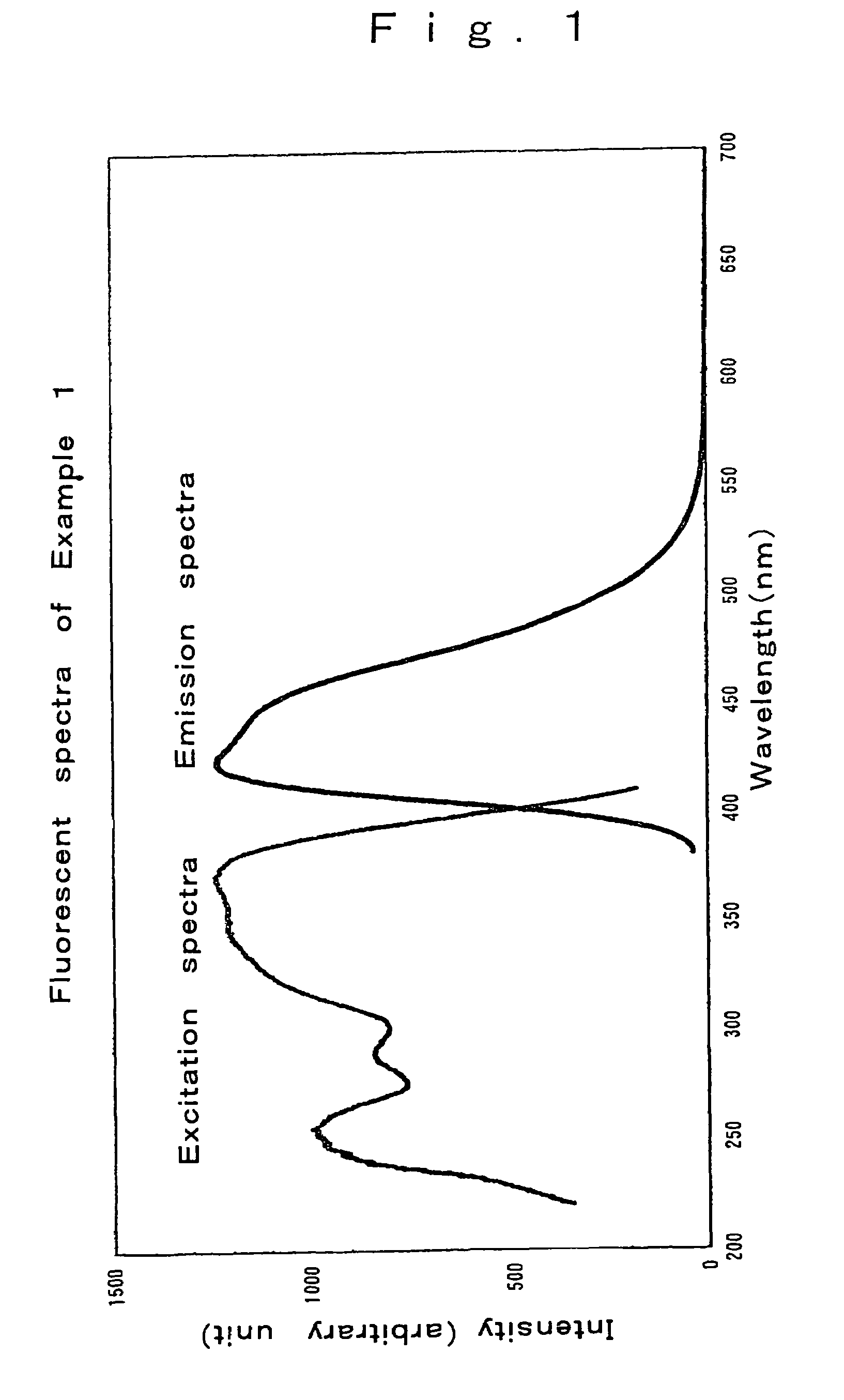

Aromatic amine derivative and organic electroluminescence device using the same

ActiveUS20060210830A1Long lastingHigh color purityOrganic chemistryDischarge tube luminescnet screensOrganic electroluminescenceAmine derivatives

A aromatic amine derivative having an specific structure having a diphenyl amino group, and two or more of substituent bonding to benzene ring thereof, and in an organic electroluminescence device which comprises at least one organic thin film layer comprising a light emitting layer sandwiched between a pair of electrode consisting of an anode and a cathode, at least one of the organic thin film layer comprises the aromatic amine derivative singly or a component for a mixture thereof. The organic electroluminescence device exhibiting a long lifetime and high current efficiency as well as emitting blue light with high color purity, and also the aromatic amine derivative for realizing the organic EL device are provided.

Owner:IDEMITSU KOSAN CO LTD

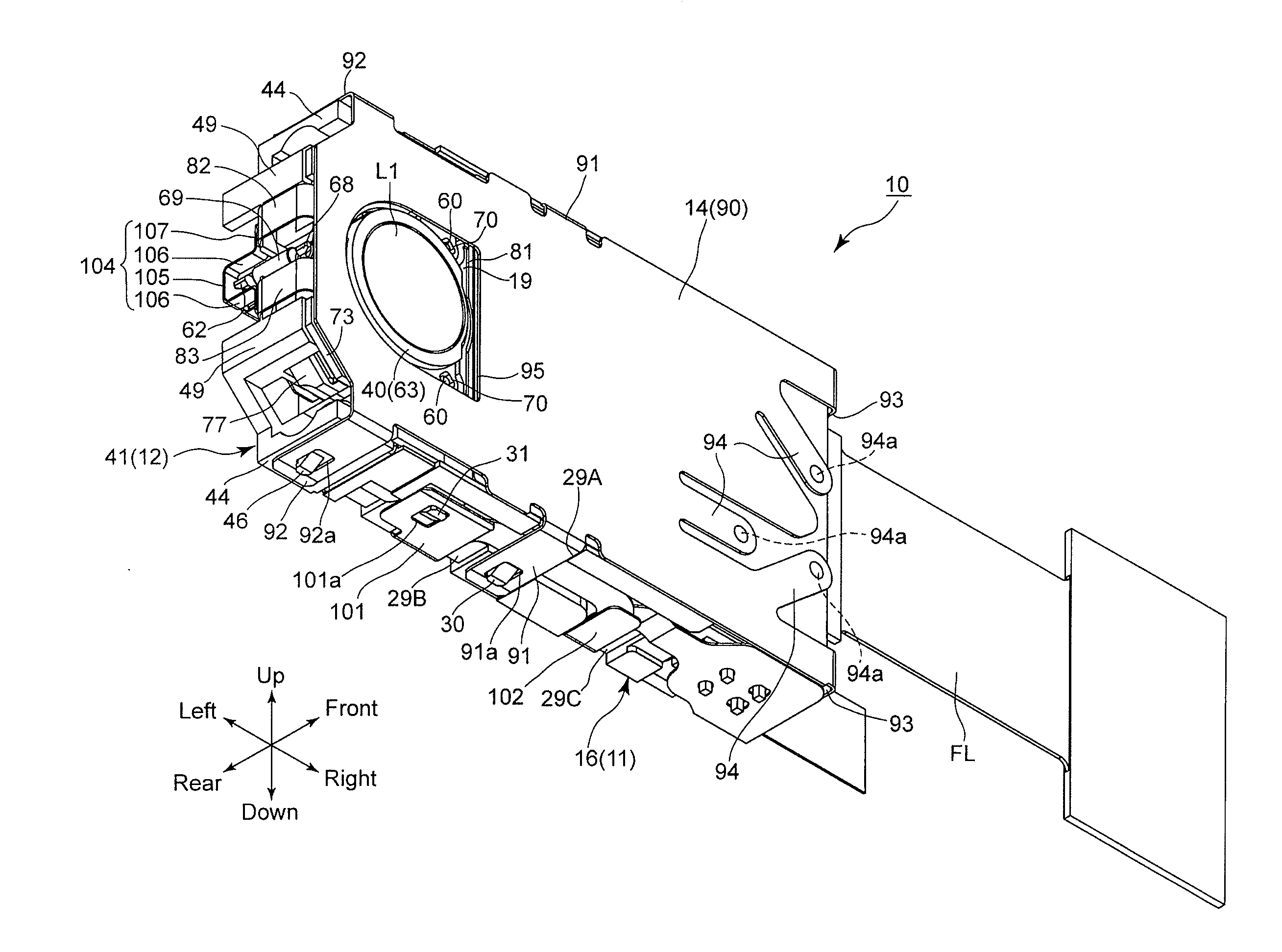

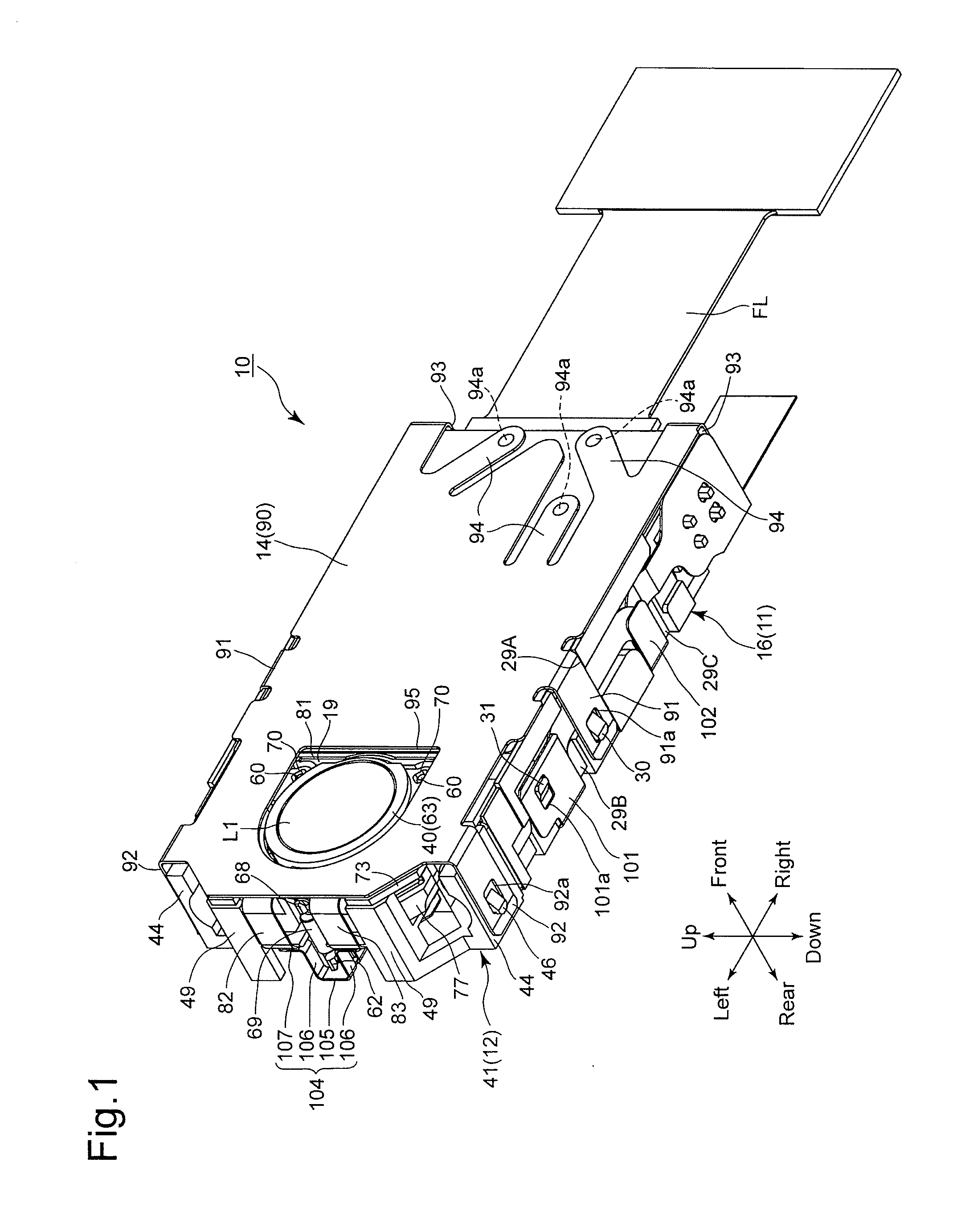

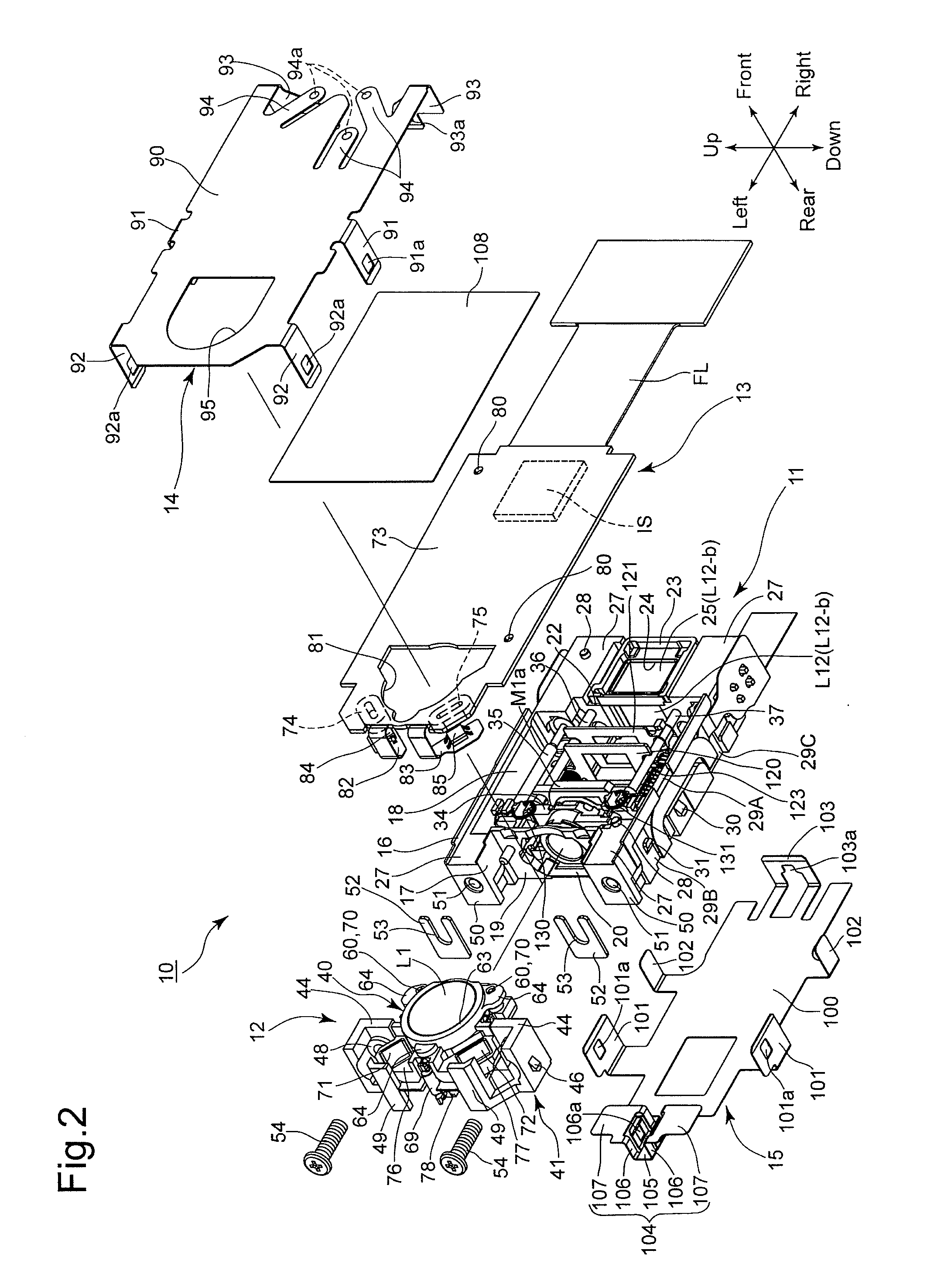

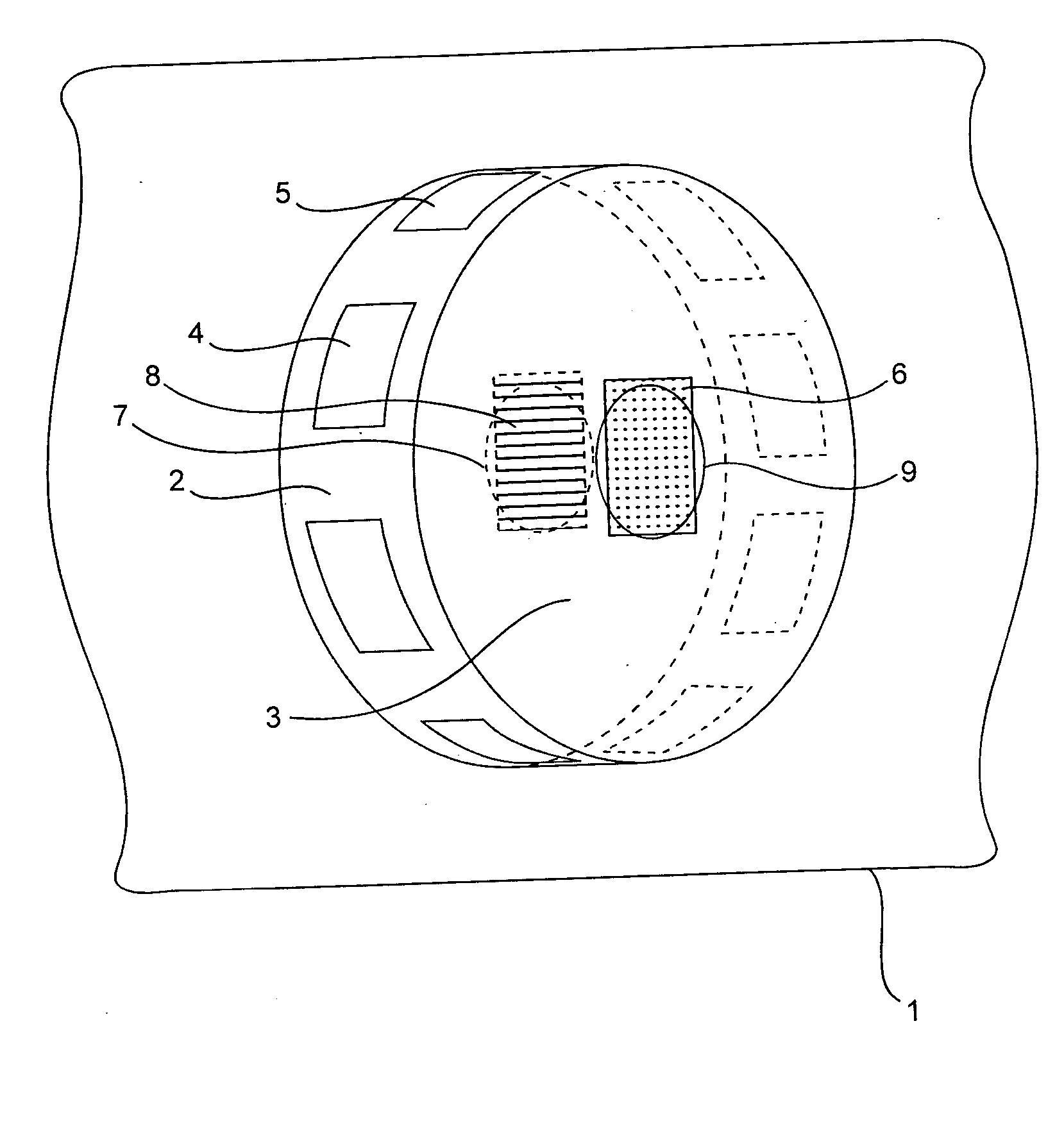

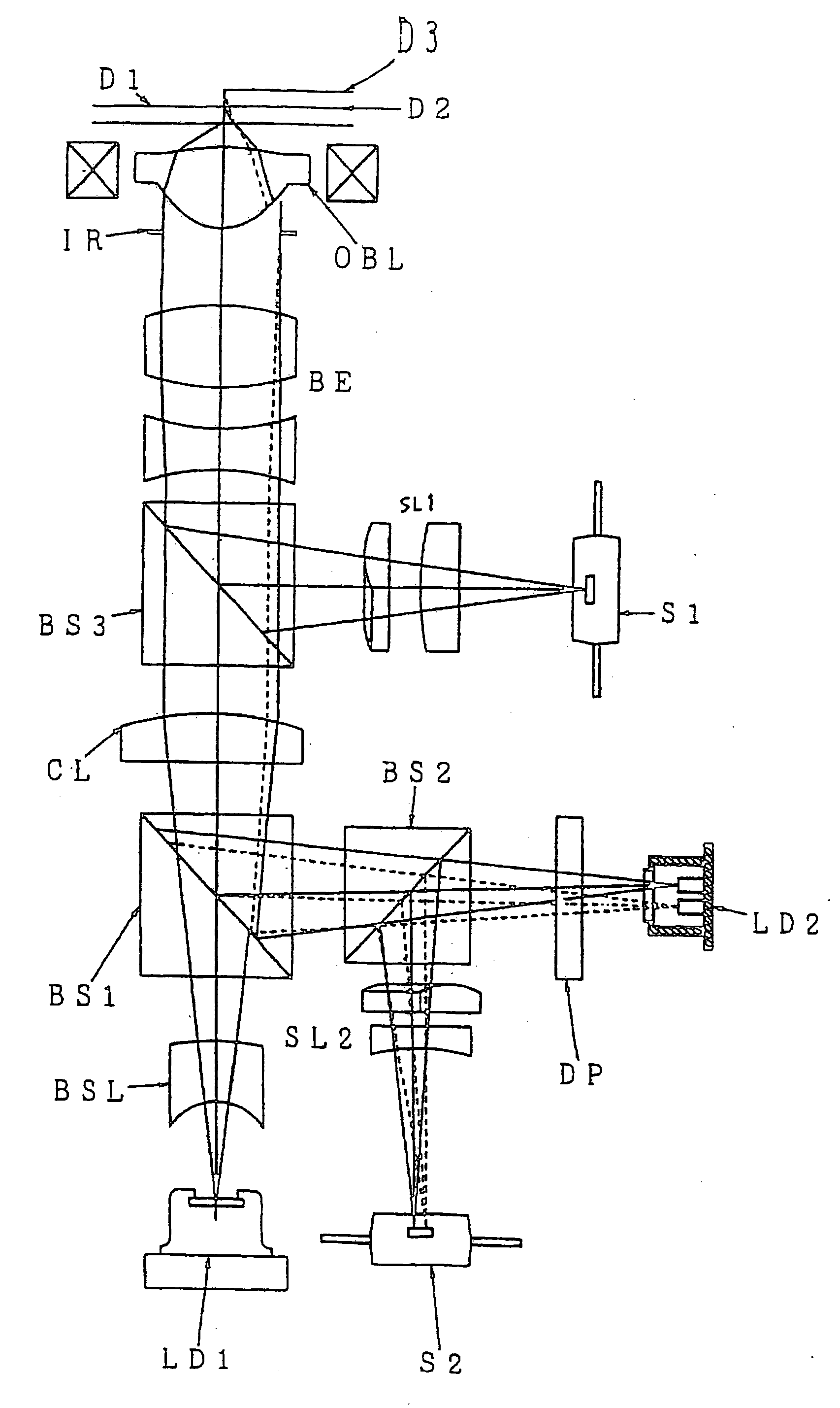

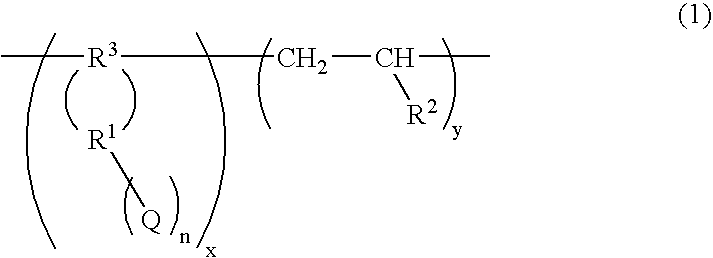

Imaging apparatus

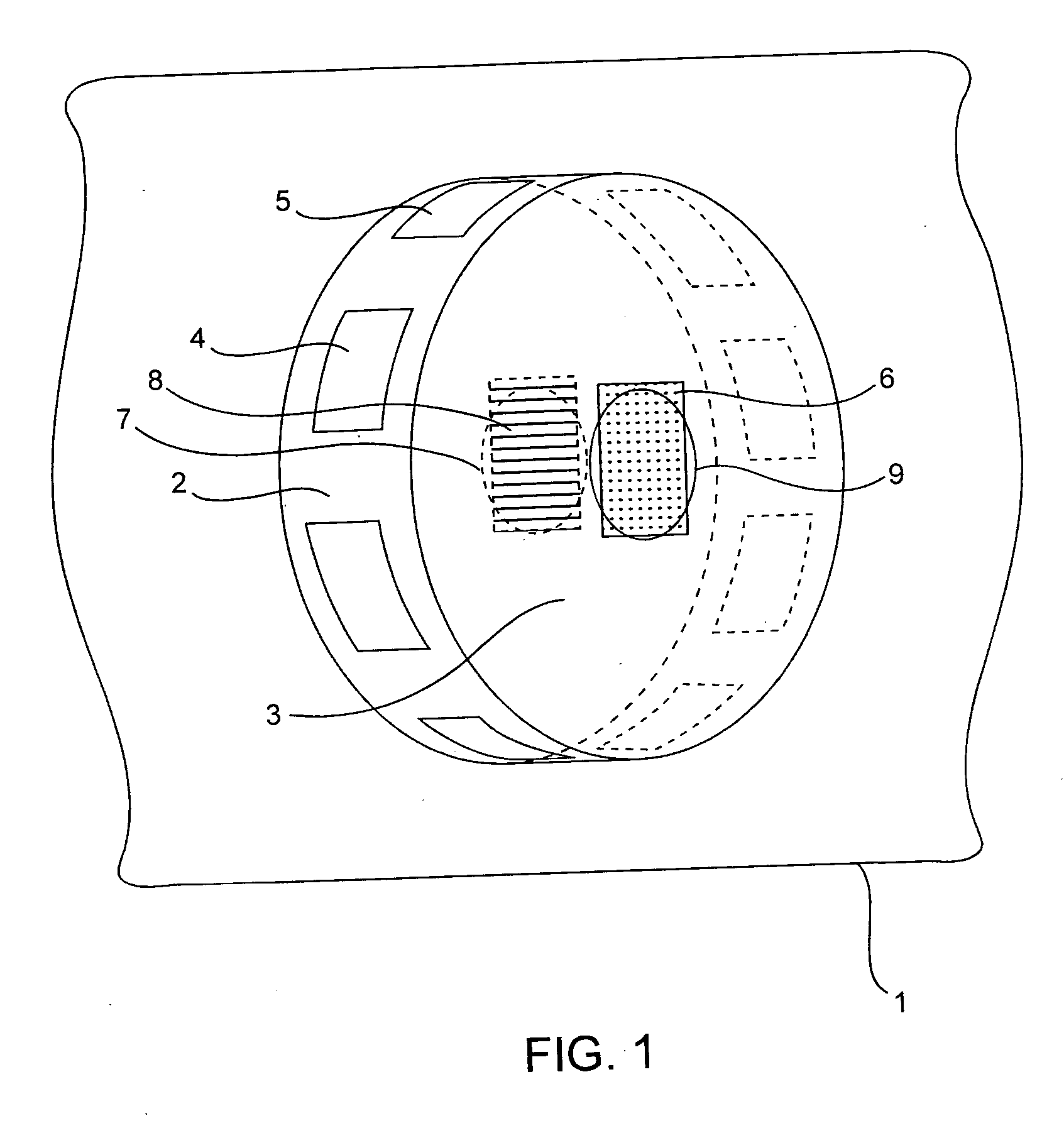

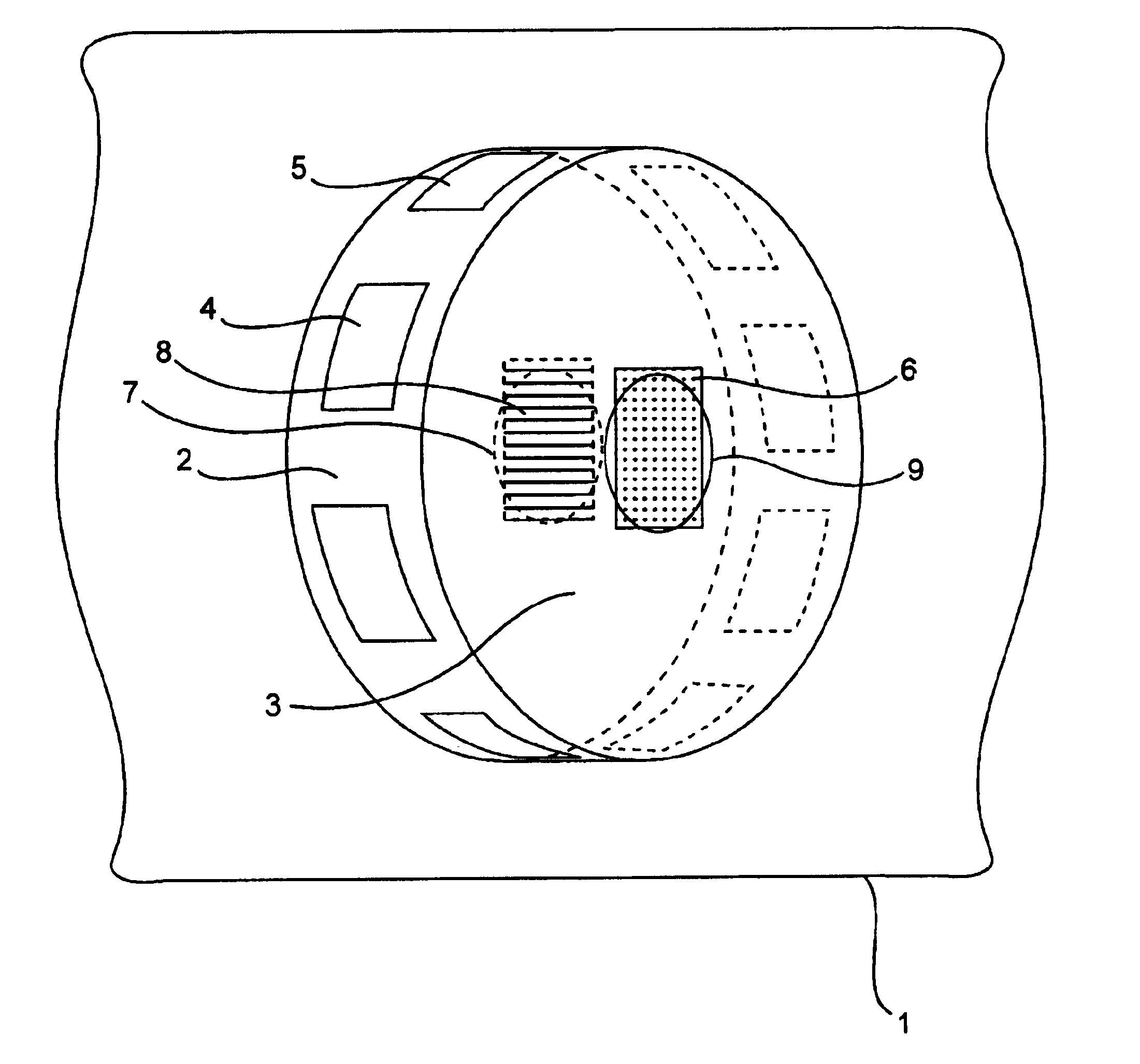

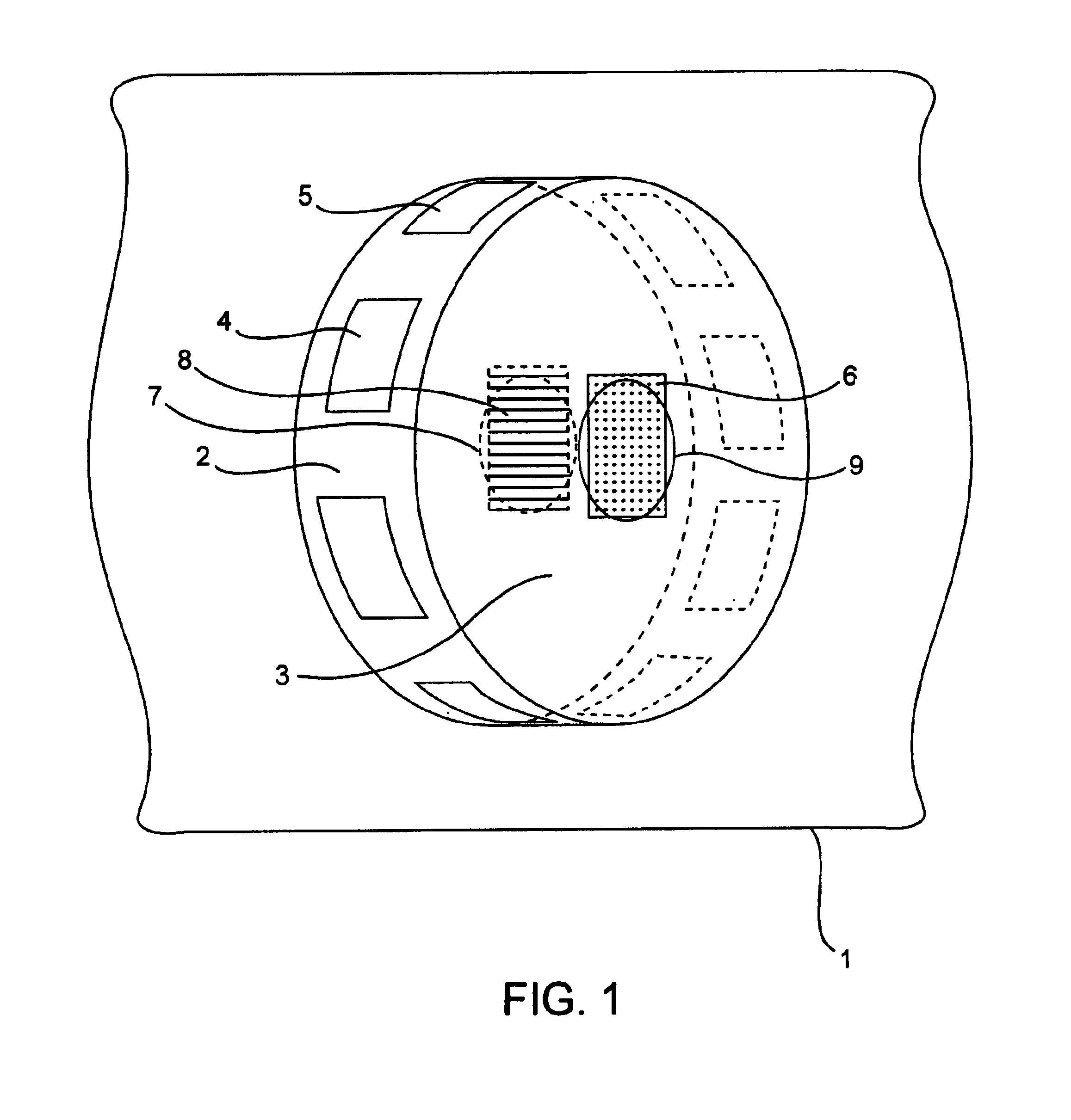

ActiveUS20130278785A1Reduce thicknessMiniaturization of the imaging apparatusTelevision system detailsPrintersOptical axisOptoelectronics

An imaging apparatus includes a front lens group, which constitutes part of an imaging optical system, at a fixed position with respect to an optical axis direction, wherein the front lens group includes a front lens element and a reflector and the reflector reflects light rays exiting from the front lens element; a movable lens group provided closer to the image plane side than the front lens group and movable along the optical axis; a support member which supports the reflector; a movable frame which supports the front lens element and is supported by the support member to be movable along a plane orthogonal to the optical axis of the front lens element; and a driver which drives the movable frame in the plane, in accordance with vibrations applied to the photographing optical system, to reduce image shake.

