Zirconia ceramic plunger and manufacturing method thereof

A technology of zirconia ceramics and production methods, which is applied in the field of mechanical equipment manufacturing, can solve problems such as poor quality of plungers, limitations of production equipment, and dependence on imports, and achieve the effects of improving production quality, improving performance, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention provides a zirconia ceramic plunger, the raw materials of which include the following components and parts by weight: 92±0.1 parts of zirconia, 5±0.1 parts of yttrium trioxide, and 3±0.1 parts of thulium trioxide. The zirconia ceramic plunger has high quality, high strength, high density and superior performance.

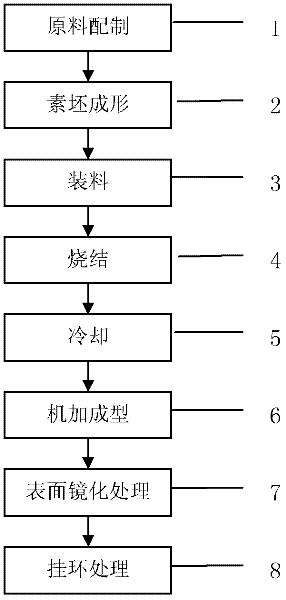

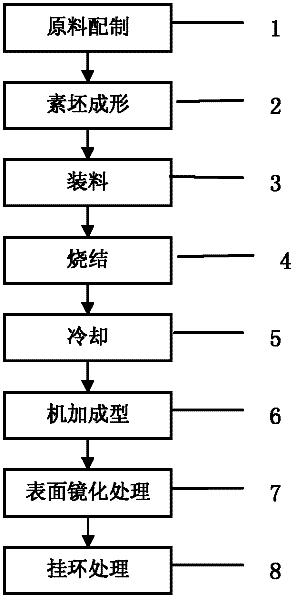

[0024] Such as figure 1 Shown, the manufacture method of zirconia ceramic plunger of the present invention comprises the steps:

[0025] Step 1. Raw material preparation: Weigh the granulated powder according to a certain proportion, including 92±0.1 parts of zirconia, 5±0.1 parts of diyttrium trioxide, and 3±0.1 parts of dithulium trioxide.

[0026] Step 2, green body forming: the raw material is made into a cuboid green body by dry pressing; the length of the green body is the length of the subsequent zirconia ceramic plunger + 10mm, and the width of the green body is the diameter of the zirconia ceramic plunger +3mm, the height of the green...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com