Formula and process for preparing environment-friendly and energy-saving light-emitting coating

A luminescent paint, environmental protection and energy saving technology, applied in the direction of luminescent paint, coating, etc., can solve the problems of poor safety effect, poor environmental protection effect, short service life and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0048] (1) Environmentally friendly luminescent paint selects the following raw materials in parts by weight, 20 parts of silicon dioxide; 8 parts of aluminum oxide; 20 parts of boric acid; 3 parts of strontium carbonate; 2 parts of lithium carbonate; 0.8 parts of copper oxide; 3 parts of neodymium oxide; 8 parts of dysprosium trioxide; 9 parts of europium oxide; 3 parts of thulium oxide; 10 parts of luminous powder.

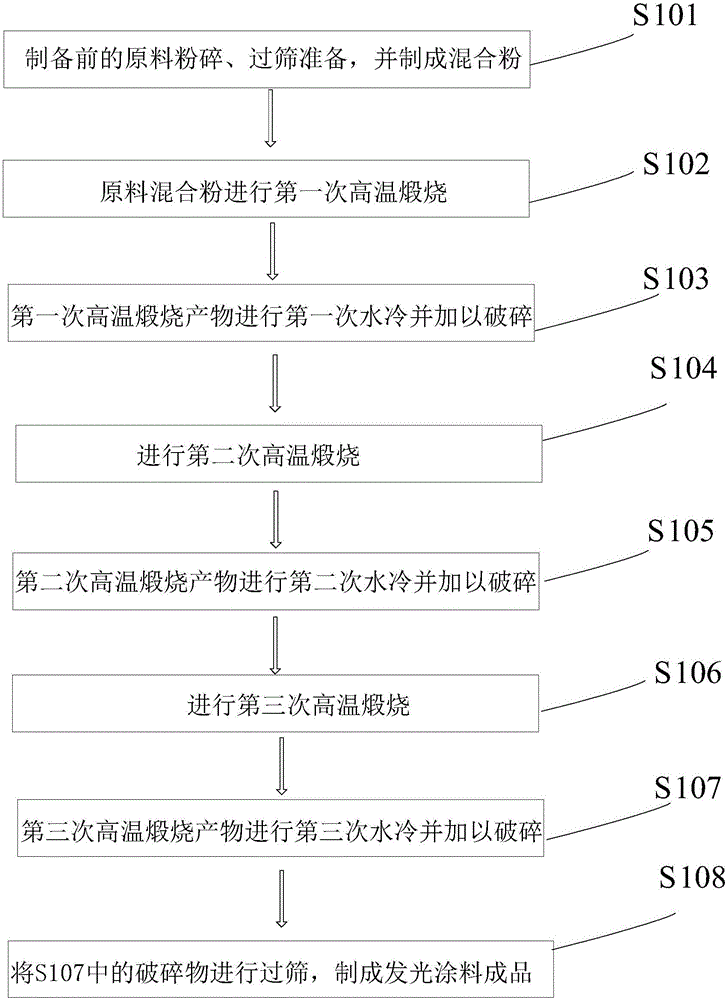

[0049] (2) Environmentally-friendly luminous paint includes the following processing process, the raw materials are crushed, sieved and prepared, and made into a mixed powder; the raw material mixed powder is calcined at a high temperature of 1450°C for the first time; the product of the first high-temperature calcined product is water-cooled for the first time for 30 minutes and crushing; performing high-temperature calcining for the second time; water-cooling and crushing the second high-temperature calcined product; performing third high-temperature calcining;...

example 2

[0051] (1) Environmentally friendly luminescent paint selects the following raw materials in parts by weight, 15 parts of silicon dioxide; 7 parts of aluminum oxide; 18 parts of boric acid; 2 parts of strontium carbonate; 1 part of lithium carbonate; 0.5 parts of copper oxide; 2 parts of neodymium oxide; 5 parts of dysprosium trioxide; 8 parts of europium oxide; 2 parts of thulium oxide; 8 parts of luminous powder. .

[0052] (2) Environmentally-friendly luminous paint includes the following processing process, the raw materials are crushed, sieved and prepared, and made into a mixed powder; the raw material mixed powder is first calcined at 1500 °C; the first high-temperature calcined product is first water-cooled for 20 minutes and crushing; performing high-temperature calcination for the second time; water-cooling and crushing the second high-temperature calcined product; performing high-temperature calcining for the third time; water-cooling and crushing the third high-tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com