Owner:HOYA CORP

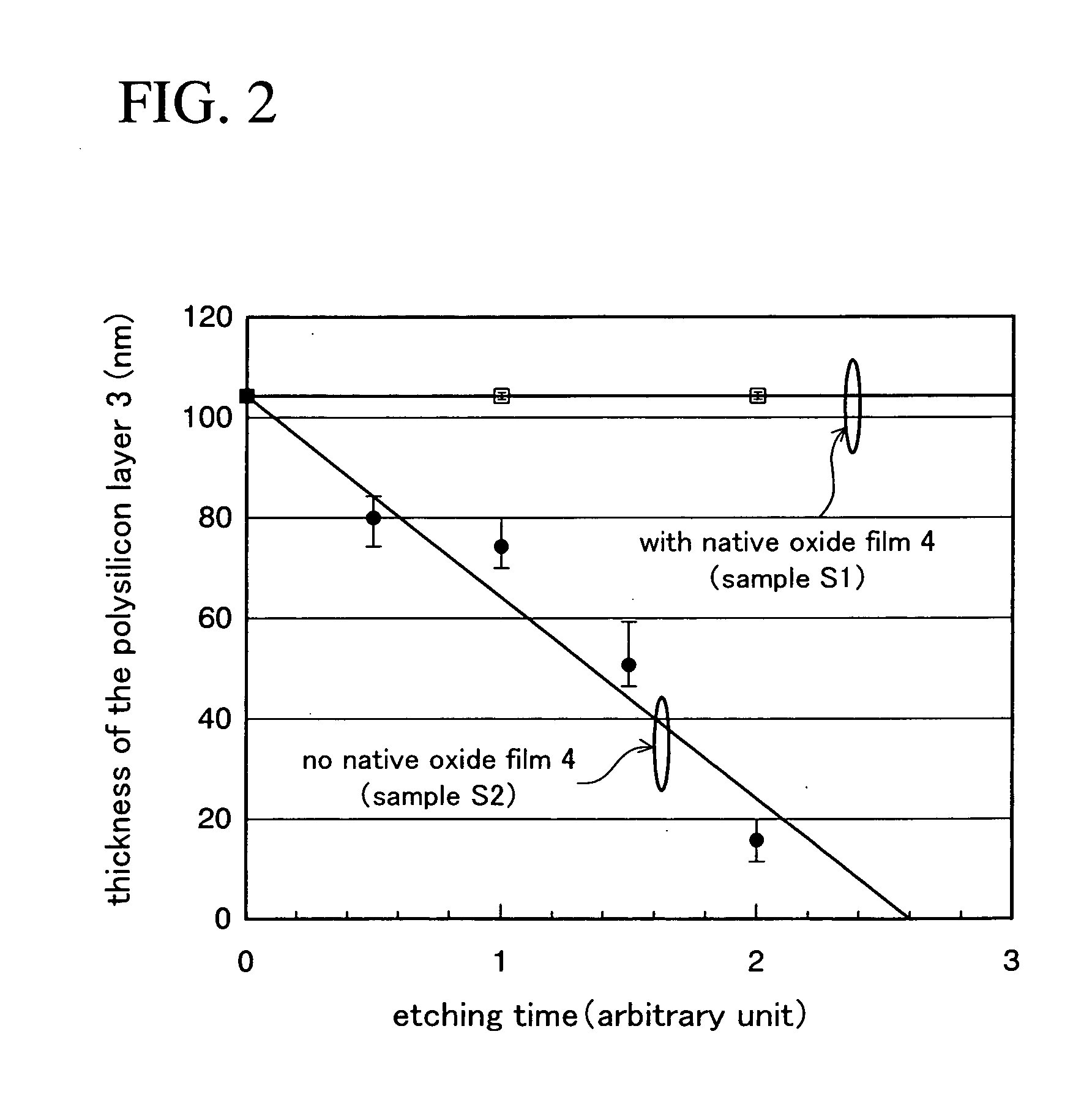

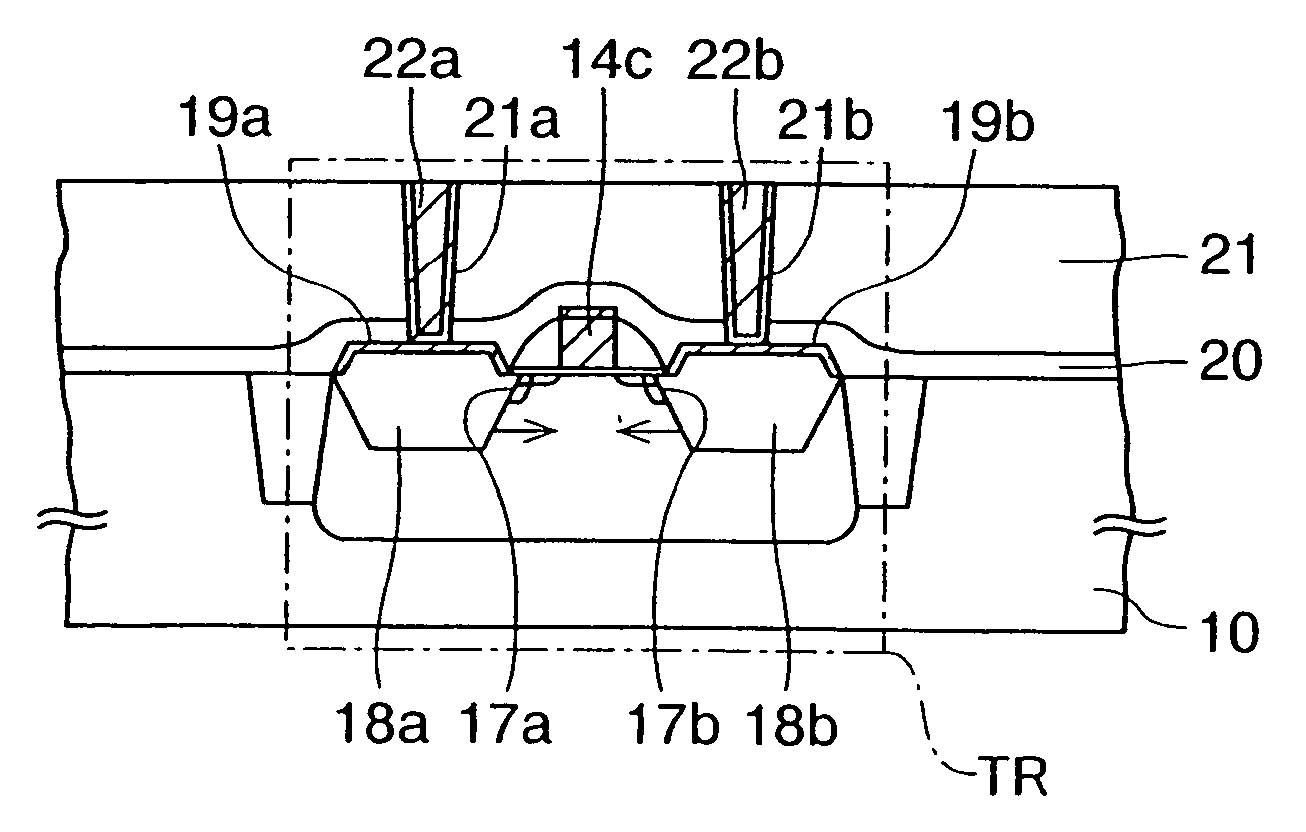

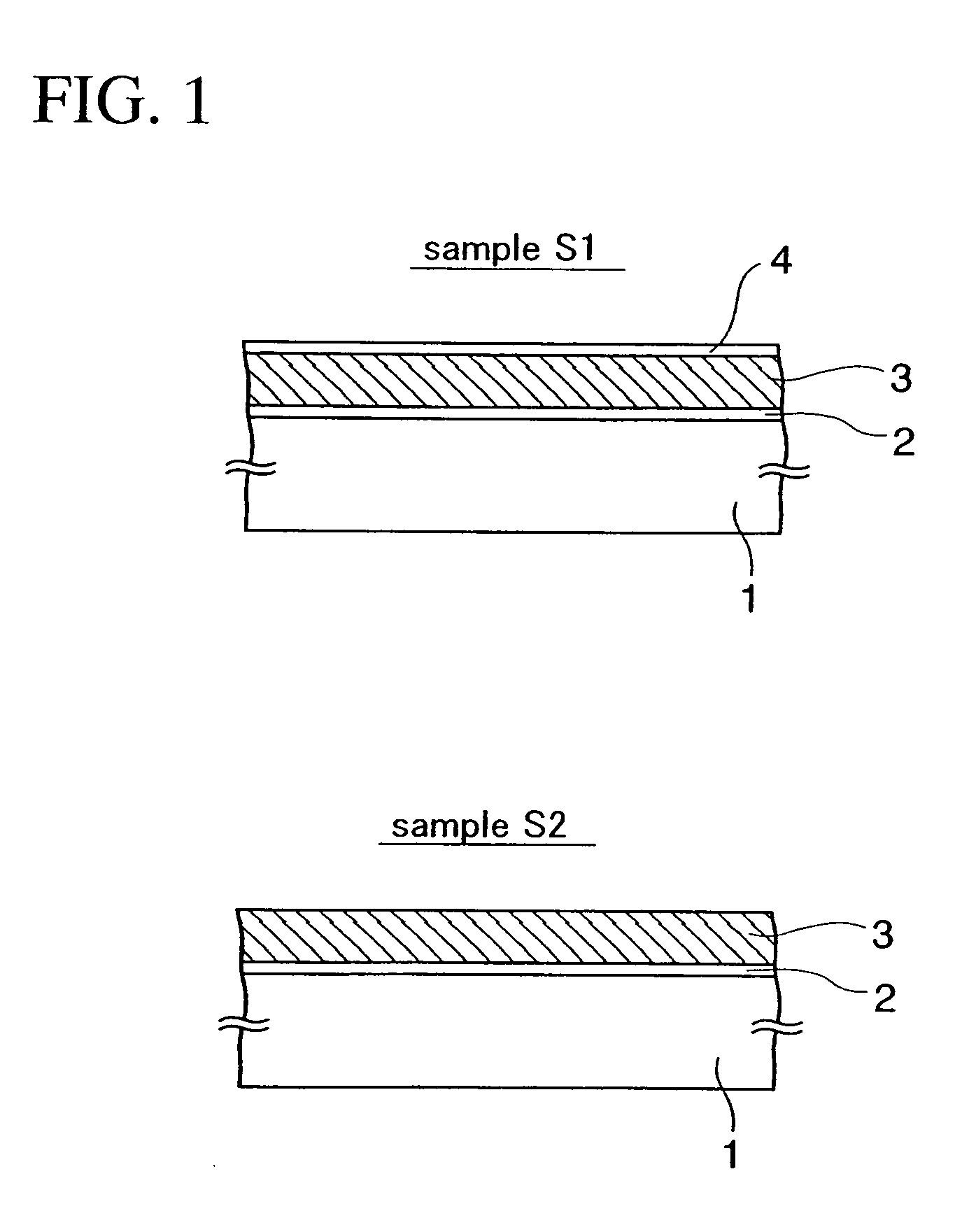

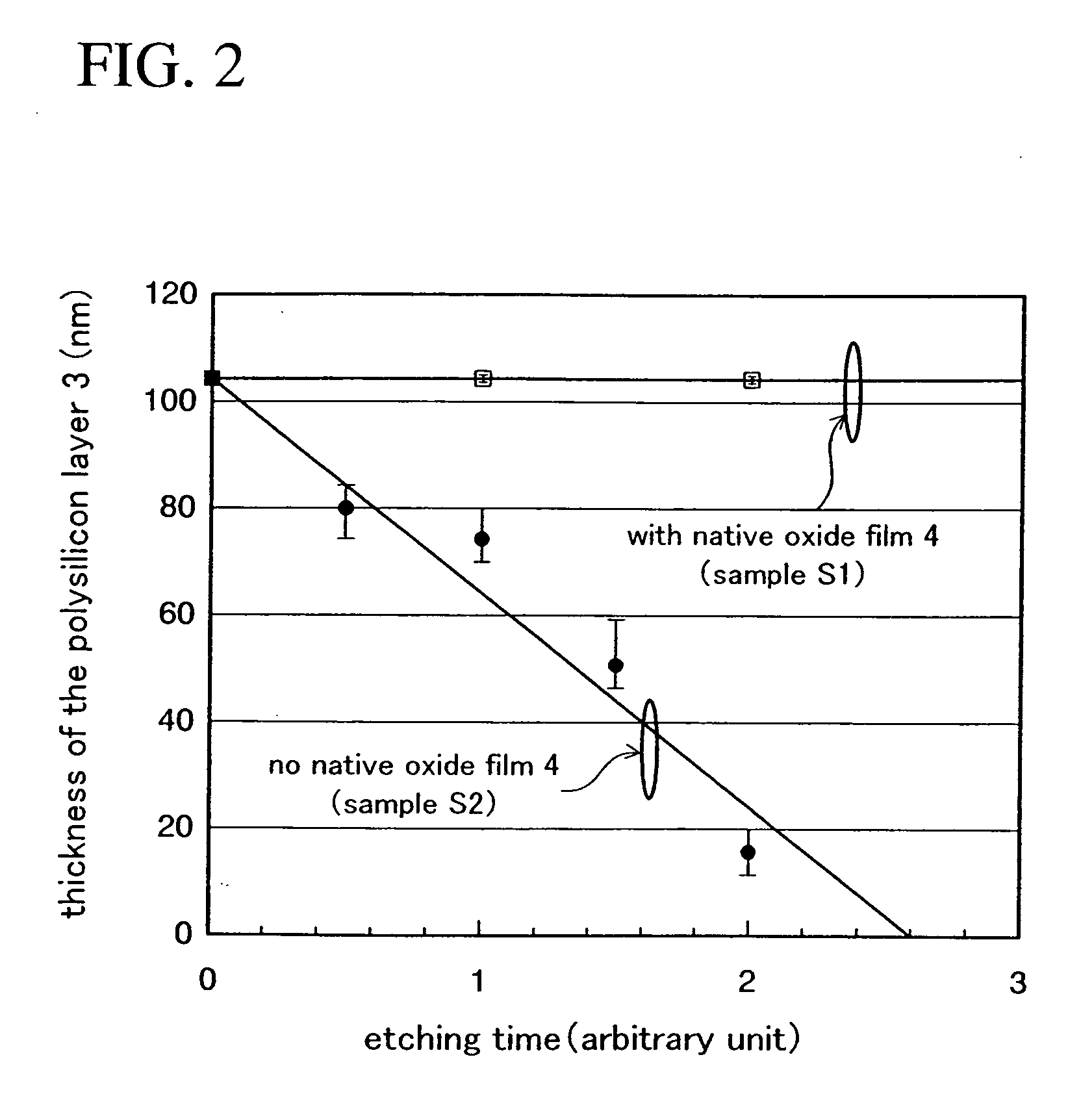

Semiconductor device, method of manufacturing the same, and method of evaluating semiconductor device

InactiveUS20050285203A1Thickness of gate be reducedReduce thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesCrystal planeSilicon

A semiconductor device has: a silicon (semiconductor) substrate; a gate insulating film and a gate electrode, which are formed on the silicon substrate in this order; and source / drain material layers formed in recesses (holes) in the silicon substrate, the recesses being located beside the gate electrode. Here, each of side surfaces of the recesses, which are closer to the gate electrode, is constituted of at least one crystal plane of the silicon substrate.

Owner:FUJITSU LTD

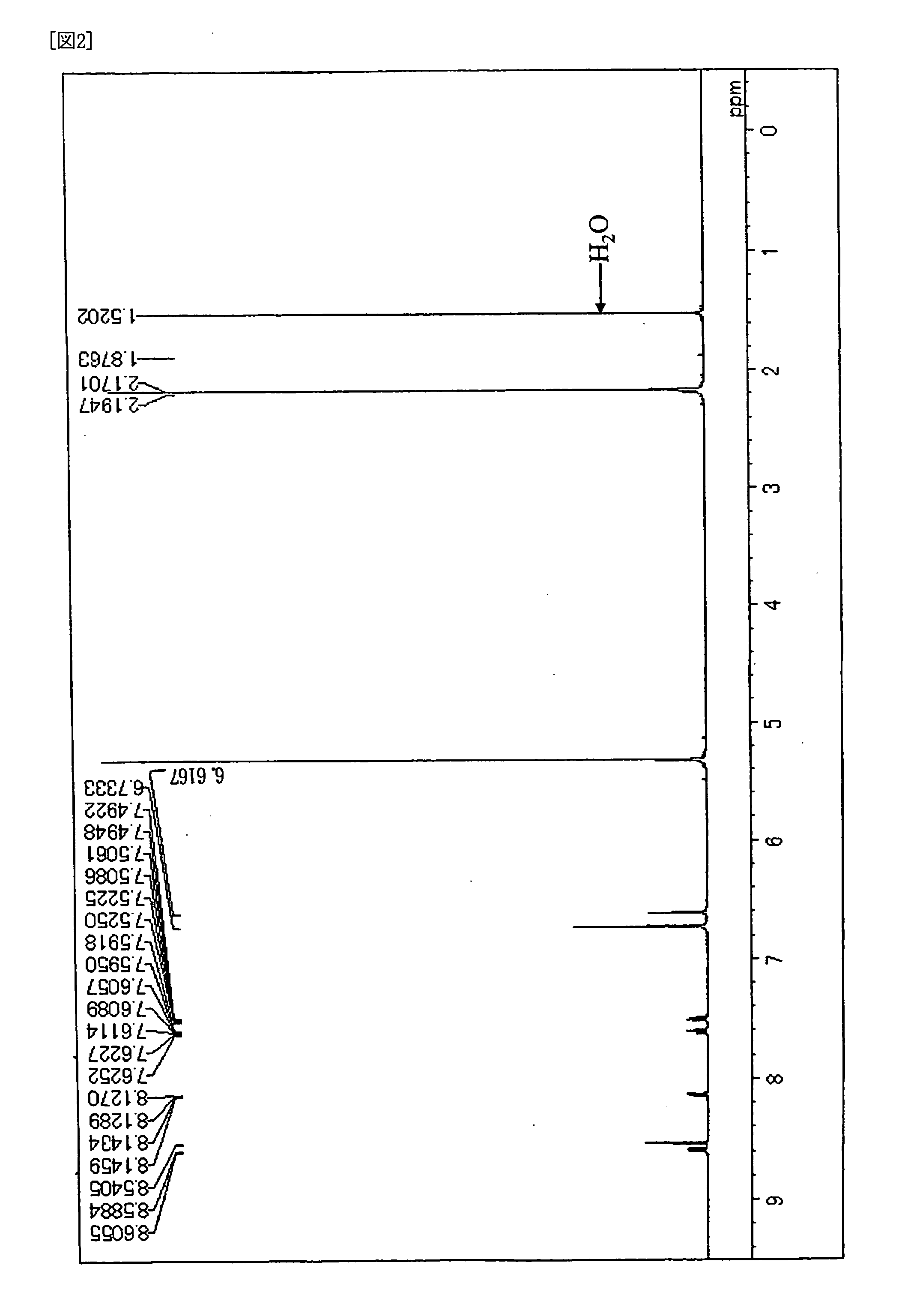

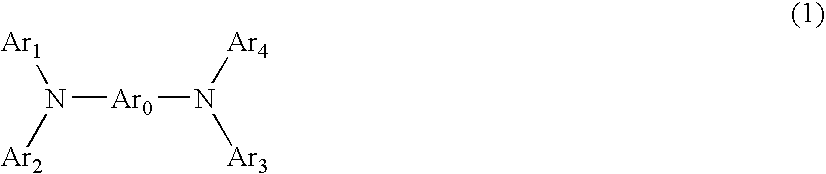

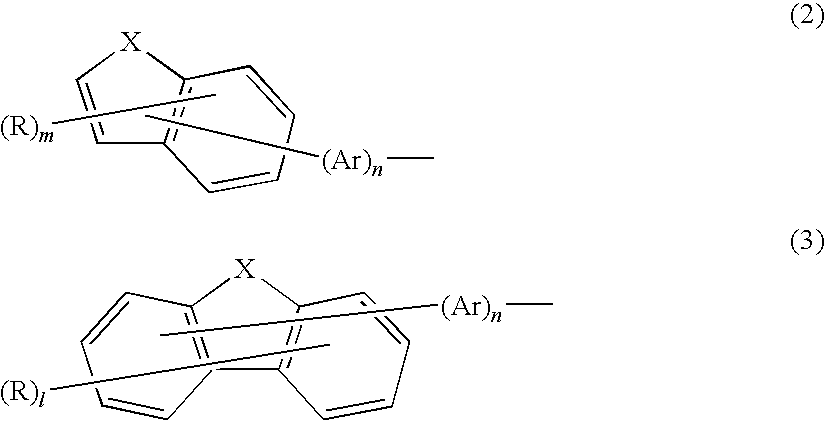

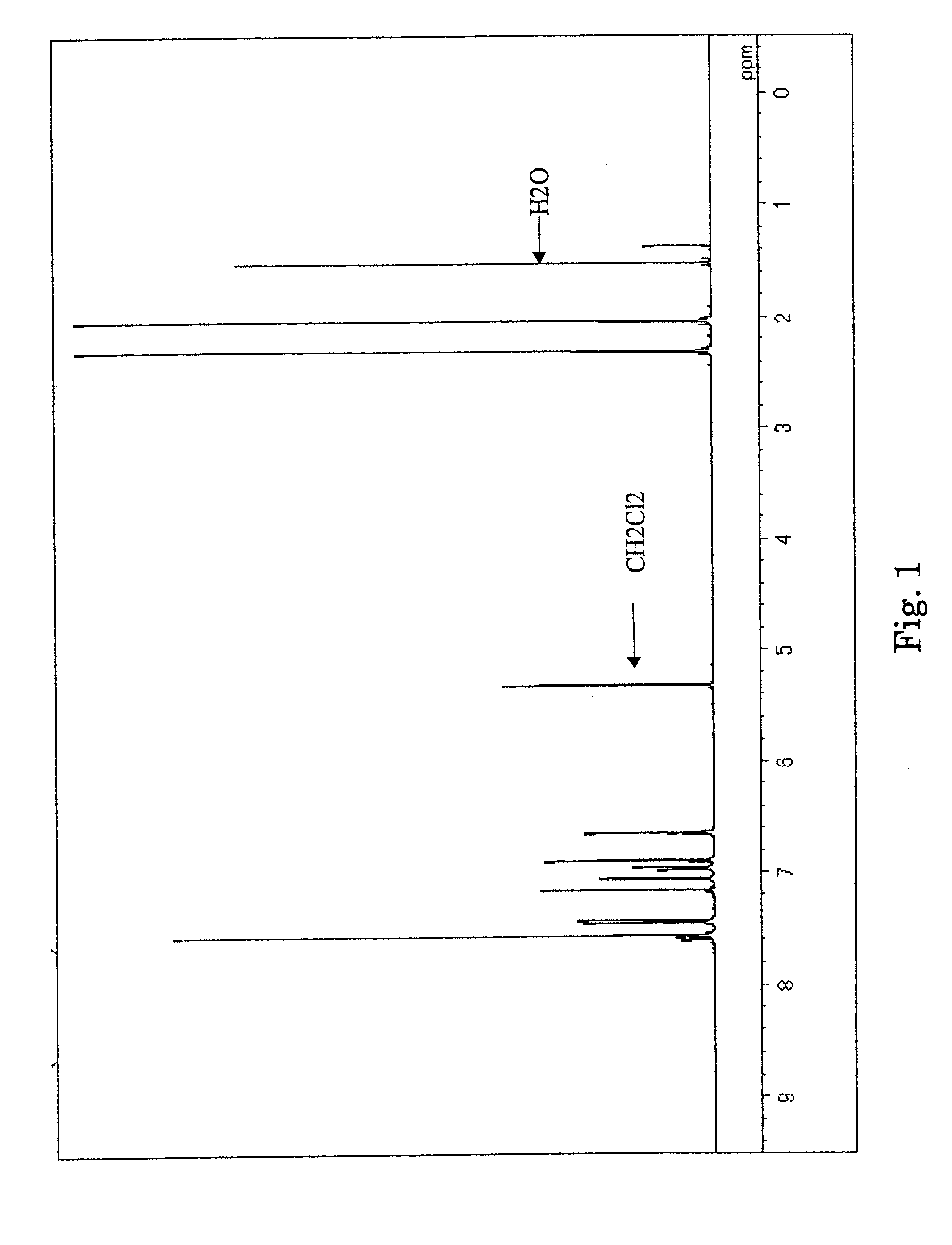

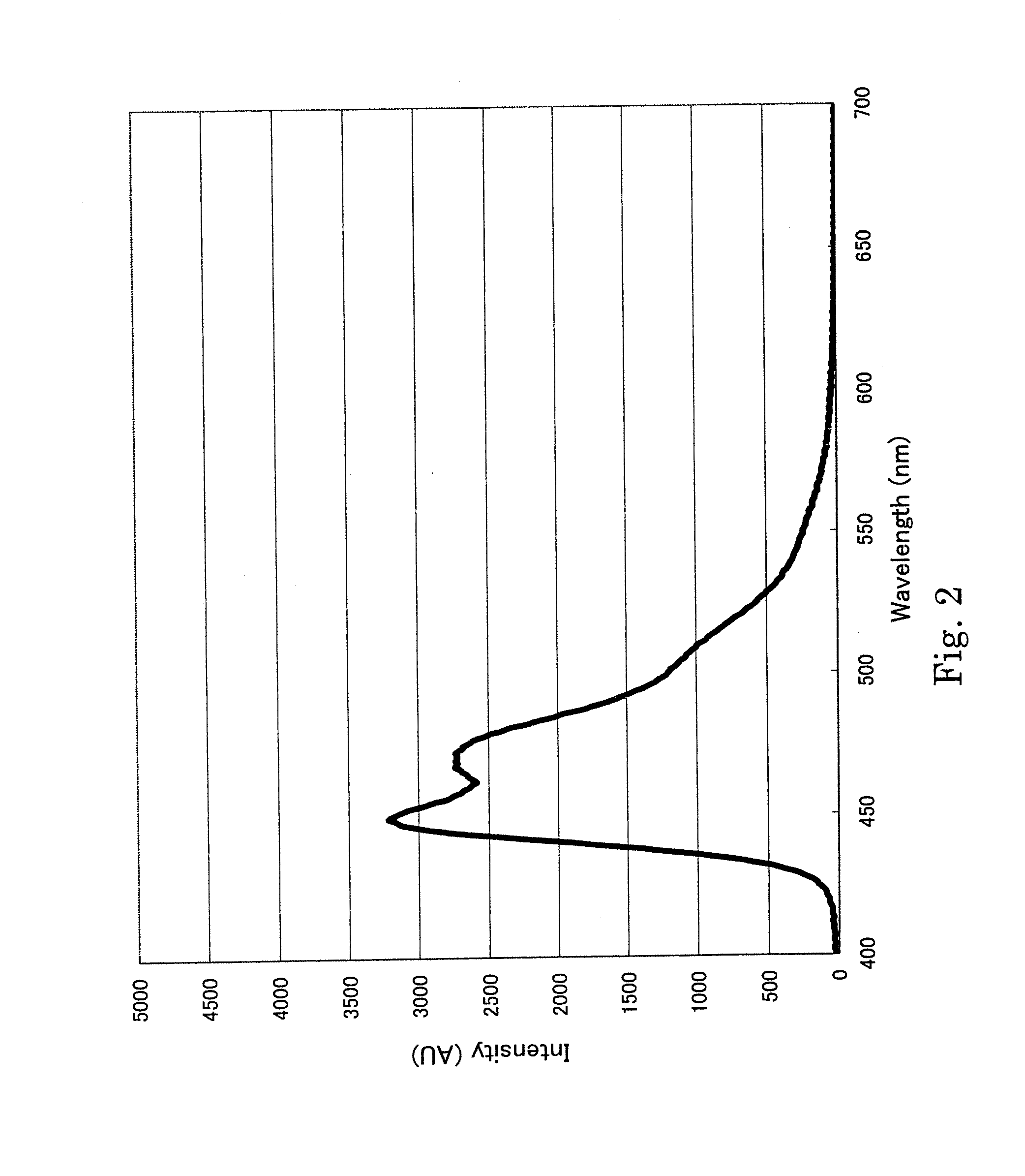

Aromatic amine derivative and organic electroluminescent device using the same

ActiveUS20100314615A1Solve low luminous efficiencyNot easy to deteriorateSilicon organic compoundsSolid-state devicesOrganic electroluminescencePerylene derivatives

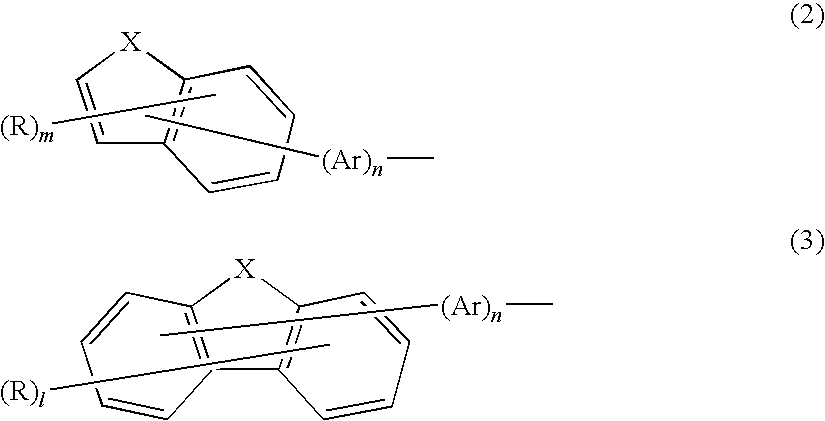

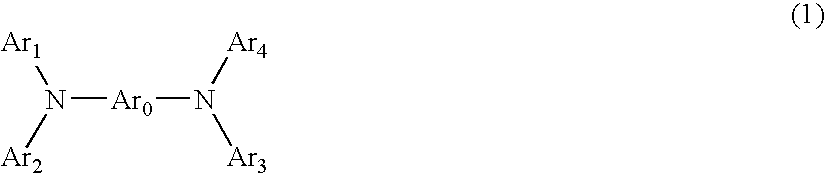

Provided are: an aromatic amine derivative in which a terminal substituent such as a dibenzofuran ring or a dibenzothiophene ring is bonded to a nitrogen atom directly or through an arylene group or the like; an organic electroluminescence device including an organic thin film layer formed of one or more layers including a light emitting layer and interposed between a cathode and an anode in which a layer of the organic thin film layer contains the aromatic amine derivative by itself or as a component of a mixture, and the device has a long lifetime and high luminous efficiency; and an aromatic amine derivative for realizing the device.

