Solvent thermal synthesis method of Lu2O3 nanorod luminescent powder

A technology of luminescent powder and synthesis method, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., and can solve the problems such as no lutetium oxide nanopowder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

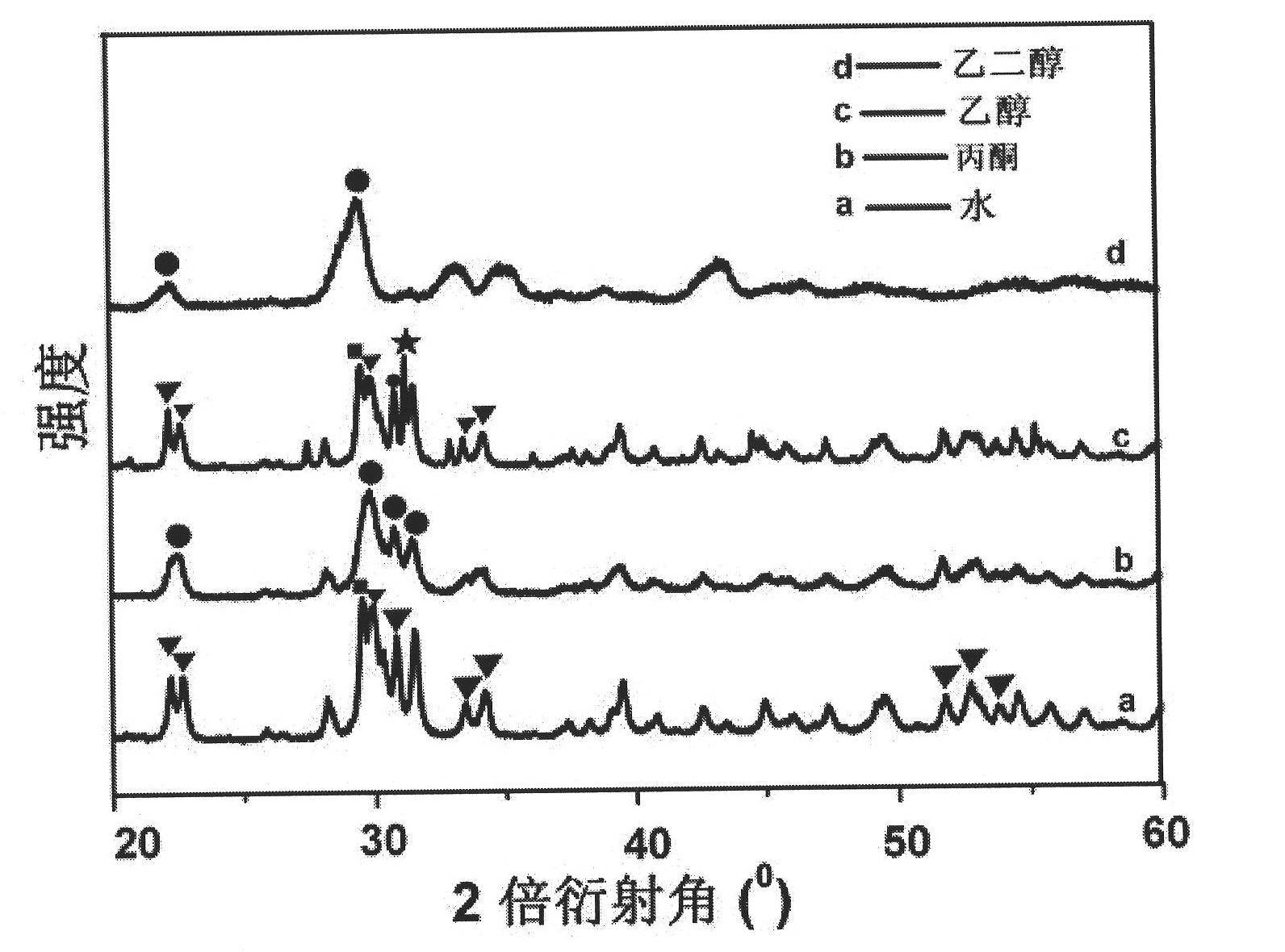

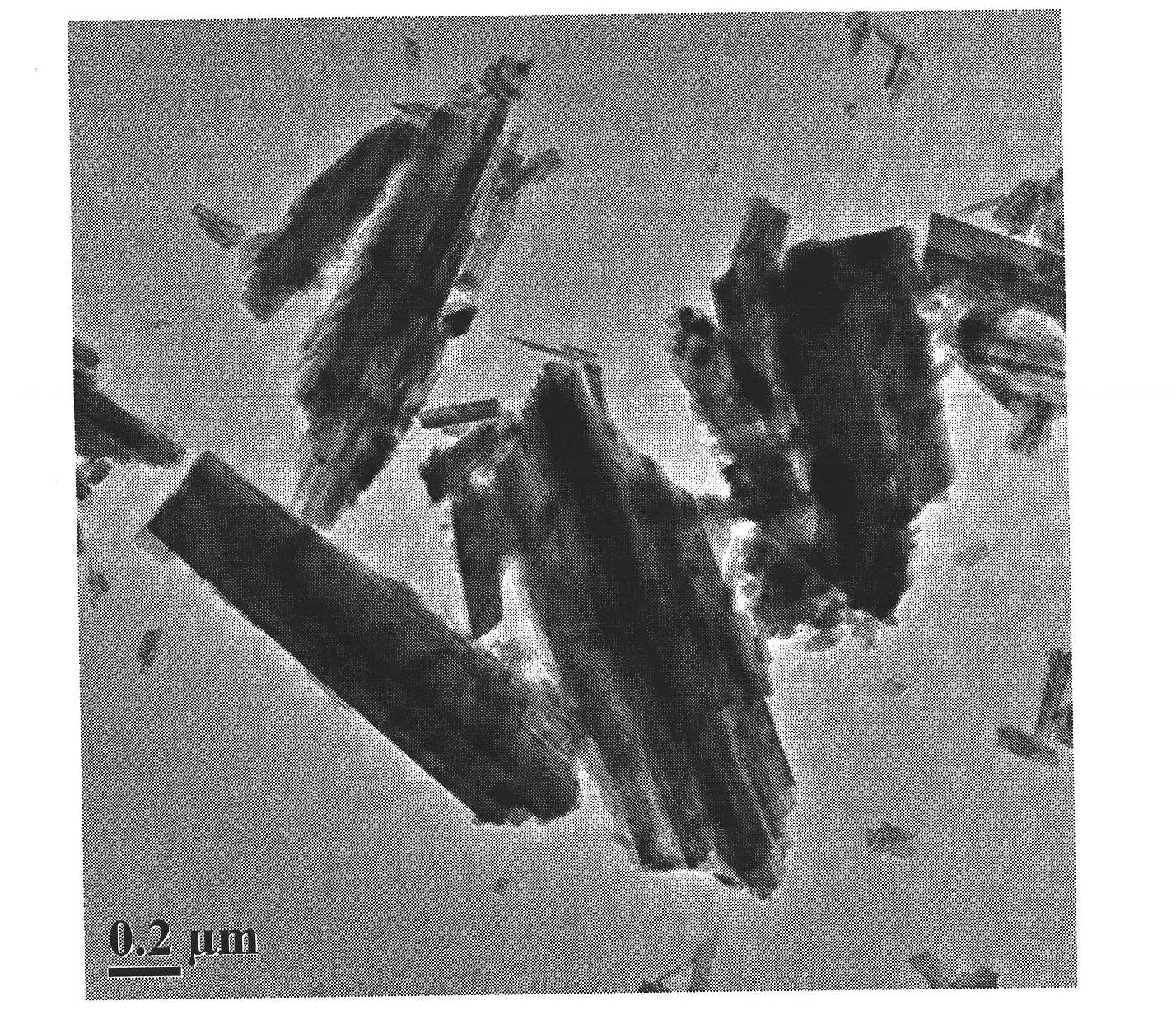

[0033] Embodiment 1: rod-shaped Lu 2 o 3 : Preparation of RE Nano Luminescent Powder

[0034] (1), the commercial Lu 2 o 3 Powder and RE 2 o 3 The powder was dissolved with concentrated nitric acid, and then diluted with deionized water to Lu(NO 3 ) 3 The concentration is 0.526mol / L, Eu(NO 3 ) 3 The concentration is 0.916mol / L, Tb(NO 3 ) 3 The concentration is 0.952mol / L, Nd(NO 3 ) 3 Concentration is 0.535mol / L, Pr(NO 3 ) 3 The concentration is 1.477mol / L, Tm(NO 3 ) 3 The concentration is 0.970mol / L. Measure a certain volume of RE(NO 3 ) 3 The solution was added to 30ml Lu(NO 3 ) 3 In the solution, the molar ratios in the mixed solution were Eu / Lu=5.8%, Tb / Lu=1.0%, Nd / Lu=1.0%, Pr / Lu=1.0%, and Tm / Lu=0.5%.

[0035] (2), under the vigorous stirring condition of magnetic stirrer, the NH of 50ml 3 NH with a content of 25-28wt% 3 ·H 2 The O solution was slowly added dropwise into the prepared mixed solution, and a white precipitate slowly formed, and the stir...

