Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67 results about "Thulium oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thulium(III) oxide is a pale green solid compound, with the formula Tm2O3. It was first isolated in 1879 from an impure sample of erbia by Per Teodor Cleve, who named it thulia. It can be prepared in the laboratory by burning thulium metal in air, or by decomposition of their oxoacid salts, such as thulium nitrate.

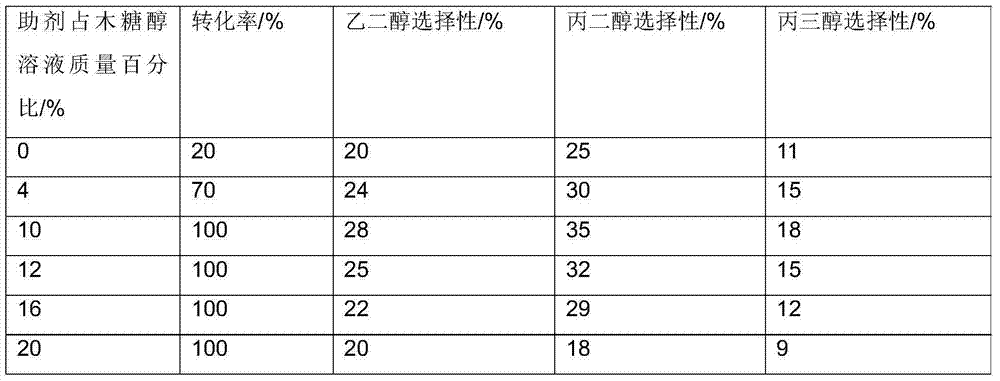

Method for preparation of low carbon alcohol by hydrogenolysis of sugar and sugar alcohol

InactiveCN104710277AEasy to achieve separationOrganic compound preparationPreparation by OH group eliminationGadolinium oxideGlycerol

The invention relates to a method for preparation of low carbon alcohol by hydrogenolysis of sugar and sugar alcohol. The method adopts sugar and sugar alcohol as the raw materials, takes one or more than two of iron, cobalt, nickel, copper, zinc, tin, platinum, ruthenium, palladium, iridium and other transition metals as the catalyst active component, and employs a rare earth oxide like promethium oxide, gadolinium oxide, terbium oxide, holmium oxide, erbium oxide, thulium oxide, cerium oxide, lanthanum oxide, praseodymium oxide, neodymium oxide, scandium oxide, yttrium oxide, dysprosium oxide, europium oxide, samarium oxide, ytterbium oxide, lutecium oxide and the like as the assistant. Under a temperature of 150-320DEG C and an H2 pressure of 1-20MPa, catalytic hydrocracking is carried out in a water solution to obtain ethylene glycol, propylene glycol, glycerol and other low carbon alcohols. The method provided by the invention has the advantages that: the rare earth oxide is added as the assistant to realize hydrocracking of sugar and sugar alcohol, rare earth oxides are insoluble in water and easy to separate, and at the end of reaction, the reaction system has no need for additional acid to neutralize.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Ytterbium-phosphate glass

Owner:L3HARRIS KIGRE INC

Transparent ceramic and preparation method thereof

The invention relates to a transparent ceramic and a preparation method thereof; the structural formula of the transparent ceramic is LnxYbyY(3-x-y)Al5O12 or LnwYbzY(2-w-z)O3, wherein, x is not less than 0.003 and not more than 0.03, y is not less than 0.006 and not more than 1.5, w is not less than 0.002 and not more than 0.02, z is not less than 0.004 and not more than 1 and Ln represents lanthanide element Ce, Tm, Pr or Tb. The preparation method comprises the following steps: adopting yttrium oxide, aluminum oxide and ytterbium oxide of which purities are not less than 99.9% and using one of cerium oxide, thulium oxide, praseodymium oxide and terbium oxide as raw materials, proportioning the raw materials powder according to the structural formula of the transparent ceramic, preparing ceramic powder material by adopting wet milling and using absolute ethanol as medium, drying the powder, pelleting, performing, pressing with 200MPa of cold isostatic pressing and obtaining LnxYbyY(3-x-y)Al5O12 or LnwYbzY(2-w-z)O3 transparent ceramic. The invention can increase the conversion efficiency of single crystal silicon and polysilicon solar cells.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

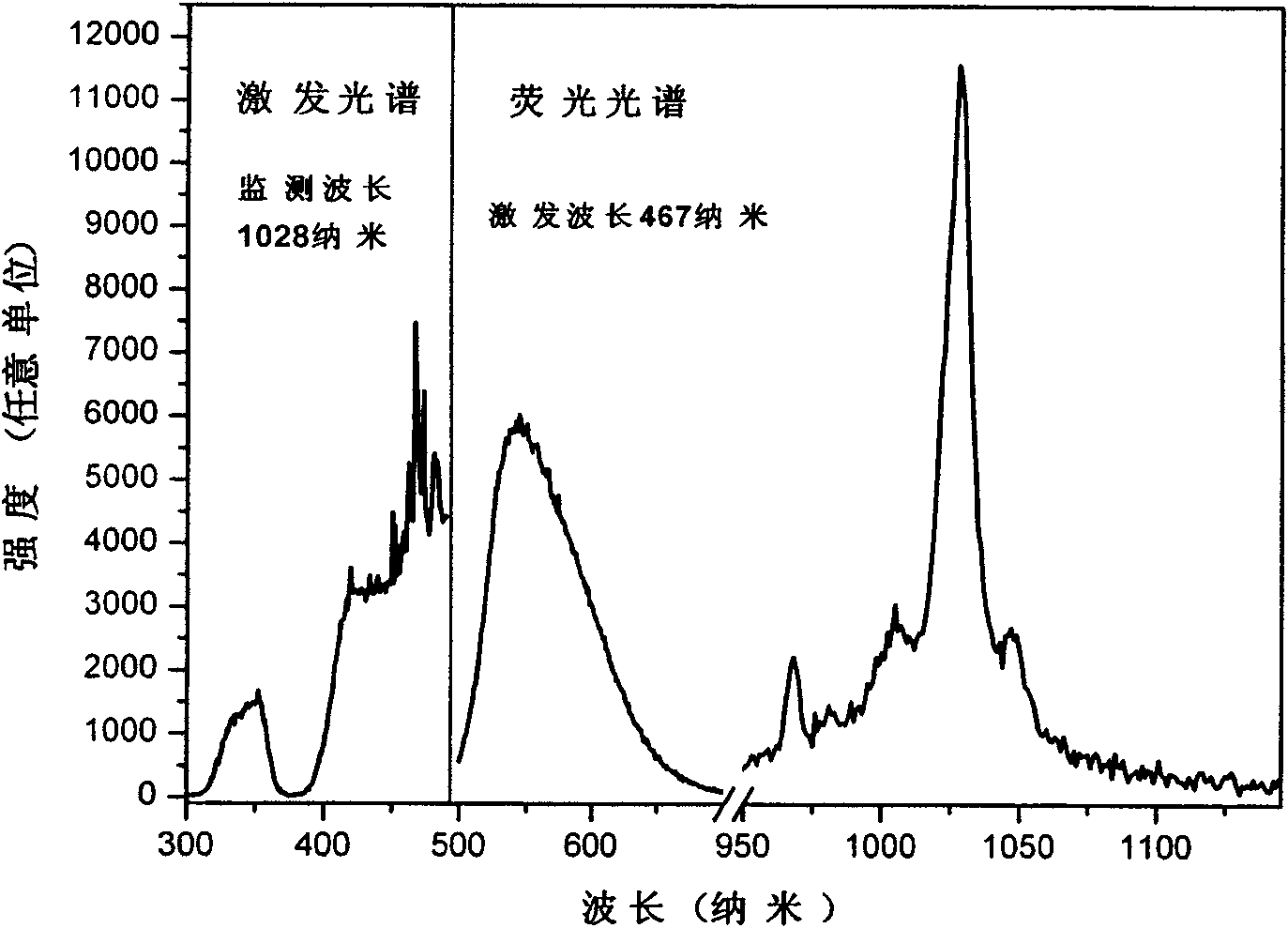

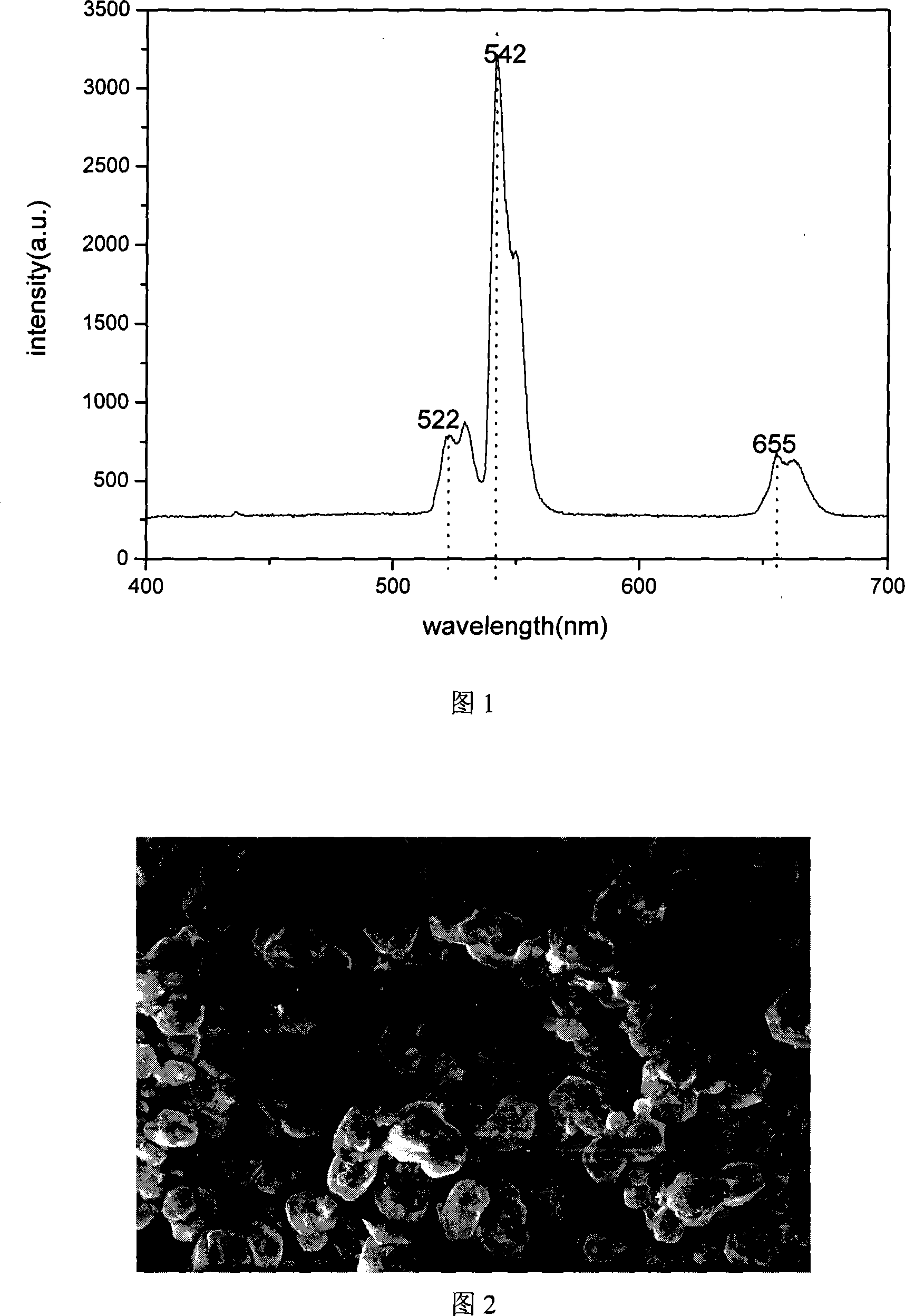

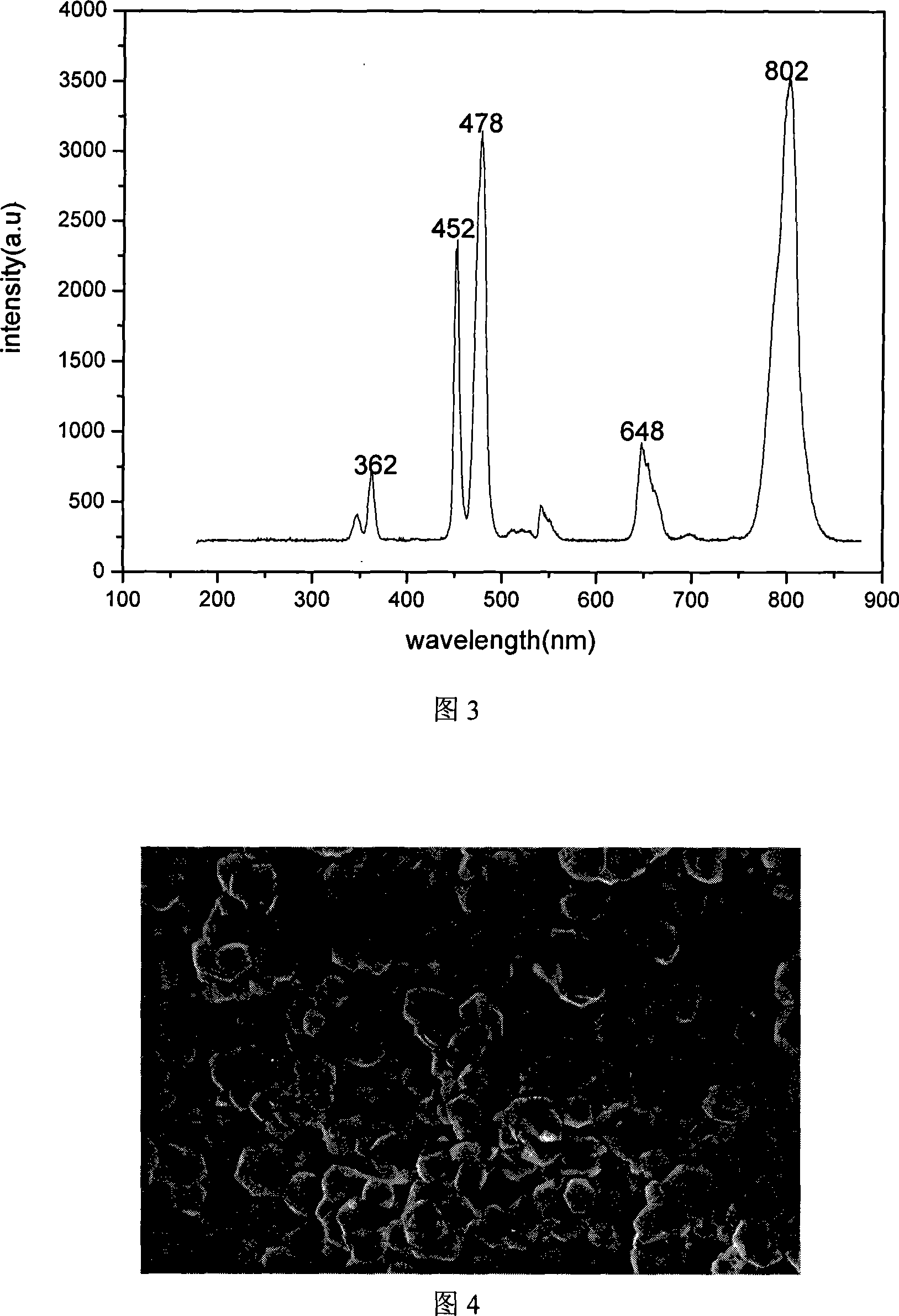

Rare earth thulium-doped aluminate fluorescent glass and preparation method thereof

InactiveCN101531459AExcellent light emitting performanceAchieve improvementRoom temperatureRare earth

The invention relates to a rare earth thulium-doped aluminate fluorescent glass, and the weight proportions of the compositions are as follows: 22% to 28% of Al2O3; 30% to 37% of CaCO3; 36% to 44% of H3BO3; and 0.5% to 1.5% of Tm2O3; the preparation method is as follows: (1) extra pure reagents alumina, calcium carbonate and boric acid are weighed, and the weight percentages are respectively as follows: 22% to 28%; 30% to 37%; 36% to 44%; 0.5% to 1.5%; thulium oxide is weighed so that the ratio between the weight of thulium oxide and the total weight of the three master batches is between 0.5% and 1.5%; fluxing agent accouting for 1% to 2% of the total weight of the four extra pure reagents is weighed, and the compositions are fully mixed; (2) the mixture is loaded in a corundum crucible and is sintered in a high temperature furnace, the atmosphere is air, the sintering temperature is 1100 to 1400 DEG C, and the sintering time is 2 to 5 hours; (3) sinter is processed in an annealing furnace at the temperature of 450 to 550 DEG C, and the processing time is 30 to 60 minutes; (4) the sinter is reduced to room temperature in air, cut into required length, washed by deionized water at the temperature of 70 to 85 DEG C, and dried at the temperature of 120 to 150 DEG C, so that the required product is obtained.