Owner:IDEMITSU KOSAN CO LTD

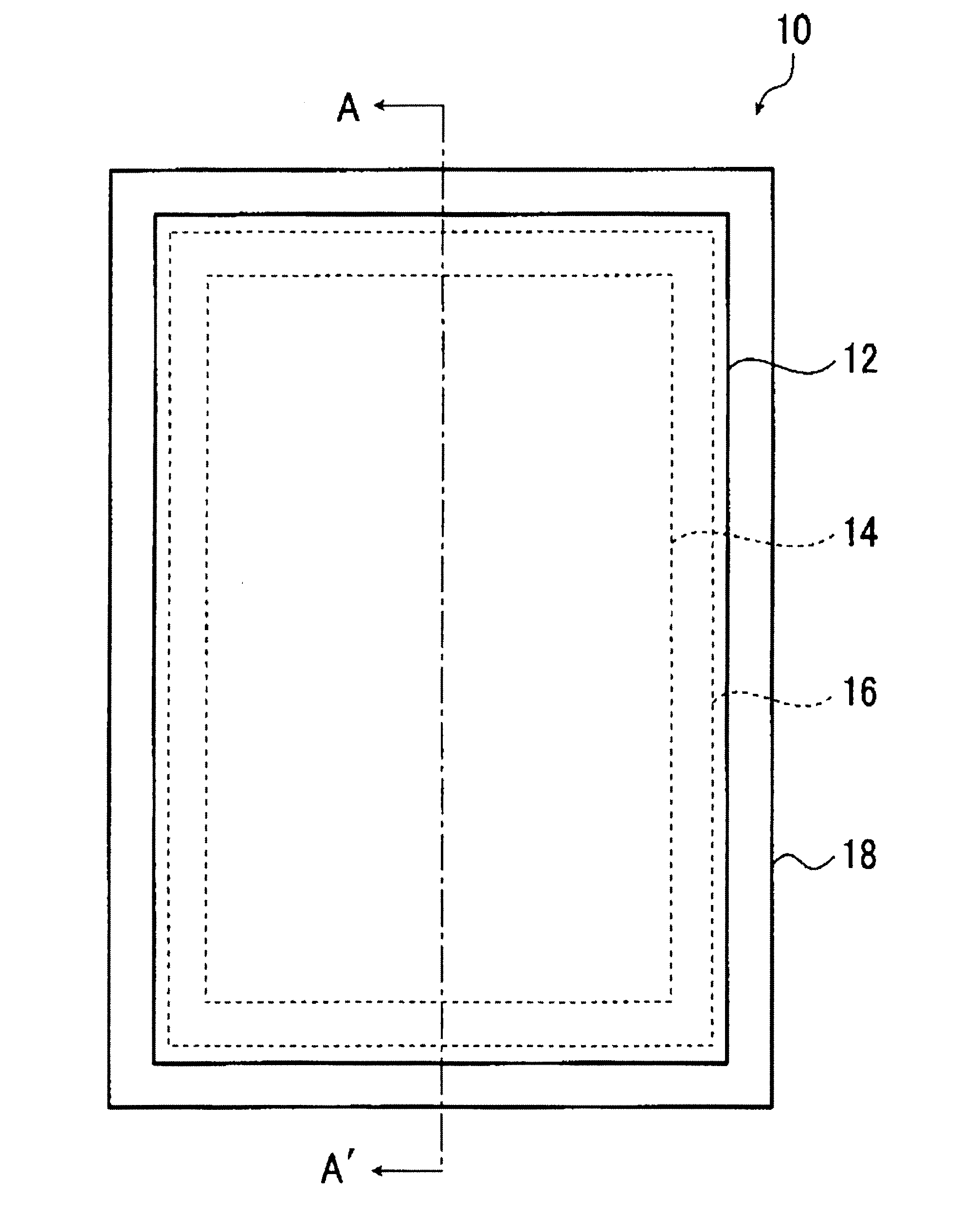

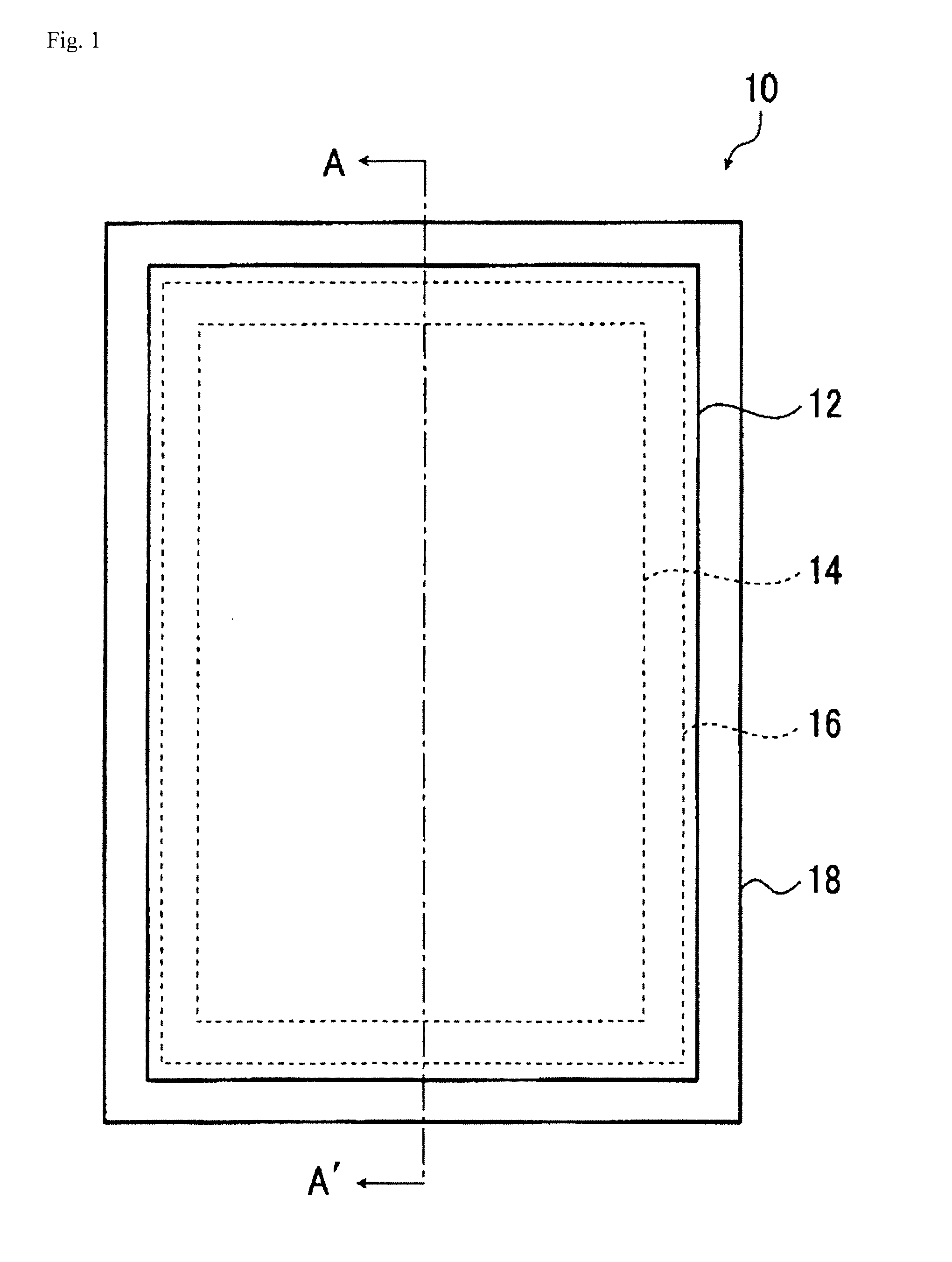

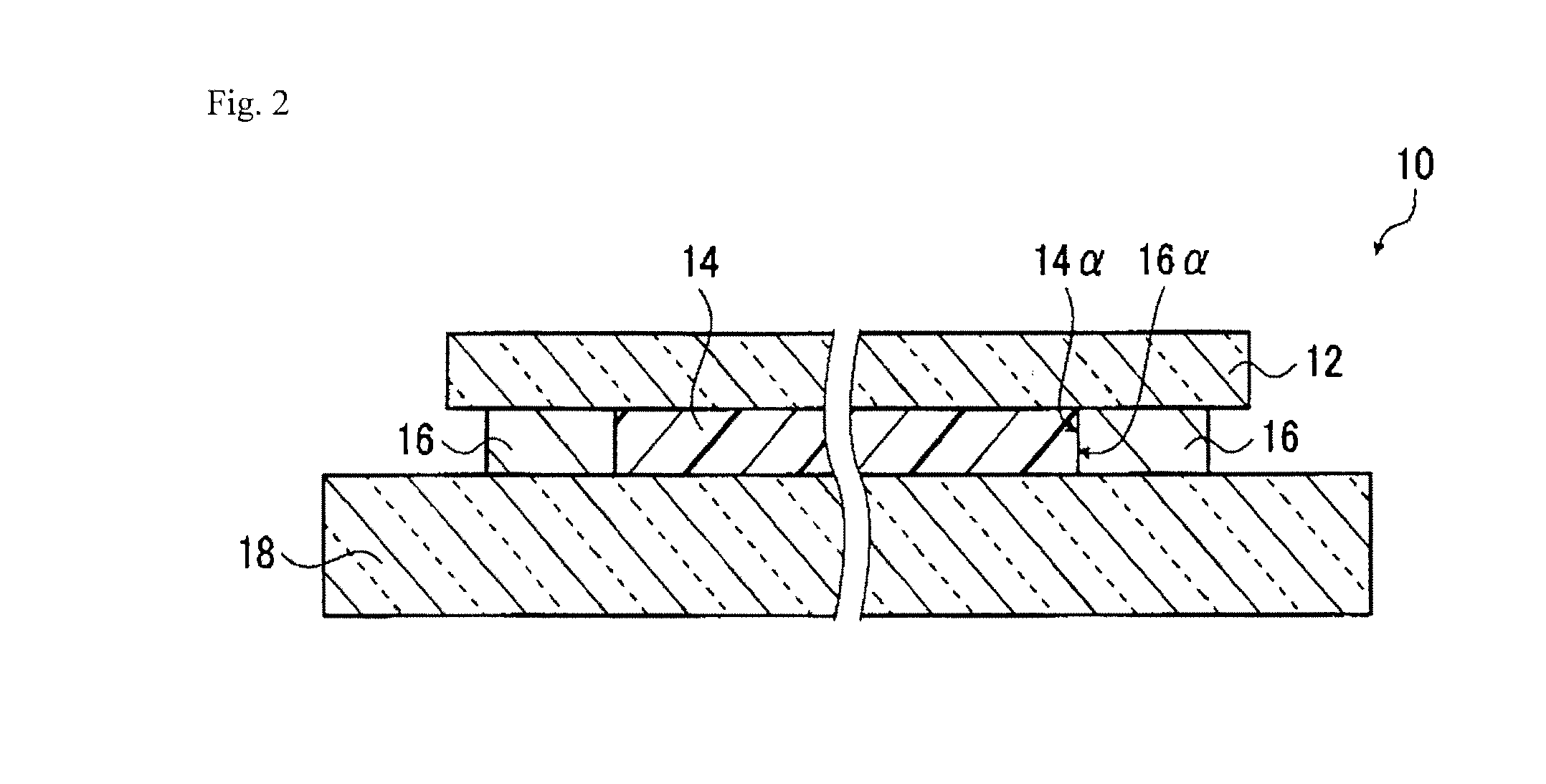

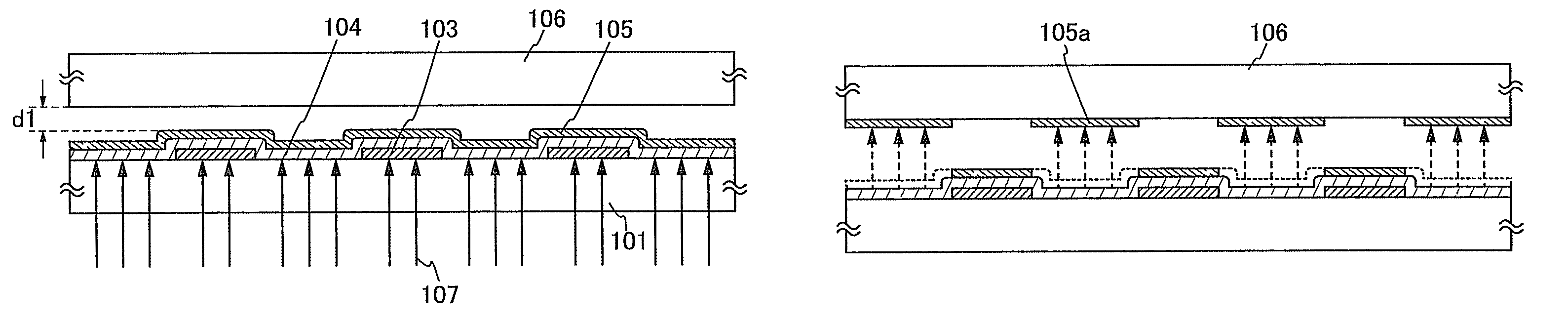

Glass laminate, display panel with support, method for producing glass laminate and method for manufacturing display panel with support

InactiveUS20110026236A1InhibitionEasy to separateLamination ancillary operationsSpecial ornamental structuresThin glassFace sheet

Disclosed is a glass laminate comprising a thin glass substrate having a first main surface and a second main surface, a supporting glass substrate having a first main surface and a second main surface, and a resin layer and an outer frame layer arranged between the thin glass substrate and the supporting glass substrate. The resin layer is fixed to the first main surface of the supporting glass substrate and is in close contact with the first main surface of the thin glass substrate, while having easy releasability from the first main surface of the thin glass substrate. The outer frame layer surrounds the resin layer on the first main surface of the supporting glass substrate so that the outside air does not come into contact with the resin layer.

Owner:ASAHI GLASS CO LTD

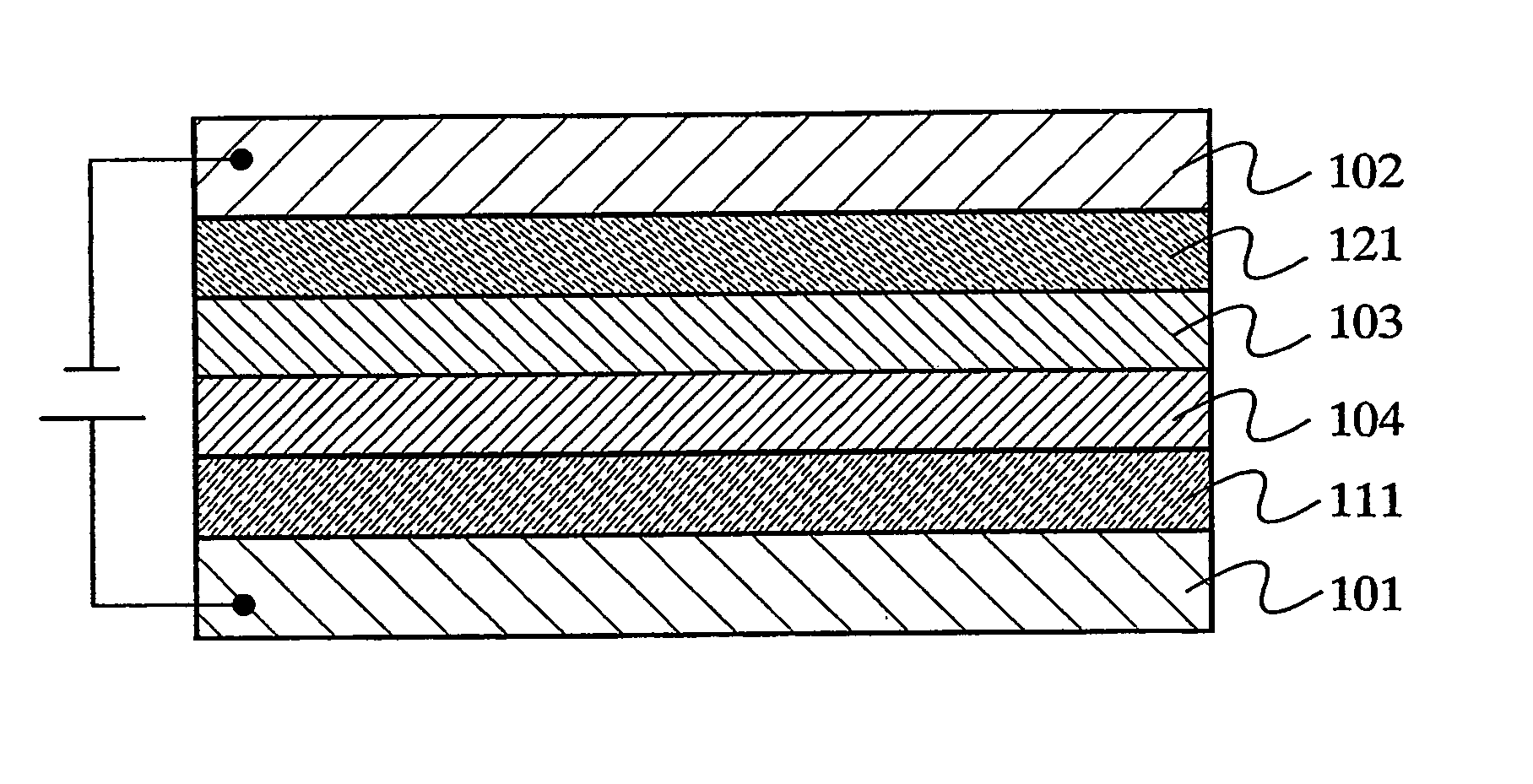

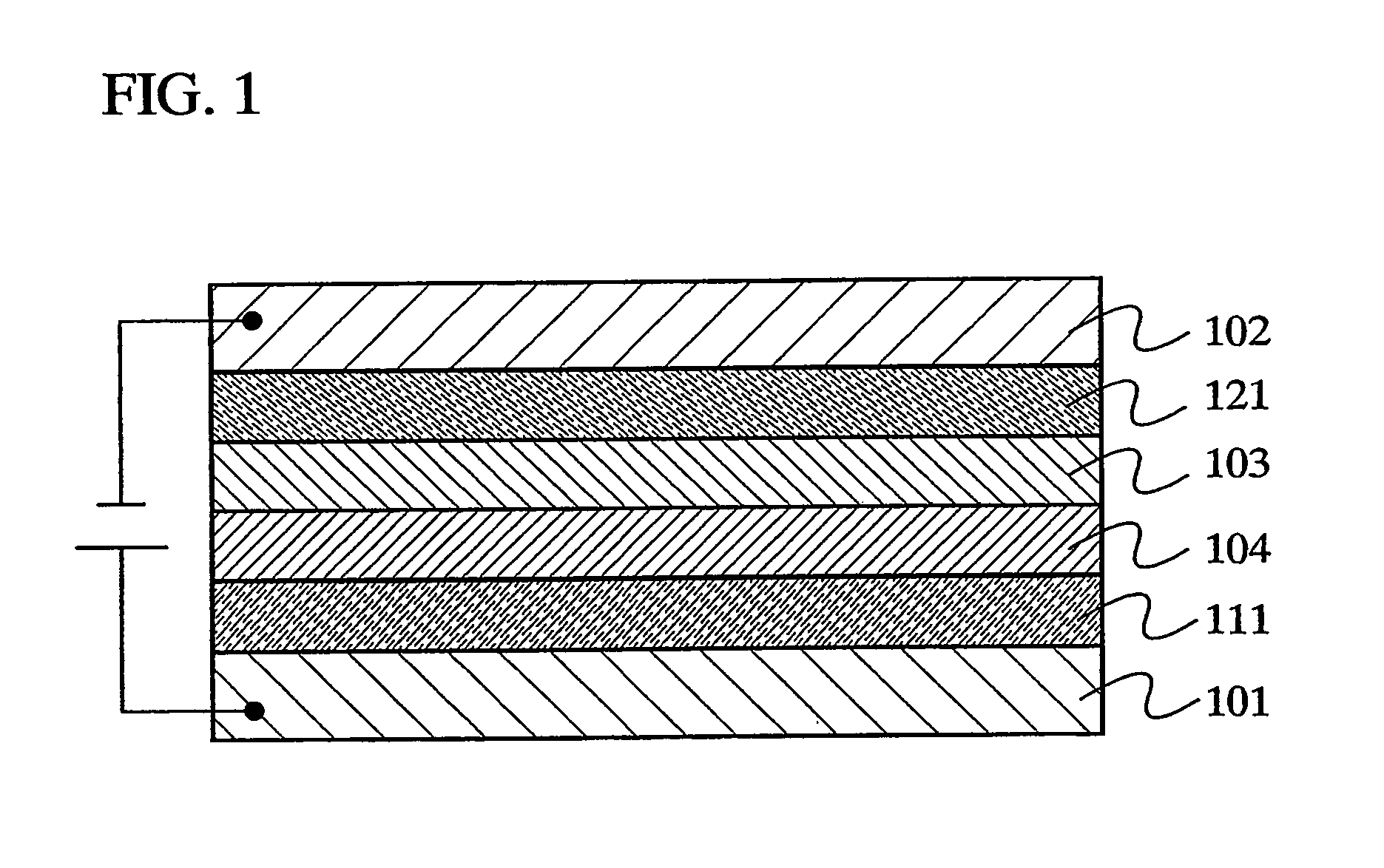

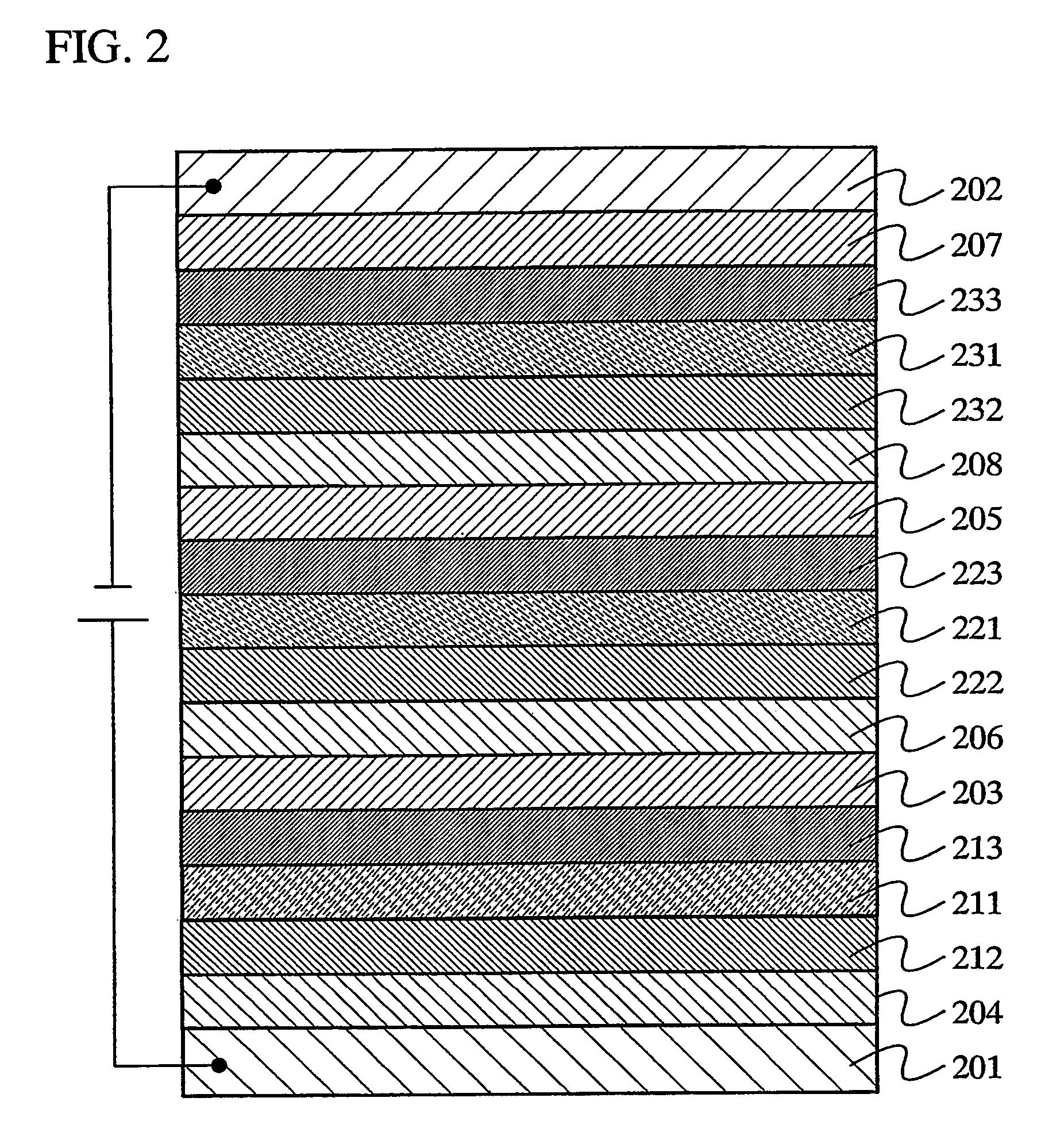

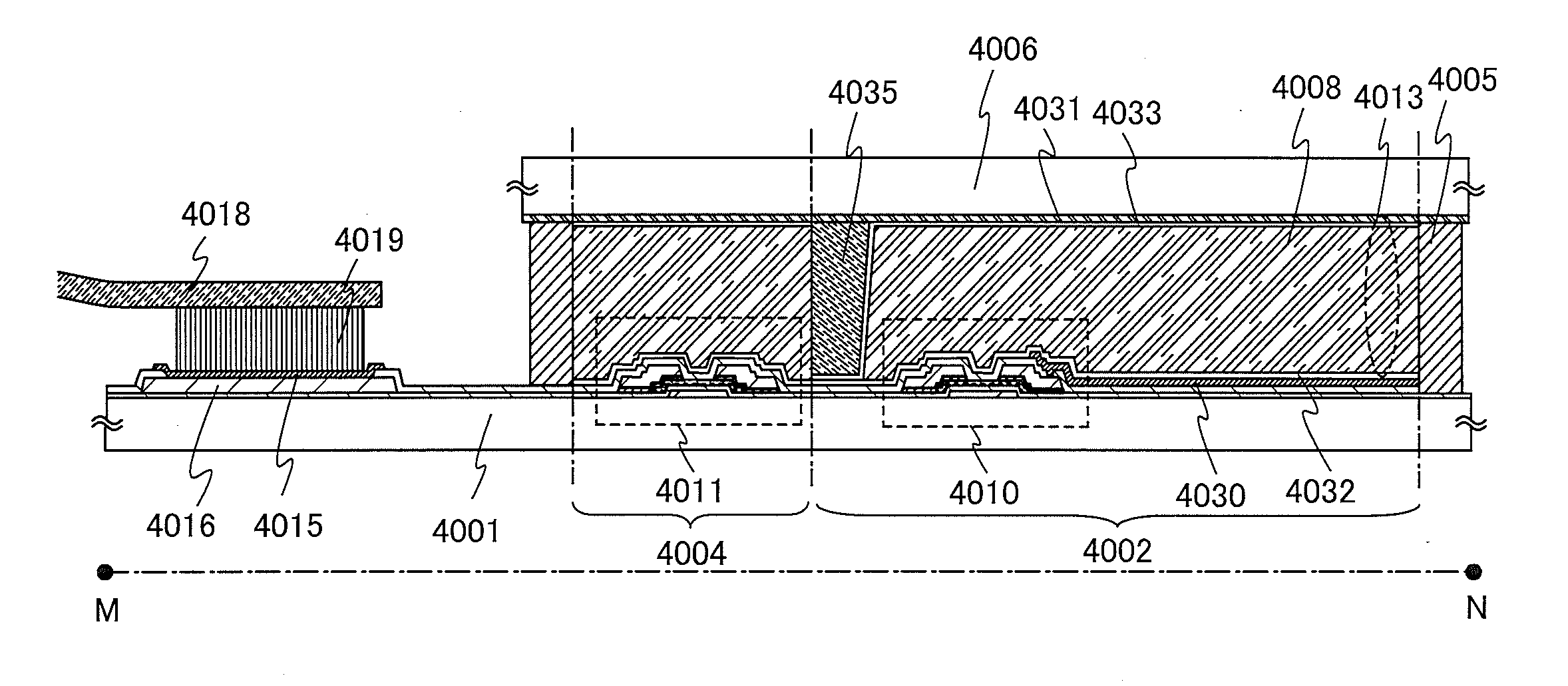

Light emitting element and light emitting device

ActiveUS7598670B2Improve moisture resistanceConvenient lightingDischarge tube luminescnet screensElectroluminescent light sourcesLight-emitting diodeLight emitting device

A light emitting element of the invention includes n pieces of light emitting layers (n is a natural number) between first and second electrodes. A first layer and a second layer are provided between the mth light emitting layer (m is a natural number of 1≦m≦n) and the m+1th light emitting layer. The first and second layers are contacted to each other. The first layer contains a substance that transports holes easily and a substance with an electron accepting property. The second layer contains a substance that transports electrons easily and a substance with an electron donating property. Molybdenum oxide is used as the substance with the electron accepting property.

