Three-wrapping-layer thulium-doped optical fiber and preparation method thereof

A three-cladding, optical fiber preform technology, applied in cladding optical fibers, multi-layer core/cladding optical fibers, etc., can solve the problem of large core refractive index, increased core numerical aperture, and reduced output laser beam quality, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention provides a method for preparing a three-clad thulium-doped optical fiber described in the above technical solution, comprising the following steps:

[0043] 1) Depositing an inner cladding layer and a loose core layer on the inner surface of the quartz deposition tube in sequence;

[0044] 2) immerse the quartz deposition tube with an inner cladding and a loose core layer deposited on the inner surface obtained in the step 1) in a solution containing thulium ions and aluminum ions;

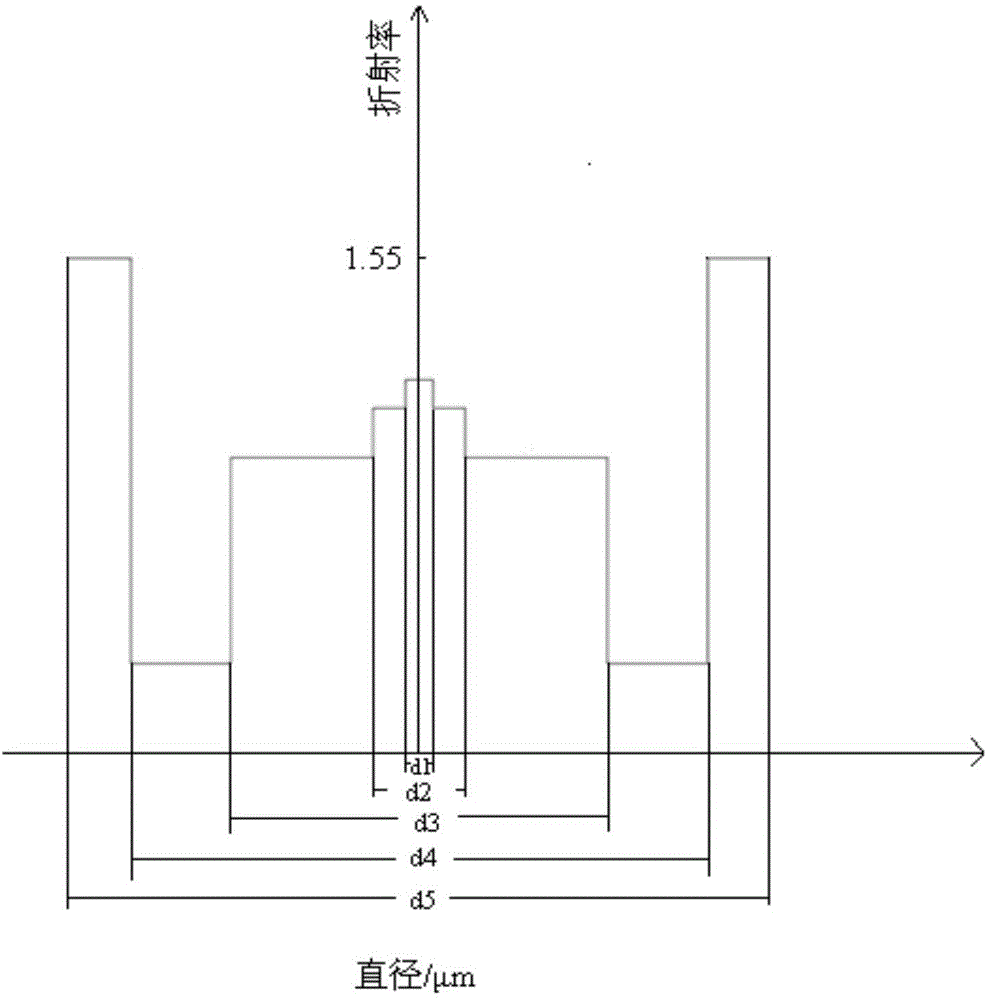

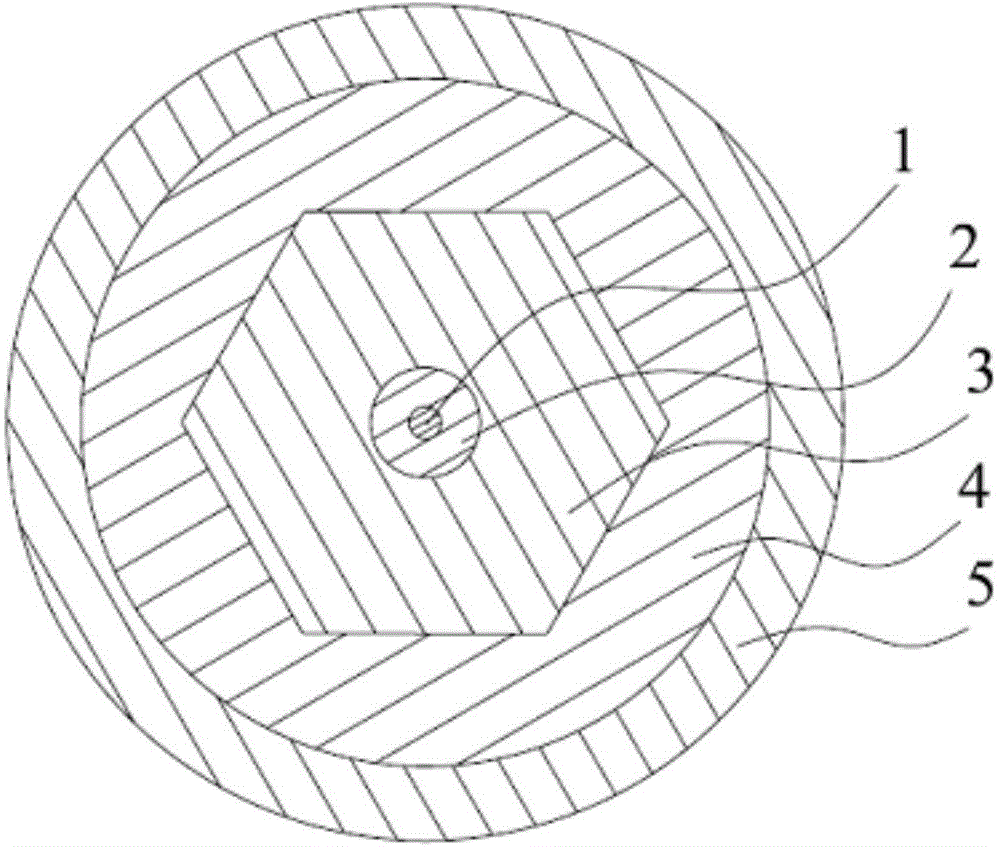

[0045] 3) Drying, sintering, and shrinking the quartz deposition tube soaked in step 2) in sequence to obtain a thulium-doped optical fiber preform, the thulium-doped optical fiber preform includes a core and an inner package that is sequentially sleeved on the surface of the core layer and outer cladding; the core includes silicon dioxide, thulium oxide, aluminum oxide and phosphorus pentoxide, the molar content of thulium oxide is 0.2 to 0.8%, and the molar content o...

Embodiment 1

[0066] After the quartz deposition tube is subjected to high-temperature flame polishing, silicon tetrachloride, germanium tetrachloride and oxygen are passed through the inner surface of the quartz deposition tube at 1970° C. to deposit an inner cladding. Then lower the temperature, pass