Embodiment 2

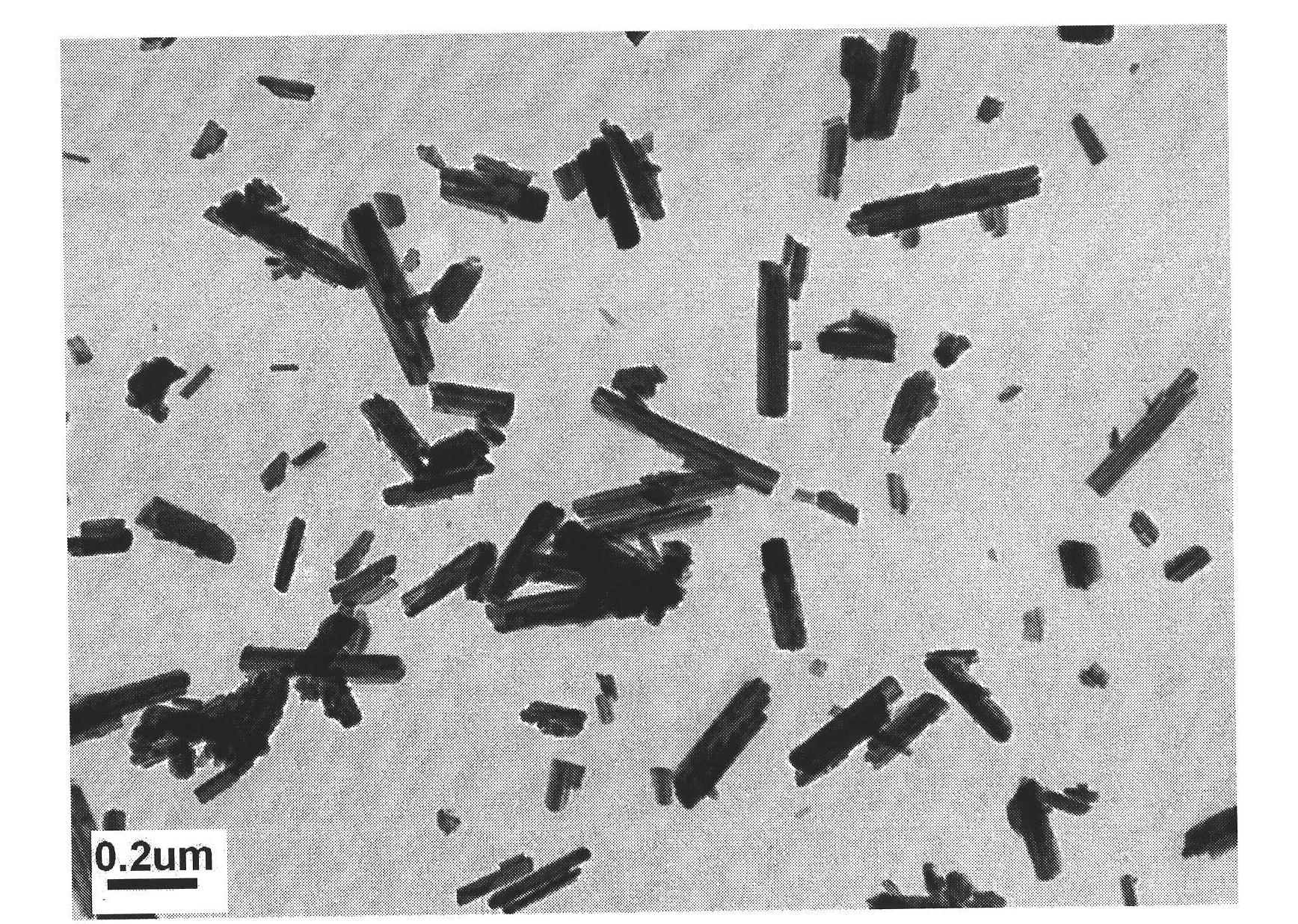

[0041] Embodiment 2: spherical and nearly spherical Lu 2 o 3 : Preparation of RE Nano Luminescent Powder

[0042] (1), the commercial Lu 2 o 3 Powder and RE 2 o 3 The powder was dissolved with concentrated nitric acid, and then diluted with deionized water to Lu(NO 3 ) 3 The concentration is 0.526mol / L, Eu(NO 3 ) 3 The concentration is 0.916mol / L, Tb(NO 3 ) 3 The concentration is 0.952mol / L, Nd(NO 3 ) 3 Concentration is 0.535mol / L, Pr(NO 3 ) 3 The concentration is 1.477mol / L, Tm(NO 3 ) 3 The concentration is 0.970mol / L. Measure a certain volume of RE(NO 3 ) 3 The solution was added to 30ml Lu(NO 3 ) 3 In the solution, the molar ratios in the mixed solution were Eu / Lu=5.8%, Tb / Lu=1.0%, Nd / Lu=1.0%, Pr / Lu=1.0%, and Tm / Lu=0.5%.

[0043] (2), under the vigorous stirring condition of magnetic stirrer, the NH of 50ml 3 NH with a content of 25-28wt% 3 ·H 2 The O solution was slowly added dropwise into the prepared mixed solution, and a white precipitate slowly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com