Owner:SEMICON ENERGY LAB CO LTD

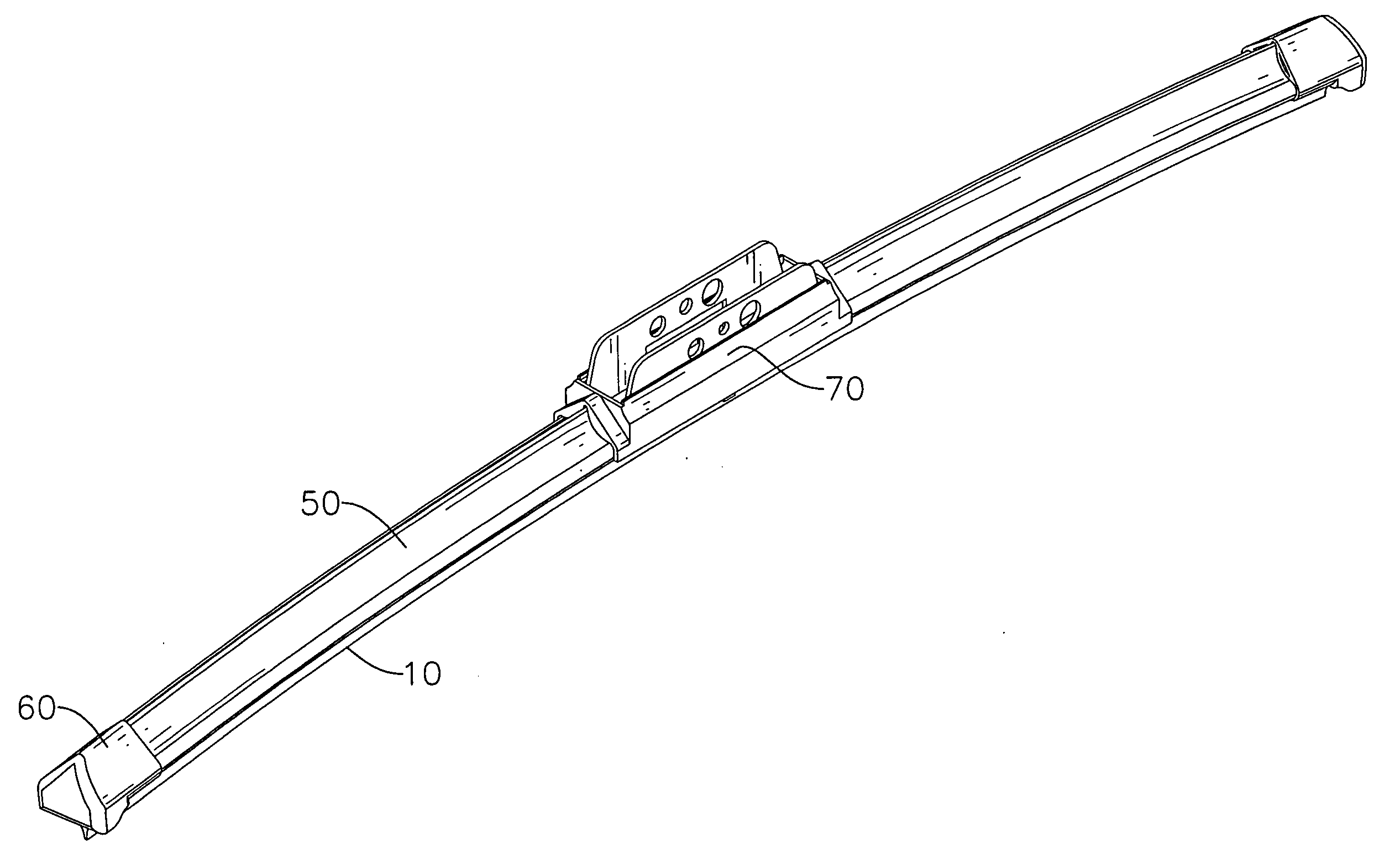

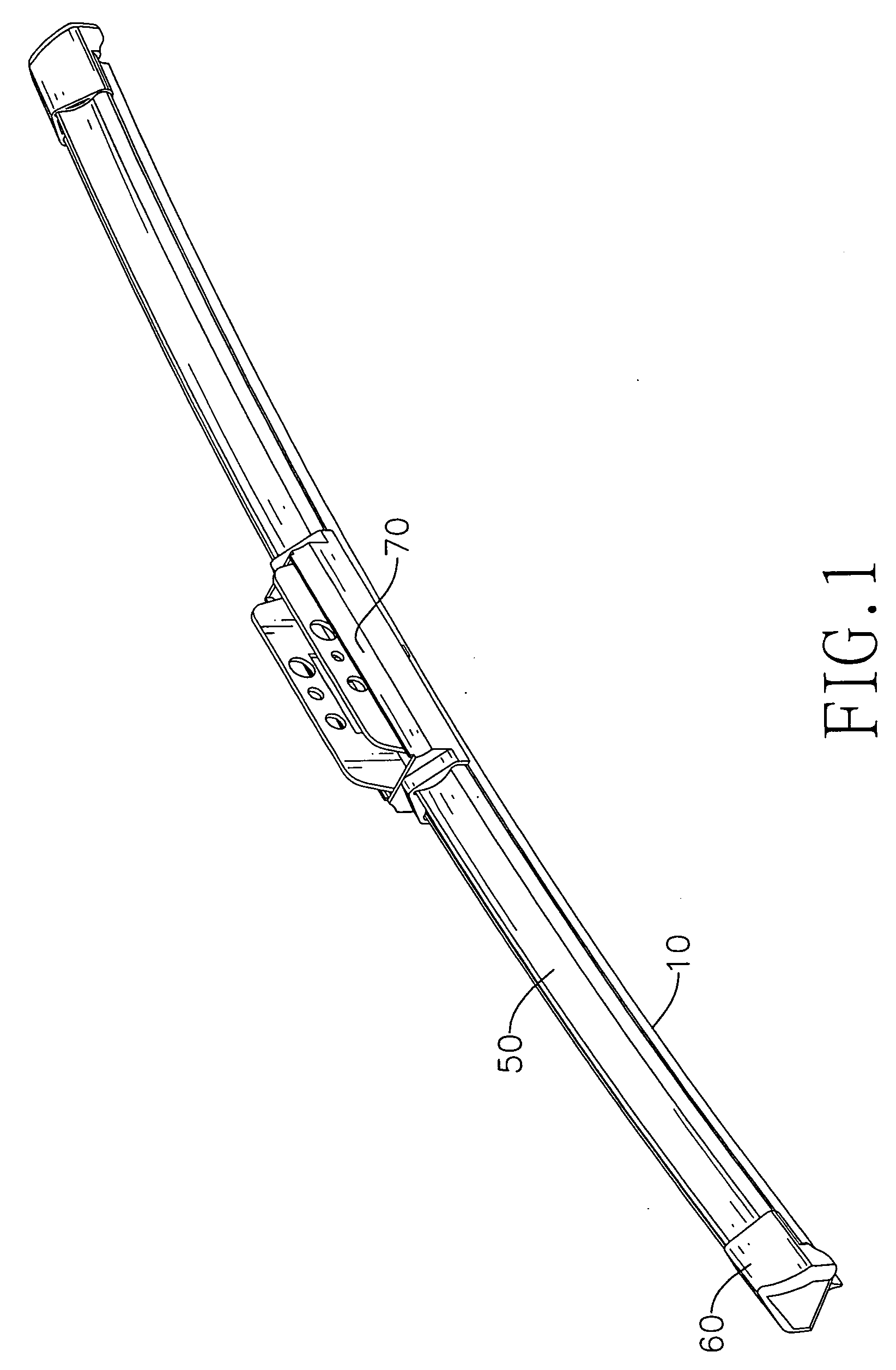

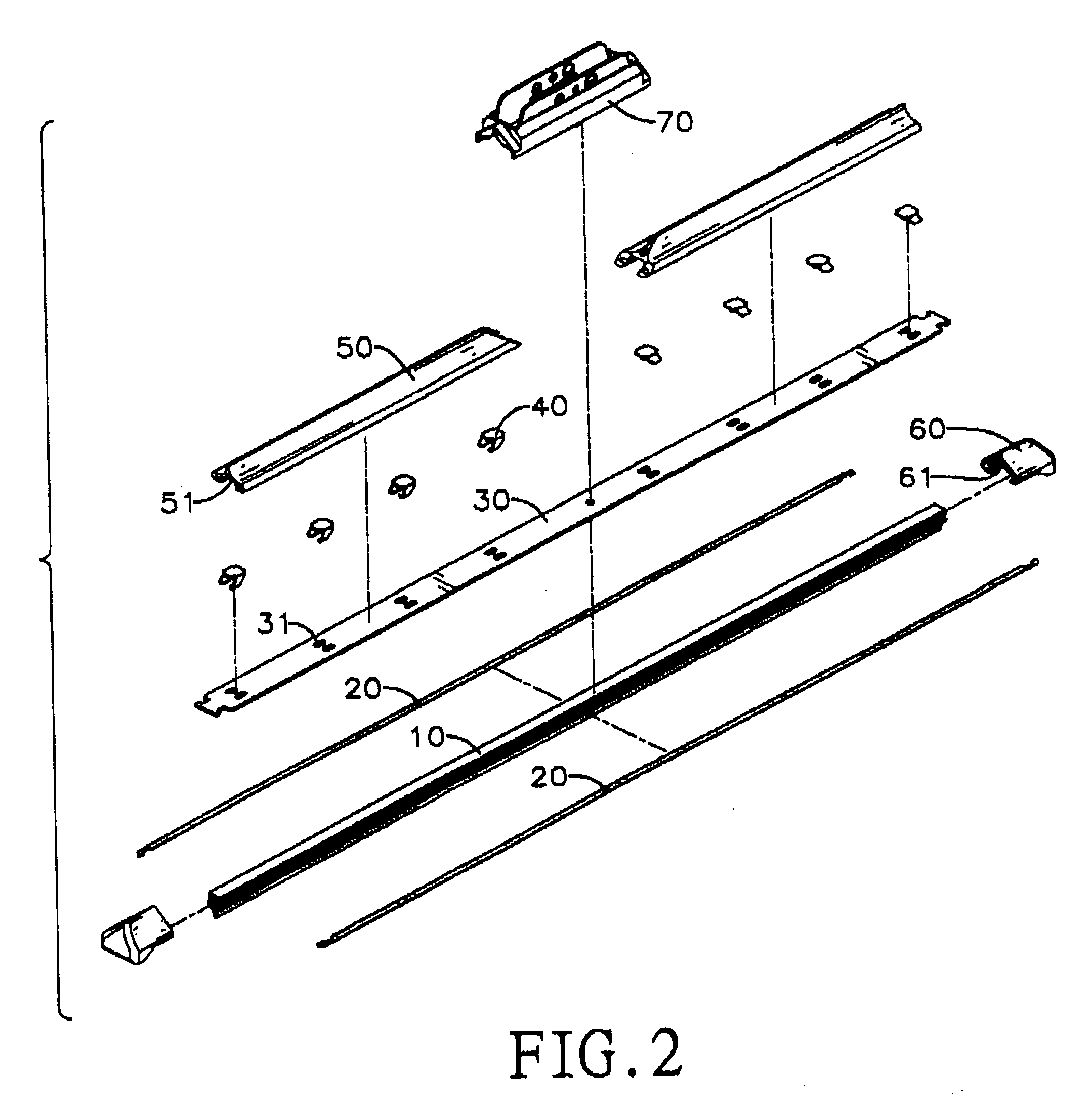

Windshield wiper

InactiveUS20100005608A1Avoid deformationNot easy to deteriorateWindow cleanersVehicle cleaningEngineeringLife span

A windscreen wiper has a rubber blade, an beam being mounted on the rubber blade, multiple clips being mounted respectively through the beam, multiple spoilers being mounted on the beam, two end caps being mounted respectively on the spoiler and around the ends of the beam and the rubber blade and a connector assembly being mounted securely on the beam and between two adjacent spoilers. The beam that is held firmly on the rubber blade, and the clips hold the beam stably on the rubber blade. Therefore, the rubber blade is connected firmly to other components of the windscreen wiper, will not deform or deteriorate easily and has improved life span.

Owner:UNIPOINT ELECTRIC MANUFACTURING CO LTD

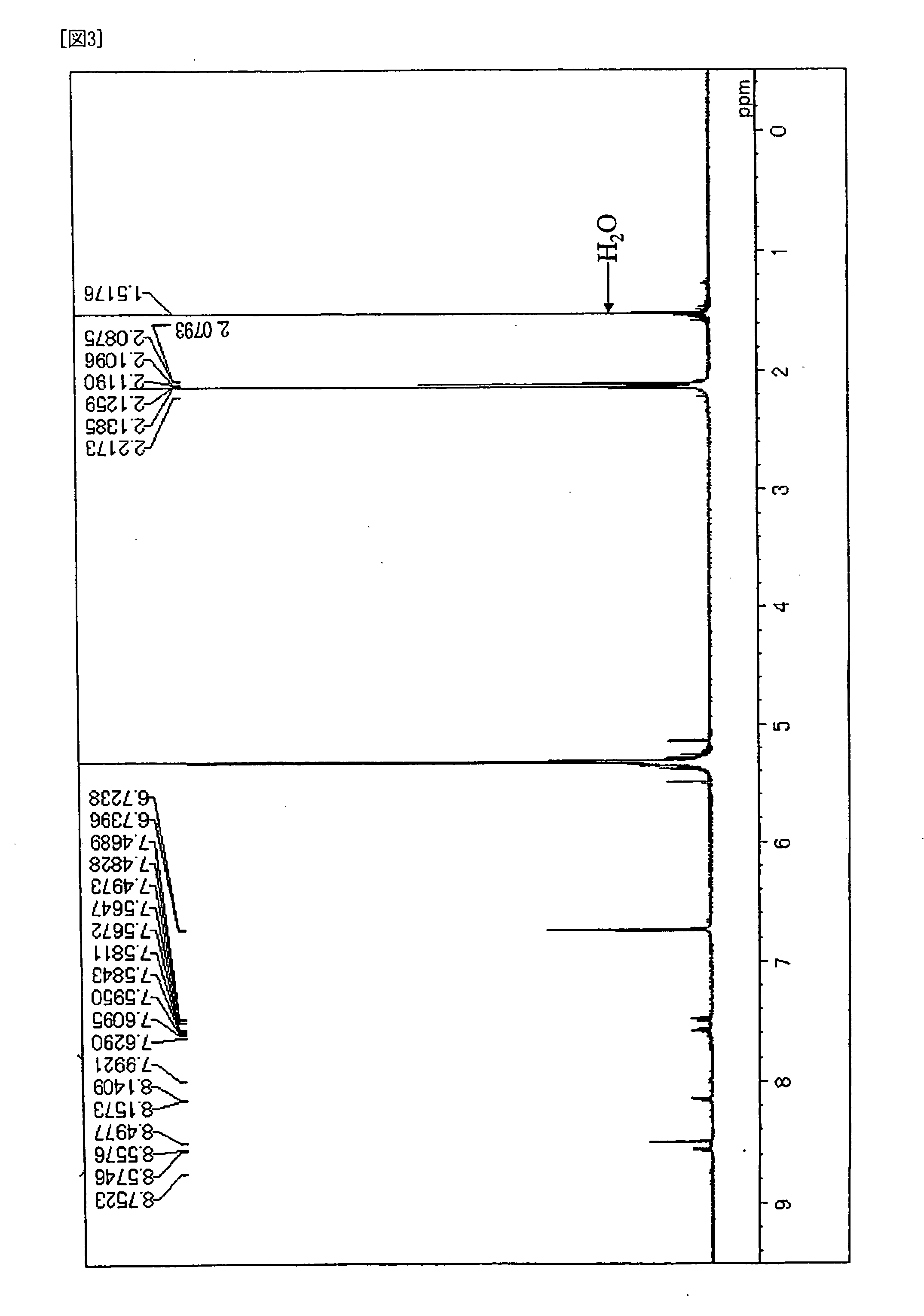

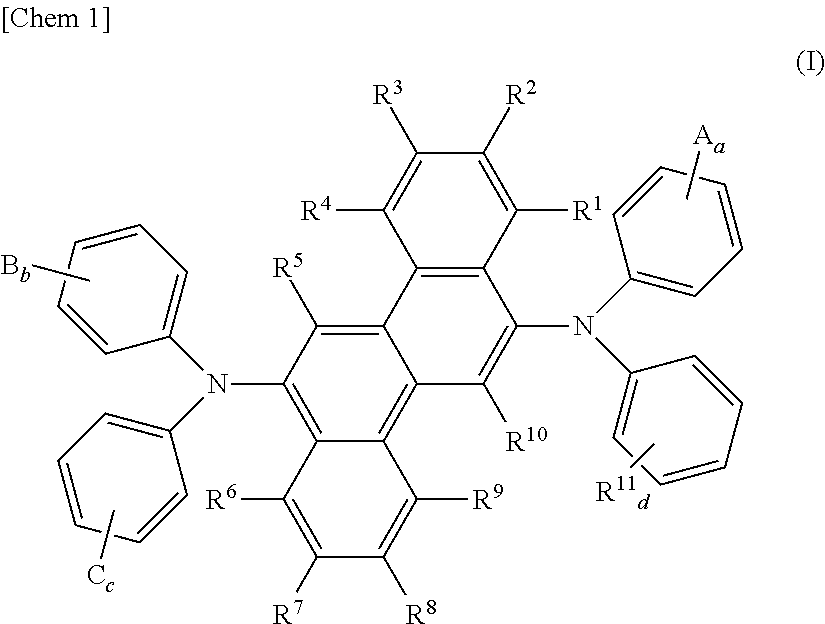

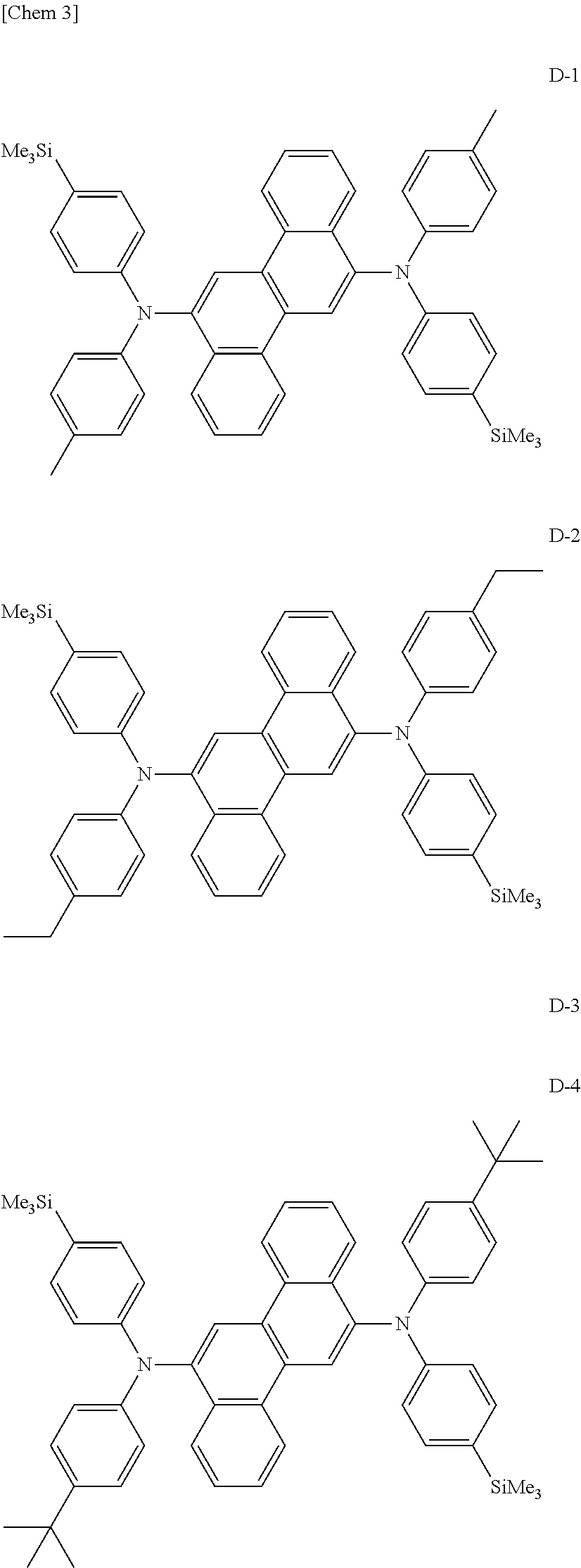

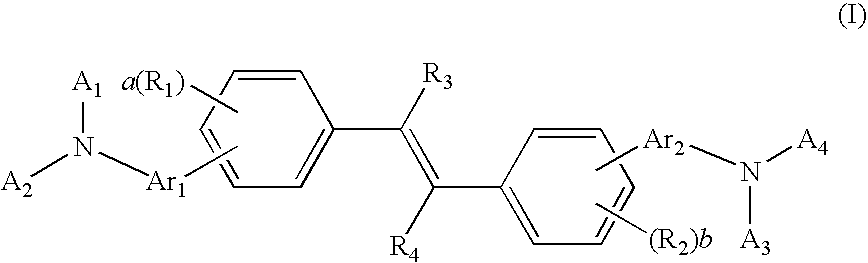

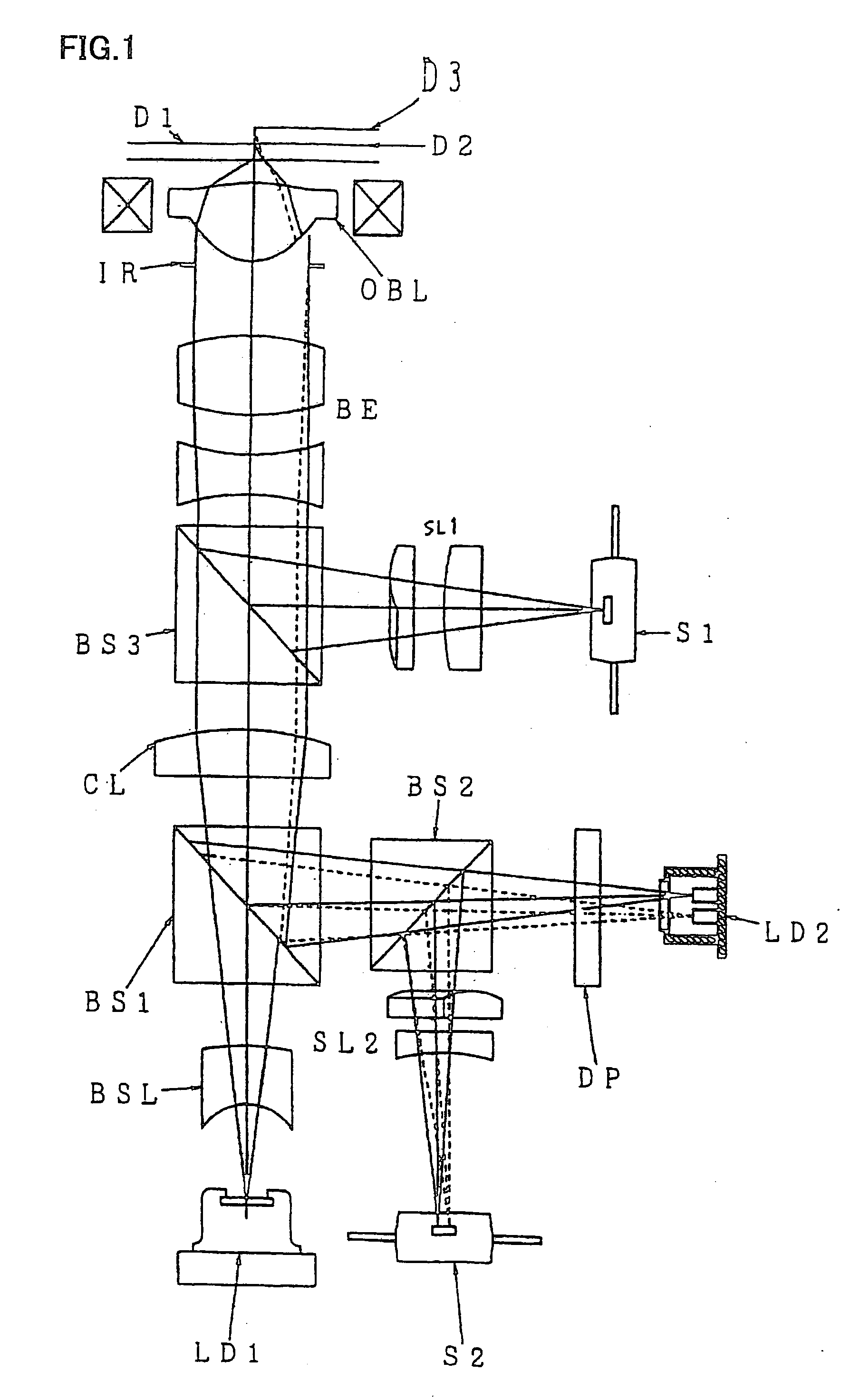

Aromatic diamine derivative and organic electroluminescent device using the same

InactiveUS20110006289A1High luminous efficiencyNot easy to deteriorateGroup 4/14 element organic compoundsSolid-state devicesSilyleneOrganic electroluminescence

Disclosed is an aromatic diamine derivative represented by the following general formula (I), which has a chrysene structure in which a phenyl group having a substituted or unsubstituted silyl group is a substituent for an amino group. Also disclosed is an organic electroluminescence device including an organic thin film layer formed of one or more layers including at least a light emitting layer and interposed between a cathode and an anode, in which at least one layer of the organic thin film layer contains the aromatic diamine derivative by itself or as a component of a mixture, the device having a long lifetime and high luminous efficiency. (In the formula, R1 to R10 each independently represent a hydrogen atom, an alkyl group having 1 to 50 carbon atoms, or the like, and R11 represents a substituted or unsubstituted alkyl group having 1 to 50 carbon atoms or the like, and at least one of A, B, and C represents a substituted or unsubstituted silyl group, and the others each represent a hydrogen atom, a substituted or unsubstituted alkyl group having 1 to 50 carbon atoms, or the like, a, b, c, and d each independently represent an integer of 1 to 5.)

Owner:IDEMITSU KOSAN CO LTD

Preparation method of layer-by-layer self-assembled hollow fiber forward osmosis membrane

ActiveCN108325400ALess materialSimple production processSemi-permeable membranesGeneral water supply conservationHollow fibreFiber

The invention discloses a preparation method of a layer-by-layer self-assembled hollow fiber forward osmosis membrane. The preparation method comprises the steps of: preparing hollow fiber forward osmosis base film, modifying hollow fiber ultrafiltration base film, repeating layer-by-layer assembly of polycation and polyanion layers, performing interface cross-linking polymerization for preparinga selective functional layer, conducting moisturizing, and carrying out treatment and storage so as to prepare the layer-by-layer self-assembled hollow fiber forward osmosis membrane. The surface of the hollow fiber self-support base film which is prepared by using a phase conversion method is activated firstly, layer-by-layer assembly of polycation and polyanion is repeated on the surface of thefilm so as to form an functional polarization layer for an electrolyte solution, and the polyamide selective layer is prepared through interfacial chemical cross-linking polymerization. The prepared hollow fiber forward osmosis membrane has a controllable thickness and an internal polarization layer with a high charge capacity, and the internal concentration polarization phenomenon can be alleviated effectively during the forward osmosis process; therefore, the hollow fiber forward osmosis membrane can simultaneously obtain high flux and low reverse salt flux, has high filtration separation efficiency, easy cleaning and a long service life, and can be widely applied to seawater desalination and concentration and desalination of brine.

Owner:西安金藏膜环保科技有限公司

Method to reduce damage caused by irradiation of halogenated polymers

InactiveUS20050279054A1Not easy to deteriorateSynthetic resin layered productsPackage sterilisationScavengerGamma irradiation

A method for producing a polymeric film resistant to degradation during sterilization such as gamma irradiation is presented. The method includes the steps of minimizing the number of free radicals formed during sterilization through use of an inert gas and a reactant scavenger within a sterilization pouch, which reactant scavenger may be acid adsorbents which scavenge the acid by-products formed during irradiation. The films retain physical and mechanical properties with long-term storage. The films are particularly amenable for use as packaging laminates in pharmaceutical, food, semiconductor and medical device industries.

Owner:ARADIGM

Method to reduce damage caused by irradiation of halogenated polymers

InactiveUS6933026B2Deteriorate with timeNot easy to deteriorateSynthetic resin layered productsPackage sterilisationScavengerGamma irradiation

A method for producing a polymeric film resistant to degradation during sterilization such as gamma irradiation is presented. The method includes the steps of minimizing the number of free radicals formed during sterilization through use of an inert gas and a reactant scavenger within a sterilization pouch, which reactant scavenger may be acid adsorbents which scavenge the acid by-products formed during irradiation. The films retain physical and mechanical properties with long-term storage. The films are particularly amenable for use as packaging laminates in pharmaceutical, food, semiconductor and medical device industries.

Owner:ARADIGM

Aromatic amine derivative and organic electroluminescence device using the same

ActiveUS20080004445A1High luminous efficiencyNot easy to deteriorateGroup 4/14 element organic compoundsDischarge tube luminescnet screensOrganic electroluminescenceAmine derivatives

To attain an organic electroluminescence device having a long lifetime and high luminous efficiency, and is capable of emitting blue light having a high color purity, and an aromatic amine derivative for realizing the device, the present invention provides an aromatic amine derivative having a specific structure, and an organic electroluminescence device including an organic thin film layer composed of one or more layers including at least a light emitting layer and interposed between a cathode and an anode, in which at least one layer of the organic thin film layer contains the aromatic amine derivative alone or as a component of a mixture.

Owner:IDEMITSU KOSAN CO LTD

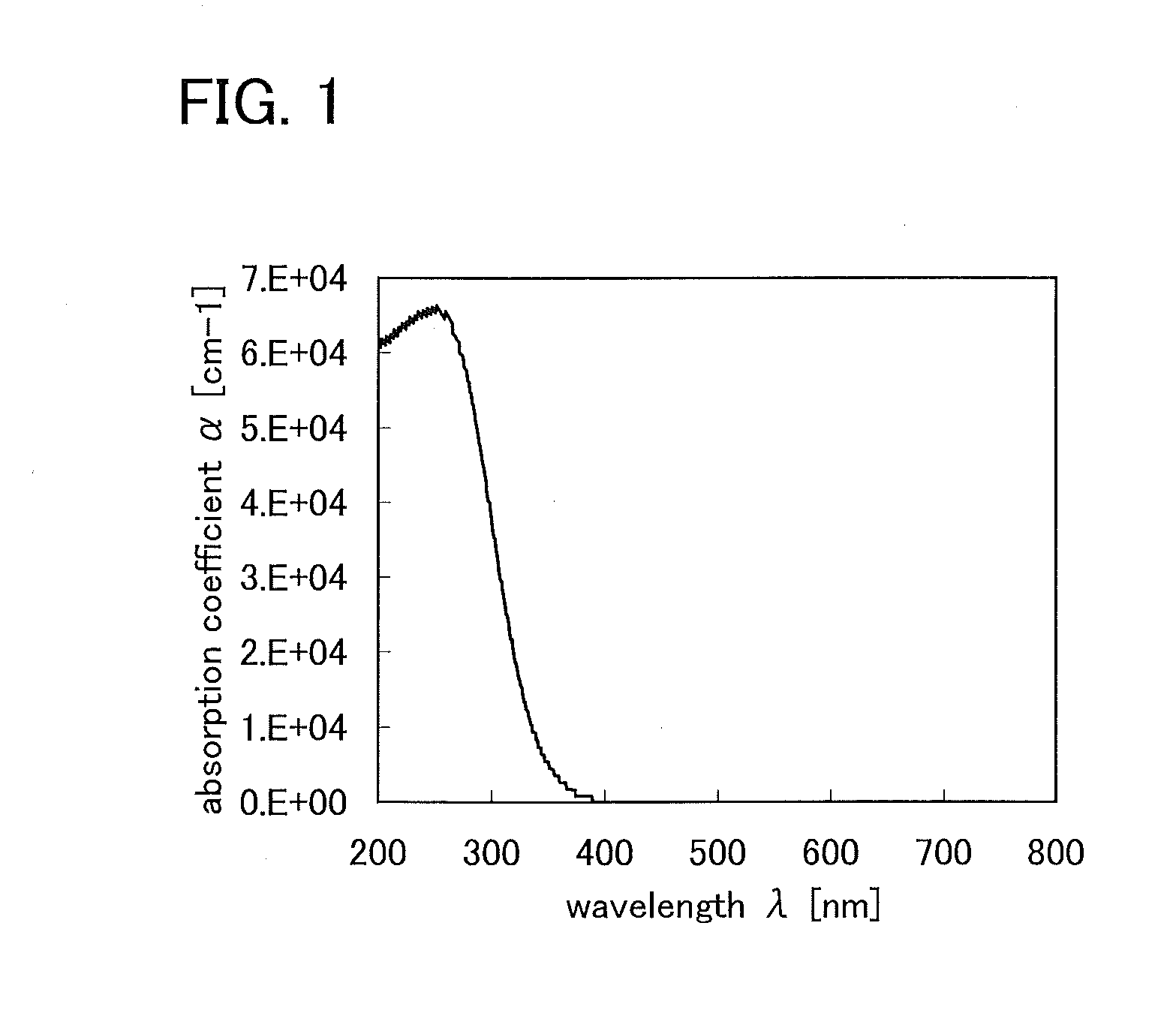

Semiconductor device

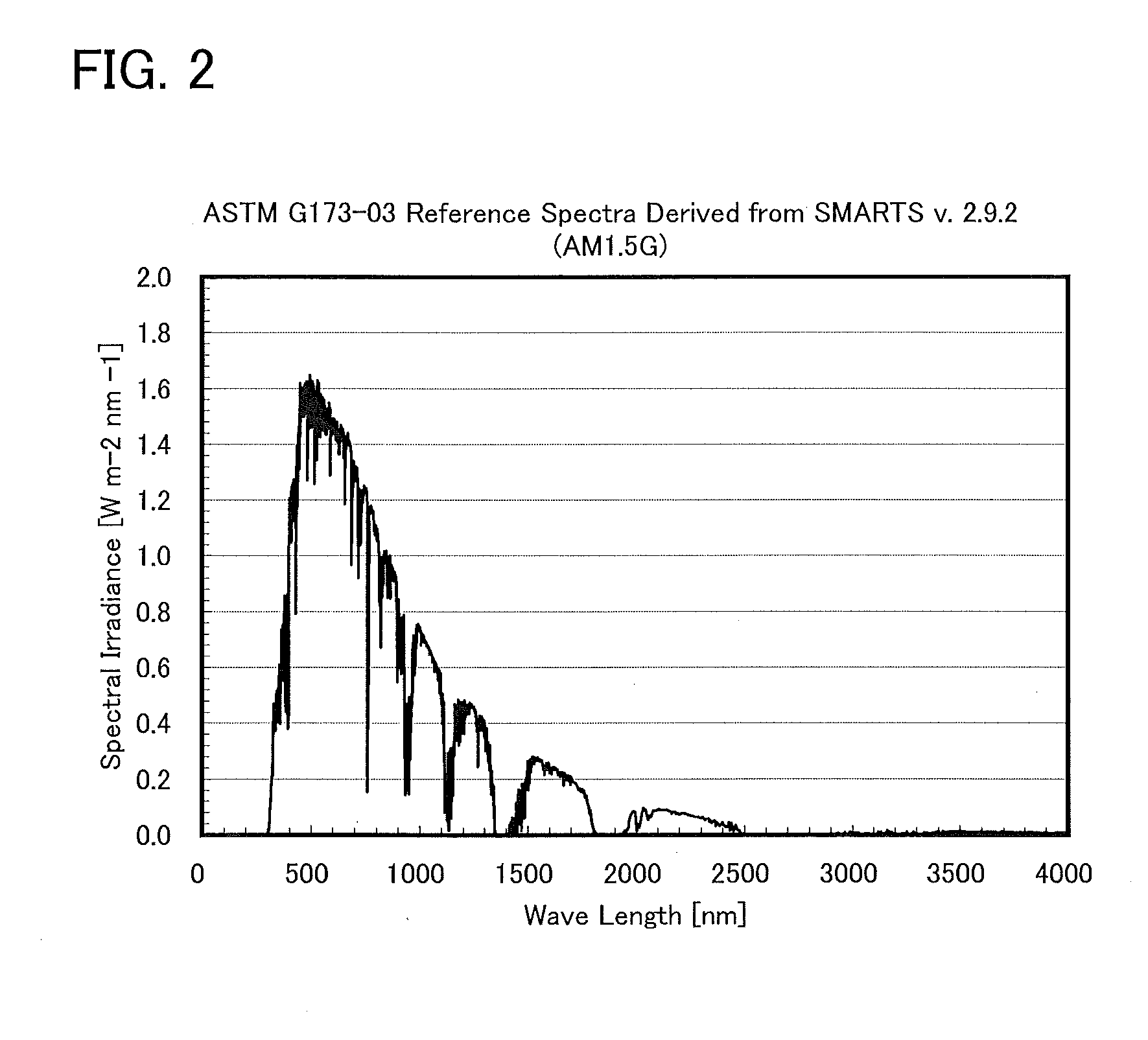

InactiveUS20120043541A1Stable electrical characteristicsNot easy to deteriorateSolid-state devicesSemiconductor devicesLength waveSemiconductor

An object is to provide a transistor in which light deterioration is suppressed as much as possible and electrical characteristics are stable, and a semiconductor device including the transistor. The attention focuses on the fact that light is reflected by a film used for forming a transistor and multiple interaction occurs. When the optical thickness of the film which causes the reflection is roughly an odd multiple of λ0 / 4 or roughly an even multiple of λ0 / 4, reflectance in a wavelength region of light which is absorbed by an oxide semiconductor is increased without a loss of a function of the film with respect to the transistor, whereby the amount of light absorbed by the oxide semiconductor is reduced and an effect of reducing light deterioration is increased.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device, method of manufacturing the same, and method of evaluating semiconductor device

ActiveUS20080142839A1Not easy to deteriorateImprove reliabilitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingCrystal planeSemiconductor

A semiconductor device has: a silicon (semiconductor) substrate; a gate insulating film and a gate electrode, which are formed on the silicon substrate in this order; and source / drain material layers formed in recesses (holes) in the silicon substrate, the recesses being located beside the gate electrode. Here, each of side surfaces of the recesses, which are closer to the gate electrode, is constituted of at least one crystal plane of the silicon substrate.

