Method for preparing rare earth ion Tm3+ and ZnO nanocrystalline codoping alumina silicate glass as well as products and application thereof

A technology of aluminosilicate glass and rare earth ions, which is applied in the field of preparation of aluminosilicate glass co-doped with rare earth ions Tm3+ and ZnO nanocrystals, which can solve the problems of poor color temperature stability, complex manufacturing process, and low color rendering index of white LEDs. problem, to achieve the effect of low raw material cost, simple equipment and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Put silicon oxide, aluminum oxide, potassium carbonate, zinc oxide, and thulium oxide powder into an agate mortar, mix well and pour into a 30ml crucible, the moles of silicon dioxide, aluminum oxide, potassium carbonate, zinc oxide, and thulium oxide The ratio is 44:11:10:35:0.05;

[0026] 2) Put the crucible in step 1) into a high-temperature furnace, heat up to 1500°C at a heating rate of 7°C / min, keep warm for 2 hours to melt, pour the molten glass on a copper plate or graphite plate at 300°C and cool to room temperature to obtain quenching Glass;

[0027] 3) Then put the tempered glass into a muffle furnace, raise the temperature to 600°C at a heating rate of 3°C / min, and then keep it at 600°C for 2 hours to obtain annealed glass;

[0028] 4) Heat-treat the annealed glass at 750°C for 5 minutes to obtain rare earth ion Tm 3+ Aluminosilicate glass co-doped with ZnO nanocrystals.

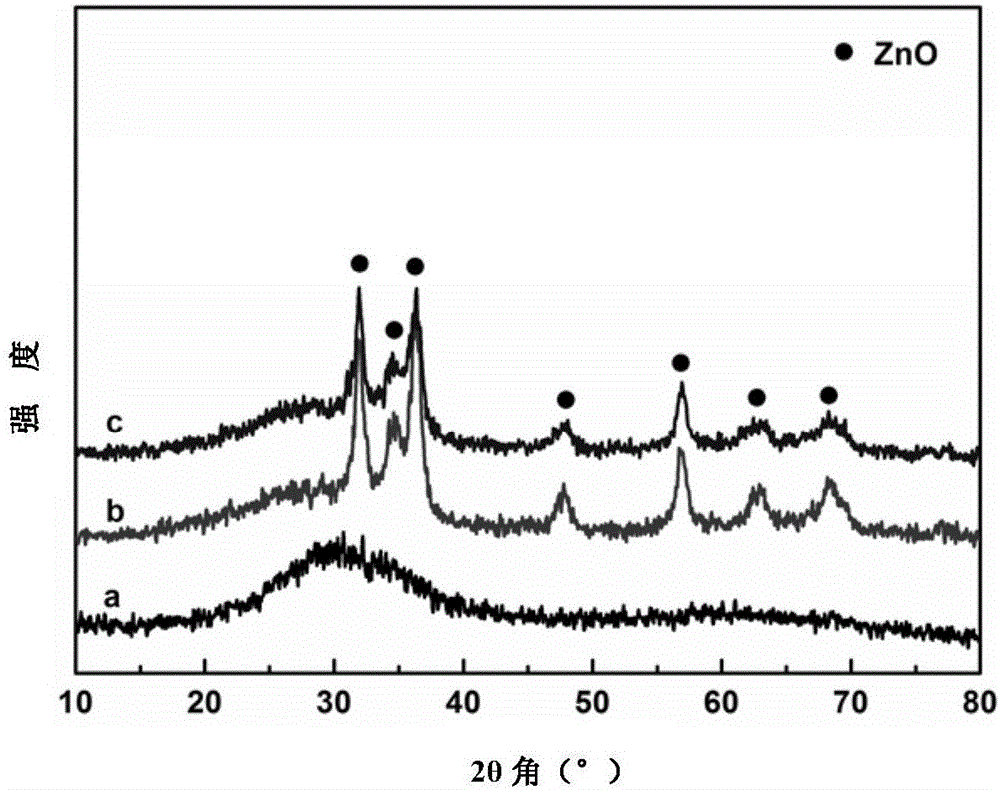

[0029] figure 1 Middle curve a is the X-ray diffraction pattern of the annealed...

Embodiment 2

[0033] 1) Put silicon oxide, aluminum oxide, potassium carbonate, zinc oxide, and thulium oxide powder into an agate mortar, mix well and pour into a 30ml crucible, the moles of silicon dioxide, aluminum oxide, potassium carbonate, zinc oxide, and thulium oxide The ratio is 44:11:10:35:0.01;

[0034] 2) Put the crucible in step 1) into a high-temperature furnace, heat up to 1500°C at a heating rate of 8°C / min, keep warm for 2 hours to melt, pour the molten glass on a copper plate or graphite plate at 400°C and cool to room temperature to obtain quenching Glass;

[0035] 3) Then put the tempered glass into a muffle furnace, raise the temperature to 600°C at a heating rate of 4°C / min and then keep it at 600°C for 2 hours to obtain annealed glass;

[0036] 4) Heat-treat the annealed glass at 750°C for 5 minutes to obtain rare earth ion Tm 3+ Aluminosilicate glass co-doped with ZnO nanocrystals.