Owner:BEIHANG UNIV

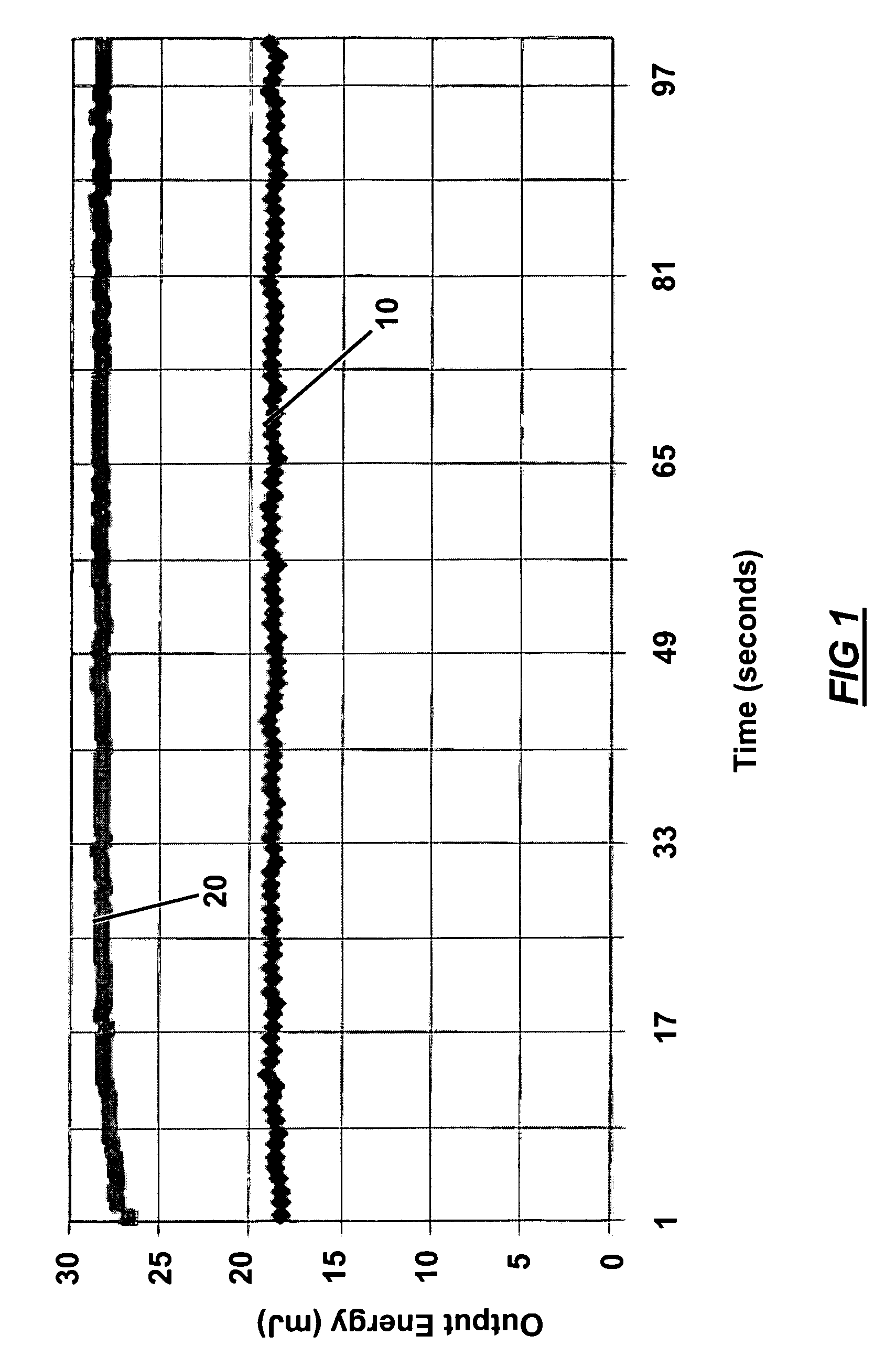

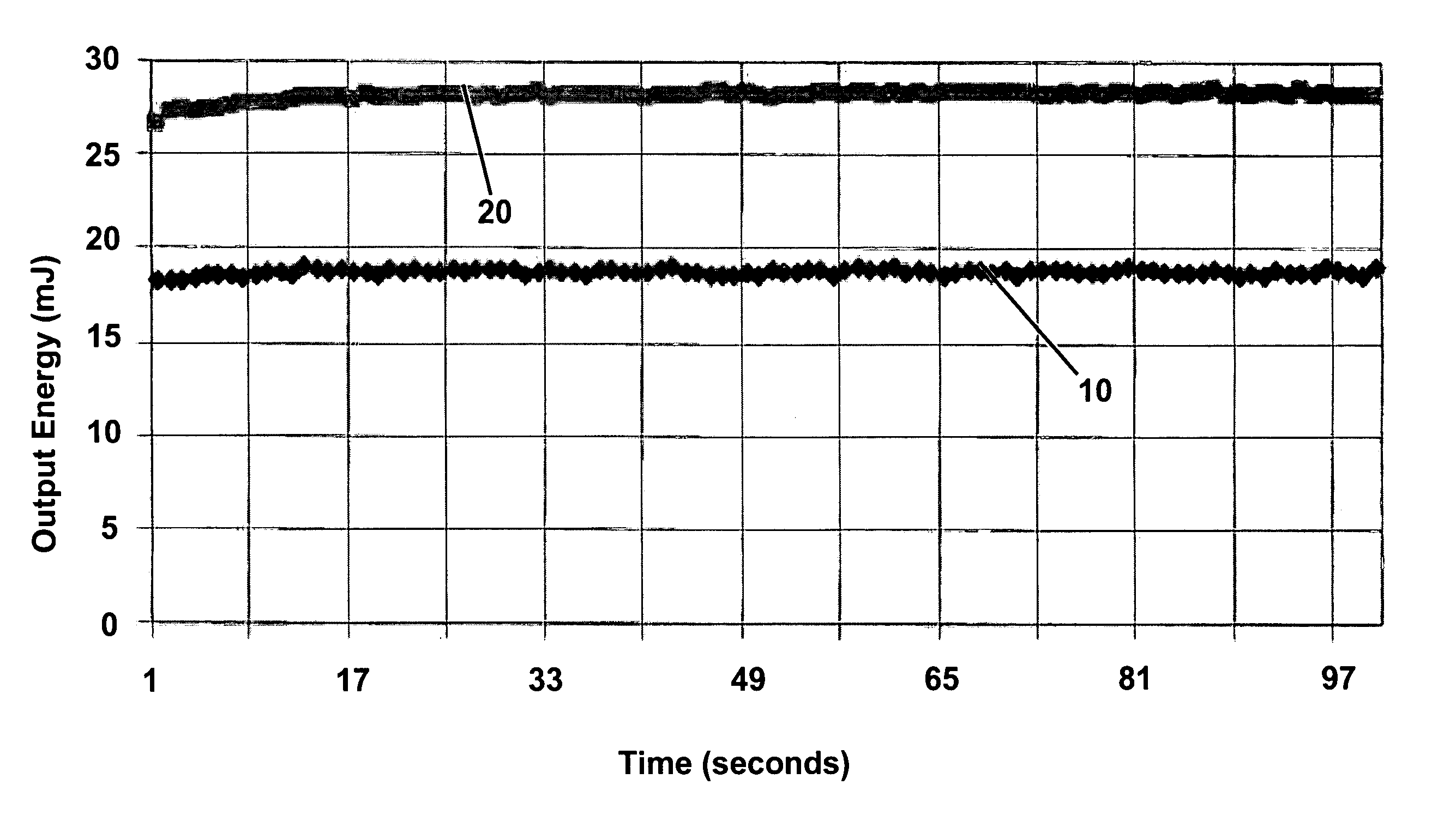

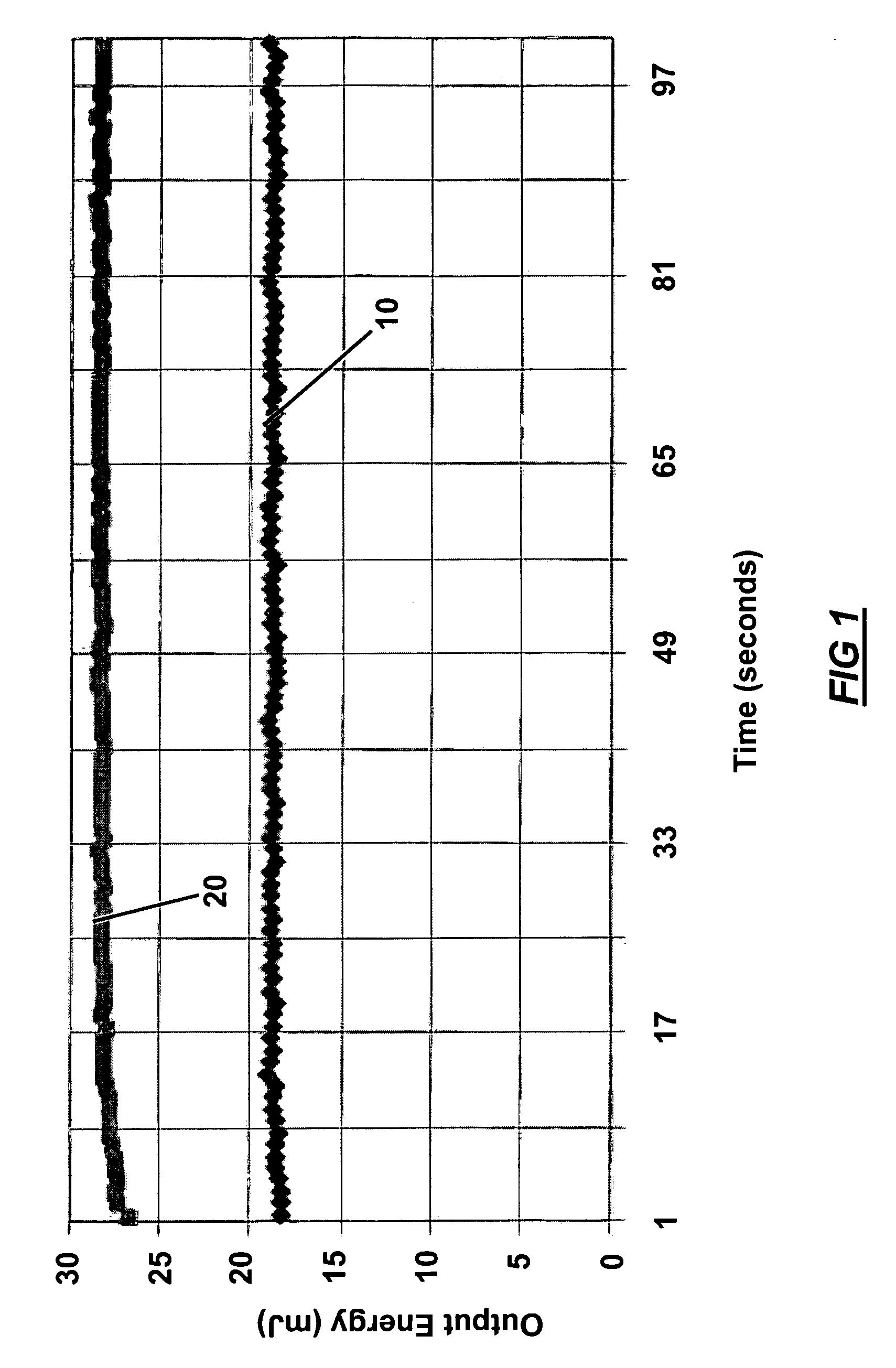

Novel ytterbium-phosphate glass

A new ytterbium-phosphate glass and a method for producing the same are disclosed. The glass finds special use in forming laser glass. Previously the level of ytterbium that could be incorporated into a phosphate glass without leading to formation of crystals or devitrification was limited. It has been found that much higher levels of ytterbium can be incorporated if an initial glass melt is formed from phosphate and ytterbium prior to adding the other components. Using the present process ytterbium-phosphate glasses having up to 30 mole percent ytterbium can be created. The new glasses function as well and often better than previous ytterbium containing glasses as laser glasses especially when combined with one or more of the lasing ions erbium oxide, neodymium oxide, holmium oxide or thulium oxide.

Owner:L3HARRIS KIGRE INC

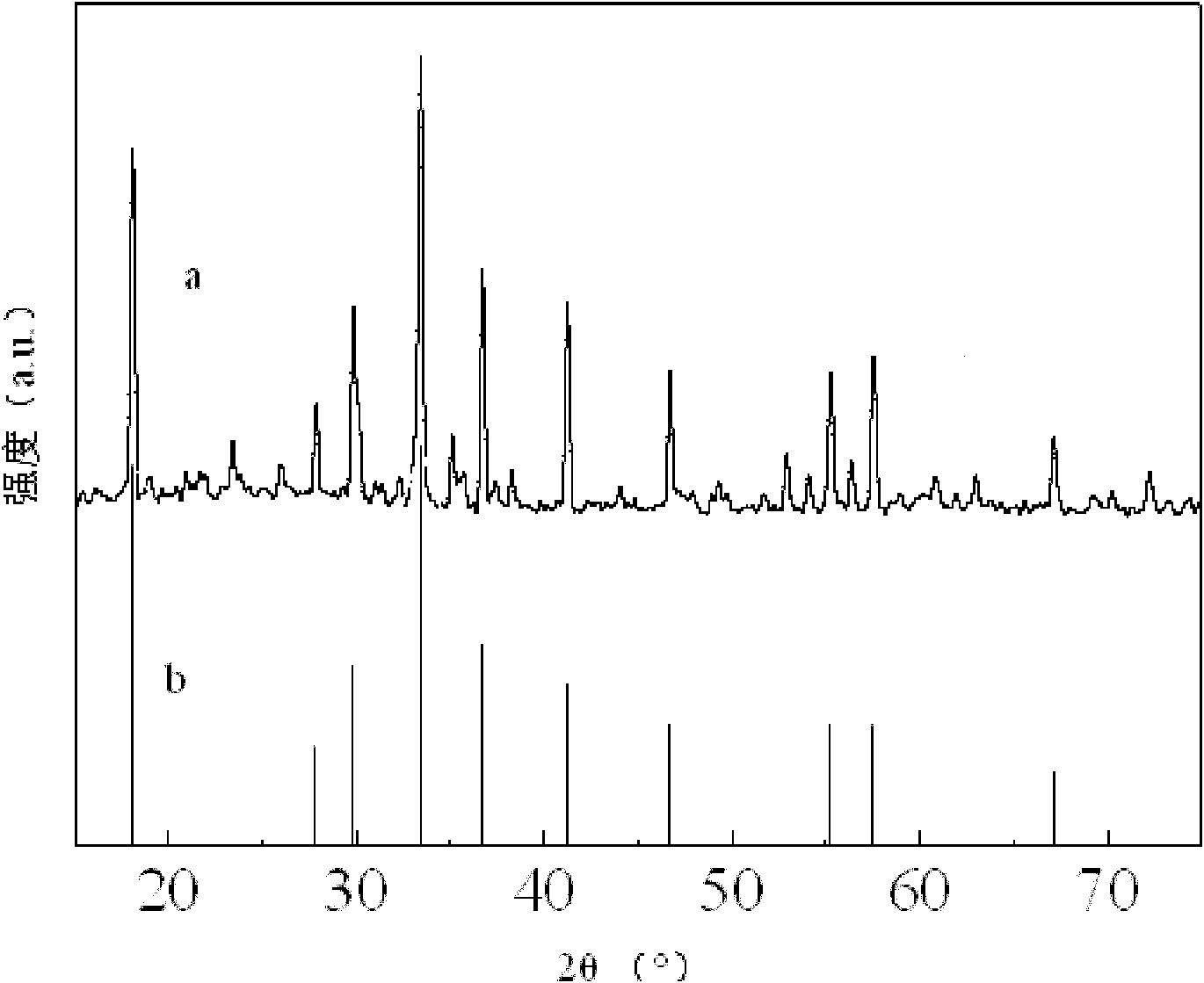

Ytterbium and thulium codoped dodecacalcium heptaluminate polycrystal and preparation method thereof

The invention discloses an ytterbium and thulium codoped dodecacalcium heptaluminate polycrystal and a preparation method thereof, relating to dodecacalcium heptaluminate polycrystal and a preparation method thereof, and solving the technical problem that the conventional blue material does not contribute to application due to wide blue wavelength distribution. The ytterbium and thulium codoped dodecacalcium heptaluminate polycrystal is prepared from calcium oxide, aluminum oxide, ytterbium oxide and thulium oxide, wherein the molar ratio of the calcium oxide to the aluminum oxide is 12:7; the amount of substance of the ytterbium oxide is 0.042-0.42 percent of that of the calcium oxide; and the amount of substance of the thulium oxide is 0.042-0.21 percent of that of the calcium oxide. The method comprises the following steps of: grinding the calcium oxide, the aluminum oxide, the ytterbium oxide and the thulium oxide powder; sheeting; and sintering under an air atmosphere to obtain the ytterbium and thulium codoped dodecacalcium heptaluminate polycrystal. Single blue light emission with wavelength of 460-490nm is obtained under excitation of light with wavelength of 980nm. The polycrystal can be used in the fields of light storage technology, optoelectronic technology, sensor technology and submarine optical cable communication.

Owner:HARBIN INST OF TECH

Super-stable temperature type electronic ceramic material

The invention discloses a super-stable temperature type electronic ceramic material and a preparation method thereof and belongs to the technical field of dielectric ceramics. The super-stable temperature type electronic ceramic material mainly comprises the following raw materials in parts by weight: 25-38 parts of barium titanate, 8-10 parts of aluminum oxide, 15-25 parts of zirconium dioxide, 10-20 parts of manganese oxide, 3-9 parts of nickel oxide, 2-8 parts of zinc oxide, 0.01-0.1 part of gallium oxide, 10-18 parts of nano silicon dioxide, 1-5 parts of magnesium oxide, 2-8 parts of nano boron nitride and 0.1-1.5 parts of thulium oxide. According to the ceramic material disclosed by the invention, the rare earth thulium oxide is used for replacing frequently-used cerium oxide and niobium pentaoxide components, and the ceramic material has obvious effects of further promoting fine crystallization of a ceramic body, improving the pressure resistance and reducing the losses. The ceramic material disclosed by the invention is simple in formula and low in price.