Owner:FUJITSU LTD

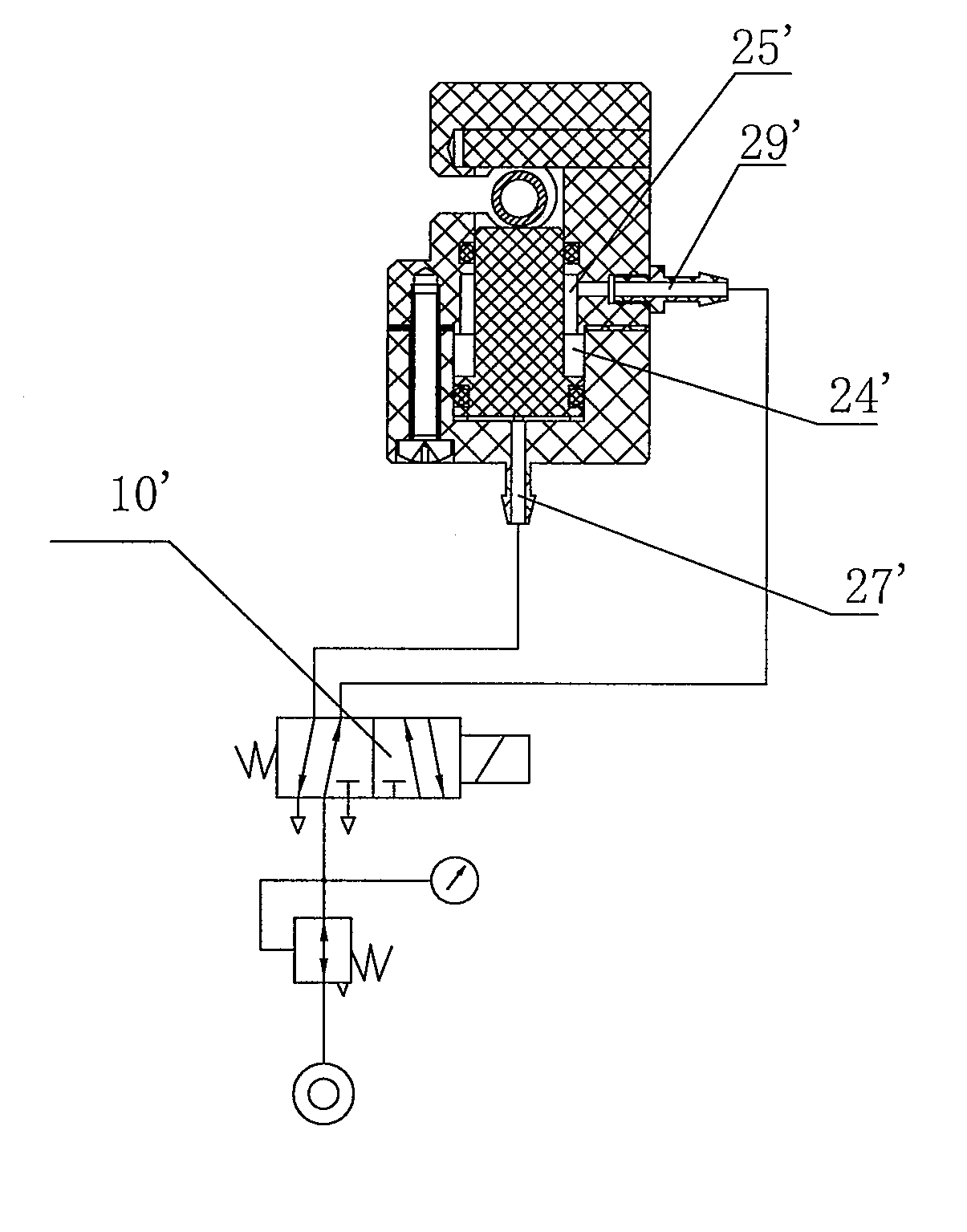

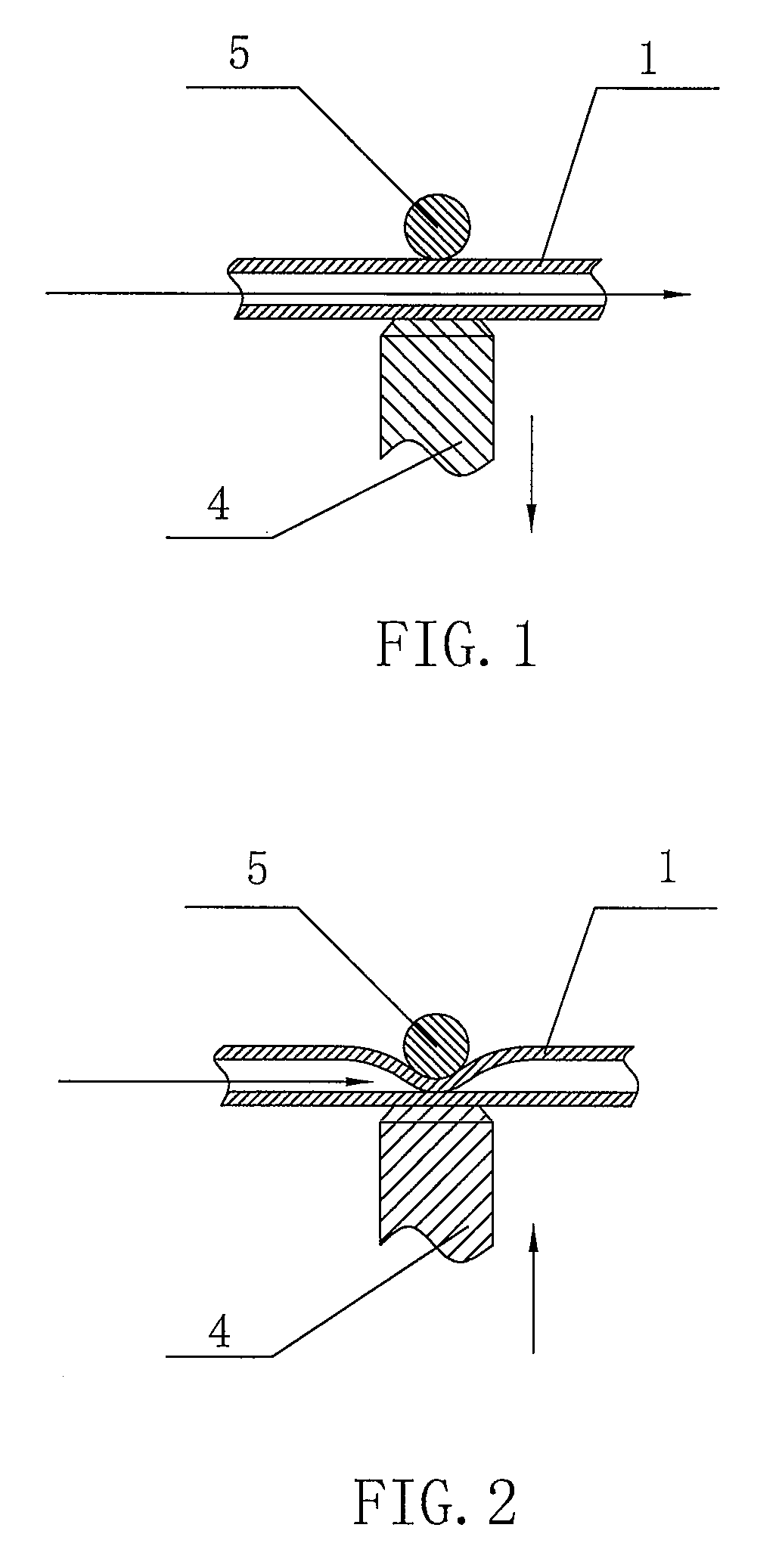

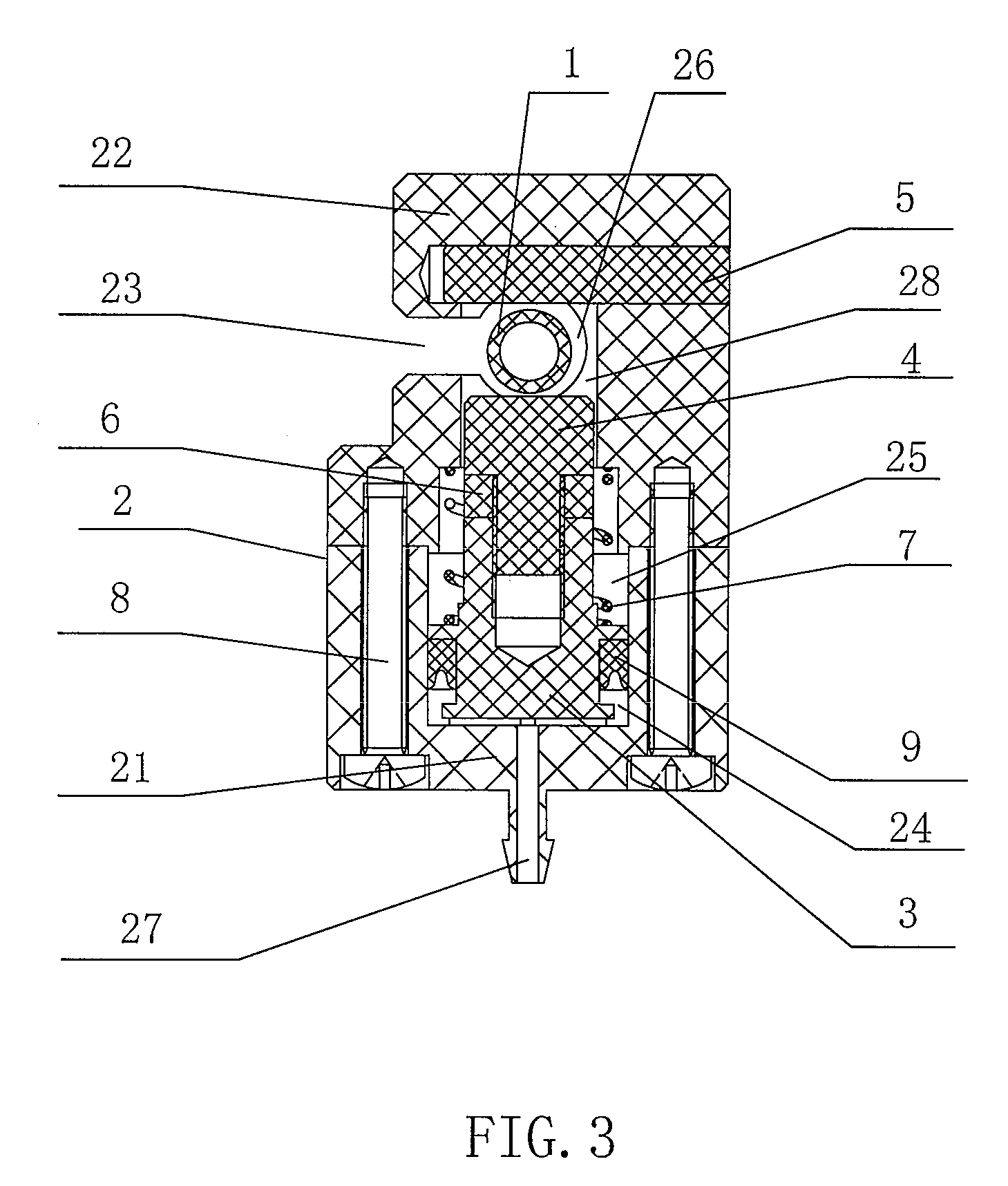

Pneumatic pinch valve

ActiveUS20070170382A1Easy constructionPreventing early fatigue and breakageDiaphragm valvesOperating means/releasing devices for valvesPinch valveEngineering

The present invention provides a pneumatic pinch valve, comprising: a lever and a pressing piece, a fluid tube receiving space being formed between the lever and the pressing piece, wherein the pneumatic pinch valve further comprises a main body providing a cavity therein, the lever being installed on the main body; a piston provided in the cavity of the main body, the piston engaging with an inner wall of the cavity of the main body so as to divide the cavity into a first cavity and a second cavity, the pressing piece being positioned in the second cavity and supported on the piston; an air inlet port provided at the first cavity, wherein air introduced into the first cavity via the air inlet port moves the piston toward the fluid tube receiving space so as to press the fluid tube through an engagement of the pressing piece on the piston with the lever, and thus intercept the fluid in the fluid tube; and an air discharge mechanism provided at the piston, by which the piston pushes the air introduced into the first cavity, and then discharges the air into outside, so that the pressing piece releases the fluid tube to allow the intercepted fluid to flow through the fluid tube. Since the pneumatic pinch valve is communicated with the air source via the air inlet port and controls the interception and release of fluid in the flow passage in a pneumatic manner, the construction of the pneumatic pinch valve is simple. Moreover, since the pressurized amount of the fluid tube or the pressure of the air source can be adjusted, i.e. adjusting the pinching force applied to the fluid tube, the fluid tube is not easily deteriorated during long-time operation.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

Decorative article having white coating and method for manufacture thereof

InactiveUS20040093730A1Quality improvementLow costVacuum evaporation coatingSputtering coatingPlatinumAlloy

The first personal ornament of the present invention is constituted of an ornament base article made of a metal or the like; an underlayer, preferably non-nickelic, formed on the base article; and a coloring layer constituted of an abrasion-resistant layer of 0.2-1.5 mum thick formed by dry-plating on the surface of the underlayer and an outermost layer of 0.002-0.1 mum thick formed by dry-plating on the surface of the abrasion-resistant layer. The coloring layer is a white hard coating film of a stainless-steel color. This ornament has a white coating film which gives superior quality, having high scratch resistance, not causing deterioration of appearance by scratching, and yet has high-quality image like a stainless steel film. The ornament having underlayer which does not contain nickel will not cause nickel metal allergy, and has a white coating film which gives superior quality, having high scratch resistance, not causing deterioration of appearance by scratching, and yet has high-quality image like a stainless steel film. The second personal ornament of the present invention is constituted of the aforementioned ornament base article; an underlayer formed on the base article; a titanium carbide layer of 0.5-1.0 mum thick formed by dry-plating on the surface of the underlayer; and an ornamental coating layer of 0.03-0.06 mum thick formed from platinum (alloy) by dry-plating on the surface of the titanium carbide layer. The ornamental coating layer is constituted of a hard white film having a platinum (alloy) color. This ornament has high scratch resistance, not causing deterioration of appearance by scratching, and yet has superior quality with a characteristic platinum (alloy) color. The present invention provides also a process for producing the above ornaments.

Owner:CITIZEN WATCH CO LTD

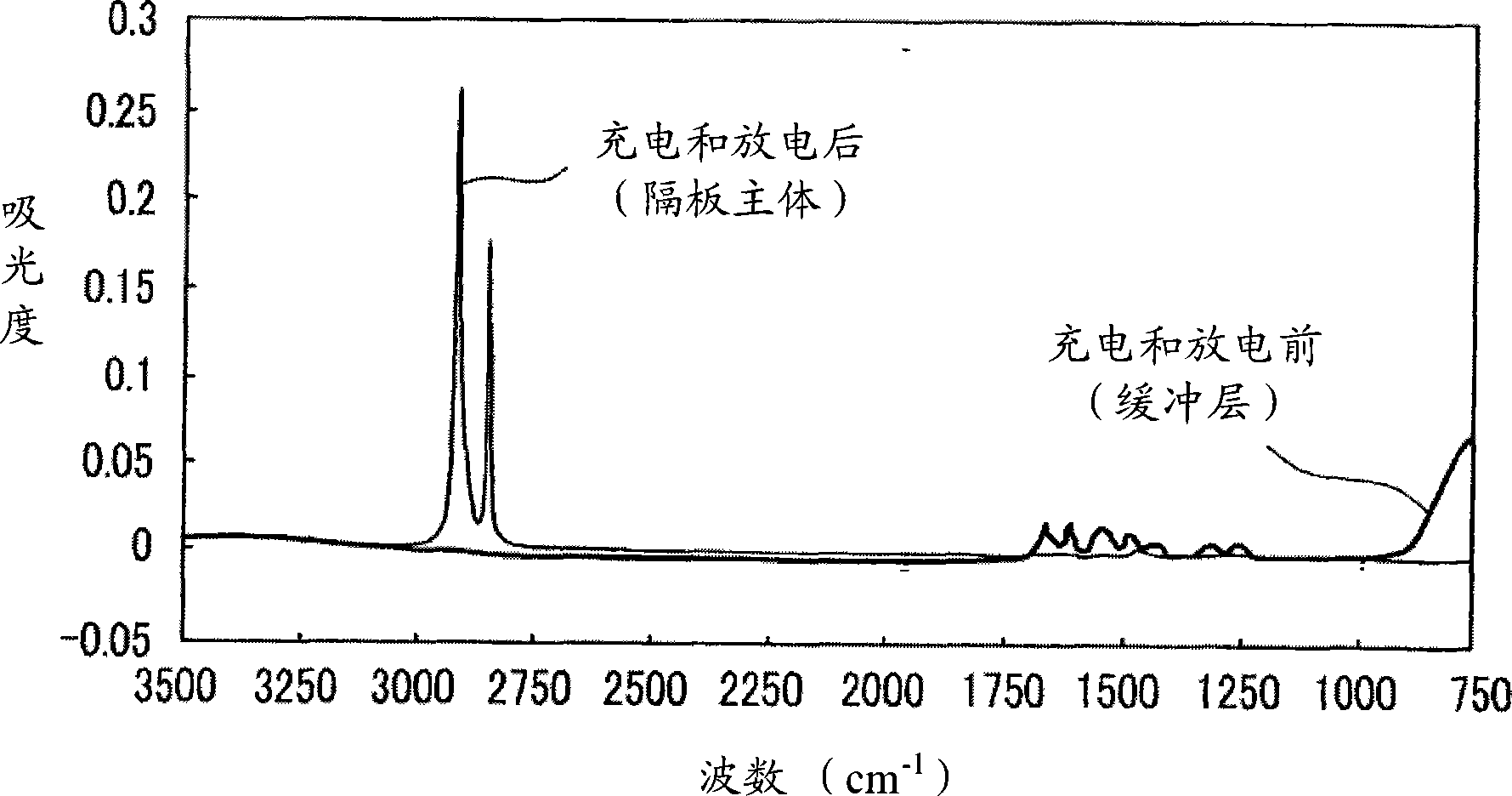

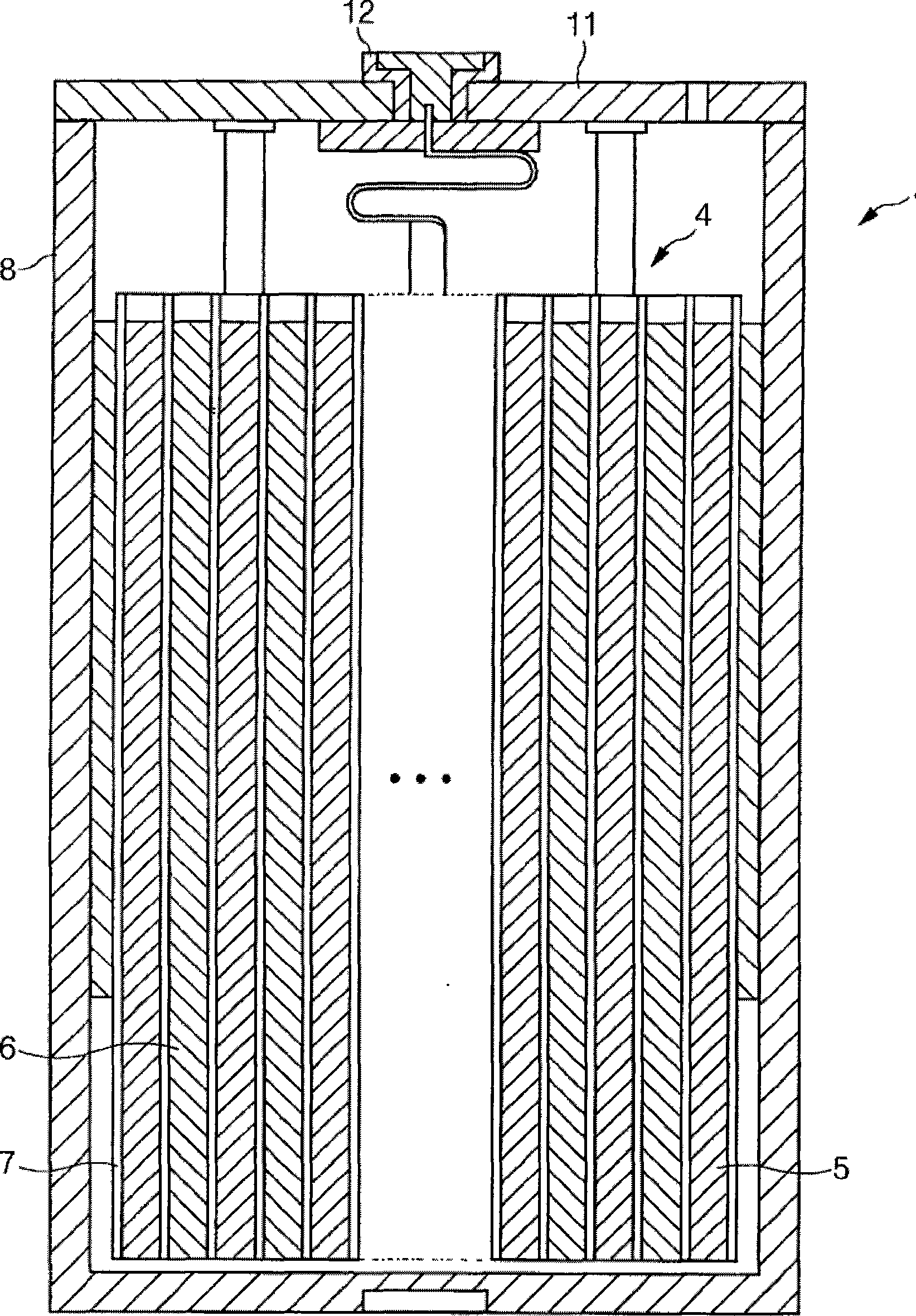

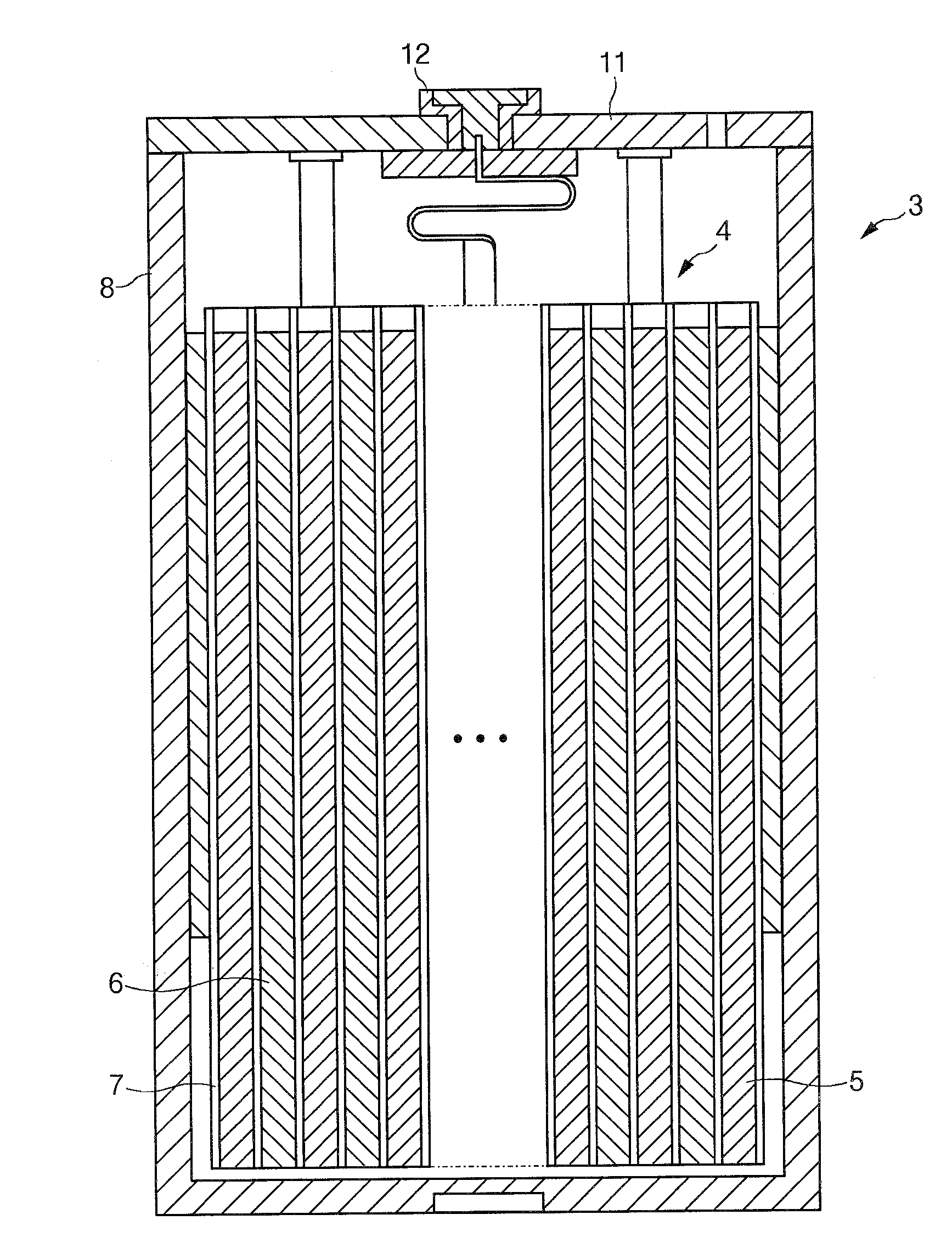

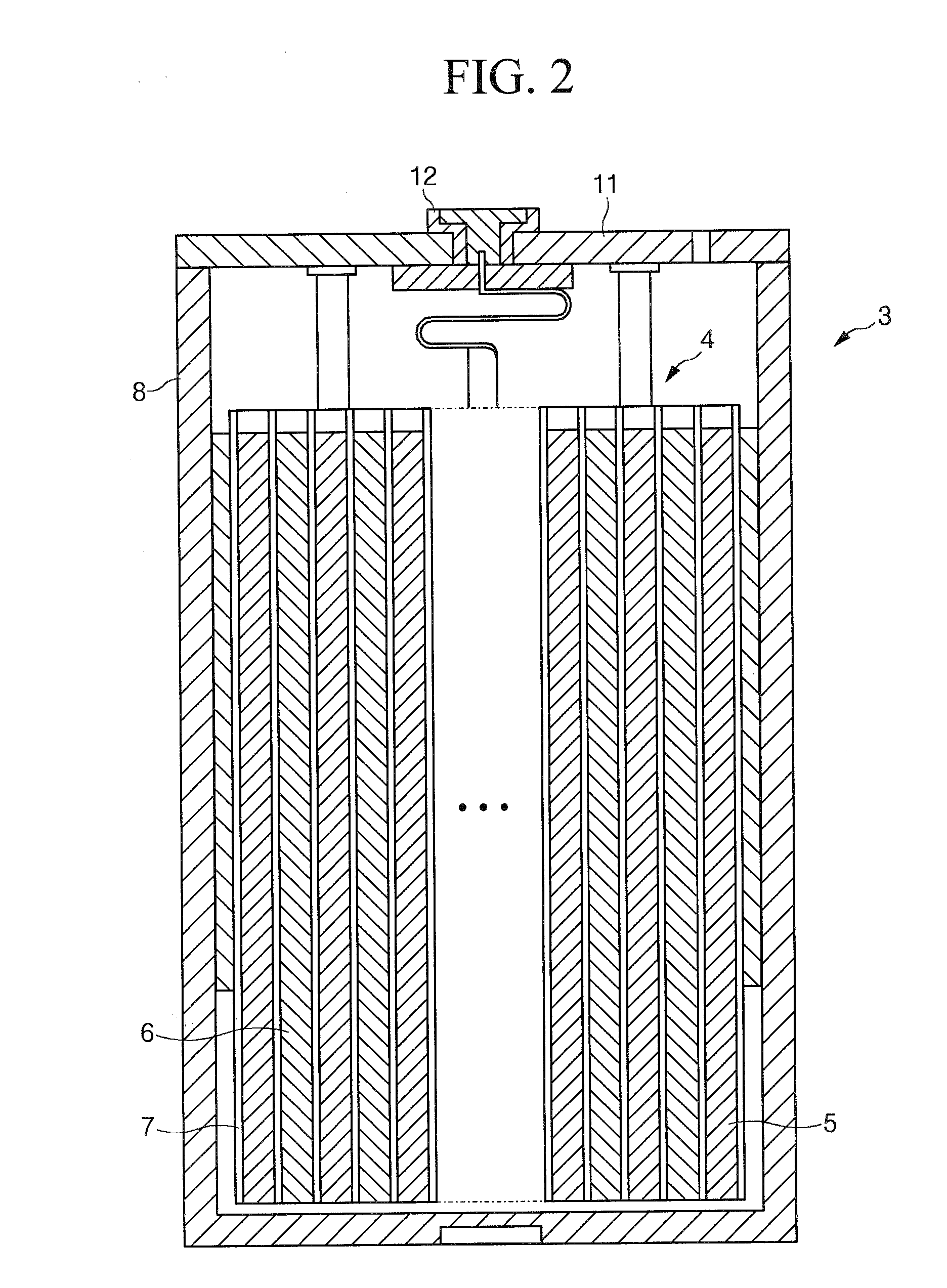

Separator for non-aqueous rechargeable lithium battery

ActiveCN101459232ARapid contractionNot easy to deteriorateSecondary cellsCell component detailsNitratePhosphate

A separator for non-aqueous rechargeable lithium batteries and a non-aqueous rechargeable lithium battery including the separator are provided. The separator includes a separator body and a composite including an organic compound and an inorganic compound supporting the separator body, where the organic compound has a higher melting point than that of the material composing the separator body, and the inorganic compound includes an element selected from the group consisting of 1A, 2A, 3A, 4A, 3B, and 5B elements from the periodic table, and combinations thereof, and at least one moiety selected from the group consisting of oxides, hydroxides, carbonates, phosphates, sulfates, nitrates, alkoxides, and combinations thereof.