through silicon tetrachloride, phosphorus oxychloride and oxygen, and adopt reverse deposition of loose core layer. Then move the blowtorch to the tail end of the deposition tube, raise the temperature and break the quartz deposition tube, so that the tail end of the quartz deposition tube is closed.

[0067] Remove the capped deposition tube from the lathe. Will contain 0.06mol / L of TmCl 3 ·6H 2 O and 1mol / L AlCl 3 ·6H 2 An aqueous solution of O was slowly added to the deposition tube containing the loose core layer and soaked for about 1.5 hours. Pour out the remaining solution, install the deposition tube on the lathe again, blow it with nitrogen, then raise the temperature to 1000°C,...

Embodiment 2

[0071] The quartz deposition tube is subjected to high-temperature flame polishing, and silicon tetrachloride, aluminum chloride and oxygen are passed through the inner surface of the quartz deposition tube at 1970° C. to deposit the inner cladding. Lower the deposition temperature to 1250°C, and pass through silicon tetrachloride, phosphorus oxychloride and oxygen to deposit a loose core layer. Then move the blowtorch to the tail end of the quartz deposition tube, raise the temperature to break the quartz deposition tube, and seal the tail end of the quartz deposition tube.

[0072] The quartz deposition tube was removed from the lathe, and the TmCl containing 0.08mol / L 3 ·6H 2 O and 1.5mol / L AlCl 3 ·6H 2 The O solution was slowly added to the quartz deposition tube containing the loose core and soaked for about 1 h. Pour out the remaining solution, install the quartz deposition tube on the lathe again, turn the deposition tube, blow nitrogen into it, then raise the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com