Owner:蔡惠文

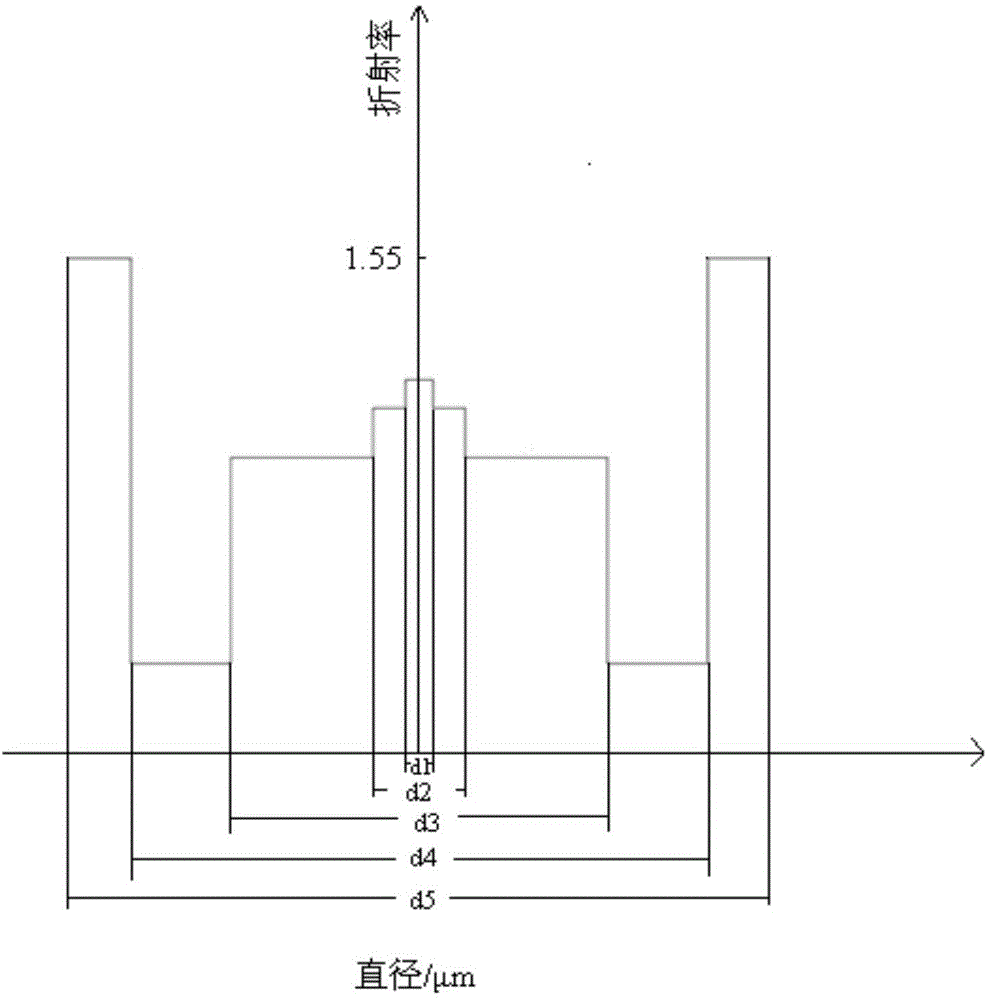

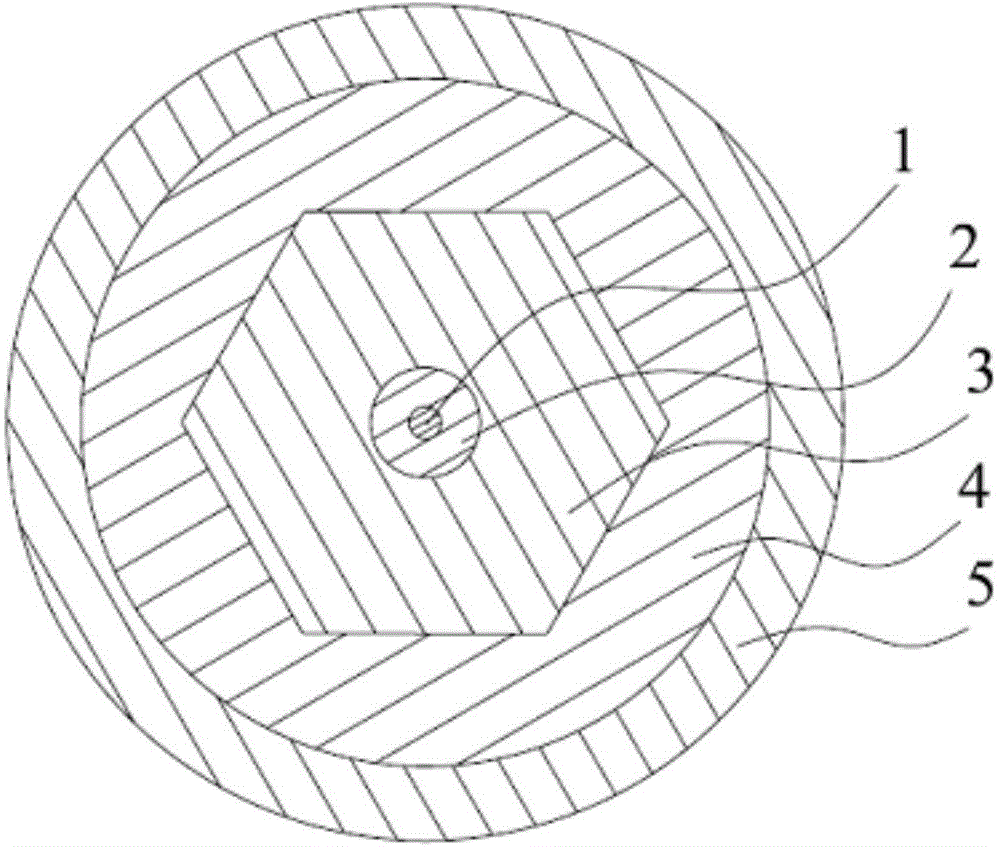

Three-wrapping-layer thulium-doped optical fiber and preparation method thereof

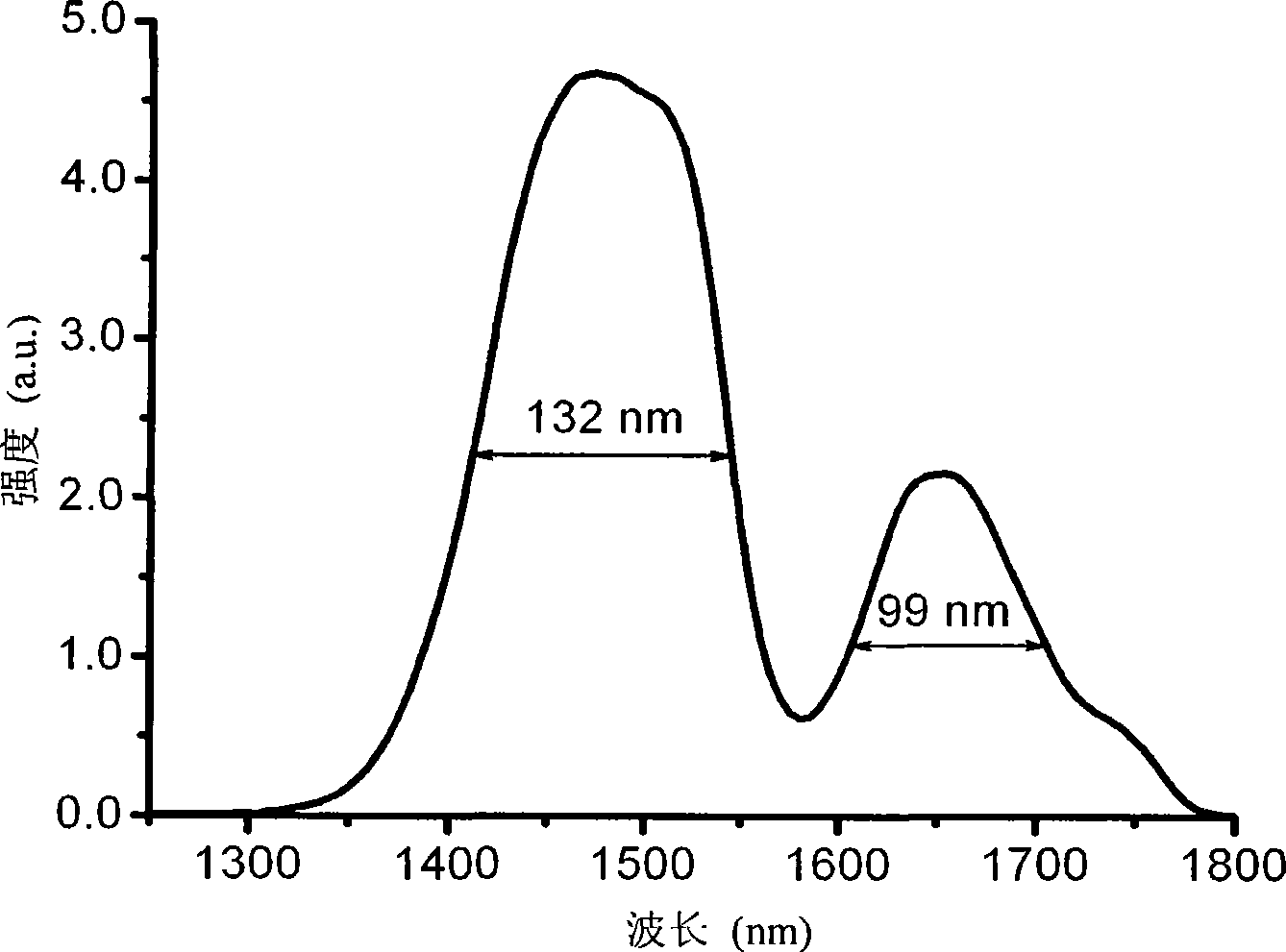

ActiveCN104932054AReduce numerical apertureImprove efficiencyOptical fibre with multilayer core/claddingFiberDopant

The invention provides a three-wrapping-layer thulium-doped optical fiber and a preparation method thereof. The three-wrapping-layer thulium-doped optical fiber comprises a fiber core, an inner wrapping layer, an outer wrapping layer and a resin layer. The fiber core comprises silicon dioxide, thulium oxide, aluminum oxide and phosphorus pentoxide, wherein the molar content of the thulium oxide is 0.2-0.8%, the molar content of the phosphorus pentoxide is 0.5-1.0%, and the molar ratio of the aluminum oxide to the thulium oxide is larger than or equal to 8; the diameter d1 of the fiber core ranges from 10 microns to 30 microns. The surface of the fiber core is sleeved with the inner wrapping layer. The inner wrapping layer comprises doping agents and silicon dioxide. The diameter of the inner wrapping layer is d2 which meet the relational expression: 2.5d1<=d2<=4d1. The surface of the inner wrapping layer is sleeved with the outer wrapping layer. The outer wrapping layer comprises silicon dioxide. The surface of the outer wrapping layer is sleeved with the resin layer. According to the three-wrapping-layer thulium-doped optical fiber, the numerical aperture of the fiber core is reduced by controlling the components in the inner wrapping layer, the content of the components in the fiber core, the diameter of the fiber core and the diameter of the inner wrapping layer, and the slope efficiency and the beam quality of output lasers are improved.

Owner:SHENZHEN XINAOKE CABLE

Preparation method of rare earth modified pressure-sensitive material

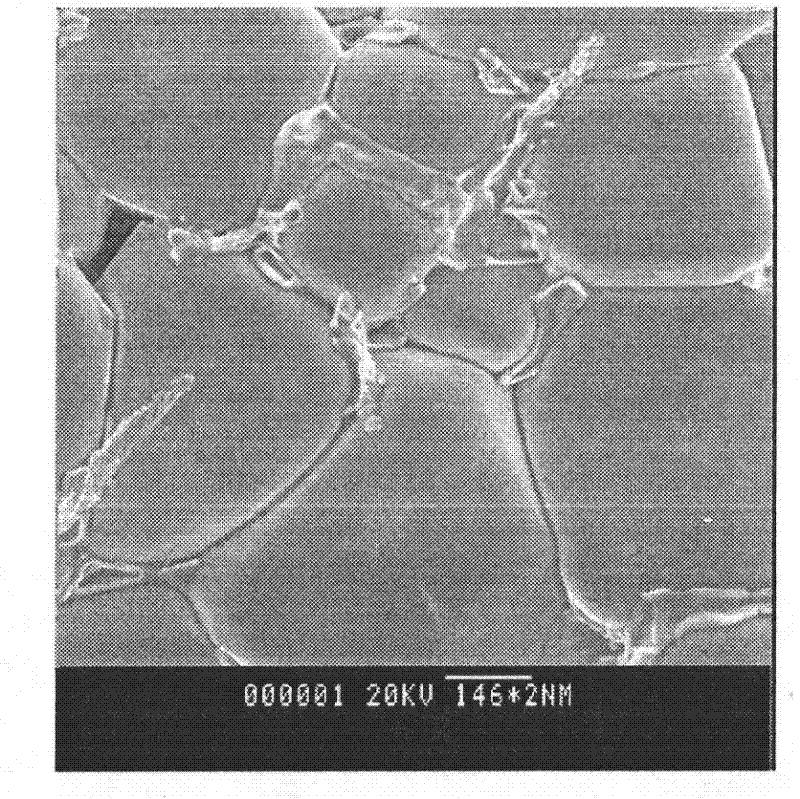

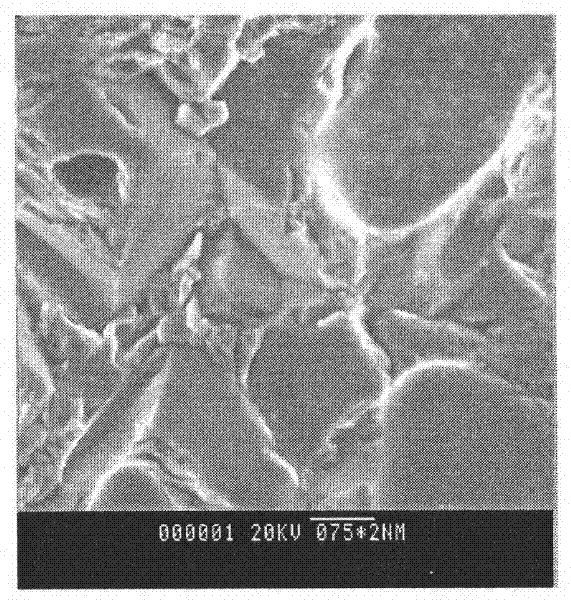

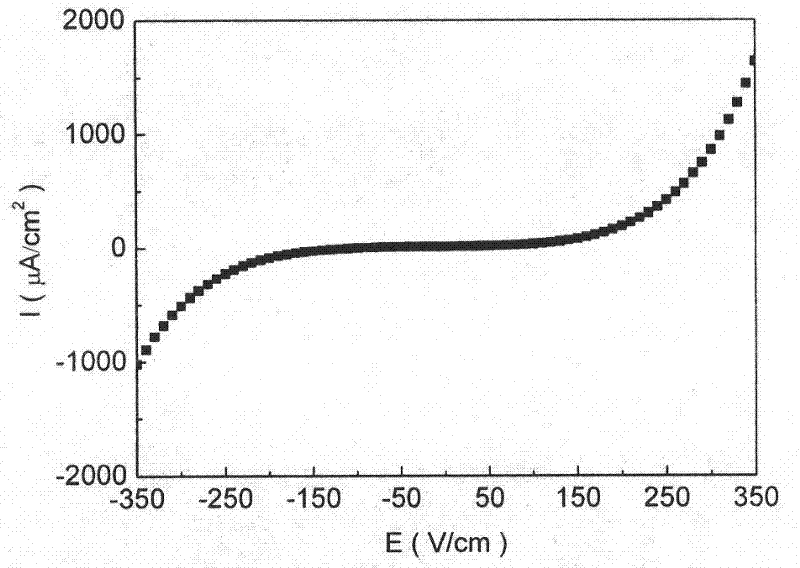

The invention discloses a preparation method of a rare earth modified pressure-sensitive material. The preparation method comprises the following steps: adding one or a combination of lanthanide series rare earth oxides in CaCu3Ti4O12 powder, wherein the total mass of added rare earth oxides is 0.01-9% of the mass of CaCu3Ti4O12 powder, and the lanthanide series rare earth metal oxides comprise lanthanum oxide, cerium oxide, praseodymium oxide, neodymium oxide, promethium oxide, samarium oxide, europium oxide, gadolinium oxide, terbium oxide, antimony oxide, holimium oxide, erbium oxide, thulium oxide, ytterbium oxide and lutetium oxide; and the rare earth modified CaCu3Ti4O12-based ceramic with good pressure-sensitive characteristic can be prepared by the process steps of ball milling, pelleting, forming, dewaxing, and high-temperature sintering. In the preparation method, since rare earth oxides are introduced to a crystal boundary, on one hand, the microscopy topography of the CaCu3Ti4O12-based pressure-sensitive material is regulated, and on the other hand, the electric property of the crystal boundary of the CaCu3Ti4O12-based pressure-sensitive material is changed, thereby reducing the leakage current of the material and improving the pressure-sensitive characteristic of the material so that the pressure-sensitive material reaches commercial requirements.

Owner:XINING GONGJIN NEW MATERIAL TECH CO LTD

Method for preparing material of frequency up conversion

InactiveCN101092562AOvercome limitationsSmall particlesLuminescent compositionsWater bathsYTTERBIUM OXIDE

This invention discloses a method for preparing frequency up conversion material. The method comprises: adding concentrated HNO3 into yttrium oxide, ytterbium oxide and erbium oxide (or thulium oxide), heating to dissolution in a water bath to obtain yttrium nitrate solution, ytterbium nitrate solution and erbium nitrate solution (or thulium nitrate solution), mixing to obtain mixed solution A, adding glycine to obtain mixed solution A1, placing mixed solution A1 in a furnace, cooling to obtain white powder A2, adding NaF and NH4F to obtain mixture A3, placing mixture A3 in a furnace, and performing thermal treatment to obtain the target product. Compared with hydrothermal method, the method in this invention has such advantages as low thermal treatment temperature and short reaction period. The synthesized sample has such advantages as small and uniform sizes, no need for grinding, regular morphology and high luminescent efficiency.

Owner:XIAMEN UNIV

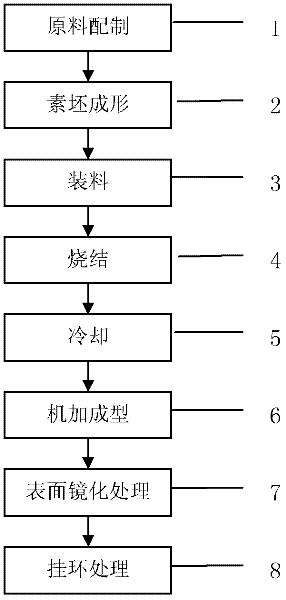

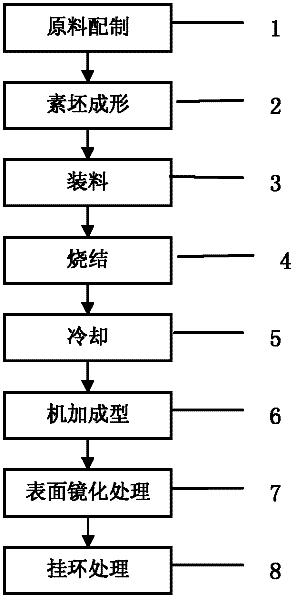

Zirconia ceramic plunger and manufacturing method thereof

The invention provides a zirconia ceramic plunger and a manufacturing method thereof. The zirconia ceramic plunger comprises raw materials of, by weight, 92+ / -0.1 parts of zirconia, 5+ / -0.1 parts of yttrium oxide and 3+ / -0.1 parts of thulium oxide. The manufacturing method comprises steps of: step 1, raw material preparation; step 2, biscuit formation; step 3, charging; step 4, sintering; step 5, cooling; step 6, moulding by machining; step 7, surface light and fineness treatment to obtain the zirconia ceramic plunger. The zirconia ceramic plunger of the present invention utilizes a high pressure oscillation high temperature sintering technology; according to pressurization and the pressurization oscillation technology, the sintered zirconia ceramic plunger is more compact, has no pore or crack, so as to enhance product performance, improve production quality and guarantee stability of production quality.

Owner:SHENZHEN JINGNAN PORCELAIN

Preparation process of a self-lubricating ceramic material cutting tool

The invention relates to the technical field of cutting tools, in particular to a preparation process of self-lubricating ceramic material cutting tools, which is characterized in that the process steps are: (1) Nano-thulium zirconium ceramic powder prepared by hydrothermal precipitation method, its composition The content and mass percentage are: 7% to 38% of thulium oxide, 62% to 93% of zirconia, (2) after adding TiC composite, ball milling, (3) adding solid lubricant, the radius of the solid lubricant particle ceramic composite material The ratio is 0.225≤r / R≤0.419, (4) mixed after ball milling, (5) vacuum dried, (6) put into graphite mold, (7) prepared by hot pressing sintering process, and the sintering temperature is 1500°C-1700°C , holding time 40 minutes. Compared with the prior art, the present invention has a simple technological process, and the self-lubricating ceramic tool has the functions of anti-friction, anti-wear and lubrication, saves the cooling and lubrication system, reduces equipment investment, avoids environmental pollution caused by cutting fluid, and realizes clean production. reduce manufacturing cost.