Owner:SAMSUNG SDI CO LTD

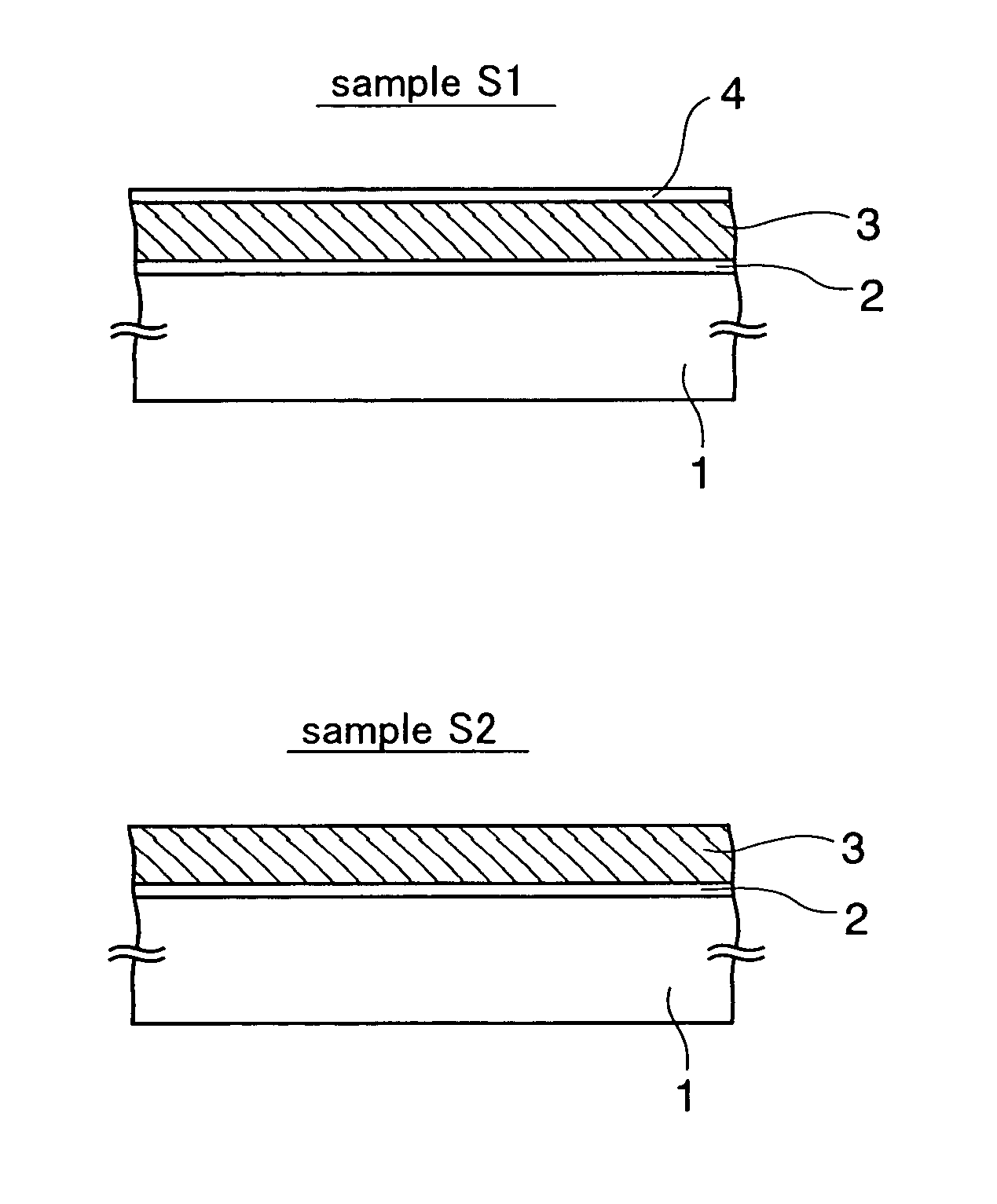

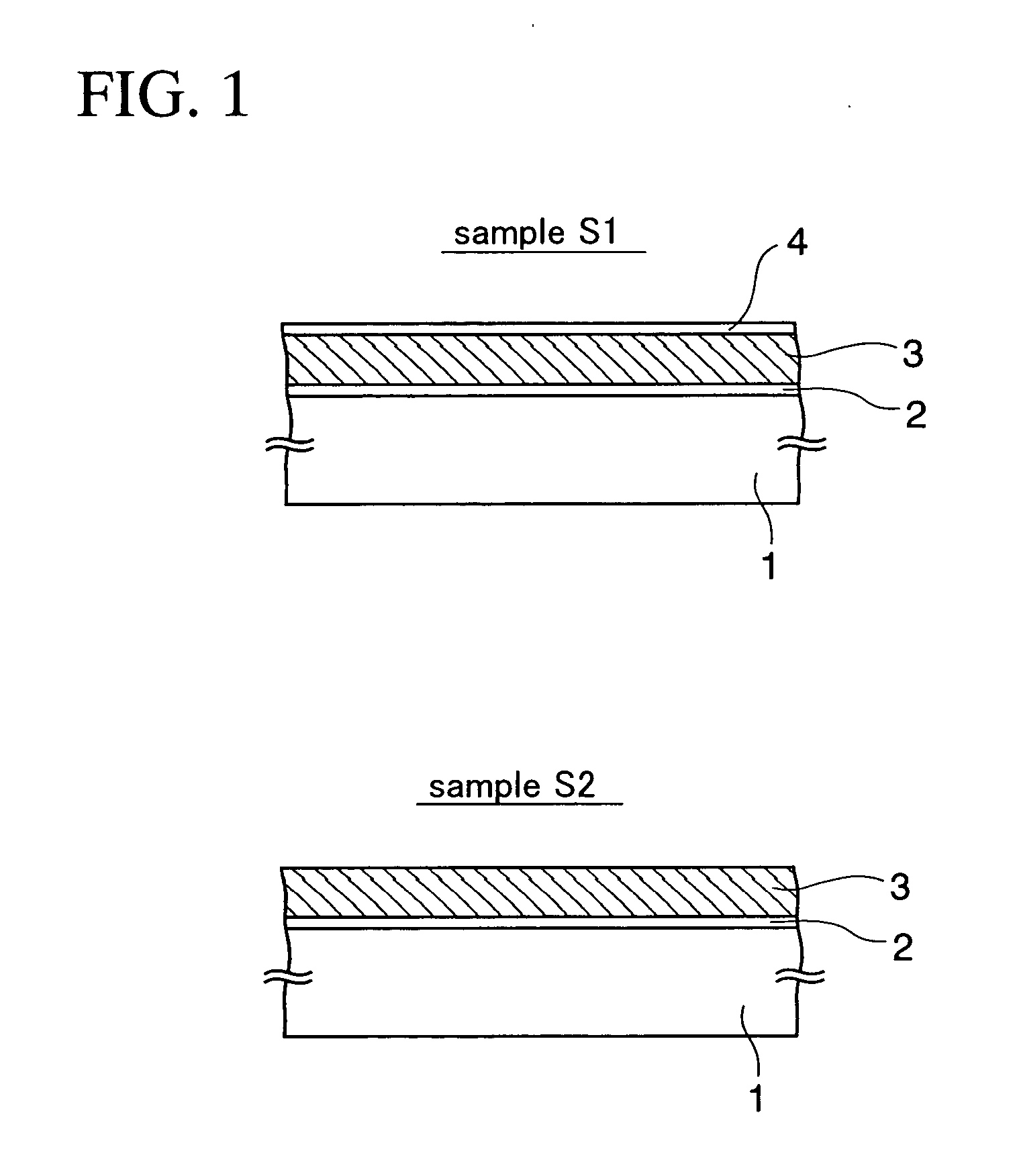

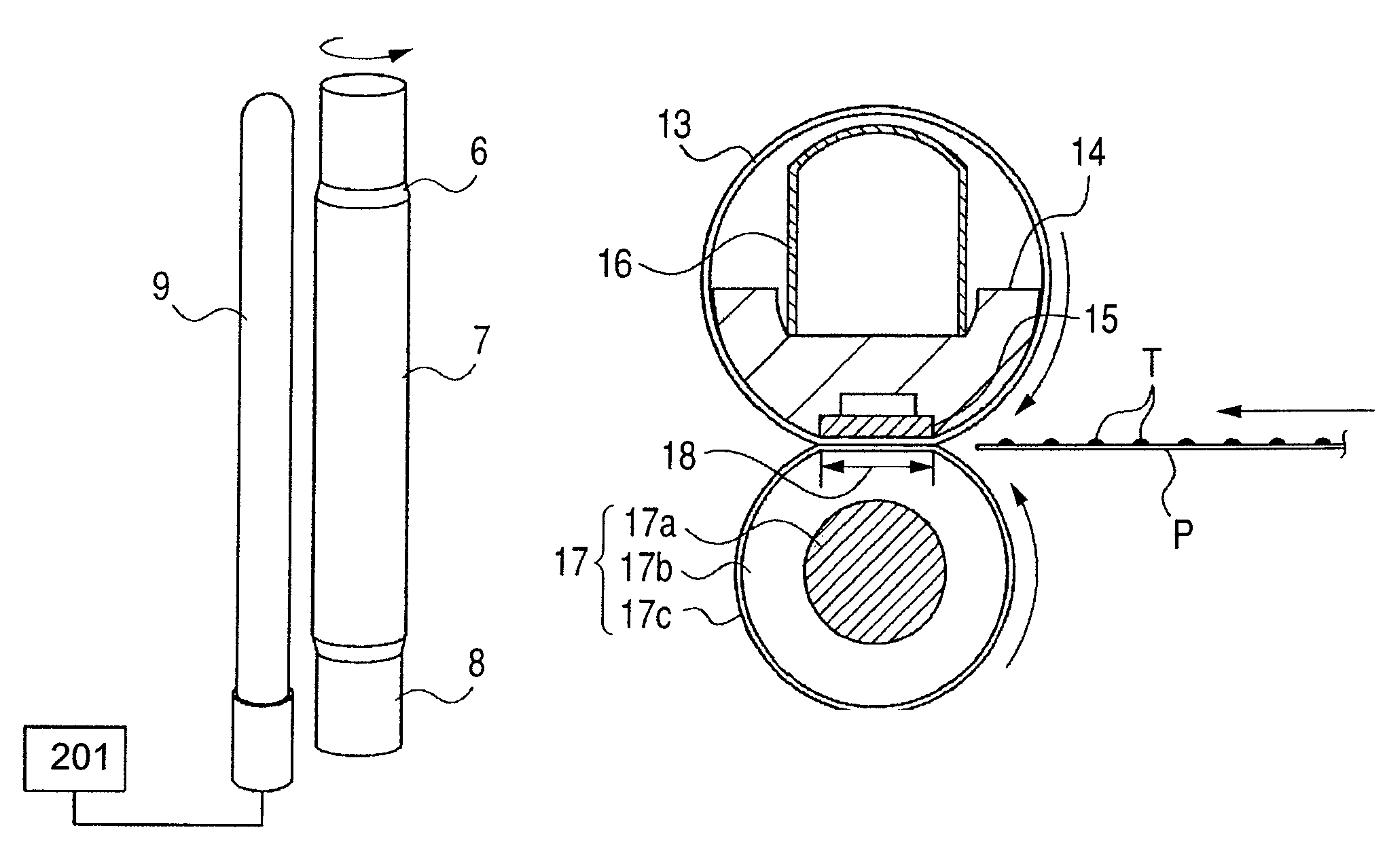

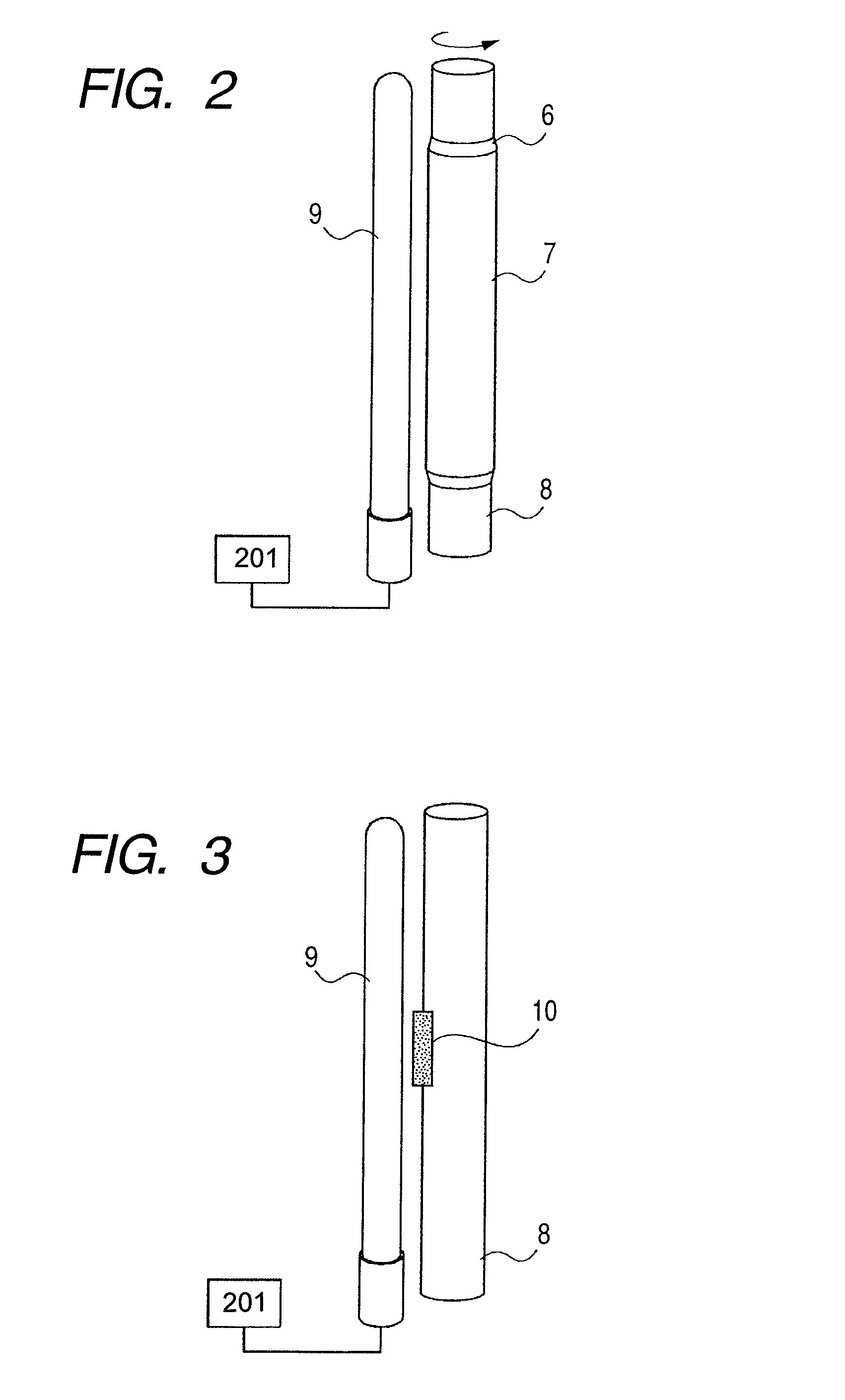

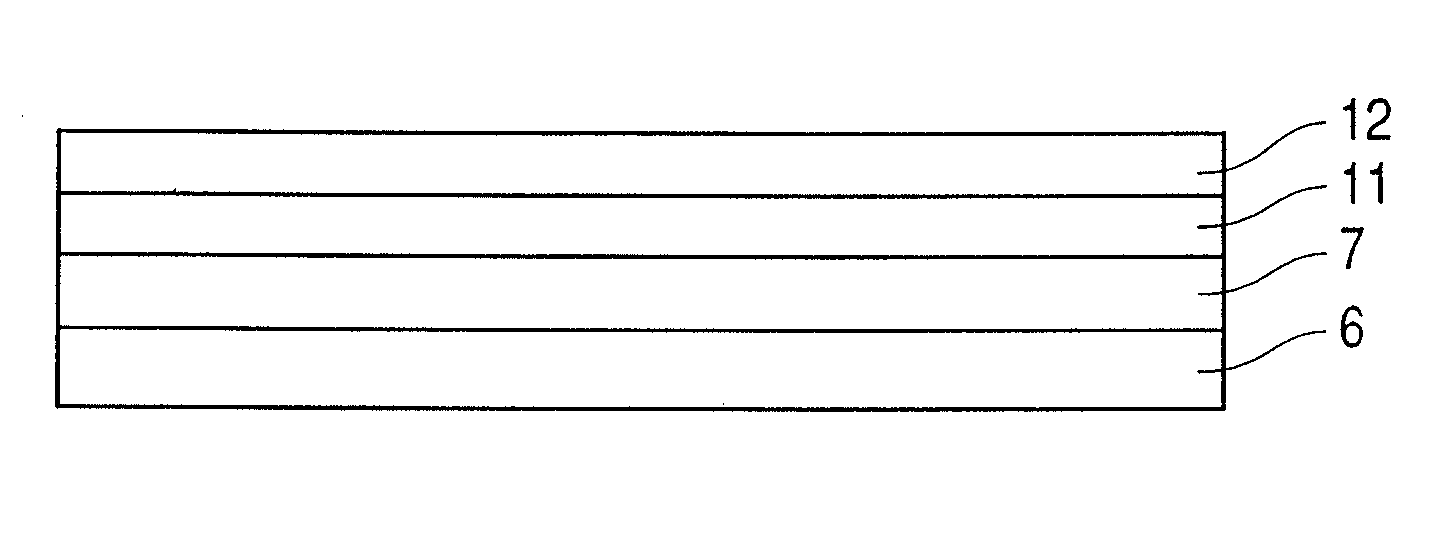

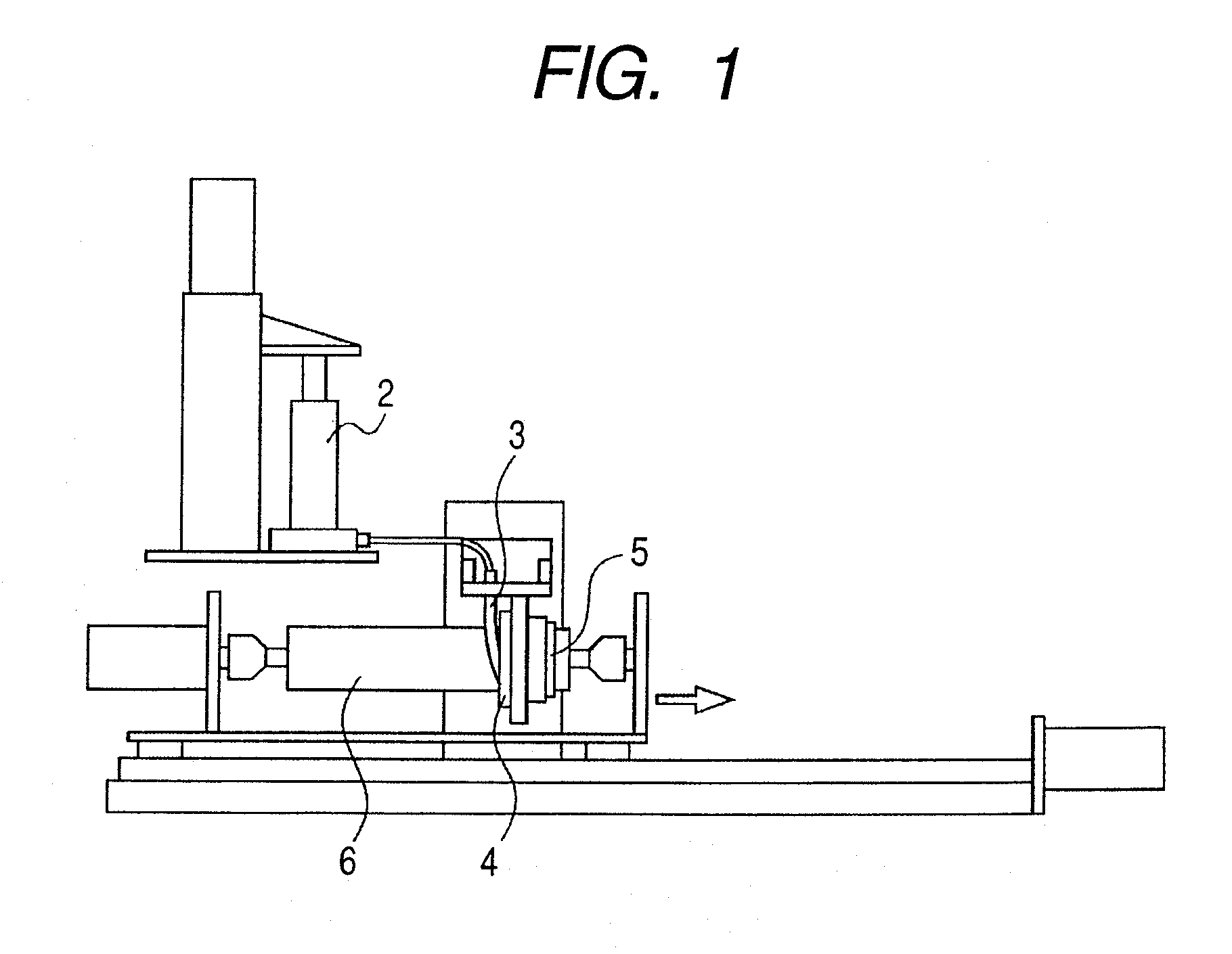

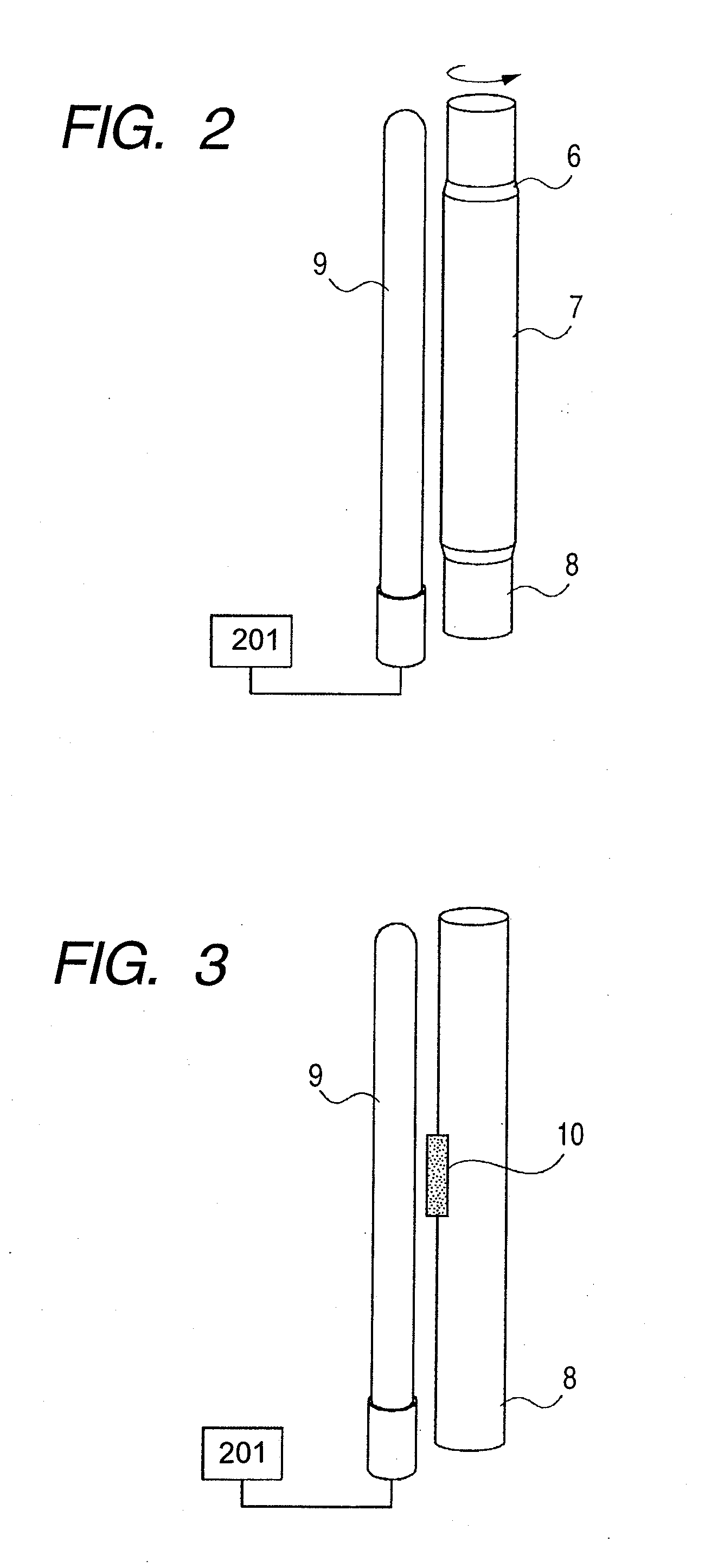

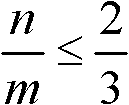

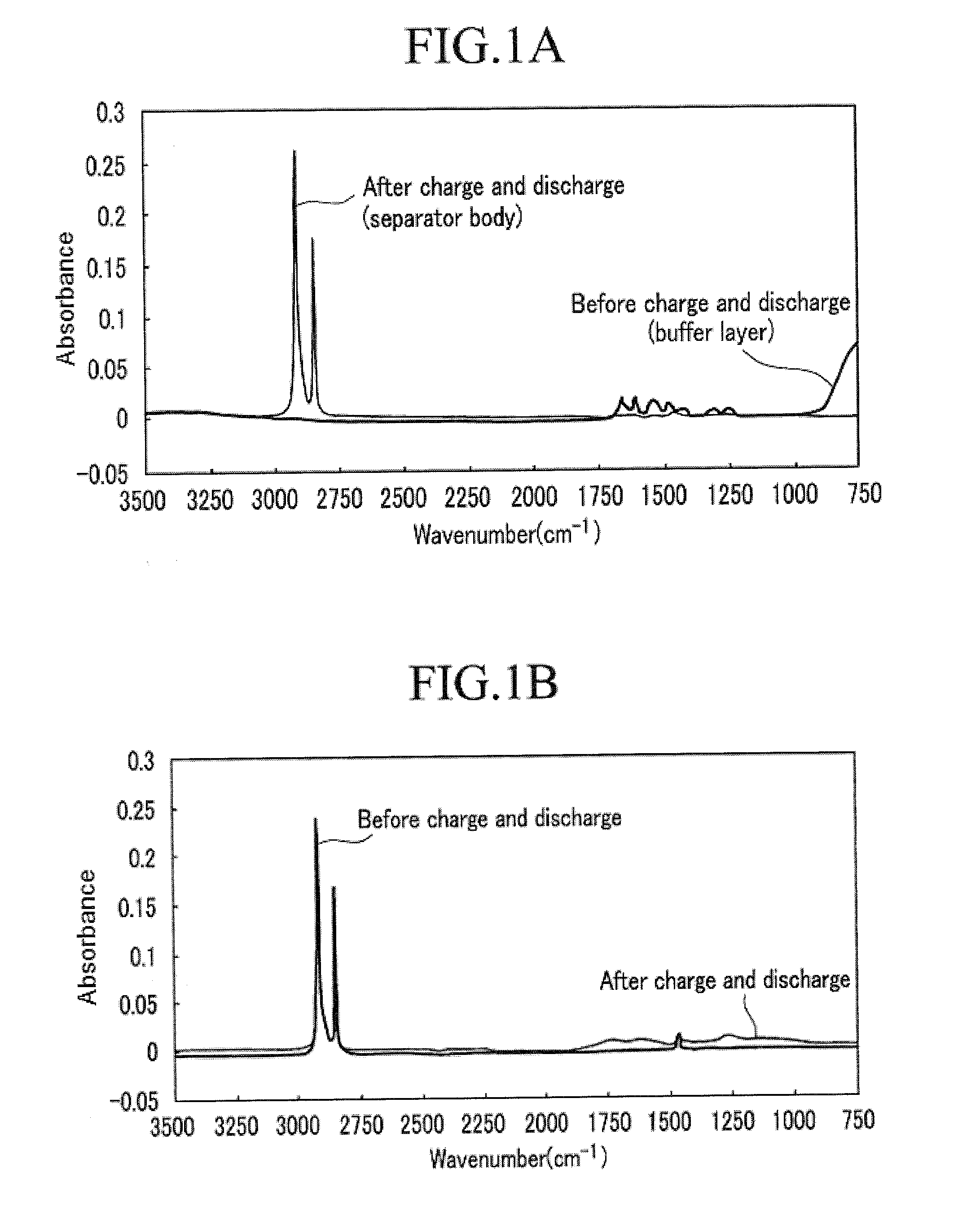

Electrophotographic fixing member and manufacturing method thereof, fixing apparatus, and electrophotographic image forming apparatus

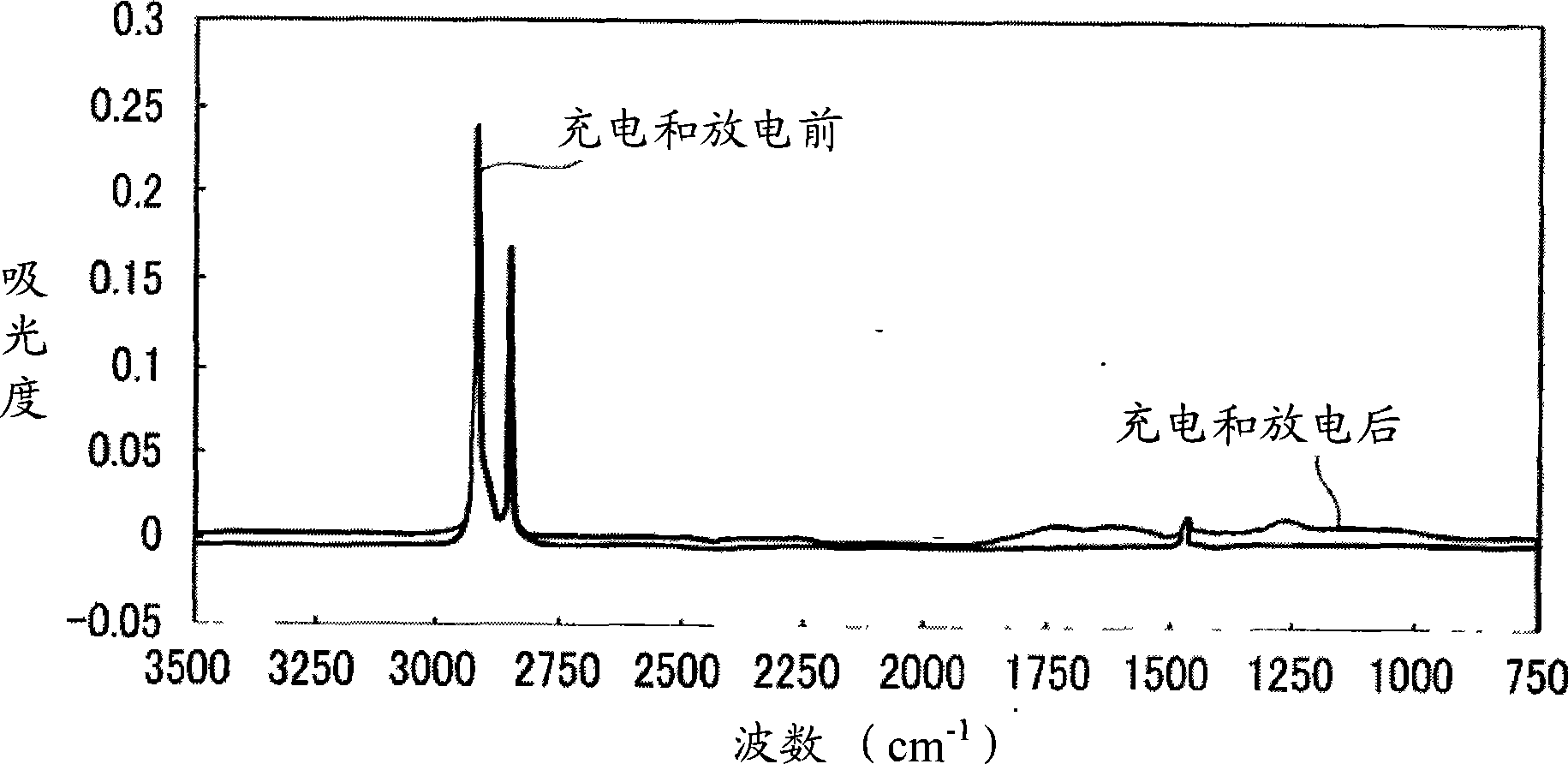

ActiveUS7725068B2Not easy to deteriorateAlleviating an aging of the rubberShaft and bearingsPortable power-driven toolsRubber elasticityAdhesive

An electrophotographic fixing member is provided, which is excellent in toner releasability and hard to change in rubber elasticity of a silicone rubber elastic layer. The fixing member is laminated with a substrate, a cured silicone rubber layer, a cured silicone rubber adhesive layer and a fluorine resin layer, wherein when infrared light absorption strength ratios (1020 cm−1 / 1260 cm−1) at 1020 cm−1 and 1260 cm−1 determined by sampling the portions of 5 μm and 20 μm from the outer surface of the cured silicone rubber layer are taken as α(5) and α(20), respectively, a relationship of α(5) and α(20) satisfies1.03≦α(5) / α(20)≦1.30and α(20) is 0.8 or more and 1.2 or less.

Owner:CANON KK

Electrophotographic fixing member and manufacturing method thereof, fixing apparatus, and electrophotographic image forming apparatus

ActiveUS20080199233A1Not easy to deteriorateAlleviating an aging of the rubberShaft and bearingsPortable power-driven toolsAdhesiveRubber elasticity

An electrophotographic fixing member is provided, which is excellent in toner releasability and hard to change in rubber elasticity of a silicone rubber elastic layer. The fixing member is laminated with a substrate, a cured silicone rubber layer, a cured silicone rubber adhesive layer and a fluorine resin layer, wherein when infrared light absorption strength ratios (1020 cm−1 / 1260 cm−1) at 1020 cm−1 and 1260 cm−1 determined by sampling the portions of 5 μm and 20 μm from the outer surface of the cured silicone rubber layer are taken as α(5) and α(20), respectively, a relationship of α(5) and α(20) satisfies1.03≦α(5) / α(20)≦1.30and α(20) is 0.8 or more and 1.2 or less.