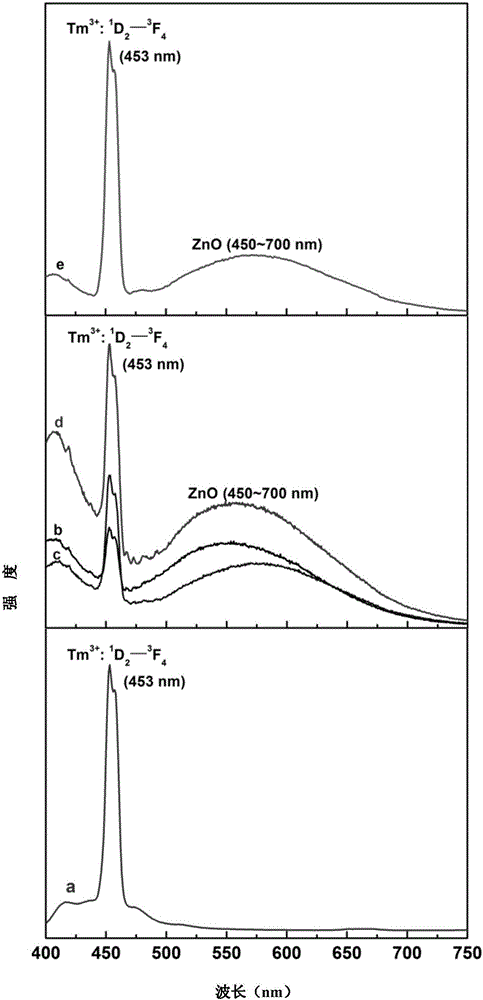

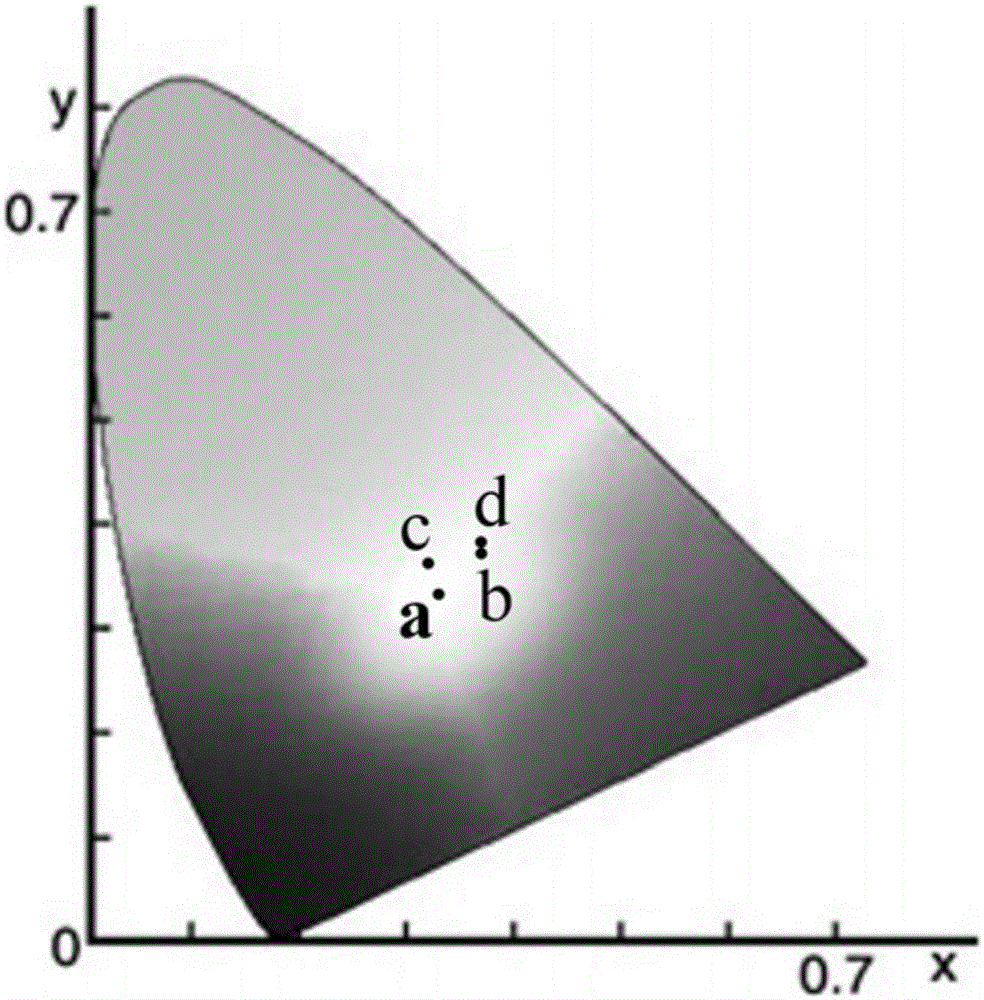

[0037] figure 2 Middle curve c is the rare earth ion Tm prepared in this embodi...

Embodiment 3

[0040] 1) Put silicon oxide, aluminum oxide, potassium carbonate, zinc oxide, and thulium oxide powder into an agate mortar, mix well and pour into a 30ml crucible, the moles of silicon dioxide, aluminum oxide, potassium carbonate, zinc oxide, and thulium oxide The ratio is 44:11:10:35:0.005;

[0041] 2) Put the crucible in step 1) into a high-temperature furnace, heat up to 1500°C at a heating rate of 9°C / min, keep warm for 2 hours to melt, pour the molten glass on a copper plate or graphite plate at 500°C and cool to room temperature to obtain quenching Glass;

[0042] 3) Then put the tempered glass into a muffle furnace, raise the temperature to 600°C at a heating rate of 5°C / min and then keep it at 600°C for 2 hours to obtain annealed glass;

[0043] 4) Heat-treat the annealed glass at 750°C for 5 minutes to obtain rare earth ion Tm 3+ Aluminosilicate glass co-doped with ZnO nanocrystals.

[0044] figure 2 Middle curve d is the rare earth ion Tm prepared in this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com