Owner:上海景文材料科技发展有限公司

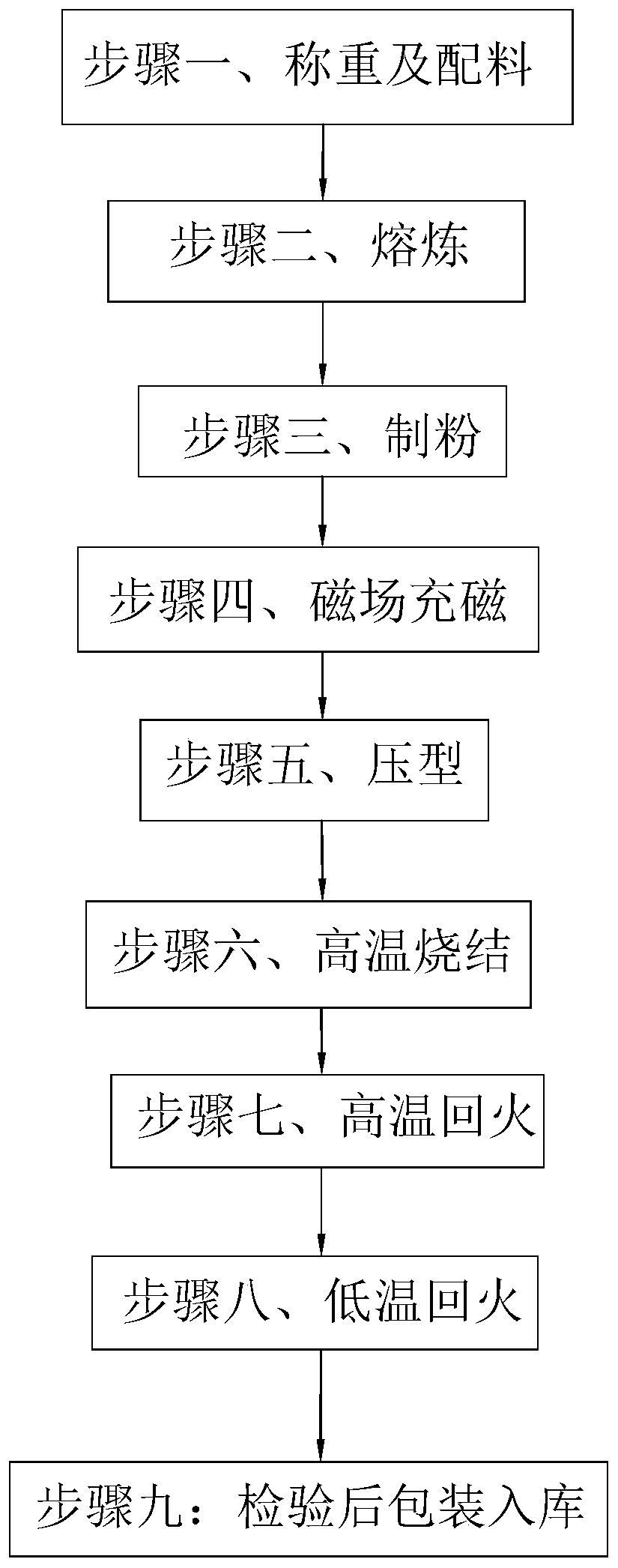

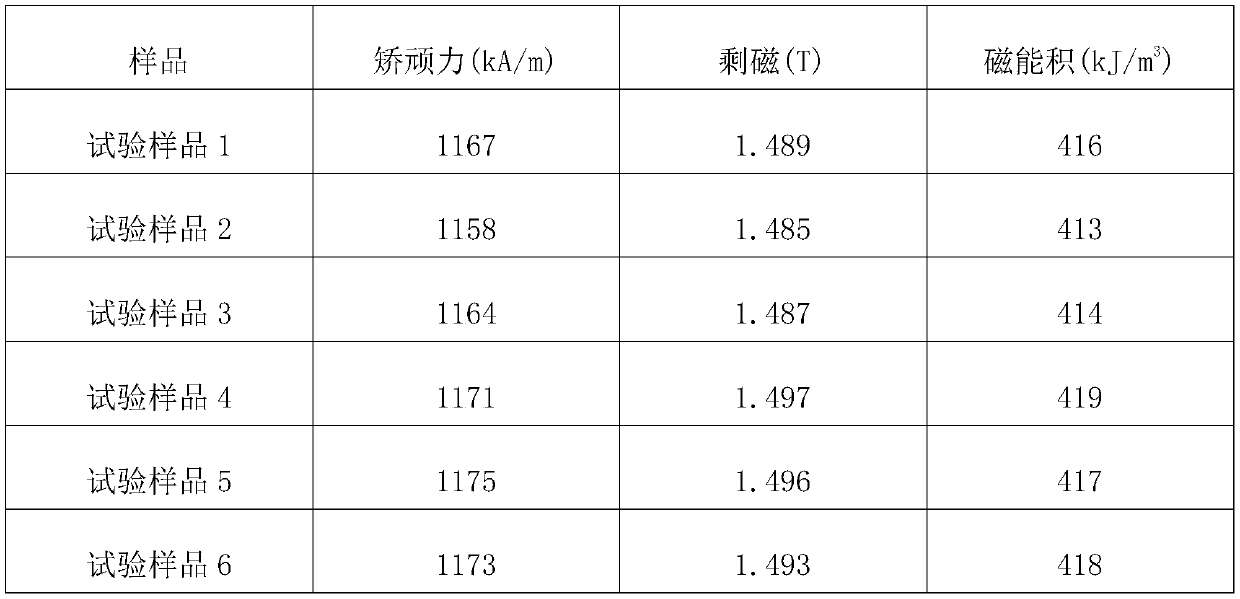

Neodymium iron boron permanent magnet material and preparation method thereof

InactiveCN110504077AImprove coercive forceImprove squarenessInductances/transformers/magnets manufactureMagnetic materialsTemperingNiobium

The invention discloses a neodymium iron boron permanent magnet material and a preparation method thereof, and belongs to the technical field of permanent magnet materials. The neodymium iron boron permanent magnet material is technically characterized by comprising the following components in percentage by weight: 30-45% of neodymium, 2-2.5% of niobium, 2.5-4.2% of cobalt, 0.15-0.2% of zinc, 0.2-0.5% of gallium, 2.5-4.8% of boron, 0.1-0.5% of tungsten, 2.5-4% of thulium oxide and the balance of iron. The preparation method of the neodymium iron boron permanent magnet material comprises the following steps: weighing and dosing, smelting, pulverizing, magnetic field magnetizing, briquetting, high-temperature sintering, high-temperature tempering, low-temperature tempering, inspection, packaging and warehousing. The coercive force of the neodymium iron boron permanent magnet material is effectively improved, so that the neodymium iron boron permanent magnet material has excellent performances of improving the square degree and improving the temperature stability.

Owner:宁波可可磁业股份有限公司

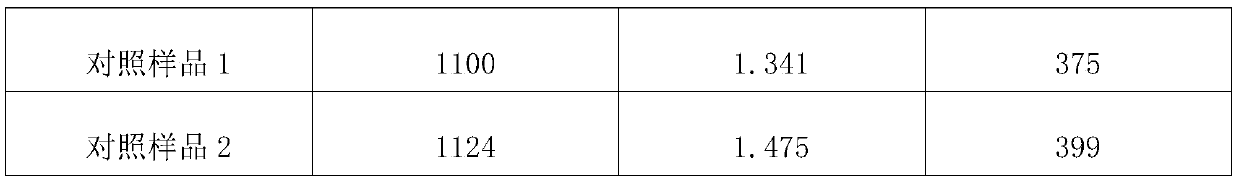

Near-infrared light emitting lanthanum oxysulfide fluorescent powder and method for preparing same

ActiveCN108410464AHigh color purityHigh strengthMaterial nanotechnologyNanoopticsYTTERBIUM OXIDEAmmonium sulfate

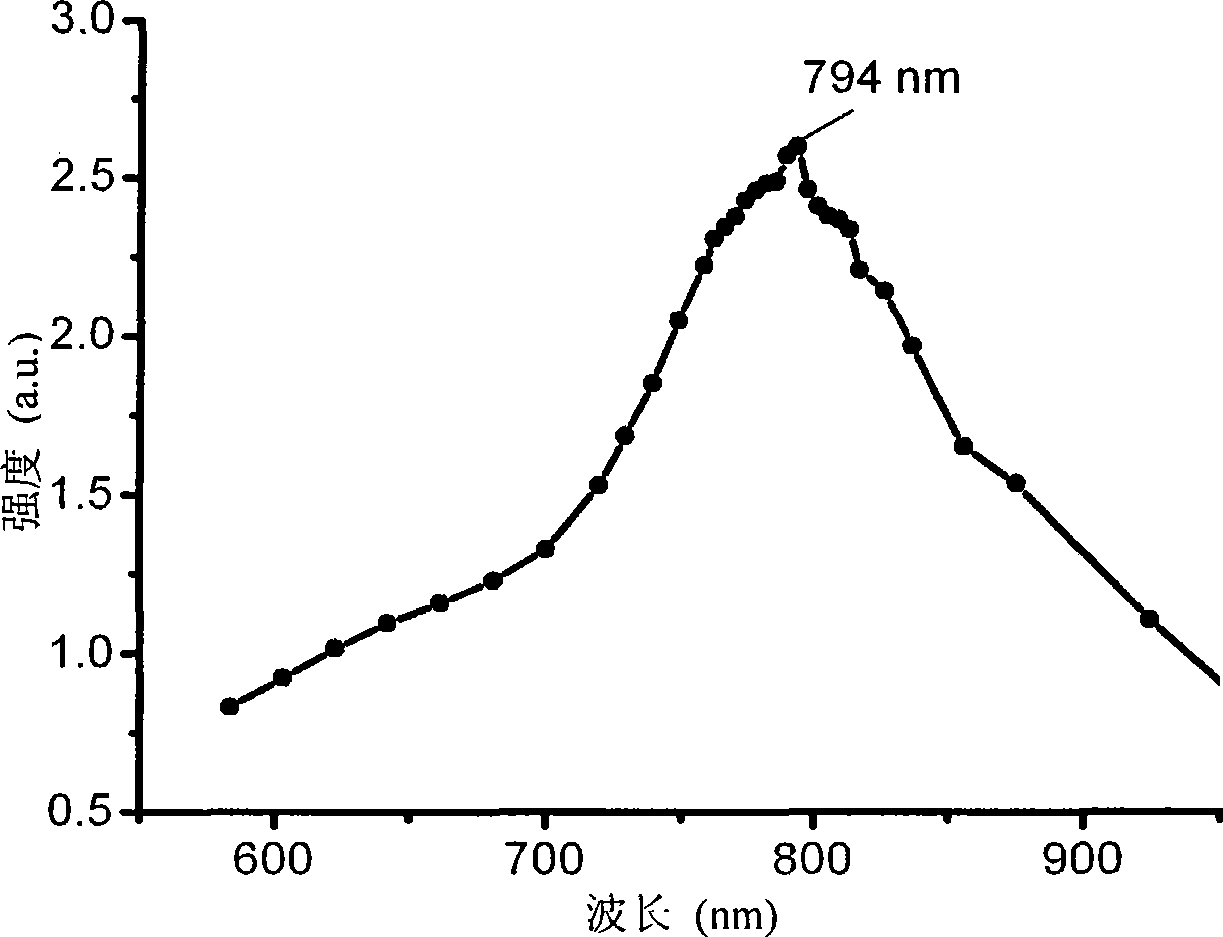

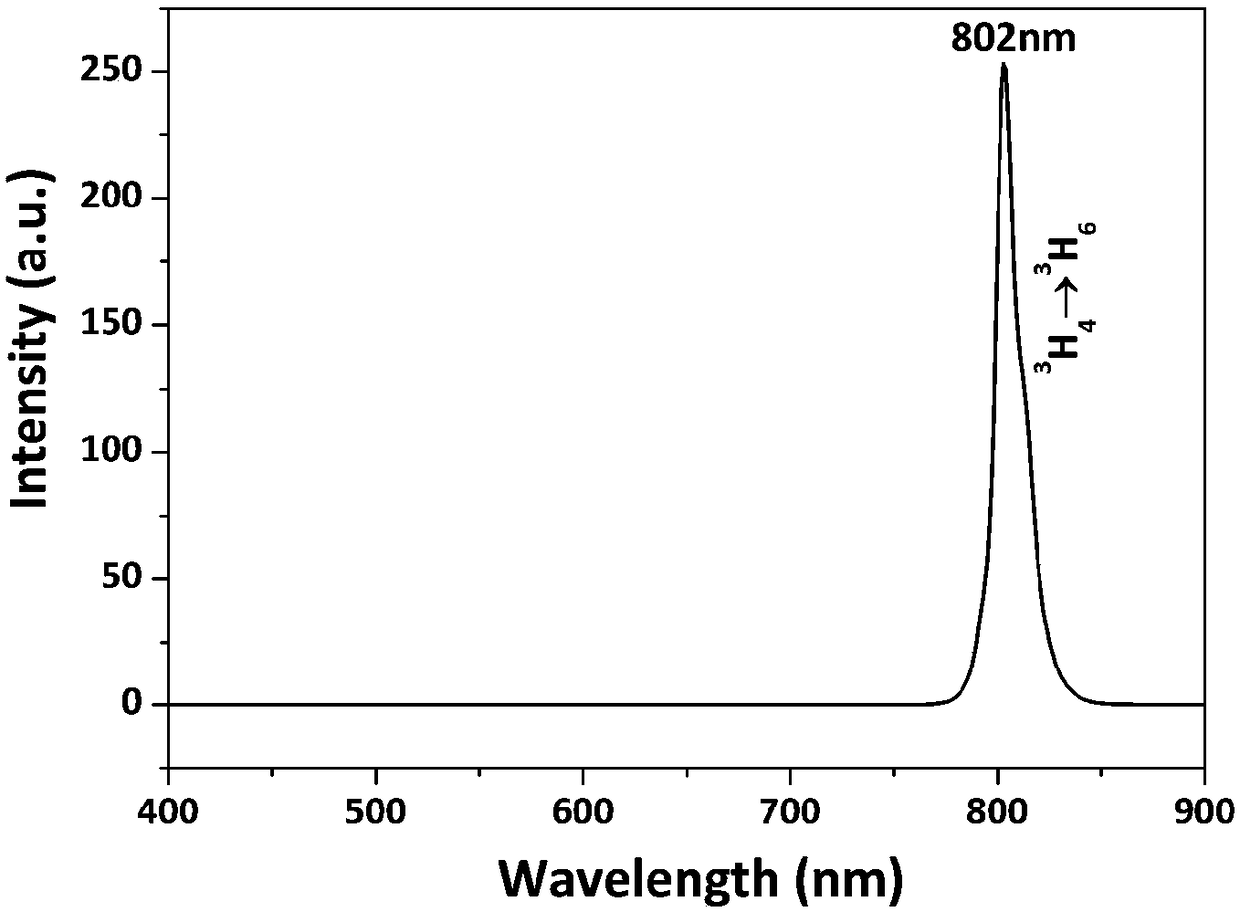

The invention discloses near-infrared light emitting lanthanum oxysulfide fluorescent powder and a method for preparing the same. A chemical formula of the near-infrared light emitting lanthanum oxysulfide fluorescent powder is (La<x>Yb<y>Tm<z>)<2>O<2>S. The sum of the x, the y and the z is equal to 1, the x is larger than or equal to 0.7 and is smaller than or equal to 0.98, the y is larger thanor equal to 0.01 and is smaller than or equal to 0.2, and the z is larger than or equal to 0.01 and is smaller than or equal to 0.1. The method includes adding distilled water into lanthanum oxide powder, ytterbium oxide powder and thulium oxide powder; stirring and heating the lanthanum oxide powder, the ytterbium oxide powder and the thulium oxide powder to obtain liquid, and dropwise dropping concentrated nitric acid until the liquid is clear; preparing lanthanum nitrate solution, ytterbium nitrate solution and thulium nitrate solution with corresponding concentration; mixing the lanthanumnitrate solution, the ytterbium nitrate solution and the thulium nitrate solution with one another according to proportions to obtain mixed solution; adding ammonium sulfate particles into the mixed solution and stirring the ammonium sulfate particles and the mixed solution until the mixed solution is clear; adding ammonia water into the mixed solution, regulating the pH (potential of hydrogen), and stirring the mixed solution to obtain uniform suspension; carrying out reaction at the temperatures for the time under the control; separating and drying products and calcining the products in hydrogen to obtain the near-infrared light emitting lanthanum oxysulfide fluorescent powder. The near-infrared light emitting lanthanum oxysulfide fluorescent powder and the method have the advantages that nearly pure near-infrared light (with the lengths of 802nm) can be emitted by the near-infrared light emitting lanthanum oxysulfide fluorescent powder prepared by the aid of the method, stray lightpositioned in visible light regions nearly can be completely quenched, and accordingly the color purity and the mark signal strength can be advantageously improved.

Owner:BOHAI UNIV

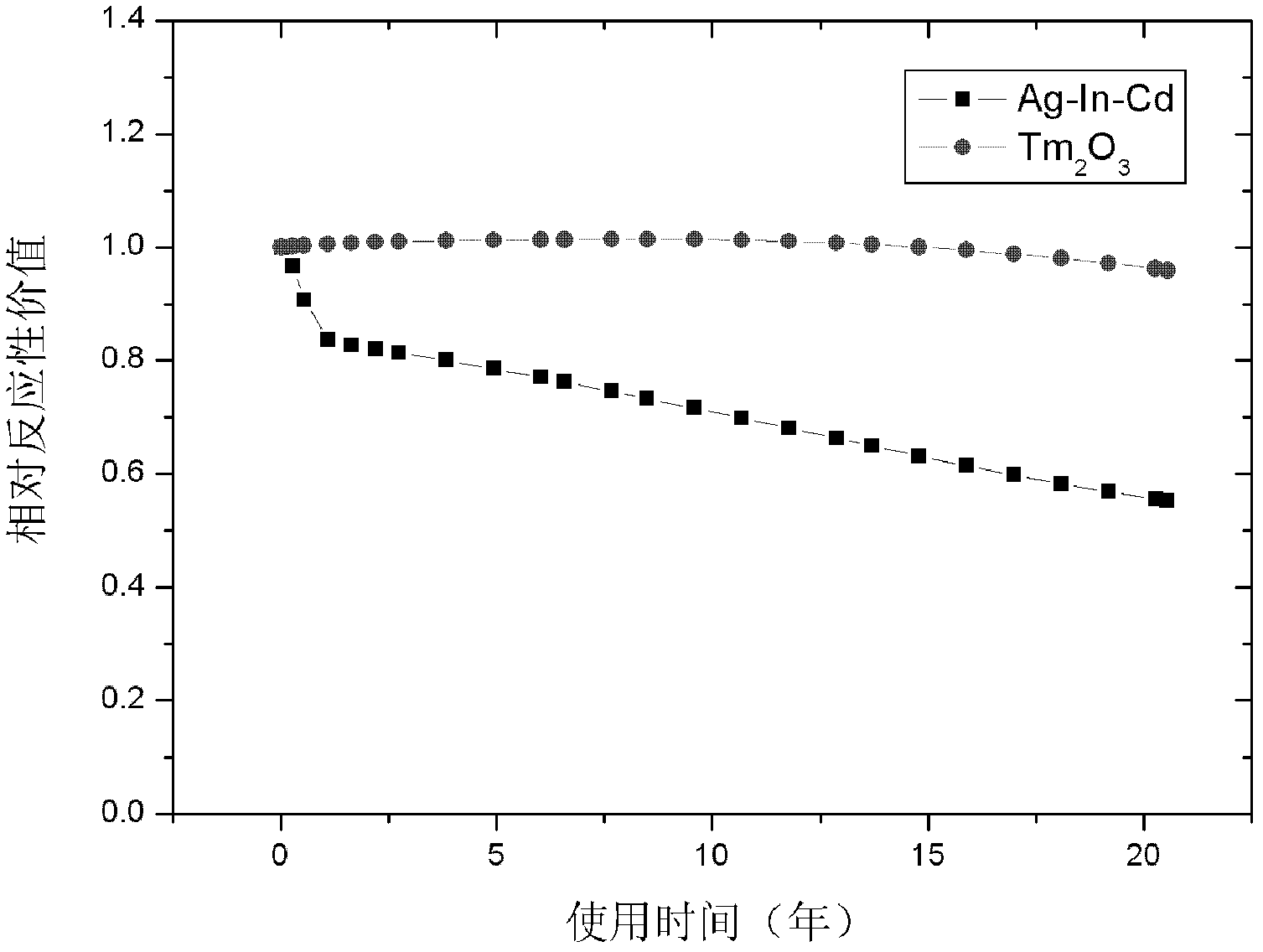

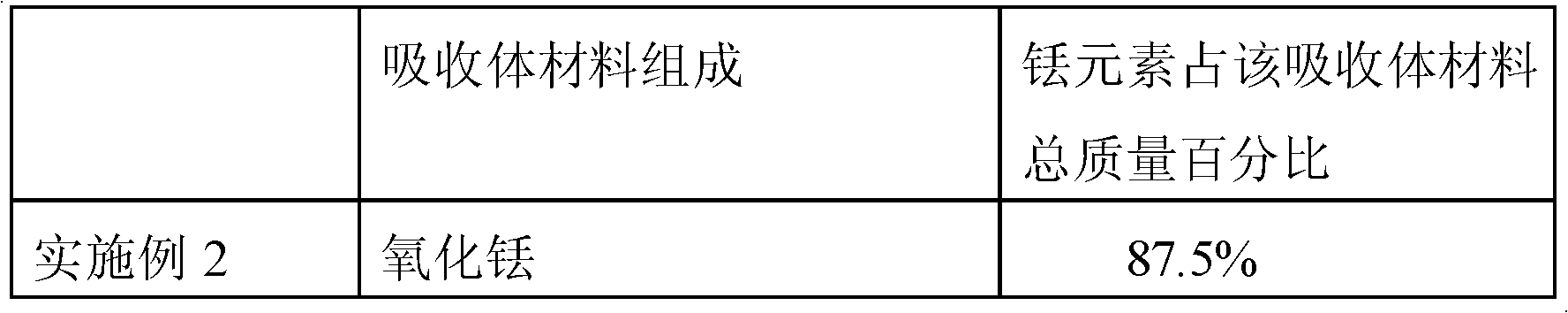

Long service life gray control rod and absorber

ActiveCN102915772AReactive value is smallExtended service lifeNuclear energy generationNuclear reaction controlAlloyMaterials science