Owner:CANON KK

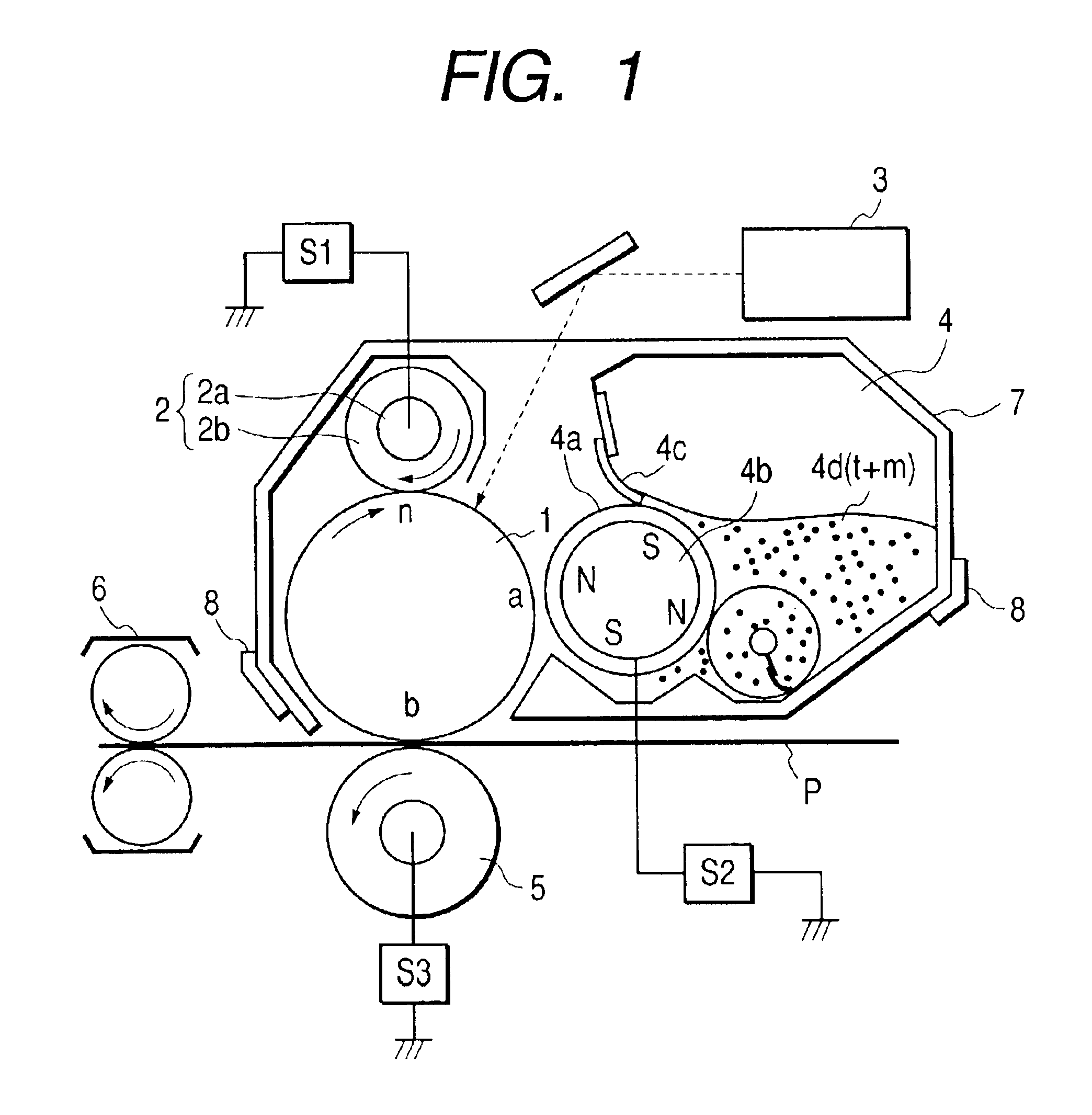

Resin-filled ferrite carrier for electrophotographic developer and electrophotographic developer using the ferrite carrier

A resin-filled ferrite carrier for an electrophotographic developer obtained by filling voids of a porous ferrite core material with a resin, wherein the resin is a silicone resin having a phenyl group, and an electrophotographic developer using this ferrite carrier.

Owner:POWDERTECH

Aromatic amine derivative and organic electroluminescent device using the same

ActiveUS8518560B2High luminous efficiencyNot easy to deteriorateSilicon organic compoundsDischarge tube luminescnet screensBenzeneDibenzofuran

Provided are: an aromatic amine derivative in which a terminal substituent such as a dibenzofuran ring or a dibenzothiophene ring is bonded to a nitrogen atom directly or through an arylene group or the like; an organic electroluminescence device including an organic thin film layer formed of one or more layers including a light emitting layer and interposed between a cathode and an anode in which a layer of the organic thin film layer contains the aromatic amine derivative by itself or as a component of a mixture, and the device has a long lifetime and high luminous efficiency; and an aromatic amine derivative for realizing the device.

Owner:IDEMITSU KOSAN CO LTD

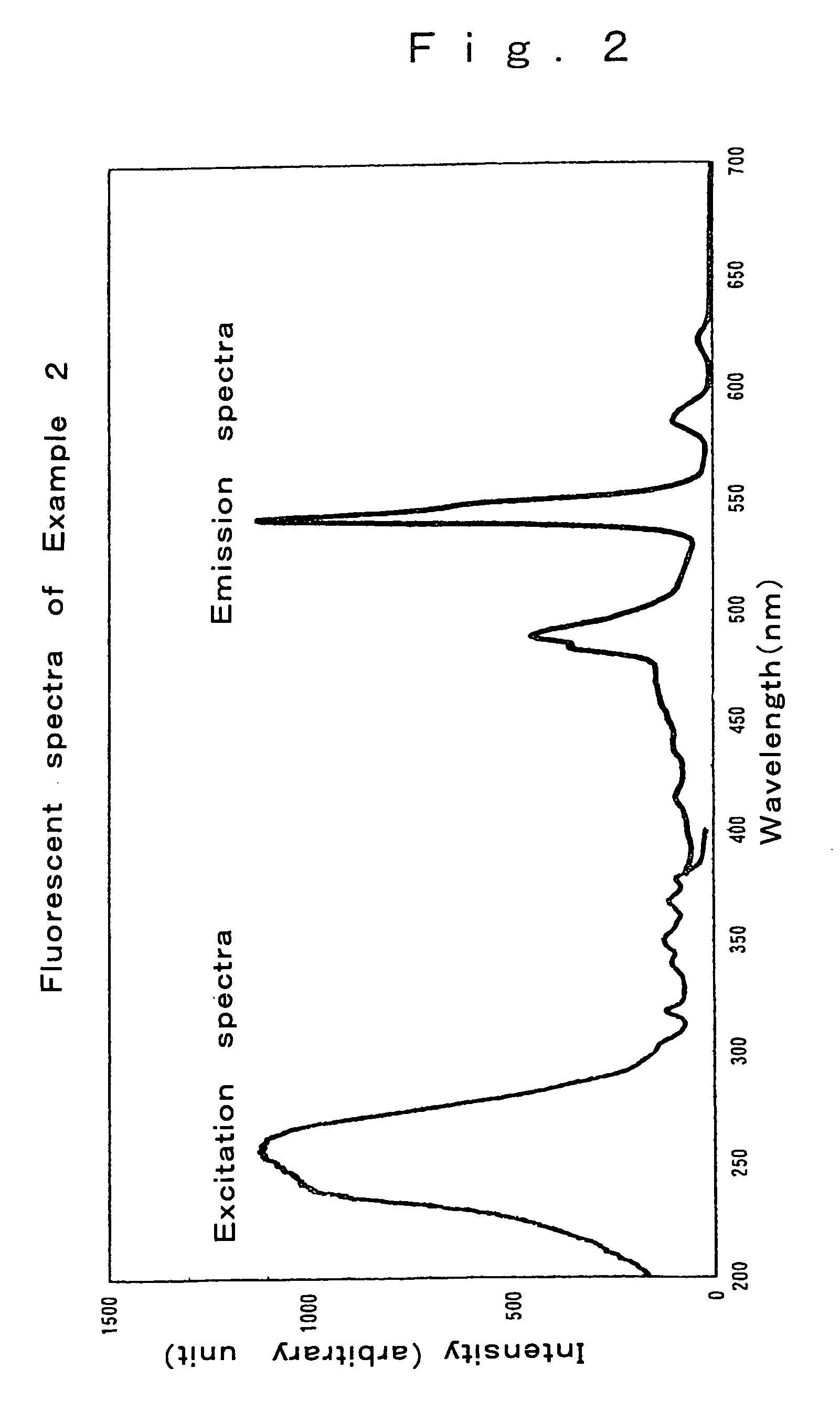

Oxynitride fluorescent material and light-emitting device

ActiveUS7470378B2Not easy to deteriorateIncrease brightnessIncadescent screens/filtersDischarge tube luminescnet screensFluorescenceRare earth ions

Sialon fluorescent materials with activated Eu or other rare earth ions have been known as fluorescent materials capable of being excited by blue light to emit yellow light. An oxynitride fluorescent material can emit light having a far wider range of wavelengths than ever before, and can be included in a light-emitting device. A fluorescent material contains as a main component a crystal phase having a general formula La3Si8N11O4 or La3Si8−xAlxN11−xO4+x where 0<x≦4, to which an optically active element (M) including one or more elements selected from Mn, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu is added and contained as a luminescence center component.

Owner:NAT INST FOR MATERIALS SCI

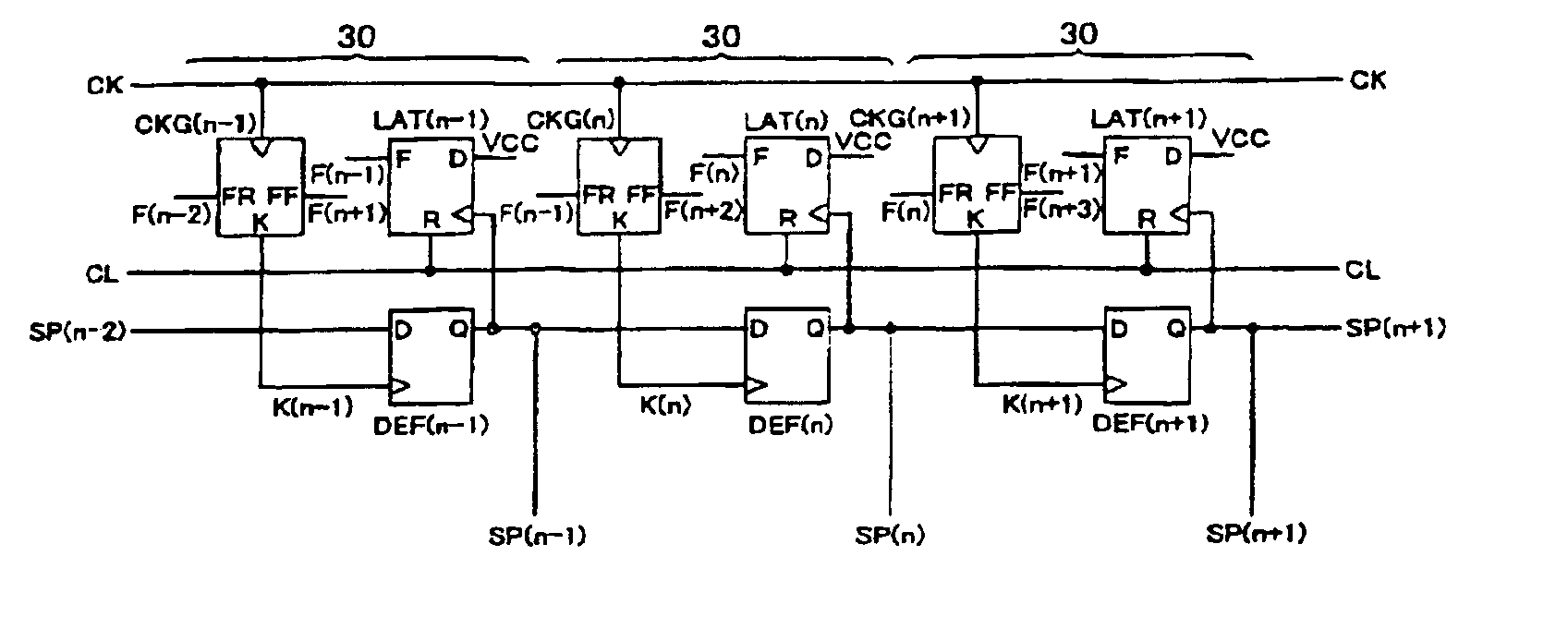

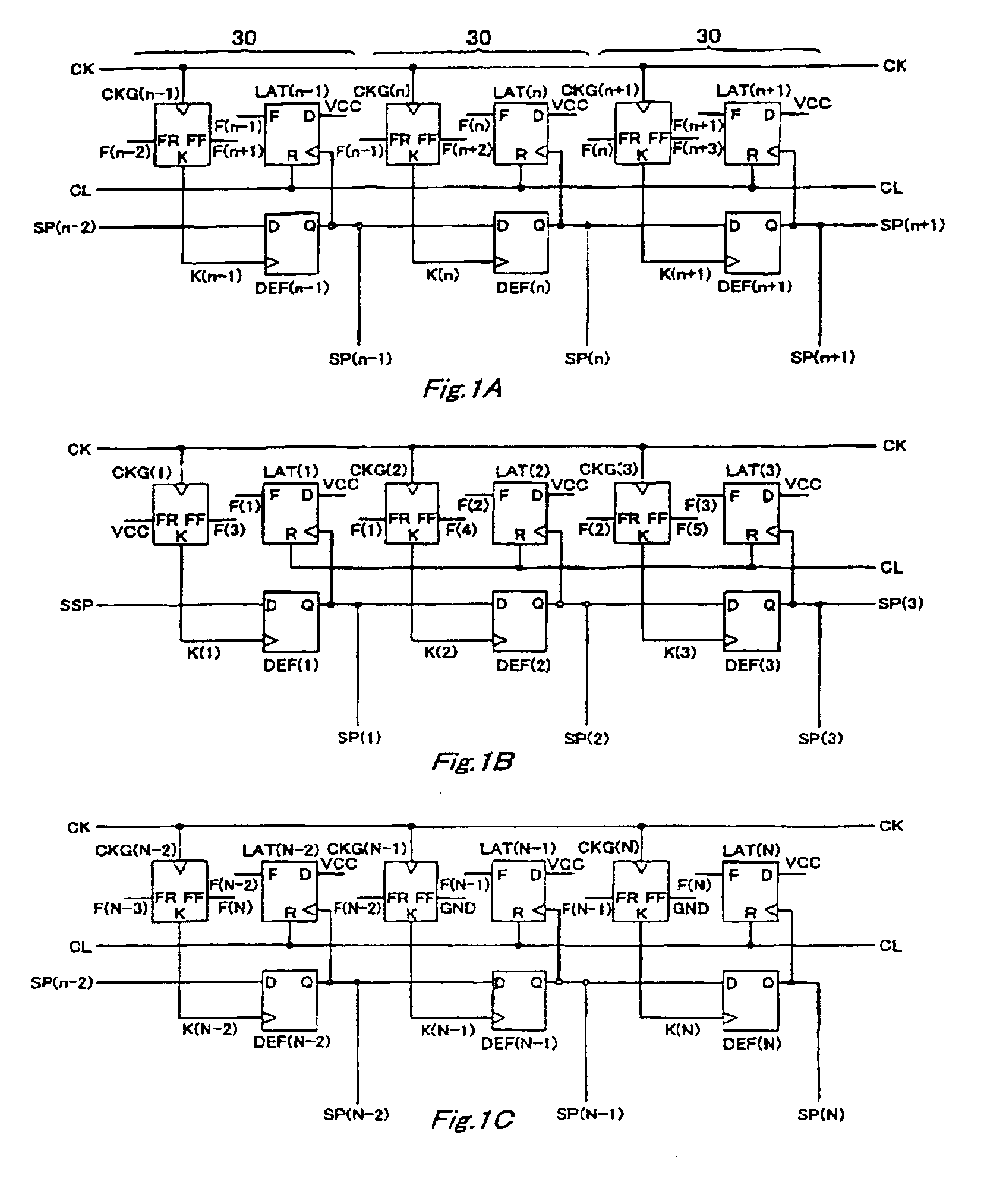

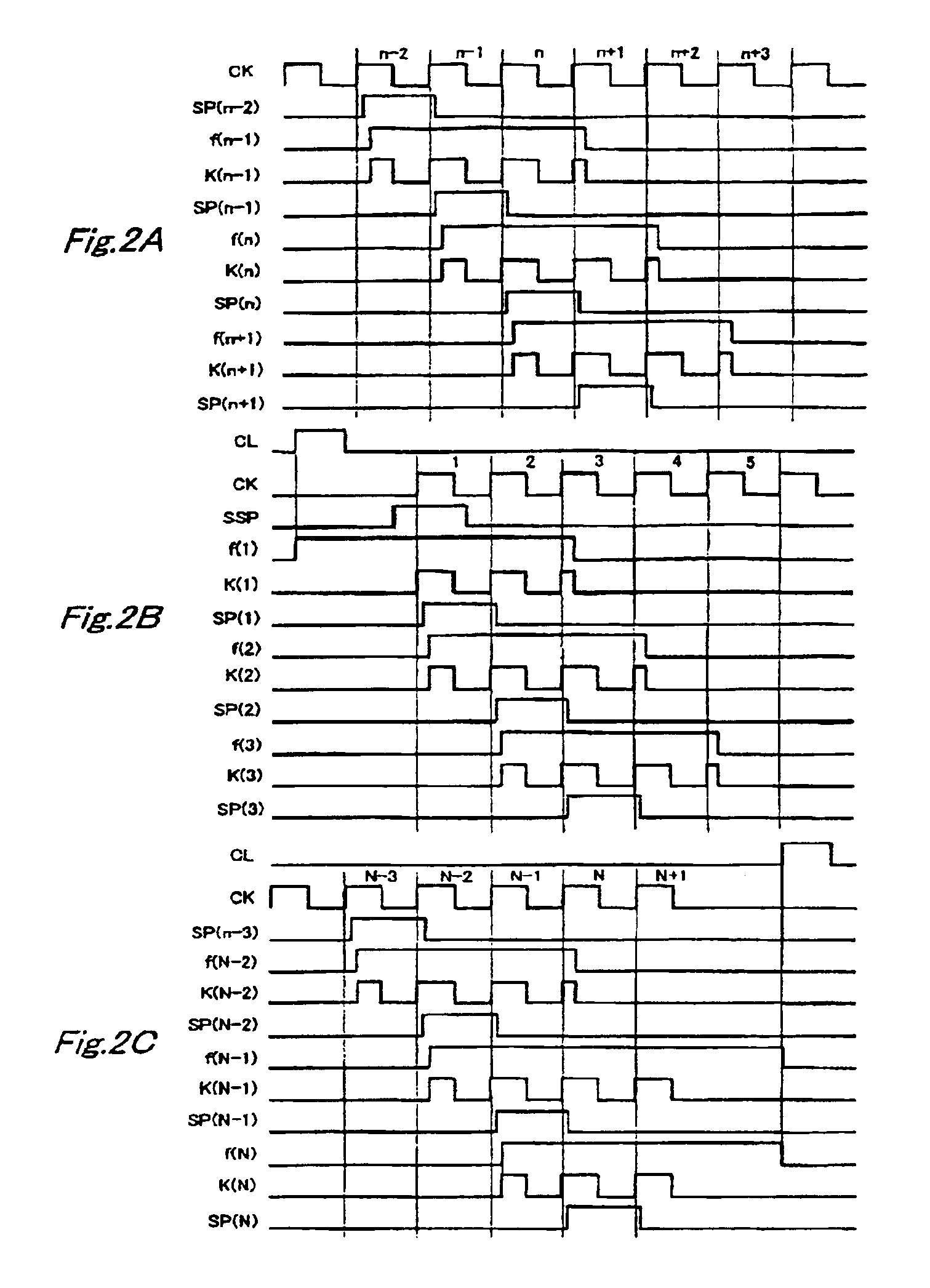

Shift register, display apparatus and information display apparatus

InactiveUS6914956B2Reduce power consumptionReduce in quantityStatic indicating devicesSolid-state devicesShift registerEngineering

A shift register includes a plurality of pulse generation portions for generating a series of pulse signals in response to a level change of inputted clock signals, and a plurality of shift pulse generation units. The plurality of shift pulse generation units has a predetermined shift pulse generation unit, with the predetermined shift pulse generation unit having a status signal generation circuit for outputting a first status signal to common wiring to which both of an earlier shift pulse generation unit and a later shift pulse generation unit are connected, and a clock supply circuit for supplying a clock signal to the pulse generation portion which belongs to the predetermined shift pulse generation unit. In addition, there is a first period in which the clock supply circuit supplies the clock signal to the pulse generation portion which belongs to the predetermined shift pulse generation unit and a second period in which the clock signal is not supplied. During the first period in which the clock signal is supplied, a status signal is inputted from the earlier shift pulse generation unit, and a status signal is not inputted from the later shift pulse generation unit.

Owner:CANON KK

Resin Composition And Use Thereof

InactiveUS20080304393A1Low birefringenceMoldability lowRecord information storageOptical beam guiding meansForeign matterOptical pickup

Provided is a resin composition suitable for an optical element in which the moldability, thermal resistance, mechanical strength, and low birefringence are not impaired, the deterioration is hardly generated although the laser light nearby the UV is used, change in the optical properties during the use are extremely small, particularly the light transmittance is maintained high, and a foreign substance is hardly deposited on a surface of the molded product such as an optical element, also provided is an optical element obtained by molding the resin composition, and an optical pickup device using the optical element. The thermoplastic resin composition contains the polymer having a specific structure and two kinds of specific optical stabilizers in a specific mass ratio among a hindered amine light stabilizer having the molecular weight of 400 to 5,000; the optical element is obtained by molding the thermoplastic resin composition; and the optical pickup device includes the optical element.

Owner:MITSUI CHEM INC

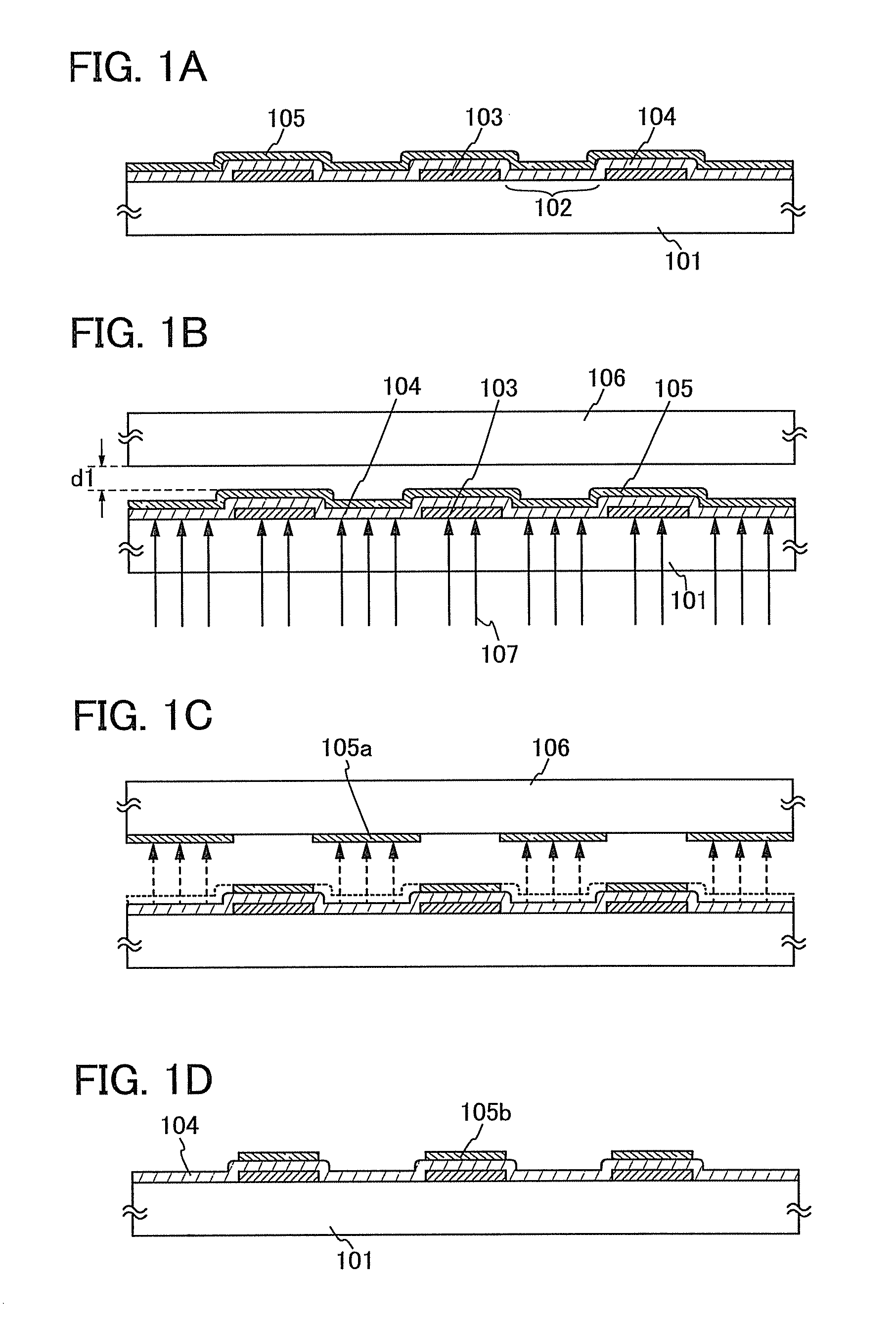

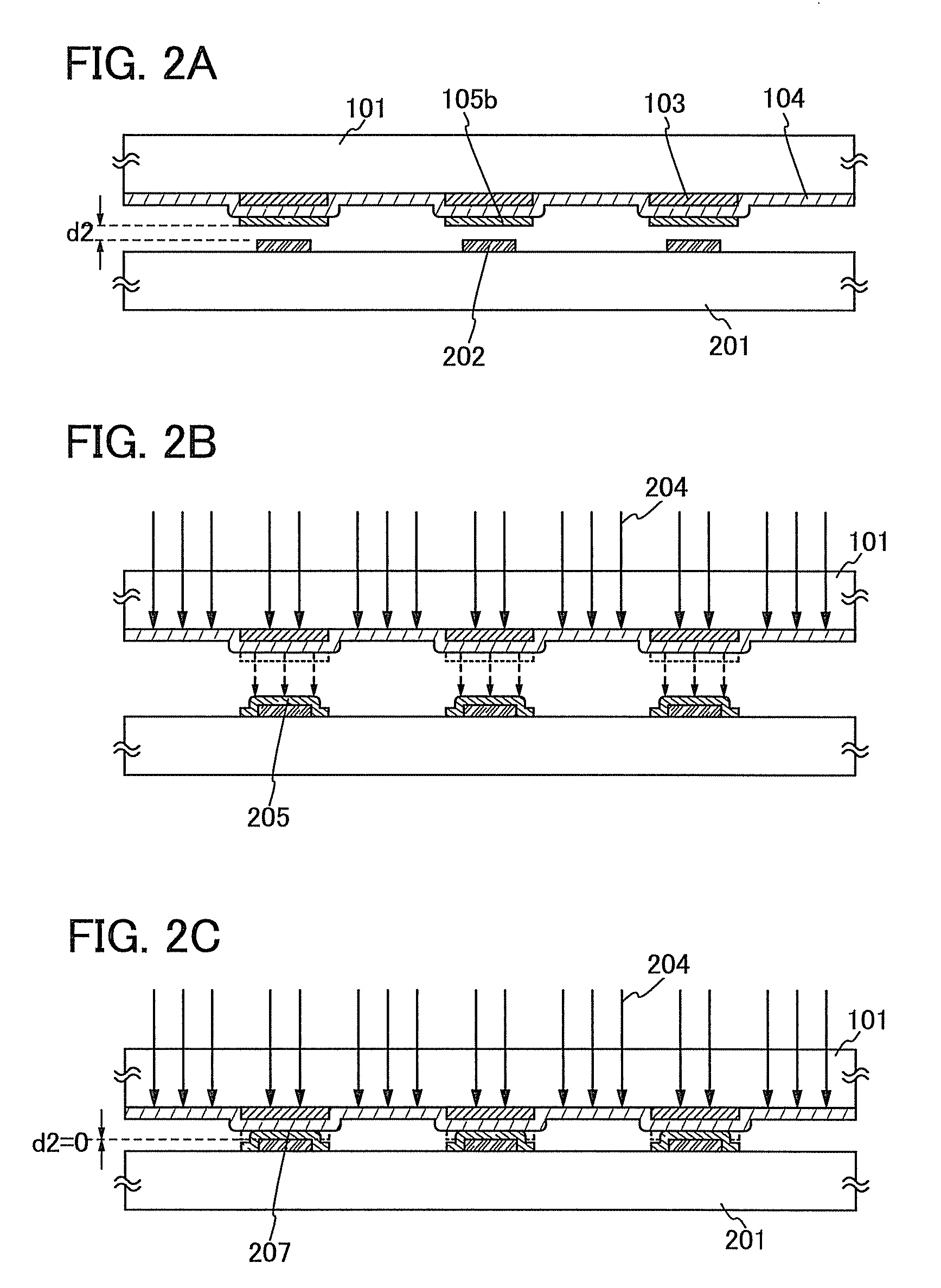

Method for manufacturing light-emitting device

InactiveUS7993945B2High definitionLong lastingElectroluminescent light sourcesSolid-state devicesEvaporationOptoelectronics

An object is to provide a method for manufacturing a light-emitting device with high definition, high light-emitting characteristics, and the long lifetime by employing a method in which a desired evaporation pattern can be formed and an excess evaporation of a material layer which is to be the transfer layer is prevented and in which deterioration of the material or the like is hard to occur in a transfer step. This is a method for manufacturing a light-emitting device, in which irradiation with first light is performed to pattern a material layer over a first substrate which is an evaporation donor substrate and irradiation with second light is performed to evaporate the material layer patterned onto a second substrate which is a deposition target substrate.

Owner:SEMICON ENERGY LAB CO LTD

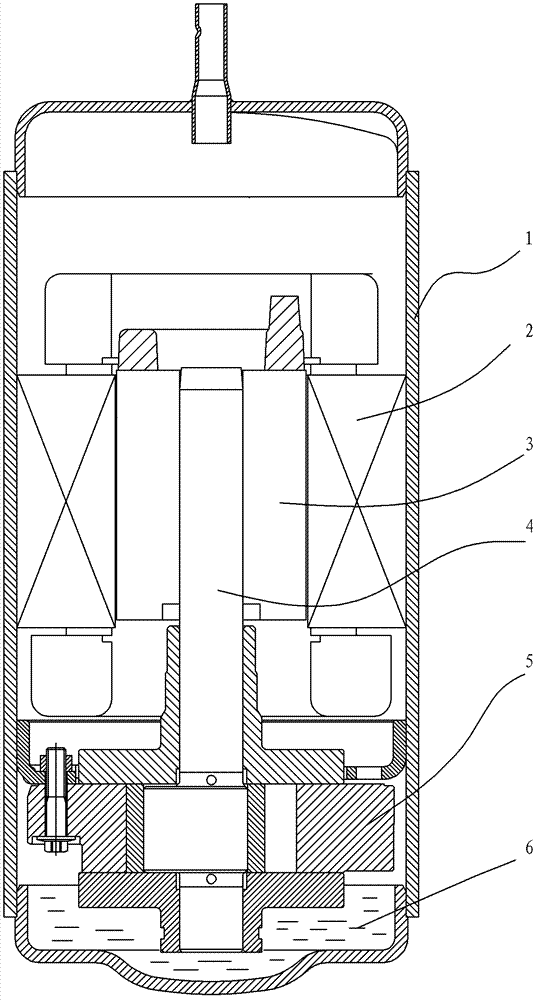

Compressor

InactiveCN103089570AReduce solubilityLess encapsulationPositive displacement pump componentsAdditivesSolubilityPulp and paper industry

Disclosed is a compressor. A motor is contained in a closed shell. A compression mechanism for compressing refrigerant is connected with the motor through a rotary shaft. The compressor is provided with refrigerating machine oil. The refrigerant is hydrocarbon refrigerant. Base oil of the refrigerating machine oil is made of polyalkane propylene and meets the requirements of a general formula a as followed. More than one of antioxidant, acid catcher, defoamer and squeeze antiwear agent is added into the refrigerating machine oil. The refrigerating machine oil and the hydrocarbon refrigerant are low in solubility. System performance and compressor reliability are both stable when coolant sealing amount is low.

