Method for preparing material of frequency up conversion

A technology for converting materials and frequencies, applied in the field of fluorescent materials, can solve the problems of limited application and low up-conversion efficiency, and achieve the effects of regular shape, shortened reaction cycle, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

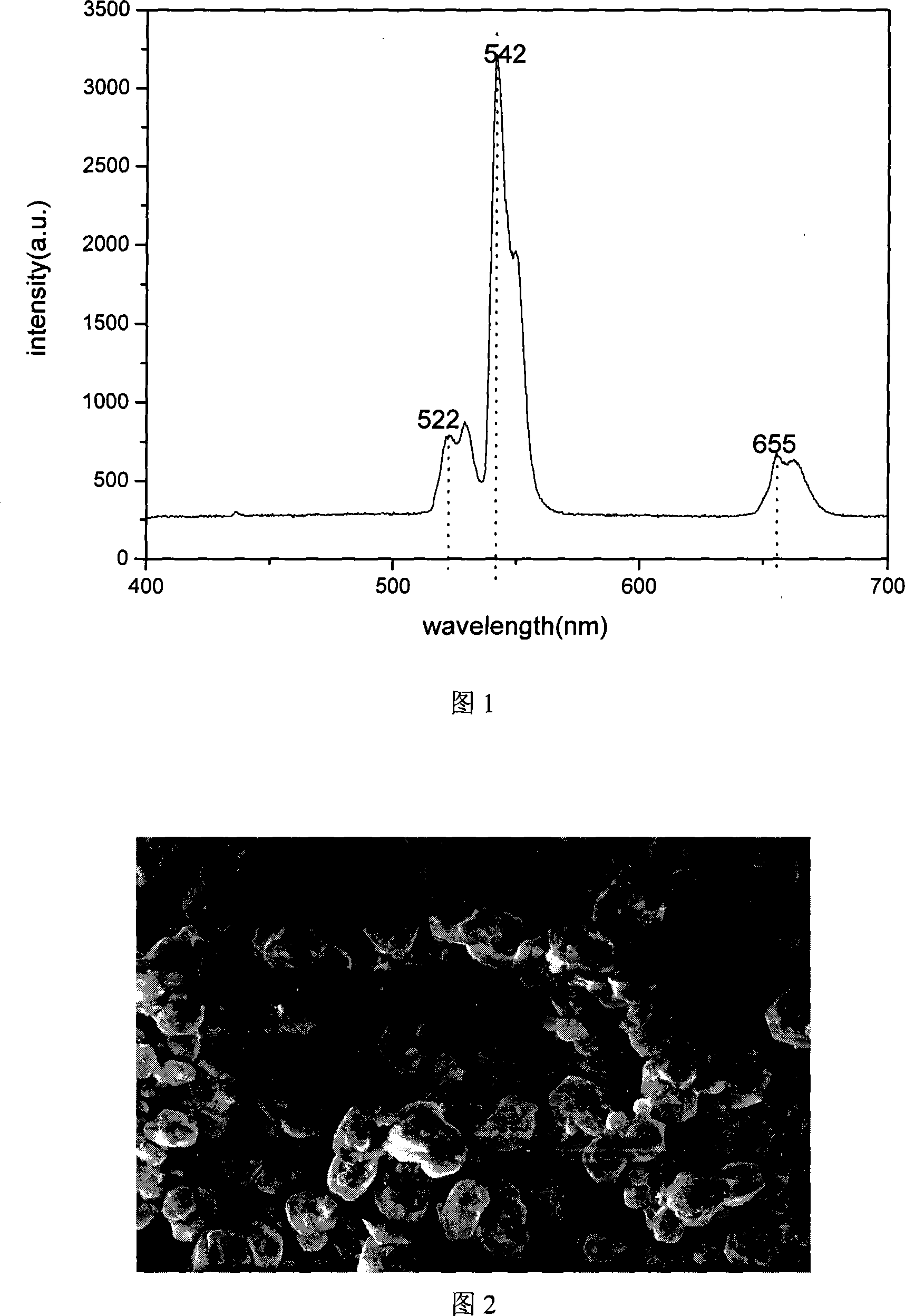

Embodiment 1

[0024] (1) Preparation of rare earth nitrate solution

[0025] Accurately weigh Y 2 o 3 14.114g, add 25ml concentrated nitric acid, heat to 70°C in a water bath, fully dissolve it under magnetic stirring, transfer to a 250ml volumetric flask to constant volume, and configure as Y 3+ A solution with a concentration of 0.500mol / l; accurately weigh Yb 2 o 3 9.852g, add 12ml concentrated nitric acid, heat to 80°C in a water bath, fully dissolve it under magnetic stirring, transfer to a 250ml volumetric flask to constant volume, and configure as Y 3+ A solution with a concentration of 0.200mol / l; weigh Er 2 o 3 0.957g, add 0.5ml concentrated nitric acid, heat to 70°C in a water bath, fully dissolve it under magnetic stirring, transfer to a 250ml volumetric flask to constant volume, and configure as Er 3+ A solution with a concentration of 0.020mol / l; weigh the Tm 2 o 3 0.242g, add 0.3ml concentrated nitric acid, heat to 70°C in a water bath, fully dissolve it under magne...