The invention provides a long service life gray control rod and an absorber. An absorber material comprises one or more of thulium, a thulium alloy or a thulium compound. The absorber material comprises one or more of the thulium, the thulium alloy or thulium oxide, wherein the thulium element occupies 10 to 99.9 percent of the total mass percentage of the absorber material. The gray control rod is a slender solid tubular structure; and the gray control rod is made of the material comprising one or more of the thulium, the thulium alloy or the thulium compound. According to the gray control rod and the absorber which are disclosed by the invention, mainly, the thulium, the thulium alloy or the thulium compound is used as the absorber material, so that the variation of the reactivity worth of a gray control rod assembly along with the fuel consumption is very small, the service life of the gray control rod assembly is greatly prolonged and the gray control rod assembly can be used for over 20 years.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

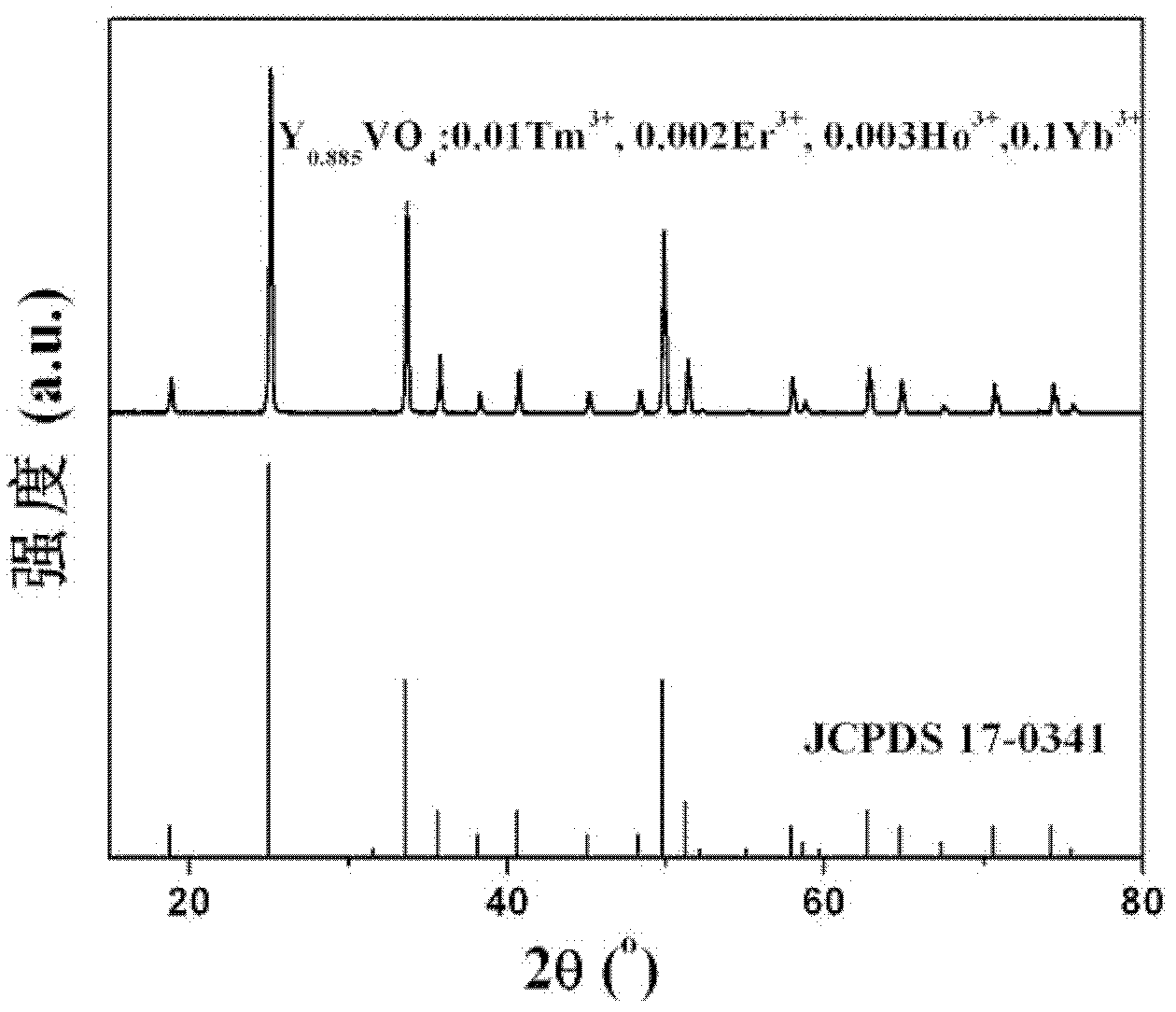

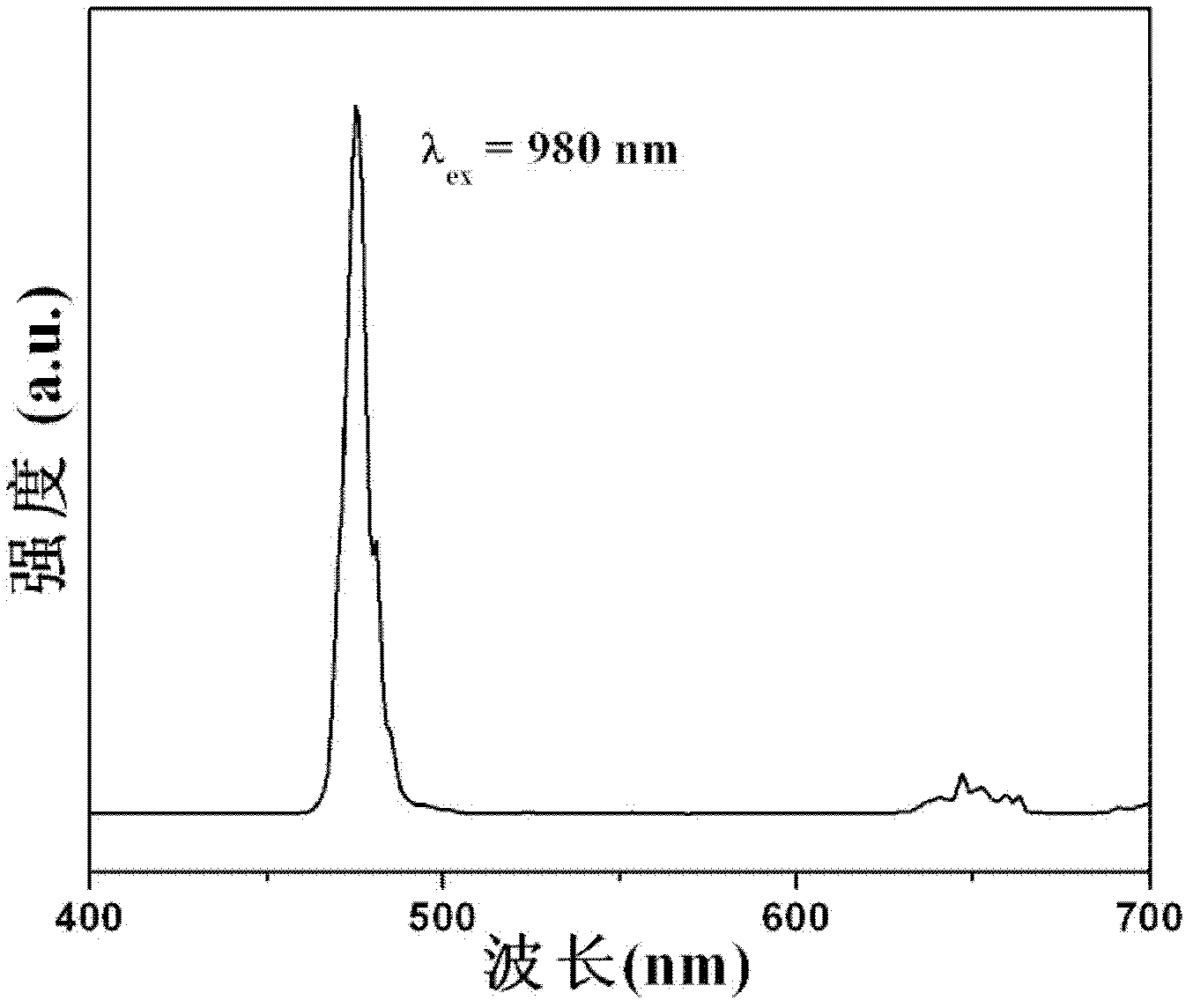

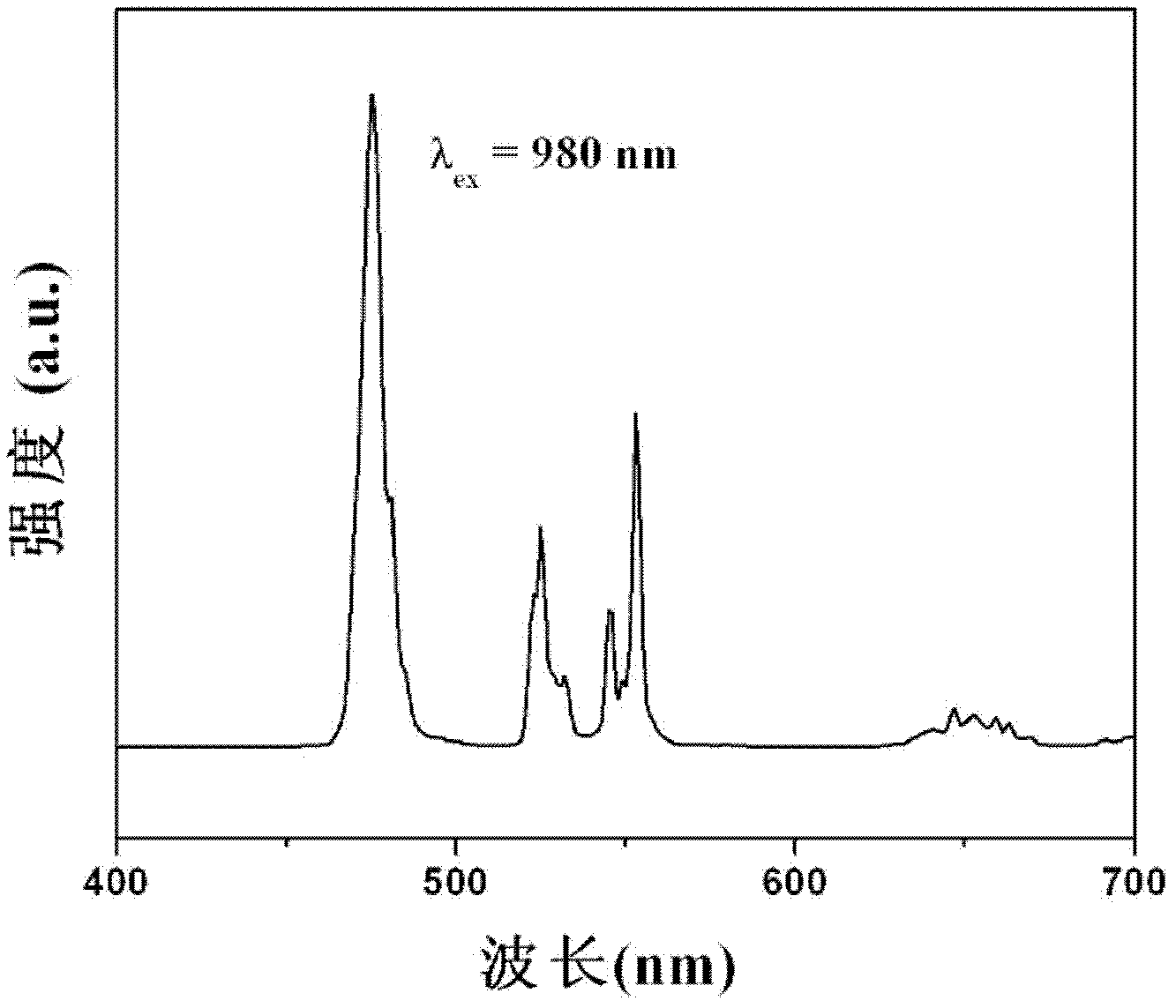

Vanadate upconversion material fluorescent powder, and preparation method and application thereof

InactiveCN102585827AAvoid pollutionGas discharge lamp usageLuminescent compositionsYTTERBIUM OXIDEVanadate

The invention discloses vanadate upconversion material fluorescent powder, and a preparation method and application thereof. The vanadate upconversion material fluorescent powder has a chemical composition formula Y0.89-x-yVO4:0.01Tm<3+> / xEr<3+> / yHo<3+> / 0.1Yb<3+>, wherein x is 0 to 0.002, and y is 0 to 0.003. The invention also discloses the preparation method for the material, and the preparation method comprises the following steps of: weighing yttrium oxide, vanadium pentoxide, thulium oxide, holmium oxide, erbium oxide and ytterbium oxide in a molar ratio of the chemical composition formula, grinding and mixing uniformly, pre-sintering at the temperature of 650 DEG C, and keeping constant temperature of 650 DEG C for six hours; cooling, grinding again, sintering at the temperature of 1,200 DEG C, and keeping the constant temperature of 1,200 DEG C for six hours; and cooling to obtain the vanadate upconversion material fluorescent powder. The vanadate upconversion material fluorescent powder is high in luminous efficiency and stability and meets the requirement of a white light light-emitting diode (LED).

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Performance controllable silicon nitride ceramic implant and preparation method thereof

ActiveCN109678524AHigh hardnessImprove bending strengthTissue regenerationProsthesisTitanium carbideStrontium oxide

The invention relates to a performance controllable silicon nitride ceramic implant and a preparation method of the implant. The implant comprises silicon nitride and additives, wherein the additivescomprise a first additive, a second additive and a third additive; the first additive is one or a mixture of more than one of magnesium oxide, aluminum oxide, yttrium oxide, strontium oxide, cerium oxide, chromic oxide, titanium carbide, titanium nitride and boron nitride; the second additive is one or a mixture of more than one of erbium oxide, thulium oxide, ytterbium oxide and lutetium oxide; and the third additive is one or a mixture of more than one of praseodymium oxide, samarium oxide, cerium dioxide, neodymium sesquioxide and calcium titanate. An outer layer of the implant mainly comprises alpha phase silicon nitride; the interior of the implant mainly comprises beta phase silicon nitride, so that the implant achieves an effect of the hard surface and the tenacious interior; the hardness and wear resistance as well as fracture toughness and strength of the implant can be improved; cracks are resisted; and corresponding damage risks are reduced.

Owner:苏州玄陶商务咨询有限公司

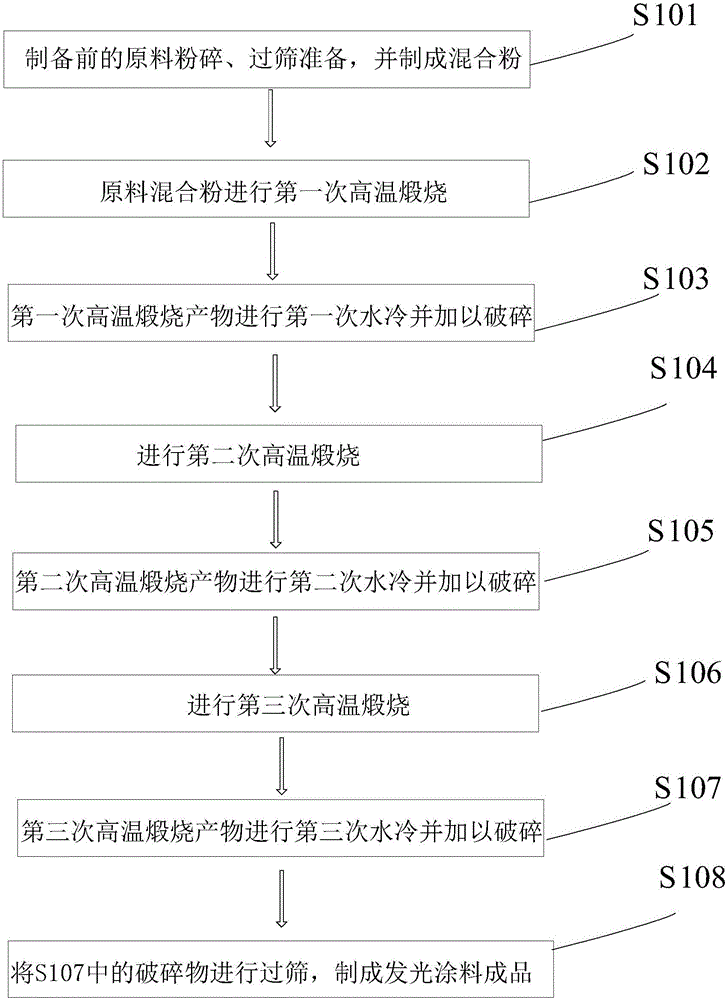

Formula and process for preparing environment-friendly and energy-saving light-emitting coating

The invention provides a formula and process for preparing an environment-friendly and energy-saving light-emitting coating, and belongs to the technical field of coatings. The environment-friendly light-emitting coating comprises 3-30 parts of silicon dioxide, 7.2-9 parts of aluminum trioxide, 18.3-22 parts of boric acid, 2-5.6 parts of strontium carbonate, 1-3.3 parts of lithium carbonate, 2.5-5.5 parts of bismuth trioxide. 0.2-0.8 part of titanium dioxide, 0.5-1.5 parts of copper oxide, 1.5-4.5 parts of neodymium oxide, 5.5-12.2 parts of dysprosium oxide, 8-13 parts of europium oxide, 1.5-4.5 parts of thulium oxide and 8-13 parts of noctilucent powder. A processing method includes the following steps of conducting material preparing, high-temperature calcining and melting and water-cooled smashing, conducting secondary calcining and water-cooled smashing, and conducting tertiary calcining, water-cooled smashing and screening. The formula and process are stable and reliable, and the product is appropriate in light-emitting luminance at night, good in environment protection effect, long in service life and suitable for industrial production.