Owner:GUANGDONG MEIZHI COMPRESSOR

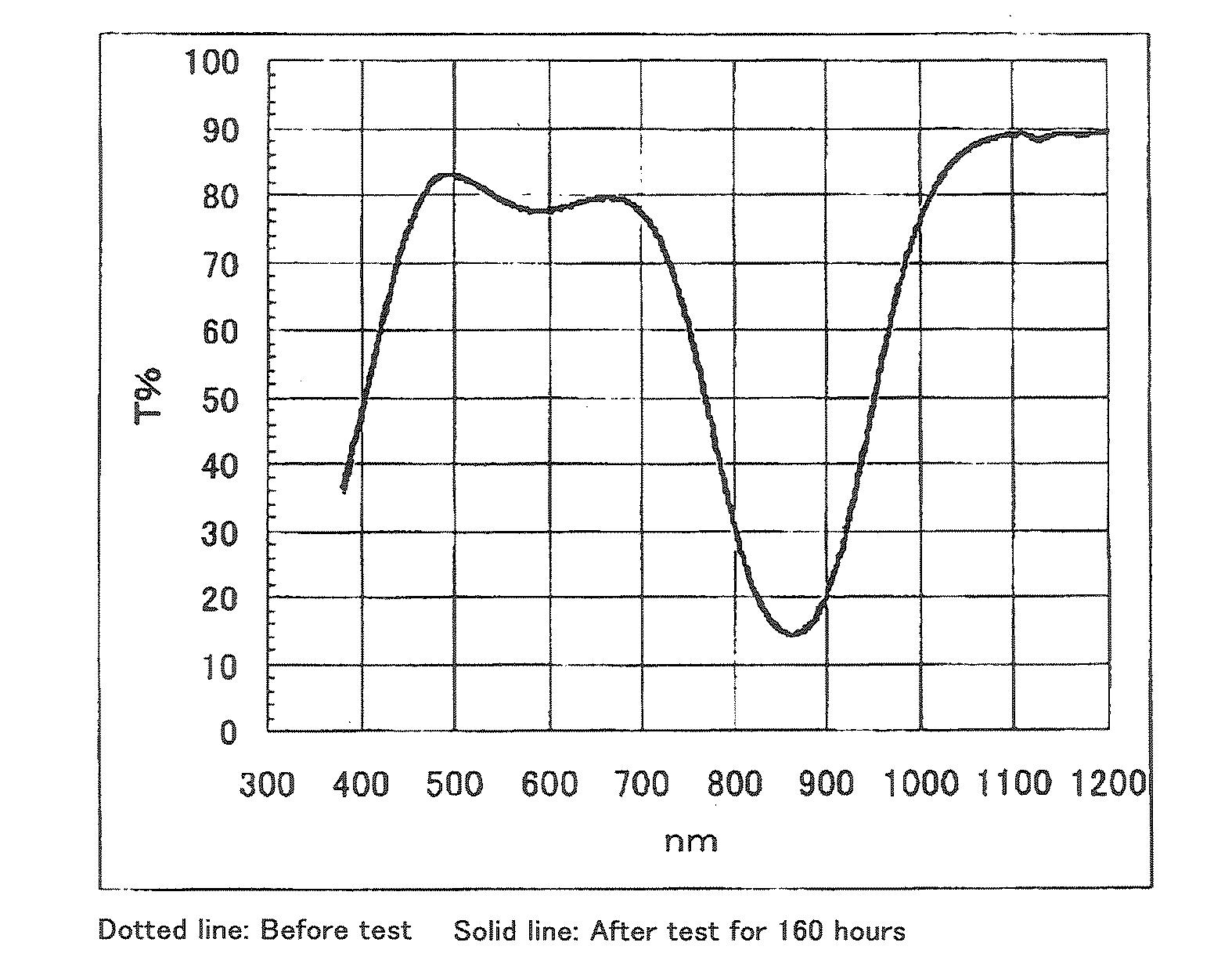

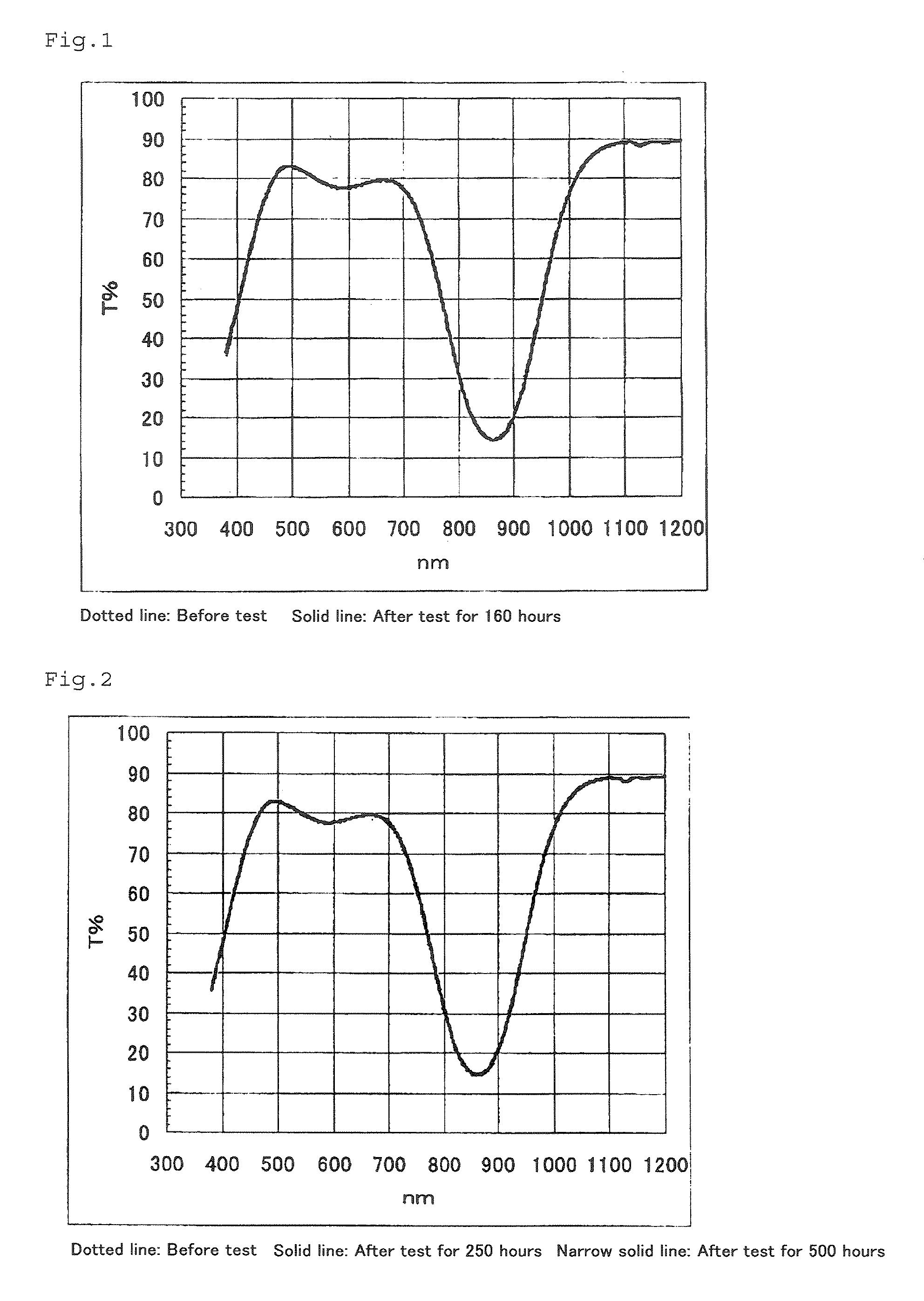

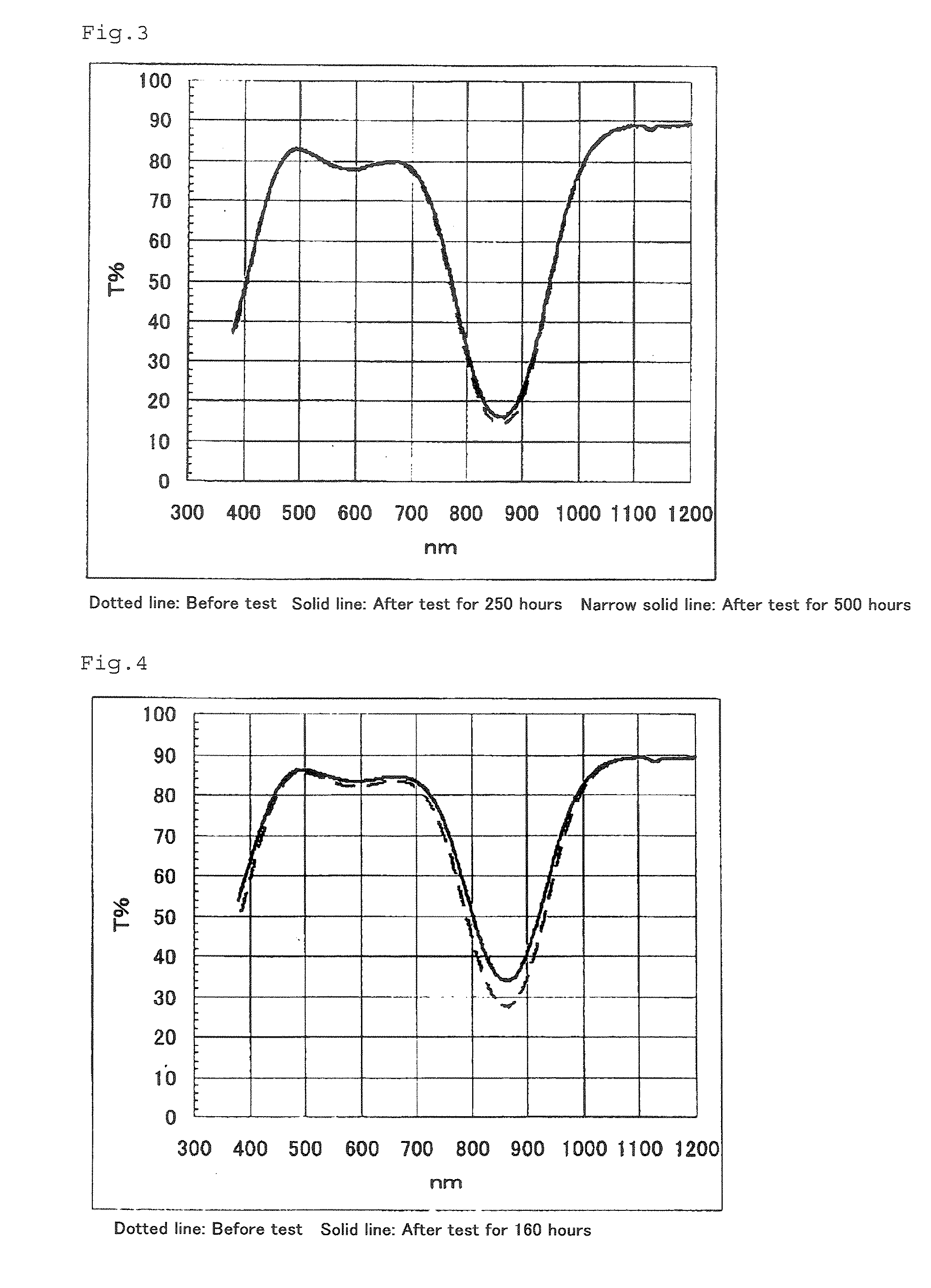

Pressure-sensitive adhesive containing near infrared absorbing coloring matter

InactiveUS20090029135A1Not easy to deteriorateGood light fastnessSilicon organic compoundsNon-macromolecular adhesive additivesInfraredNear infrared absorption

A pressure-sensitive adhesive containing a near infrared absorbing dye having excellent shielding function for near infrared rays and excellent in durability is provided.A pressure-sensitive adhesive containing a near infrared absorbing dye, wherein the layer of the pressure-sensitive adhesive has a thickness of 25±5 μm and absorption intensity at the maximum absorption wavelength of the near infrared absorbing dye after light resistance test is 50% or more for absorption intensity before the test in the light resistance test in which light with an irradiance of 64.5 W / m2 at a wavelength of 300 to 400 nm is irradiated for the layer for 160 hours.

Owner:API CORP (JP)

Separator for non-aqueous rechargeable lithium battery

ActiveUS20090155677A1Not easy to deteriorateReduce and preventCell seperators/membranes/diaphragms/spacersLi-accumulatorsPhosphateOxide

A separator for non-aqueous rechargeable lithium batteries and a non-aqueous rechargeable lithium battery including the separator are provided. The separator includes a separator body and a composite including an organic compound and an inorganic compound supporting the separator body, where the organic compound has a higher melting point than that of the material composing the separator body, and the inorganic compound includes an element selected from the group consisting of 1A, 2A, 3A, 4A, 3B, and 5B elements from the periodic table, and combinations thereof, and at least one moiety selected from the group consisting of oxides, hydroxides, carbonates, phosphates, sulfates, nitrates, alkoxides, and combinations thereof.

Owner:SAMSUNG SDI CO LTD

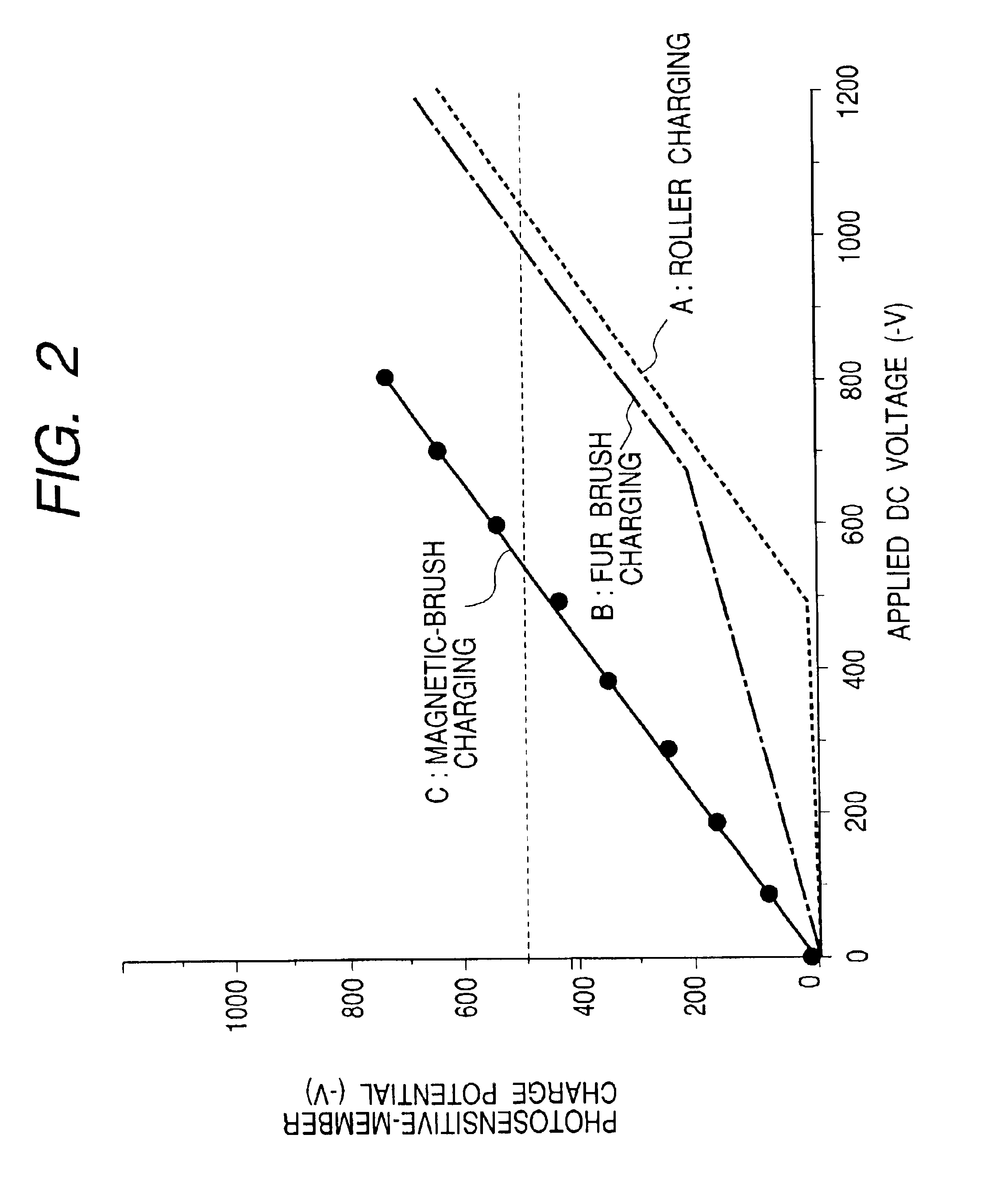

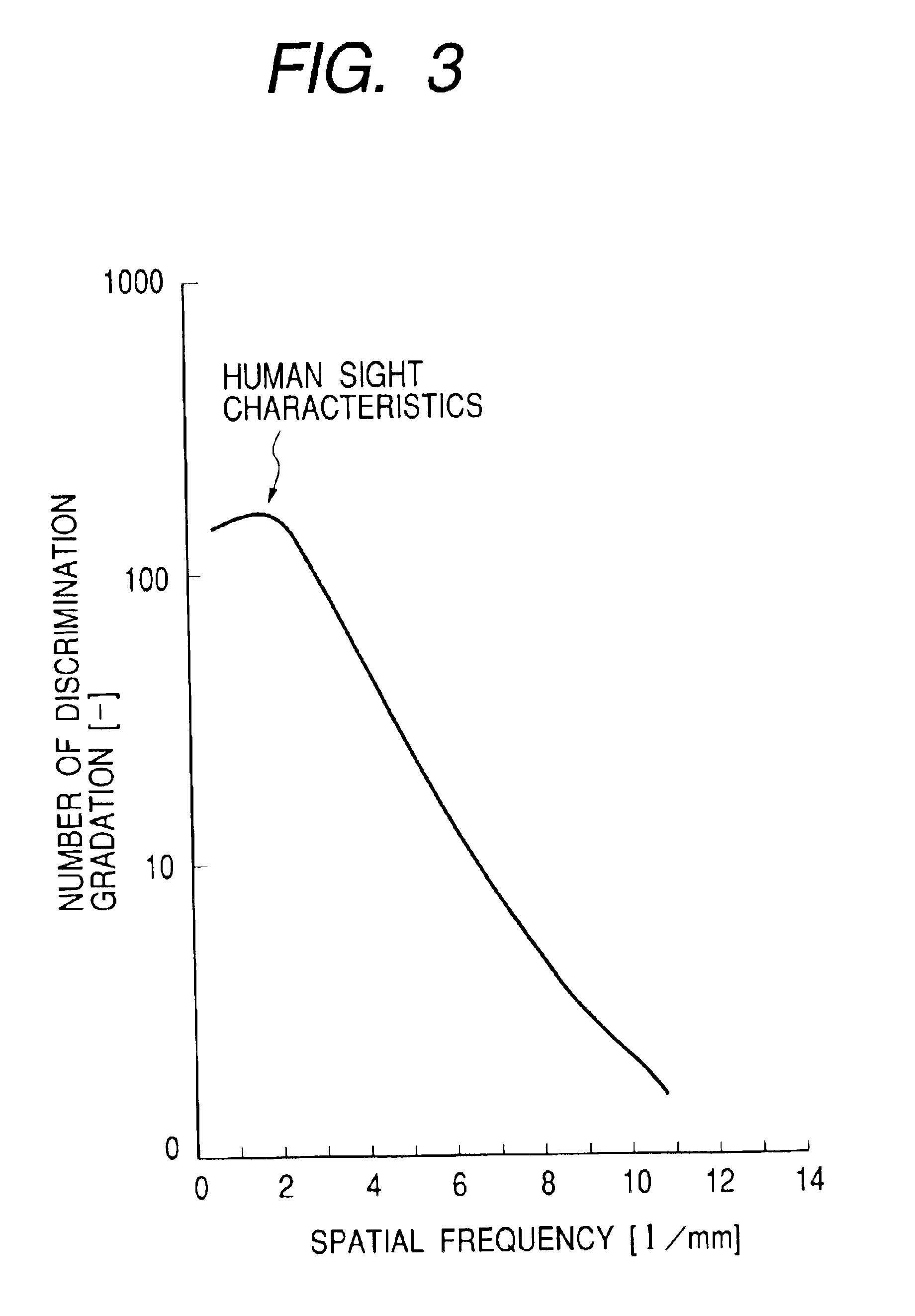

Developing assembly, process cartridge and image-forming method

InactiveUS6924076B2Low apply voltageUniform chargingDevelopersElectrographic process apparatusProjected areaEngineering

In a developing assembly, a process cartridge and an image-forming method, a specific developer and a specific developer-carrying member are used in combination. The developer comprises toner particles containing at least a binder resin and a colorant, and conductive fine particles; the toner particles having a Circularity a of less than 0.970 as found from the following expression:Circularity a=L0 / Lwhere L0 represents the circumferential length of a circle having the same projected area as a particle image, and L represents the circumferential length of a projected image of a particle.The developer-carrying member has at least a substrate and a resin coat layer formed on the substrate; the resin coat layer containing at least a coat layer binder resin and a positively chargeable material.

Owner:CANON KK

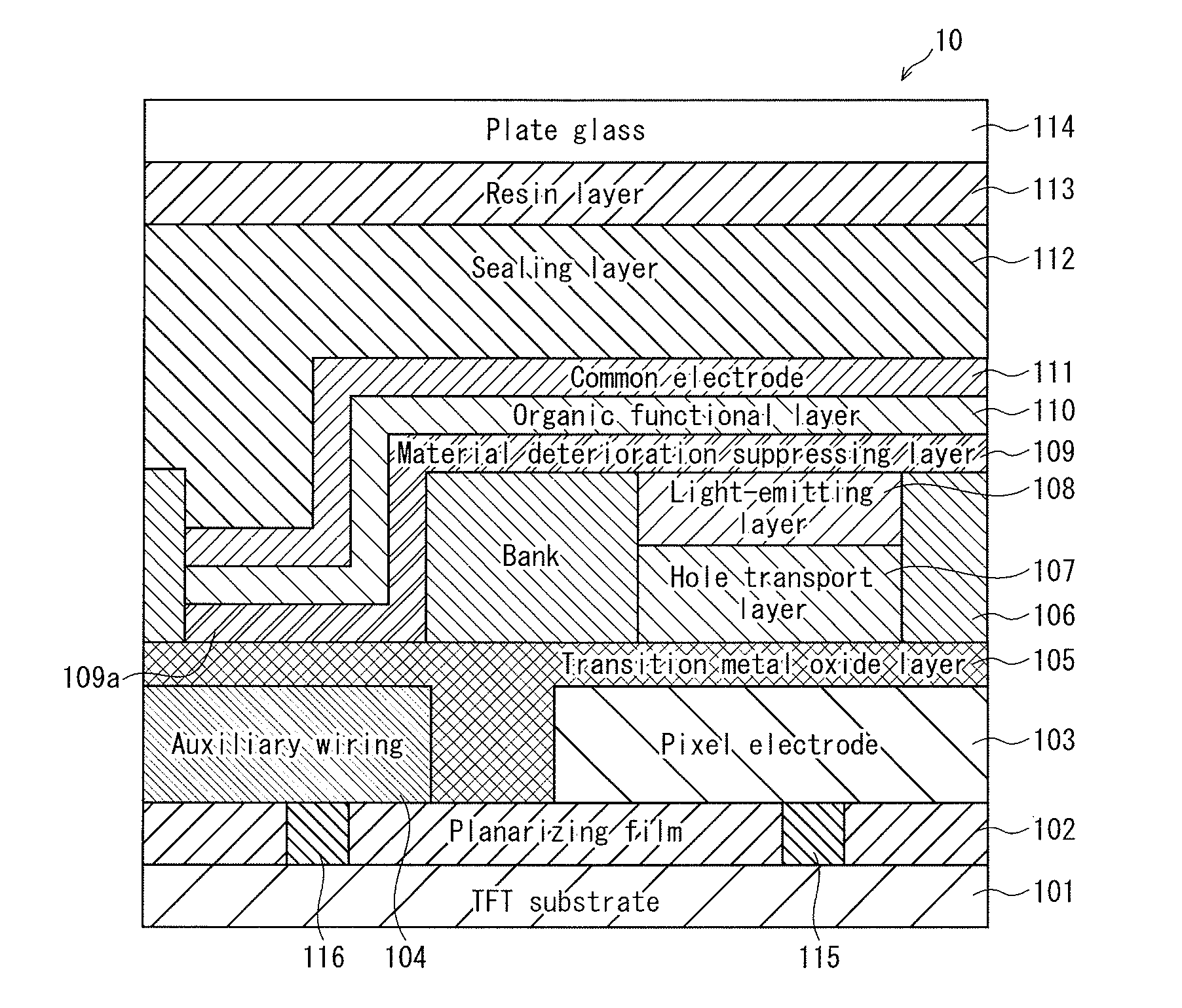

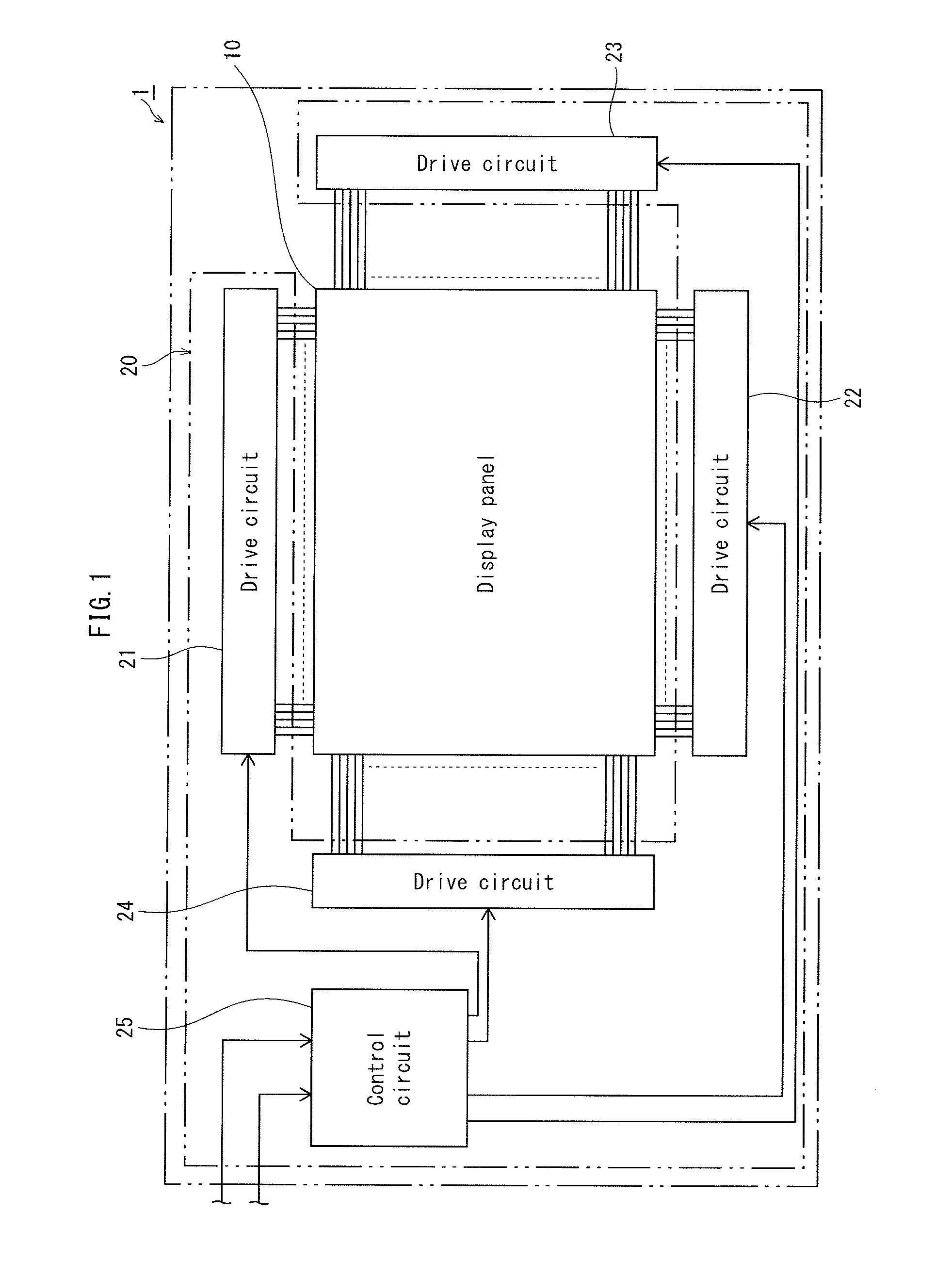

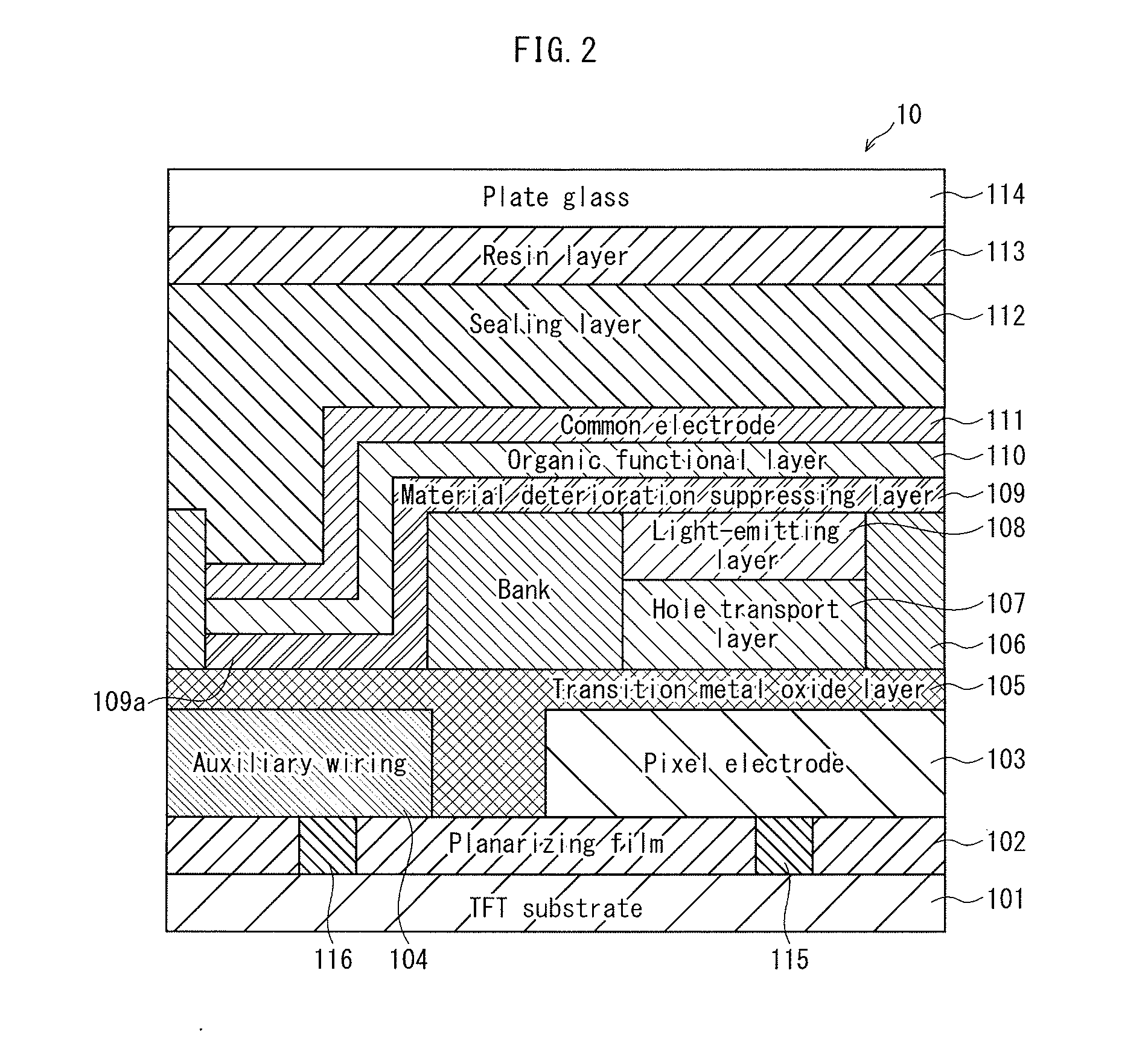

El display device and method for producing same

InactiveUS20140312337A1Easily injected into light-emitting layerLower injection barrierElectroluminescent light sourcesSolid-state devicesPhysical chemistryDisplay device

To provide a device whose life is less likely to be reduced by deterioration of a light-emitting layer material, an EL display device includes: a pixel electrode, for each pixel, above a substrate; auxiliary wiring in a different region, above the substrate, from the pixel electrode; a transition metal oxide layer on the pixel electrode and the auxiliary wiring; a light-emitting layer in a region, above the transition metal oxide layer, corresponding to the pixel; a common electrode continuously above the auxiliary wiring and the light-emitting layer, and electrically connected to the auxiliary wiring; and a material deterioration suppressing layer continuously on a portion of the transition metal oxide layer above the auxiliary wiring and the light-emitting layer, mainly containing barium, and having a thickness equal to or greater than a size of a single barium atom and smaller than 10 nm.

Owner:JOLED INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com