Transparent ceramic and preparation method thereof

A technology of transparent ceramics and structural formula, applied in the field of transparent ceramics and its preparation, can solve the problems of harmfulness to human body and environment, strong scattering of phosphor powder, easy aging, etc., and achieve the effect of improving conversion efficiency, simple preparation process and good transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Using yttrium oxide (Y) with a purity of 99.9% 2 o 3 ), alumina (Al 2 o 3 ), ytterbium oxide (Yb 2 o 3 ) and cerium oxide (CeO 2 ) powder as raw material, according to Ce 0.003 Yb 0.006 Y 2.991 al 5 o 12 The composition of the powder raw materials is configured, and then the ceramic powder is prepared by wet ball milling with absolute ethanol as the medium. The powder is dried, granulated, and pressed into tablets; then it is subjected to cold isostatic pressure above 200MPa; finally put into a vacuum The sintering furnace was sintered at 1600°C for 5 hours, and the vacuum degree in the sintering and holding stage was 2.5×10 -3 Pa, get Ce 0.003 Yb 0.006 Y 2.991 al 5 o 12 Transparent ceramic.

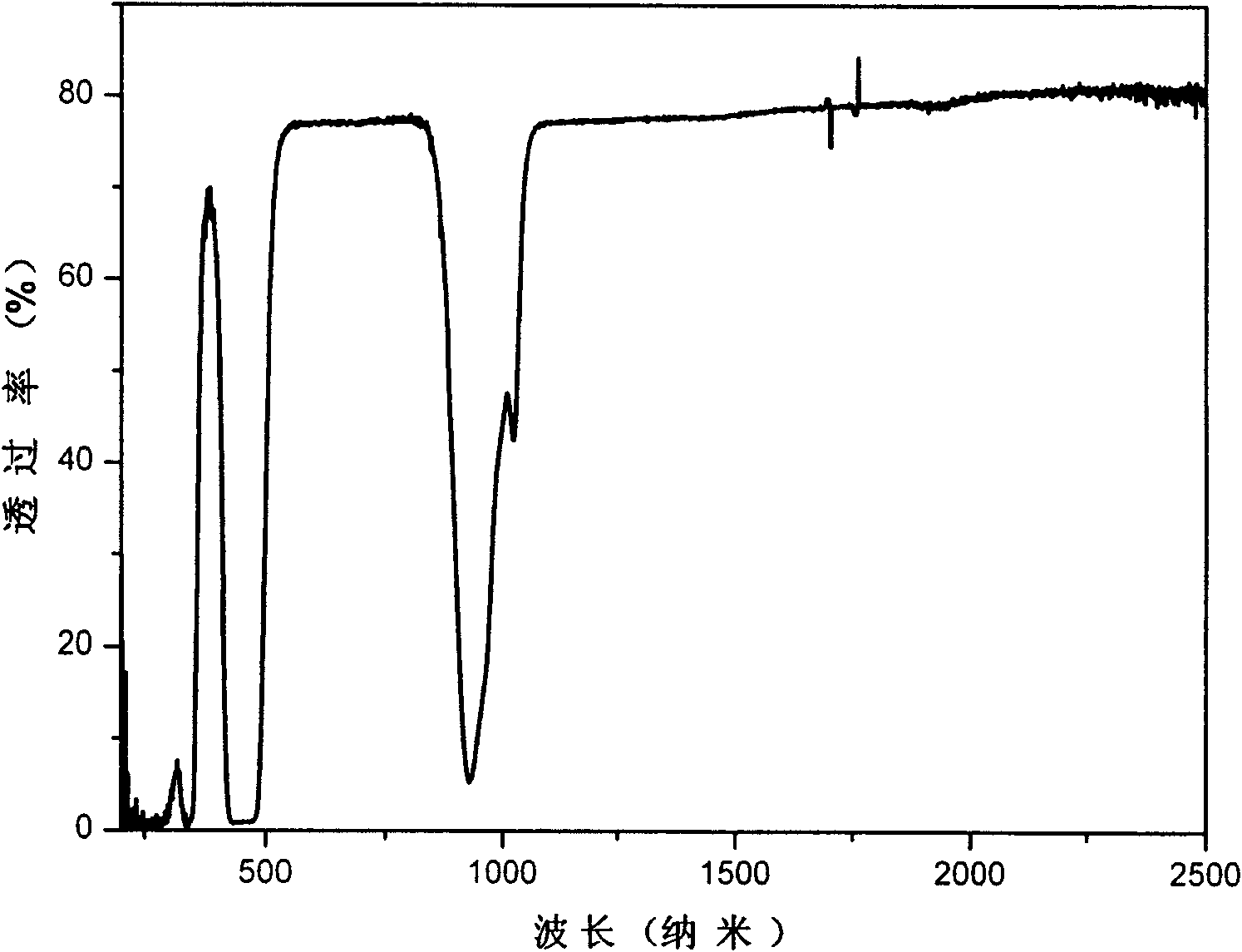

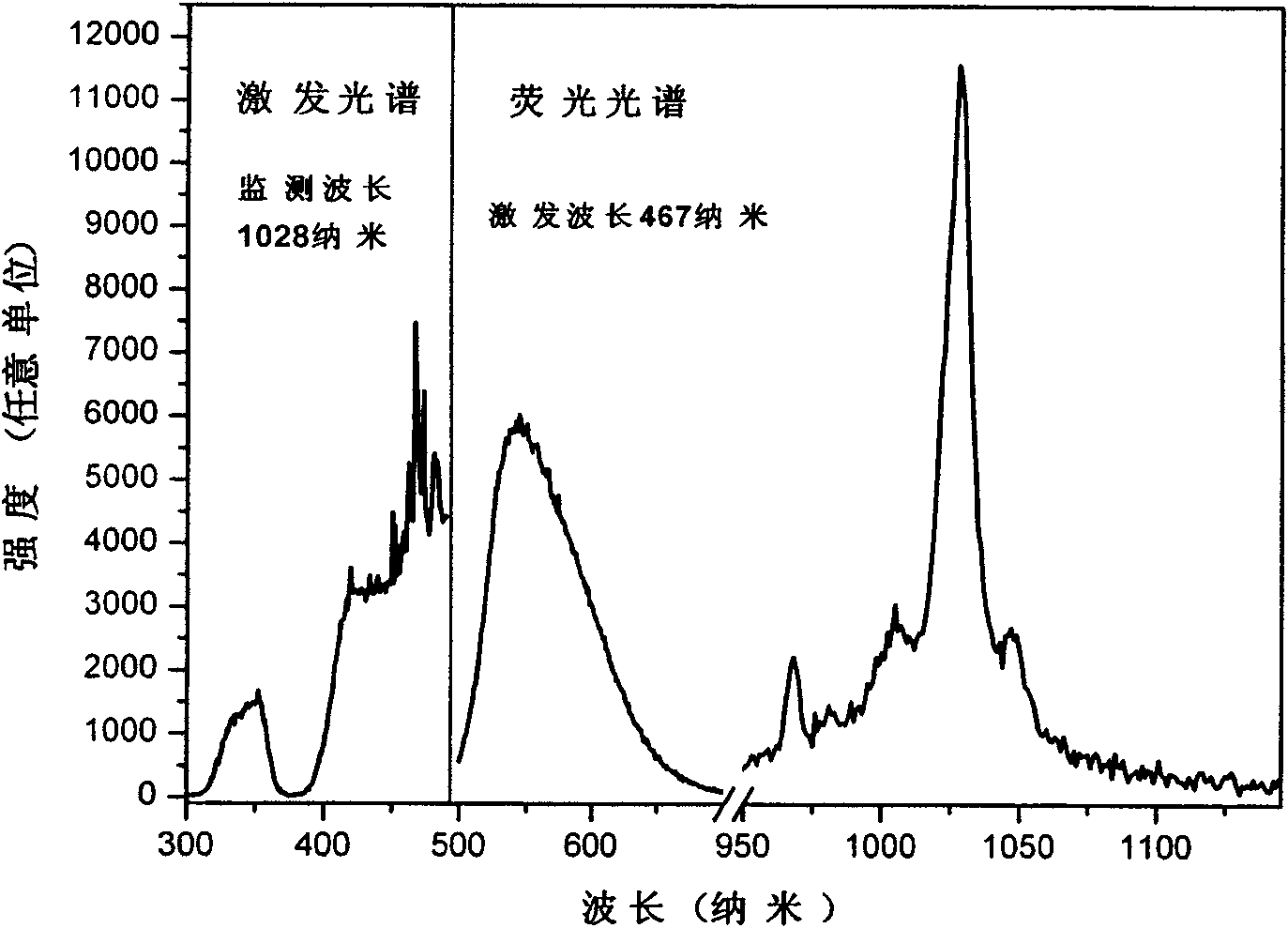

[0026] The transparent ceramics were experimented to obtain as figure 1 and figure 2 The experimental results: figure 1 Ce prepared for Example 1 of the present invention 0.03 Yb 1.5 Y 1.47al 5 o 12 Transmittance curves of transparent ceramics (thickness 1...

Embodiment 2

[0029] The sintering holding temperature is 1750°C, and other conditions are the same as in Example 1, and Ce can also be obtained 0.003 Yb 0.006 Y 2.991 al 5 o 12 Transparent ceramic.

Embodiment 3

[0031] The sintering holding temperature is 1650°C, and other conditions are the same as in Example 1, and Ce can also be obtained 0.003 Yb 0.006 Y 2.991 al 5 o 12 Transparent ceramic.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com