Owner:张云龙

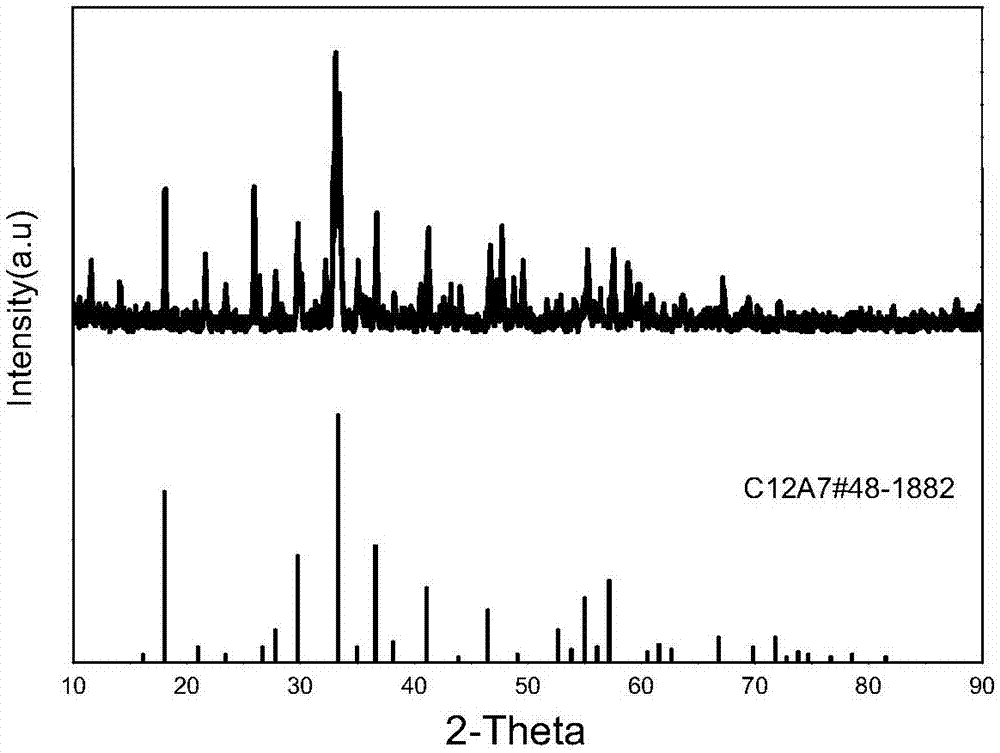

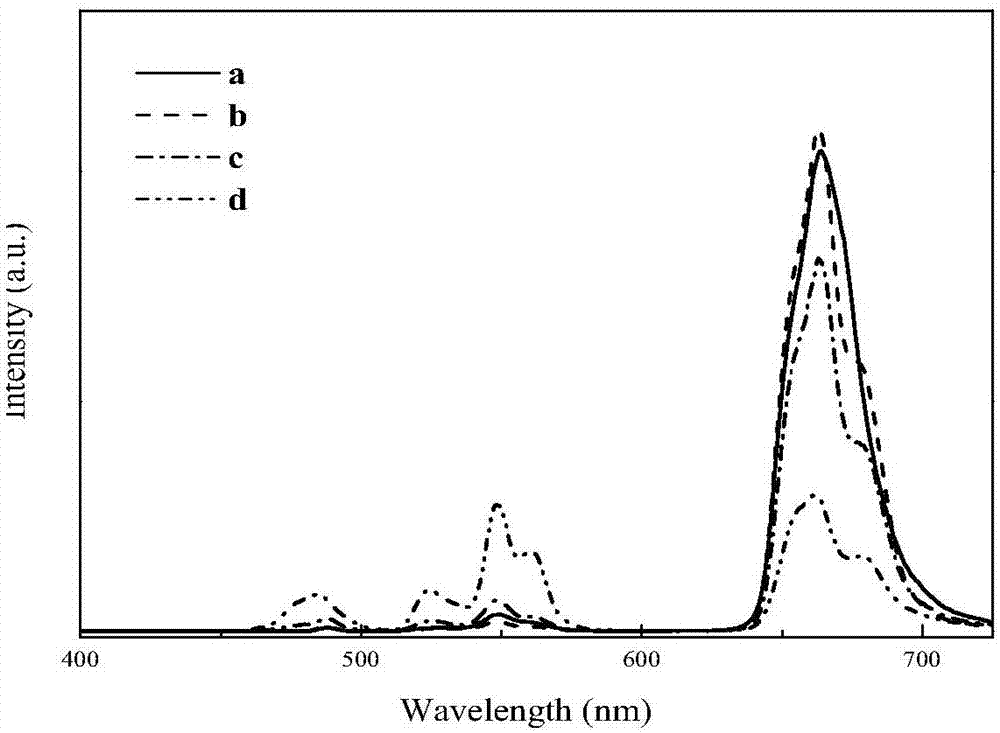

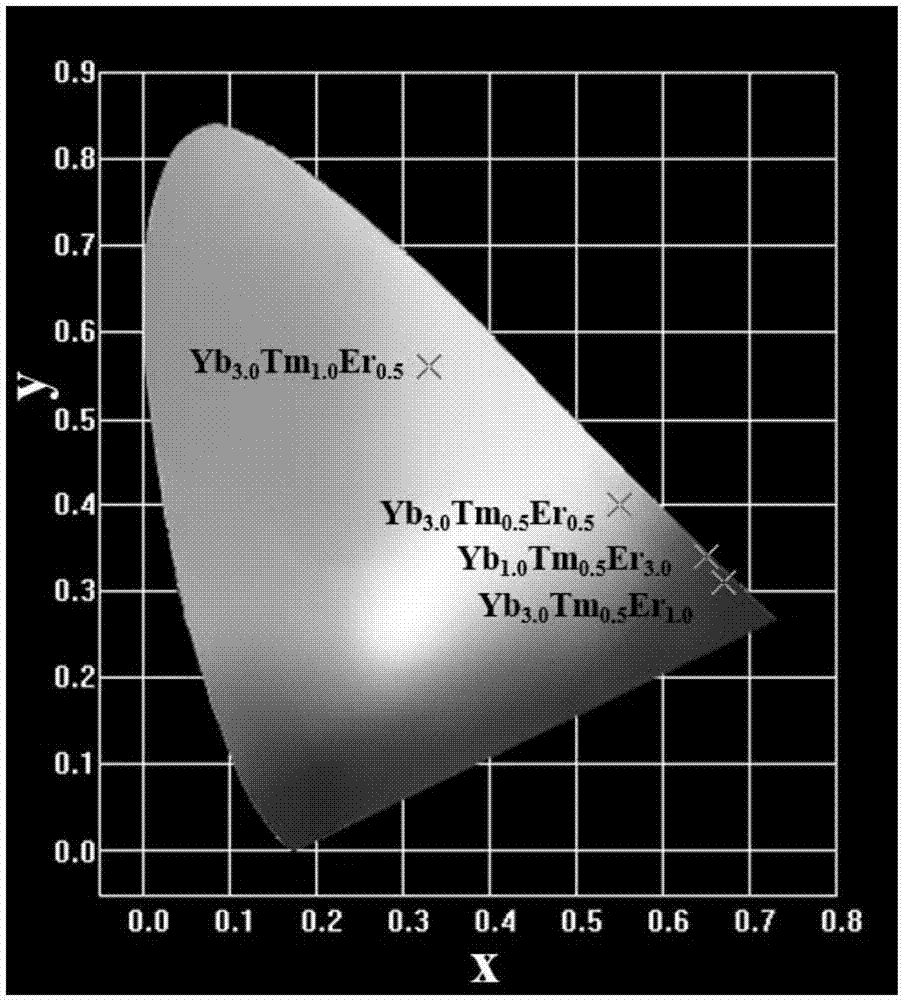

Rare-earth ion doped mayenite polycrystalline powder with up-conversion photochromic adjustability and preparation method and application

InactiveCN107011894AWith light color adjustmentNo pollution in the processLuminescent compositionsYTTERBIUM OXIDEDispersity

The invention discloses rare-earth ion doped mayenite polycrystalline powder with up-conversion photochromic adjustability. The rare-earth ion doped mayenite polycrystalline powder is prepared by grinding calcium carbonate, aluminum oxide, ytterbium oxide, thulium oxide and erbium oxide, calcining at 1320-1420 DEG C, cooling and then grinding. The molar ratio of aluminum oxide to calcium carbonate is 7:12; the doping molar concentration of tterbium oxide is 0.5-1.5%; the doping molar concentration of thulium oxide is 0.25-0.5%; and the doping molar concentration of erbium oxide is 0.25-1.5%. The doped mayenite polycrystalline powder is good in dispersity and has the photochromic adjustability, and adjustment of green light-yellow light-red light can be achieved through adjusting the doping concentration and the proportional relationship of aluminum oxide, the ytterbium oxide and the thulium oxide under the excitation of 980nm infrared light.

Owner:GUANGDONG UNIV OF TECH

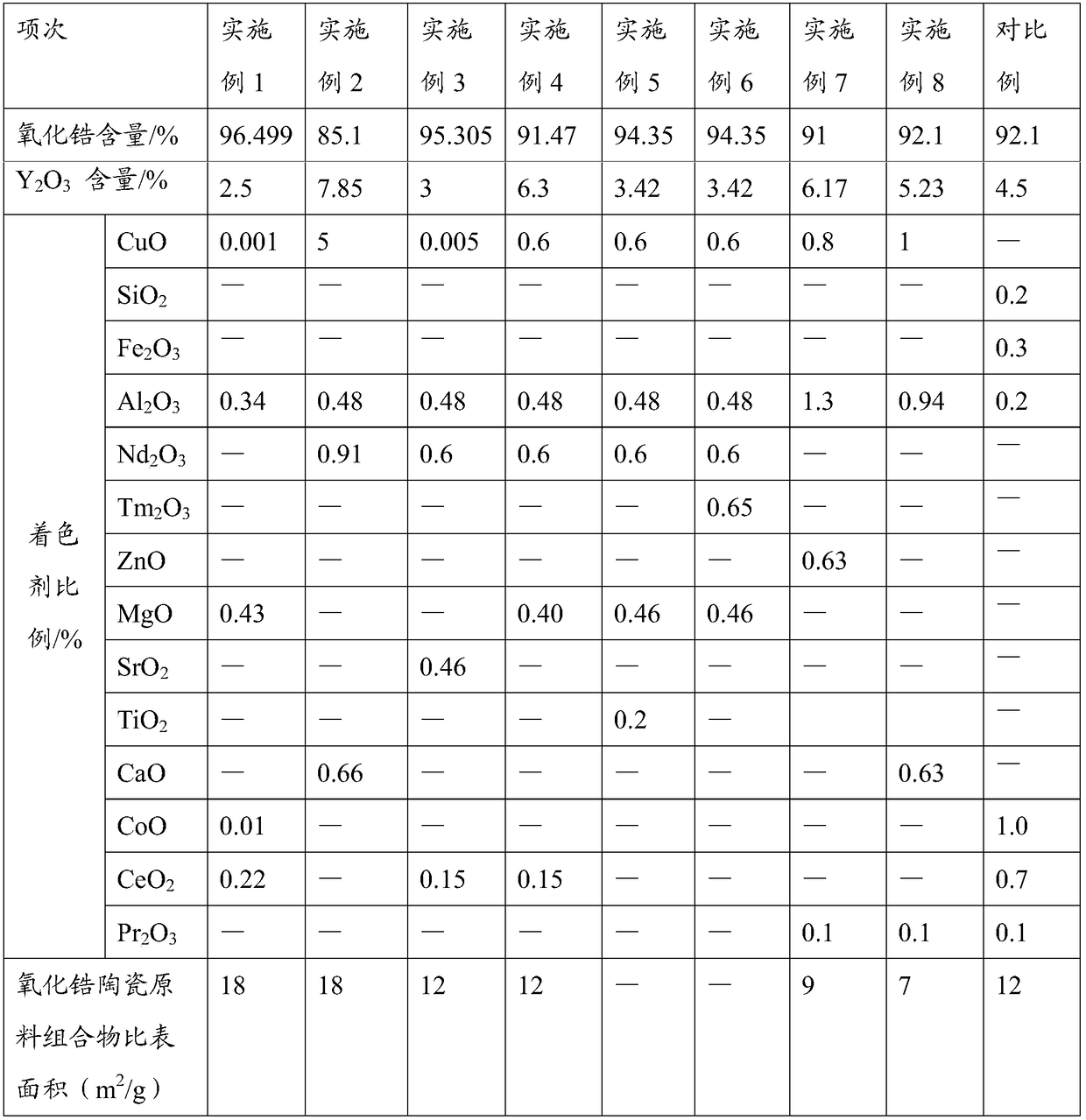

Color matching composition, zirconia ceramic raw material composition, zirconia ceramic and preparation method of zirconia ceramic

The invention relates to a color matching composition, a zirconia ceramic raw material composition, a zirconia ceramic and a preparation method of the zirconia ceramic. The color matching compositionis used for adjusting the color of the zirconia ceramic and is characterized by comprising a first component, a second component and a third component; the first component is copper oxide, the secondcomponent is chosen from at least one of aluminum oxide, thulium oxide and neodymium oxide; the third component is chosen from at least one of cerium oxide, zinc oxide, calcium oxide, cobaltous oxide,magnesium oxide, strontium oxide, titanium oxide and praseodymium oxide, wherein the mass ratio of the first component to the second component to the third component is (0.001-5):(0.001-20):(0.001-20). The color matching composition can be applied to the sapphirine zirconia ceramic obtained in the zirconia ceramic.

Owner:CHAOZHOU THREE CIRCLE GRP

Preparation method of rare earth modified high-intensity non-woven fabrics

InactiveCN108998854AImprove mechanical propertiesHigh Strength Mechanical PropertiesNon-woven fabricsMonocomponent polyesters artificial filamentPolytetramethylene terephthalateMass ratio

The invention discloses a preparation method of rare earth modified high-intensity non-woven fabrics. The preparation method comprises the following operating steps of (1) adding lutecium chloride andthulium chloride to water, then continuing adding sodium napthionate to the water, performing uniform mixing and stirring so as to obtain a mixture, raising the temperature of the mixture, and performing heat preservation so as to obtain rare earth naphthenates; (2) uniformly mixing the rare earth naphthenates with nanometer lutecium oxide, nanometer thulium oxide, sodium methallyl sulfonate andethylenediamine base propanesulfonate so as to obtain resin modifying agents; and (3) uniformly mixing polybutylene terephthalate slices with the resin modifying agents and a flow modifier to obtain anew mixture, adding the new mixture to a slice pelleting machine, performing co-mixing and granulation to obtain PBT master batches, adding the PBT master batches and the polybutylene terephthalate slices to dissolving and spraying equipment in the mass ratio of the PBT master batches to the polybutylene terephthalate slices being 1 to (15-20), and performing melt spinning and knitting so as to obtain the rare earth modified high-intensity non-woven fabrics. The non-woven fabrics prepared by the preparation method disclosed by the invention have good mechanical properties, and can be used under various high-intensity conditions.

Owner:HEFEI SHENGDA GARMENT ACCESSORIES CO LTD

Preparation method of rhododendron culture medium

The invention relates to a preparation method of a rhododendron culture medium. The preparation method comprises the steps of mixing 20-25 parts by weight of vermiculite, 30-35 parts by weight of pearl sand, 10-15 parts by weight of river sand and 10-12 parts by weight of coal slag, adding 0.1 part by weight of thulium oxide and 1 part by weight of carbendazim, uniformly mixing, covering the mixture for 1-2 days by virtue of a plastic film, flushing the mixture for 3-5 times by virtue of clean water, uniformly mixing the aired mixture by virtue of 0.4% compound fertilizer liquid, and covering the mixture for 30-45 days by virtue of the plastic film, so as to obtain the rhododendron culture medium. The preparation method has the advantages of available raw materials, low cost, environmental friendless, convenient use and good effect.

Owner:桐乡宏晨工业设计有限公司

Method for synthesizing rare earth Tm-doped CdTe:Tm quantum dot by hydrothermal method

InactiveCN103627395ARaw materials are easy to getLow costMaterial nanotechnologyNanoopticsQuantum yieldRare earth

The invention discloses a method for synthesizing a rare earth Tm-doped CdTe:Tm quantum dot by a hydrothermal method. The preparation method comprises the following operation steps: injecting a previously prepared NaHTe solution in a previously prepared mixed solution of cadmium salt, thulium oxide and a water-soluble N-acetyl-L-cysteine modifier under nitrogen protection to obtain a rare earth Tm-mixed CdTe precursor solution, then putting the precursor solution in a hydrothermal reaction kettle for reaction to prepare the rare earth Tm-doped CdTe:Tm quantum dot with adjustable fluorescence emission wavelength and high fluorescence quantum yield. The hydrothermal method has the advantages of low cost, simplicity and convenience in operation, environmental protection and the like. The obtained rare earth Tm-doped CdTe:Tm quantum dot has the advantages of excellent fluorescence performance, great biologic compatibility and low toxicity and can be widely used in the fields of biochemical analysis and biomedicine as a novel fluorescent nanometer probe.