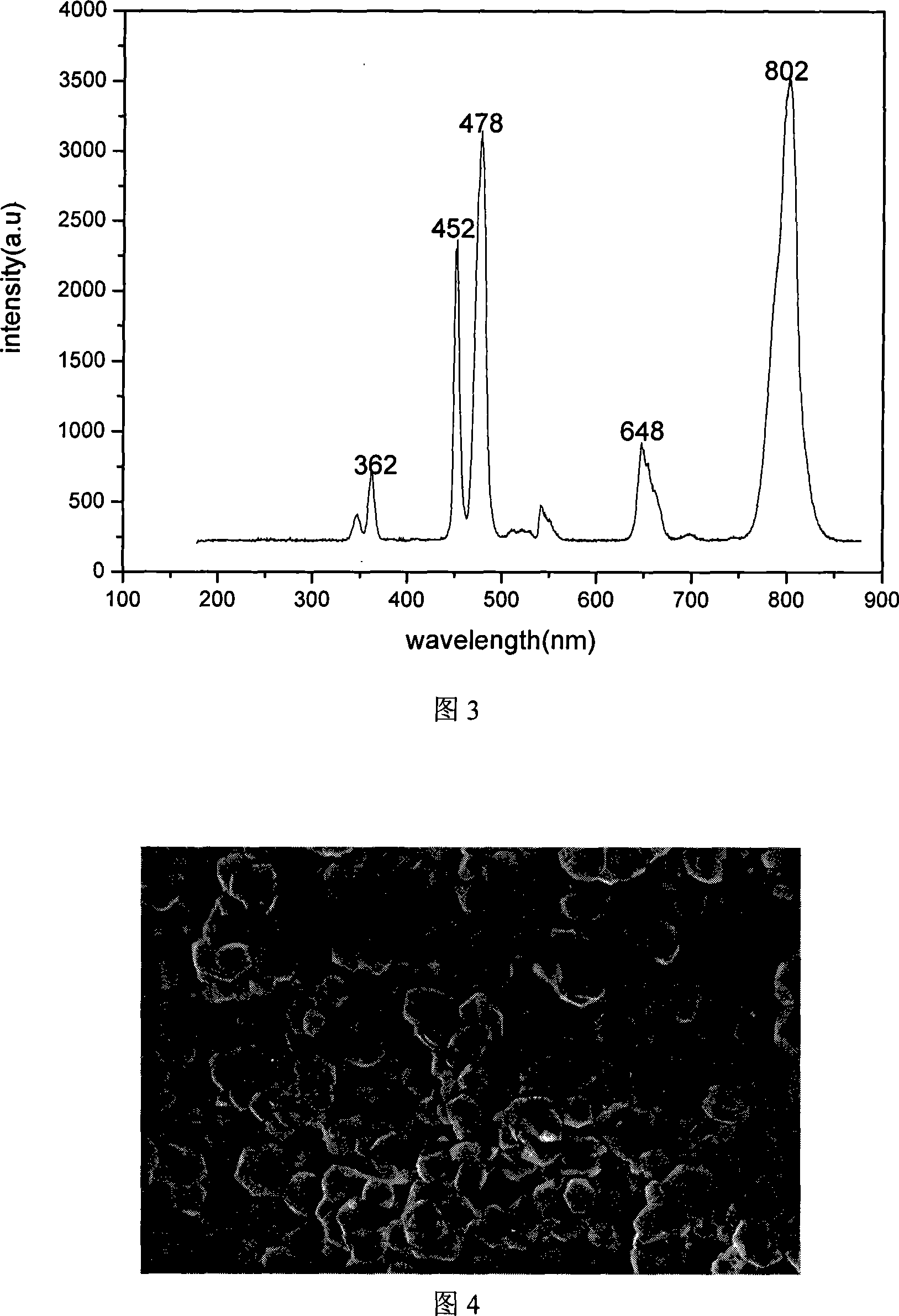

Embodiment 2

[0030] Embodiment 2: In embodiment 1, change preparation step (3) 0.552g ammonium fluoride into 0.663g; Make the molar ratio of oxide compound, sodium fluoride, ammonium fluoride be 1: 2: 12, grind and mix ; Place the mixture in an electric furnace to raise the temperature to 450°C at a rate of 3°C / min and keep it warm for 3h, which is the cost example.

Embodiment 3

[0031] Embodiment 3: similar to embodiment 1, its difference is that the 0.552g ammonium fluoride in embodiment 1 step (3) is changed into 1.104g; Make the mol ratio of oxide compound, sodium fluoride, ammonium fluoride be 1: 2:20, grind and mix; put the mixture in an electric furnace and raise the temperature to 250°C at a rate of 3°C / min and keep it warm for 4h, which is the cost example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com