Owner:GUANGXI TEACHERS EDUCATION UNIV

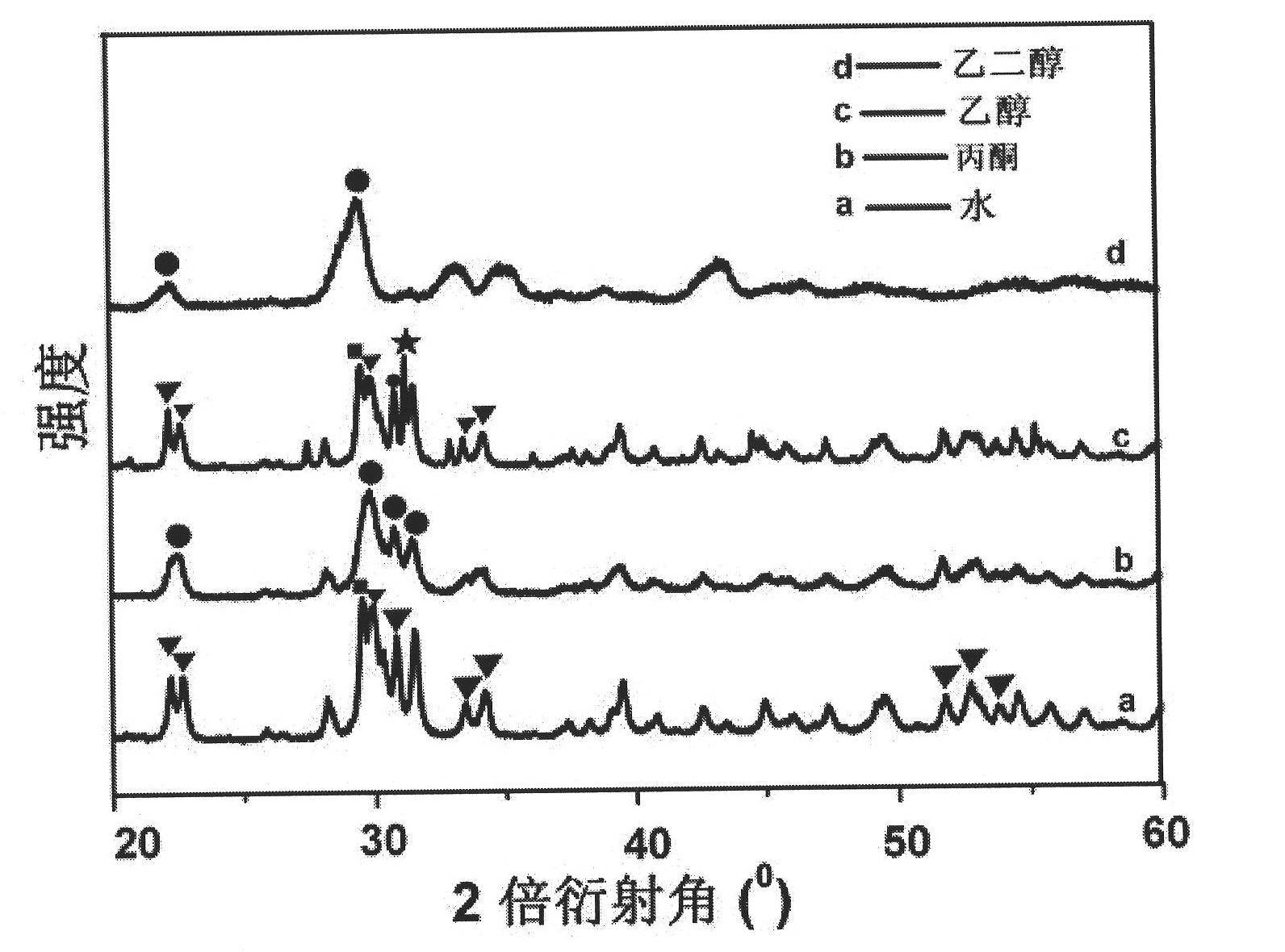

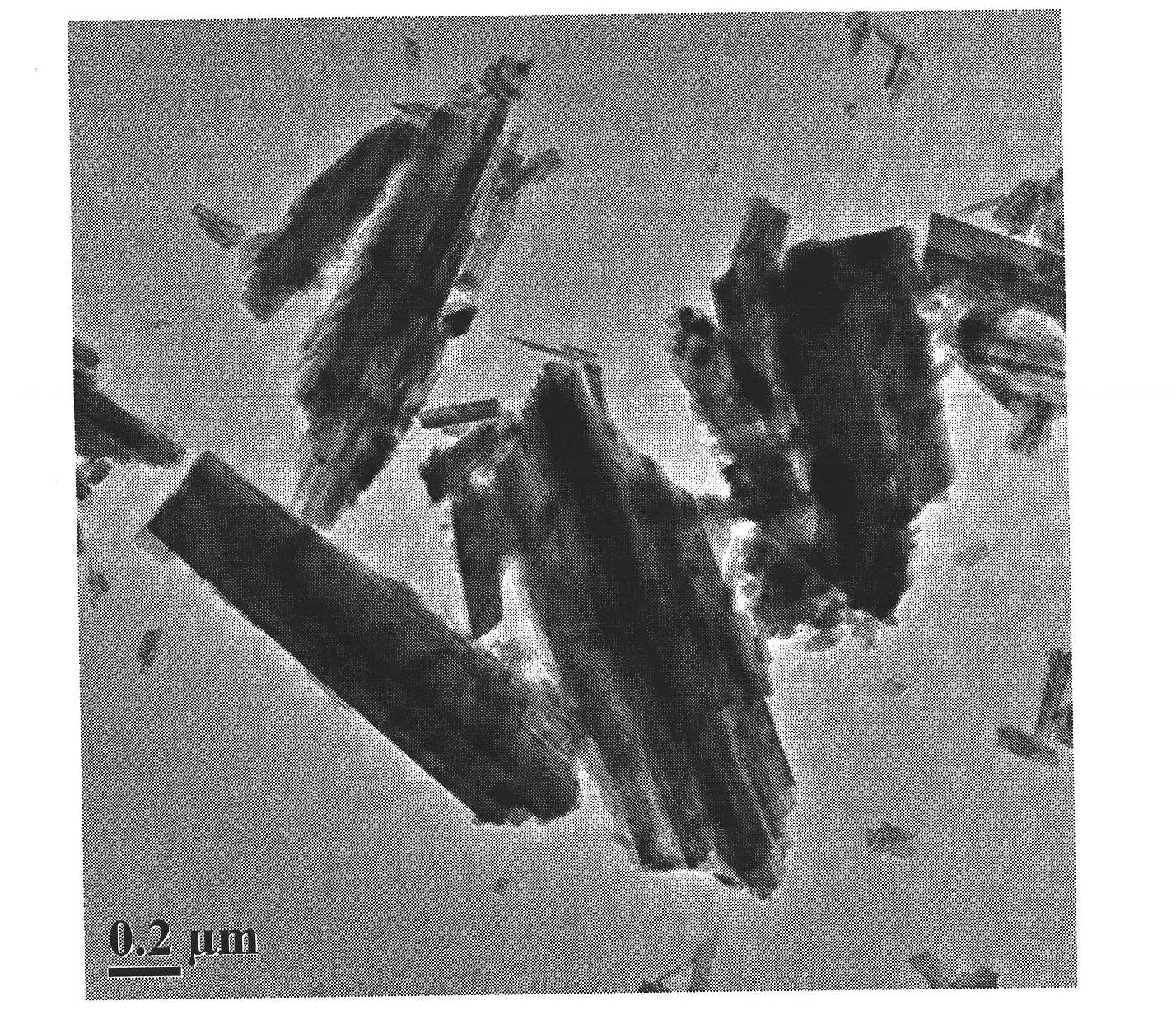

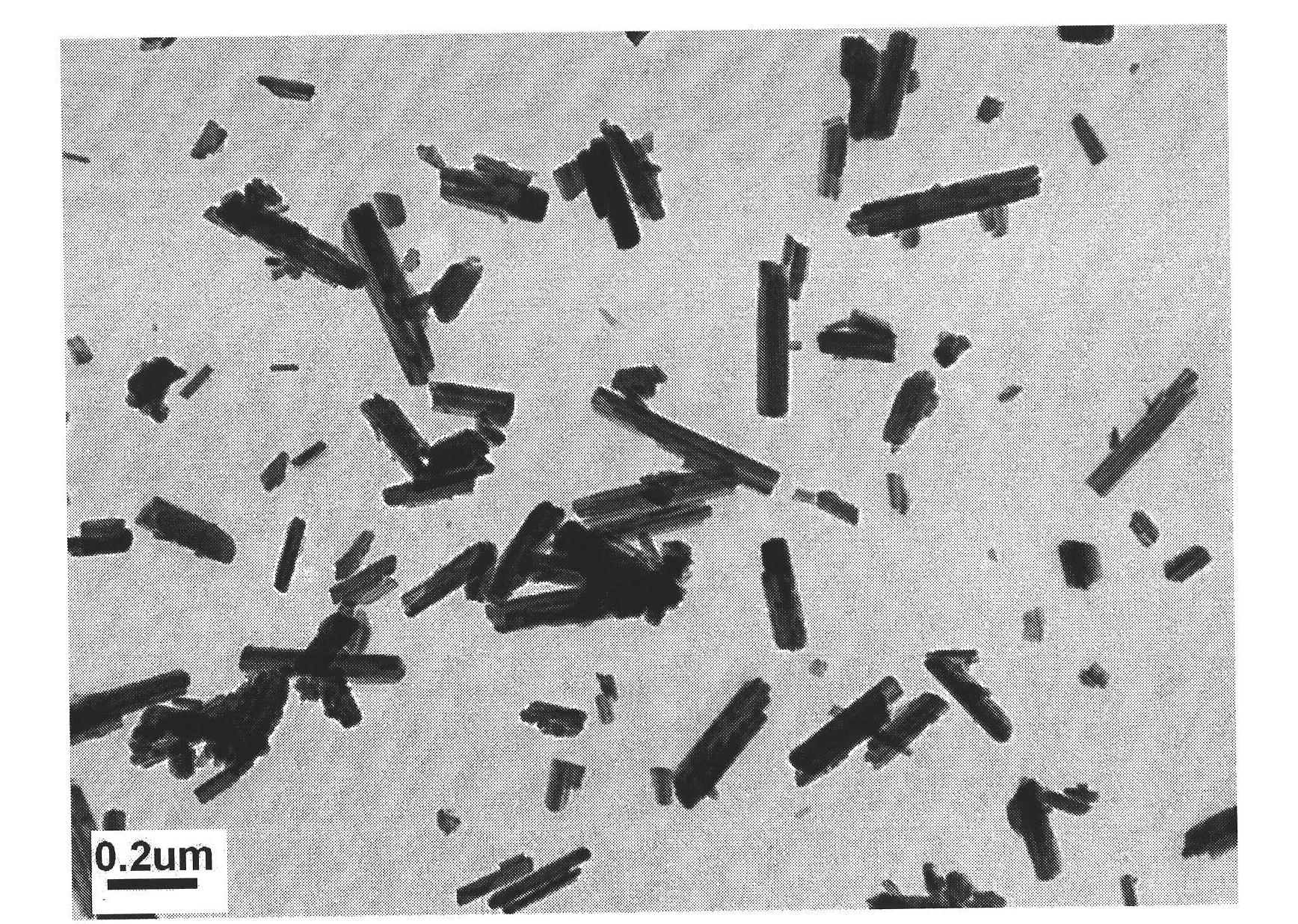

Solvent thermal synthesis method of Lu2O3 nanorod luminescent powder

InactiveCN101787279ABroaden the preparation pathEasy to manufactureLuminescent compositionsLutetiumSynthesis methods

The invention relates to a solvothermal synthesis method of Lu2O3 nanorod luminescent powder and relates to the rare earth nanometer material preparation and the microstructural regulation and control thereof. The method comprises the following steps: adopting commercial rare earth oxides (lutecium oxide, europium oxide, neodymium oxide, praseodymium oxide and thulium oxide) as raw materials, separately dissolving the raw materials in concentrated nitric acid, diluting, preparing Lu(NO3)3 solution doped with a defined concentration of RE(NO3)3 (RE is one of Eu, Tb, Nd, Pr and Tm) solution, then dropping ammonia water to react and generate precipitate, mixing the precipitate and solvents with different components and properties, placing the mixtures in a sealed reaction tank to perform solvothermal reaction at 100-300 DEG C and synthesize lutetium-based precursor products with different features; and further calcining precursor power at 400-1000 DEG C for 1-3 hours to prepare the Lu2O3 nanorod luminescent powder. The method of the invention has simple and practical process, the feature of the product can be conveniently controlled by adjusting the type of solvent during the solvothermal process, and Lu2O3 nanorod powder can be obtained.

Owner:SHANGHAI UNIV

Vitamin K3 drug intermediate 2-menaquinone synthesis method

InactiveCN108238880AReduce pollutionReduction of intermediate links in the reactionQuinone preparation by oxidationQuinone separation/purificationVitamin K31-Propanol

The invention discloses a vitamin K3 drug intermediate 2-menaquinone synthesis method, which comprises: adding 1,4-dihydroxy-2-methyl naphthalene and a potassium chloride solution in a reaction container, increasing the temperature of the solution, controlling the stirring speed, adding an acetylacetone solution, carrying out a reaction, adding thulium oxide in batches, increasing the temperatureof the solution, carrying out a reaction for 60-90 min, adding a potassium sulfate solution, reducing the temperature to 10-16 DEG C, carrying out standing layering, adding an oxalic acid solution, adjusting the pH value to 5-6, washing with a 3-chloro-1-propanol solution, washing with a chlorohexane solution, re-crystallizing in a sulfuryl chloride solution, and dehydrating with a dehydrating agent to obtain the finished product 2-menaquinone.

Owner:CHENGDU QIESITE TECH CO LTD

Extraction and purification method for thulium oxide

InactiveCN106756016AIncrease loadHigh purityProcess efficiency improvementPurification methodsElution

The invention discloses an extraction and purification method for a thulium oxide. The method comprises the steps of preparation of liquid to be purified, intermediate agent preparation, separation column preparation, elution column transformation, adsorption operation, elution ion exchange operation, collection of liquid according to the volume for sampling analysis, concentrated sedimentation, mixing and collection, waste liquid processing and the like. The existing roughly-processed collected low-purity thulium oxide is purified again, and the purity of the thulium oxide reaches 99.995%-99.99999%.

Owner:中国稀有稀土股份有限公司 +1

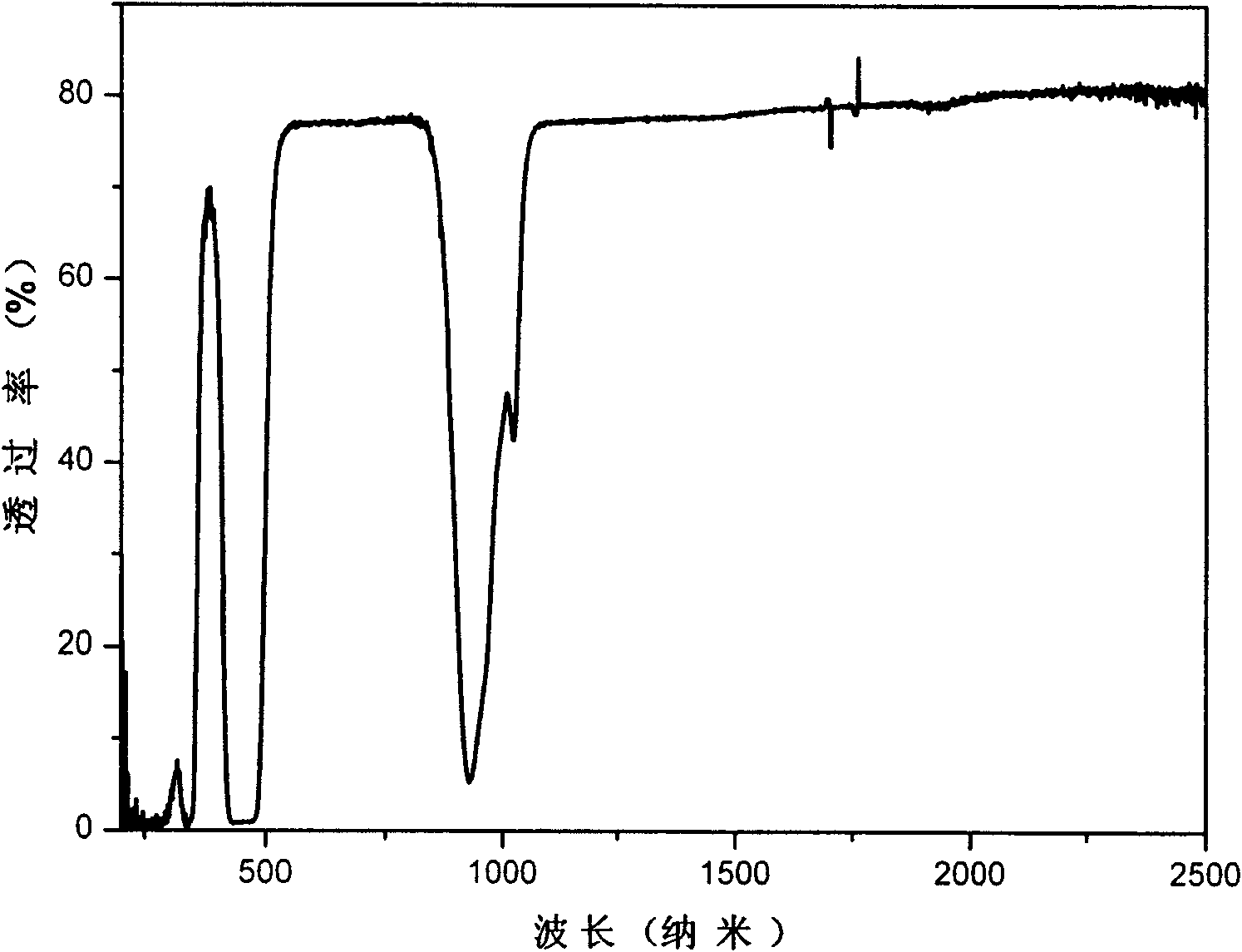

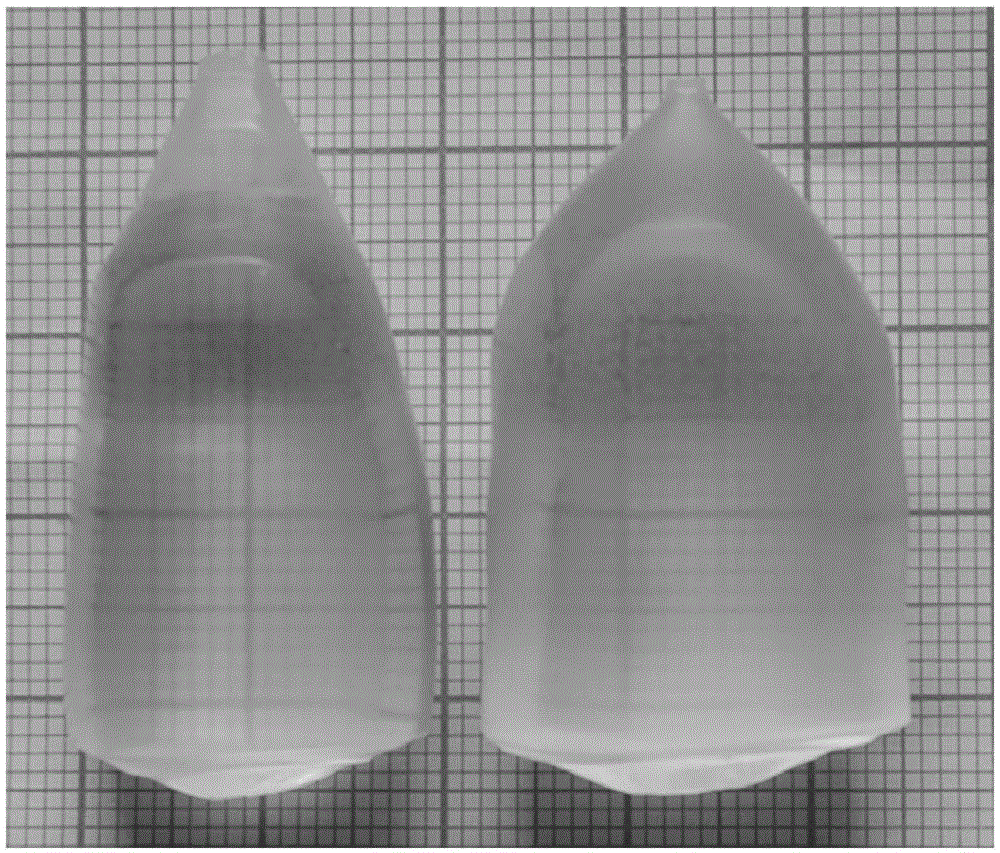

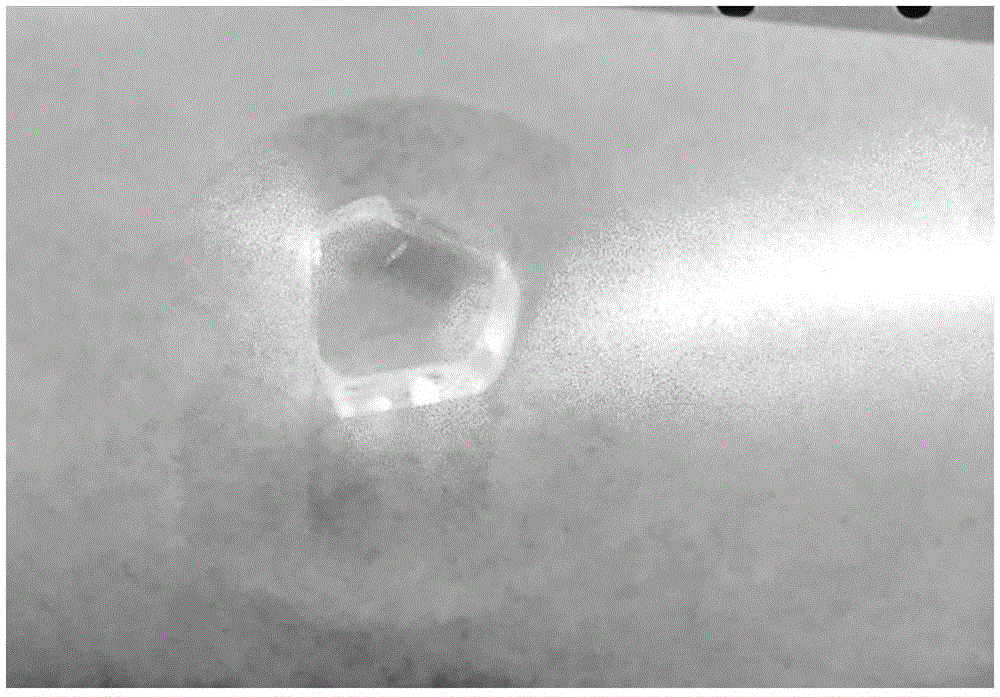

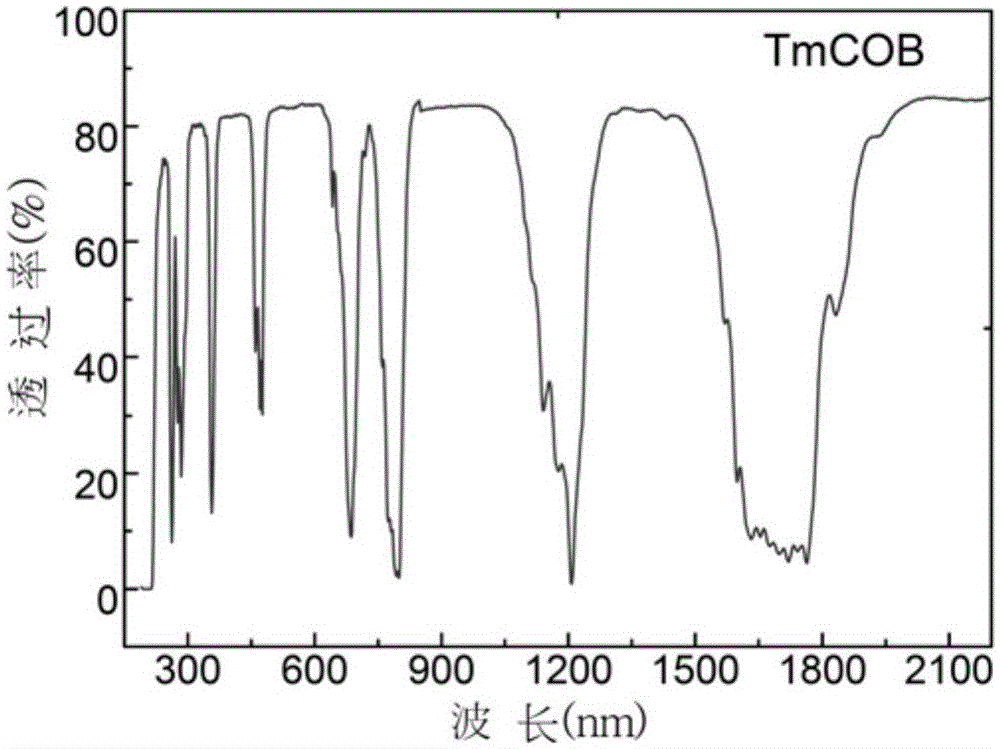

A high-performance photoelectric functional crystal calcium borate thulium oxide crystal and its growth and application

ActiveCN103422172BPolycrystalline material growthBy pulling from meltNonlinear optical crystalElectromechanical coupling coefficient

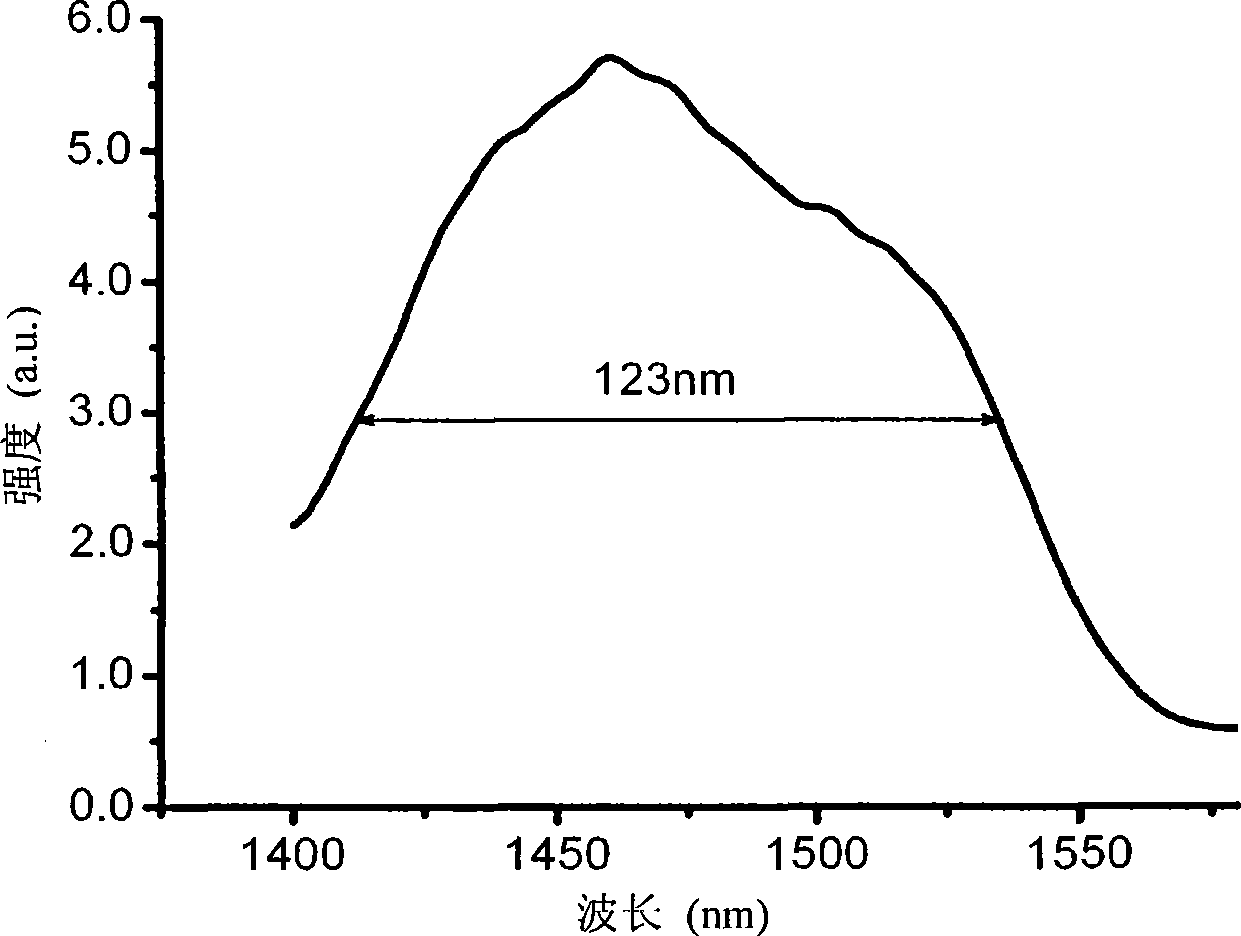

The invention relates to high-performance photoelectric functional calcium borate thulium oxide crystal and growth and application thereof. The formula of the calcium borate thulium oxide crystal is TmCa4O(BO3)3; the crystal in a non-centrosymmetric structure belongs to monoclinic m-point groups and is 101.12 DEG in cell parameter beta, boils at 1460 DEG C, and shows no change at the temperature from the room temperature to the boiling point. A growth method of the crystal includes preparation of polycrystalline material and growth by the Czochralski method; the high-quality calcium borate thulium oxide crystal 20-40mm in diameter and 20-50mm in height can be made. The TmCa4O(BO3)3 crystal is larger than 80% in optical transmittance under the frequency of 808nm-1100nm and 1300nm-156-nm, has an effective piezoelectric constant of deff=1pC / N-5pC / N and effective electromechanical coupling factor of keff=10-30%, and can be used as nonlinear optical crystals, laser crystals or piezoelectric crystals.

Owner:SHANDONG UNIV

Luminescent glass

The invention belongs to the technical field of glass, and particularly relates to luminescent glass. The luminescent glass is prepared from the following raw materials in parts by weight: 40 to 70 parts of silicon dioxide, 10 to 22 parts of aluminum oxide, 2 to 8 parts of sodium oxide, 3 to 9 parts of sodium phosphate, 0.1 to 0.7 part of thulium oxide, 0.2 to 1.4 parts of samarium oxide and 0.03 to 0.21 part of neodymium oxide. The luminescent glass disclosed by the invention is high in transparency and high in light efficiency; light rays are uniform, stable, and high in brightness.

Owner:QINZHOU ZHONGBO GLASS CO LTD

Nickel-hydrogen high-temperature super large capacity battery

InactiveCN101140988AExcellent high temperature charging performanceImproved high power performanceAlkaline accumulator electrodesCell component detailsHydrogenPower performance

The invention relates to the cell field, which is a Ni-MH high-temperature cell with ultra high capacity. The invention provides a Ni-MH high-temperature cell with ultra high capacity worked under high power and high capacity condition. The technical solution adopted in the invention is: a Ni-MH high-temperature cell with ultra high capacity which comprises anode based on Ni(OH)2, a septum and alkalescency electrolyte, an additive added into the anode for preventing oxygen separating out and bearing high temperature in anode material. The additive is a mixture of calcium oxide, thulium oxide and titanium oxide. The invention is characterized in excellent performance of high temperature electrification and high power.

Owner:邹平铭波电源有限公司

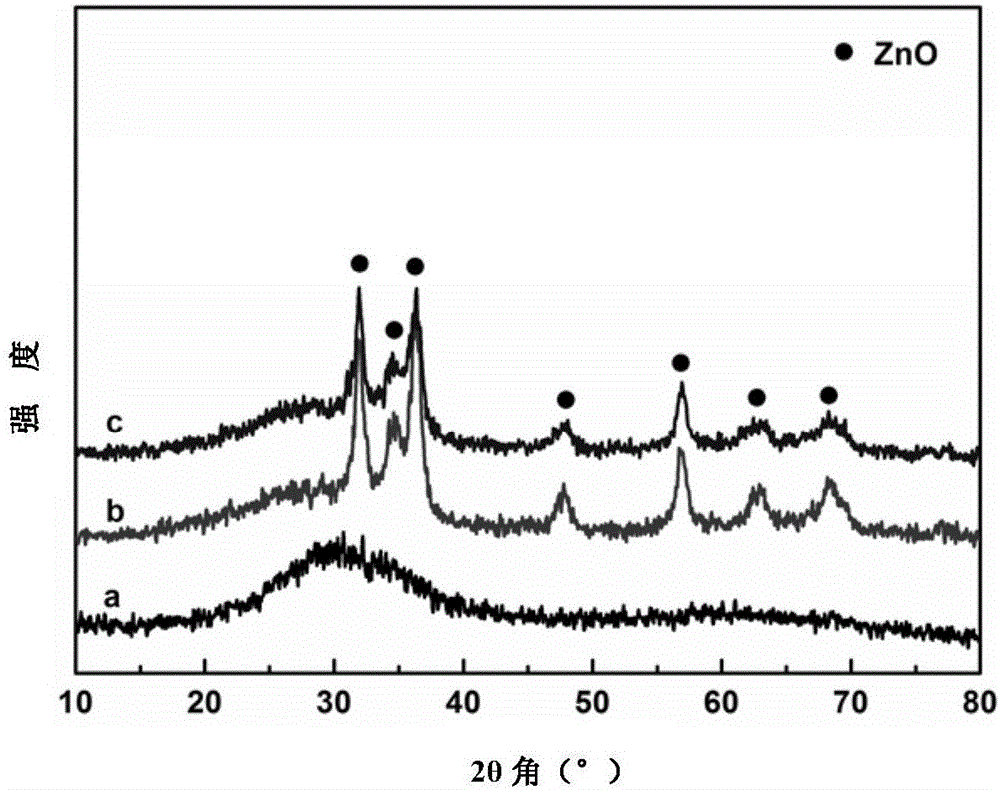

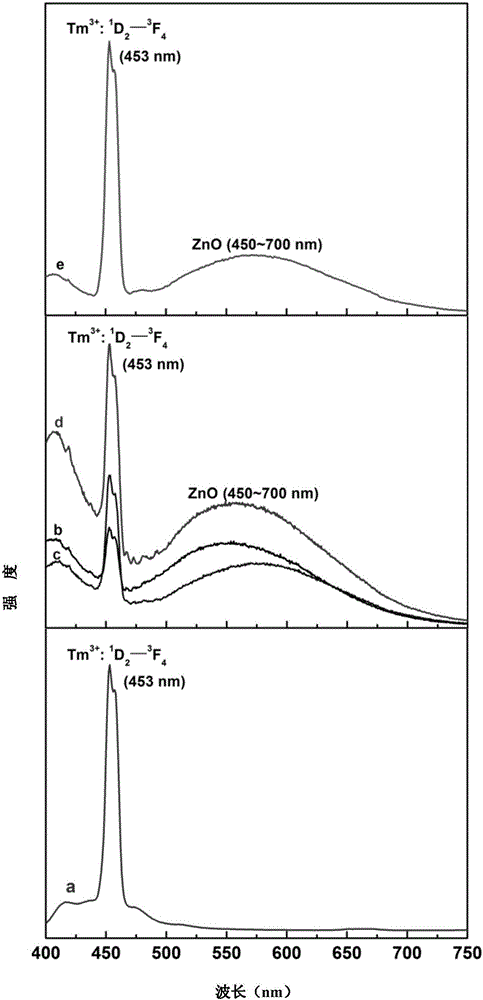

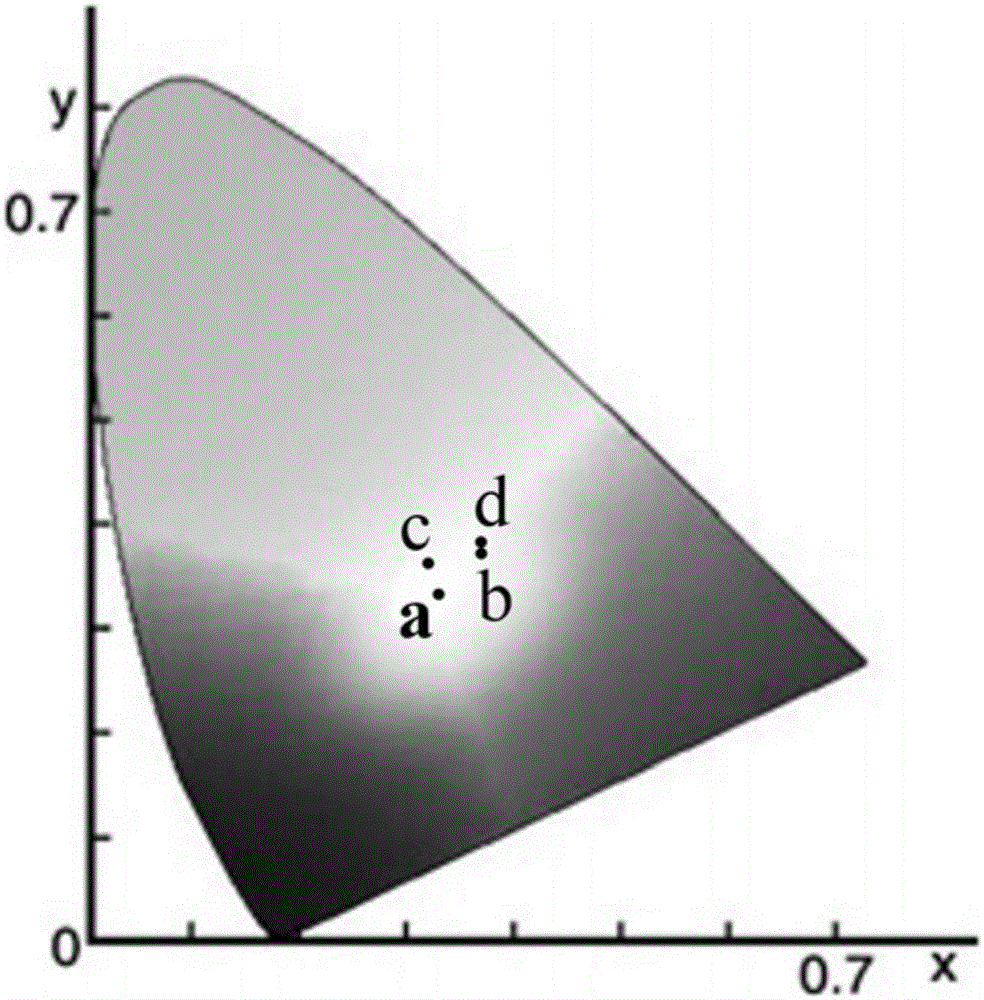

Method for preparing rare earth ion Tm3+ and ZnO nanocrystalline codoping alumina silicate glass as well as products and application thereof

The invention discloses a method for preparing rare earth ion Tm<3+> and ZnO nanocrystalline codoping alumina silicate glass. The method comprises the following steps: firstly mixing silicon oxide, aluminum oxide, potassium carbonate, zinc oxide and thulium oxide, heating and melting the mixture, and pouring the molten mixture on a copper plate or a graphite plate to cool to room temperature, thereby obtaining quenched glass, wherein the mole rate of the silicon oxide to the aluminum oxide to the potassium carbonate to the zinc oxide to the thulium oxide is 44:11:10:35:(0.005-0.05); keeping the temperature of the quenched glass, thereby obtaining annealed glass; and performing a heat treatment on the annealed glass, thereby obtaining the rare earth ion Tm<3+> and ZnO nanocrystalline codoping alumina silicate glass. The method for preparing the rare earth ion Tm<3+> and ZnO nanocrystalline codoping alumina silicate glass, provided by the invention, has the advantages of simple and convenient process and low cost, and the prepared products can achieve common emission of white lights.

Owner:ZHEJIANG UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com