Color matching composition, zirconia ceramic raw material composition, zirconia ceramic and preparation method of zirconia ceramic

A technology of zirconia ceramics and raw material composition, which is applied in the field of toning composition, and can solve problems such as poor user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

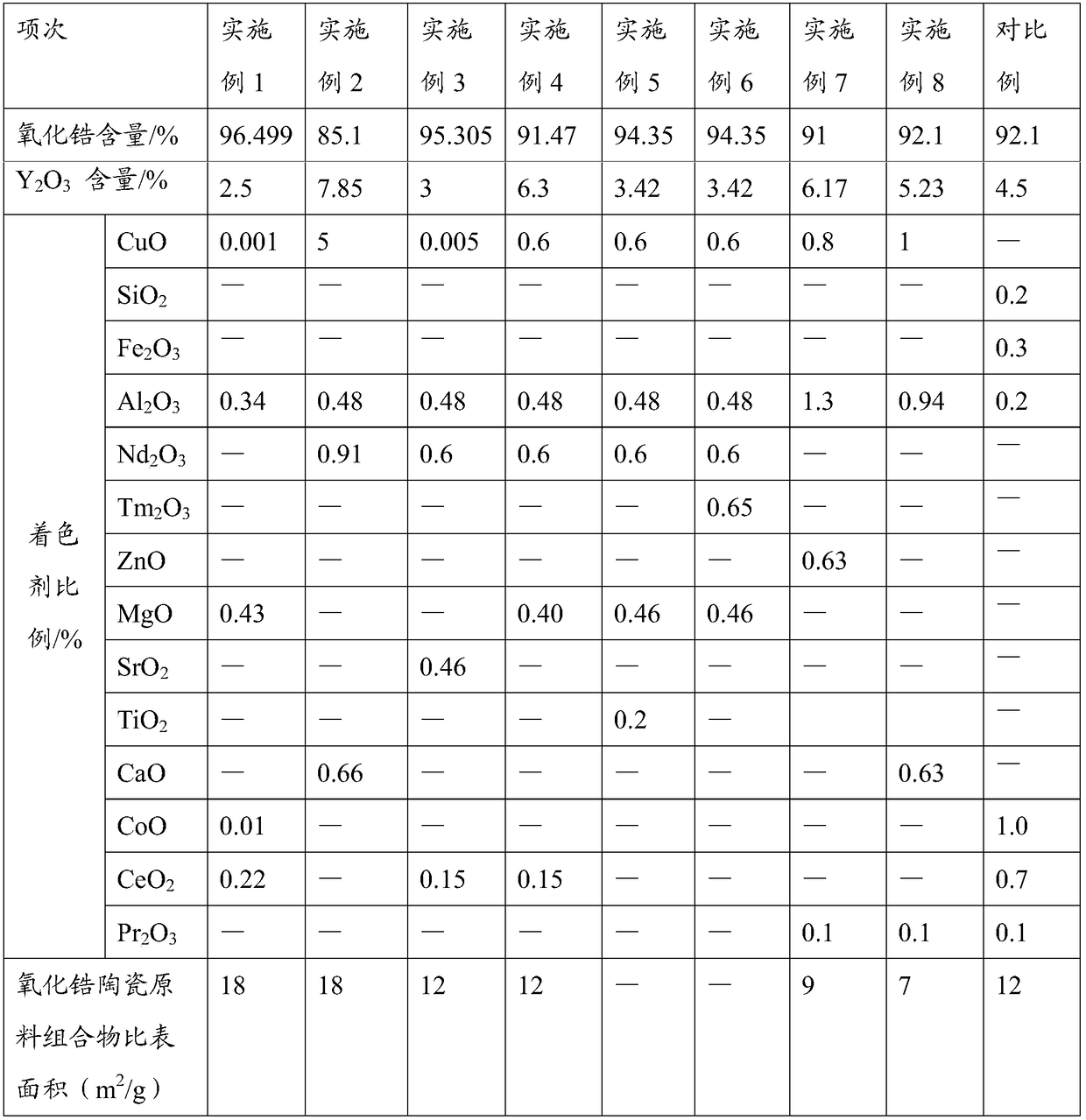

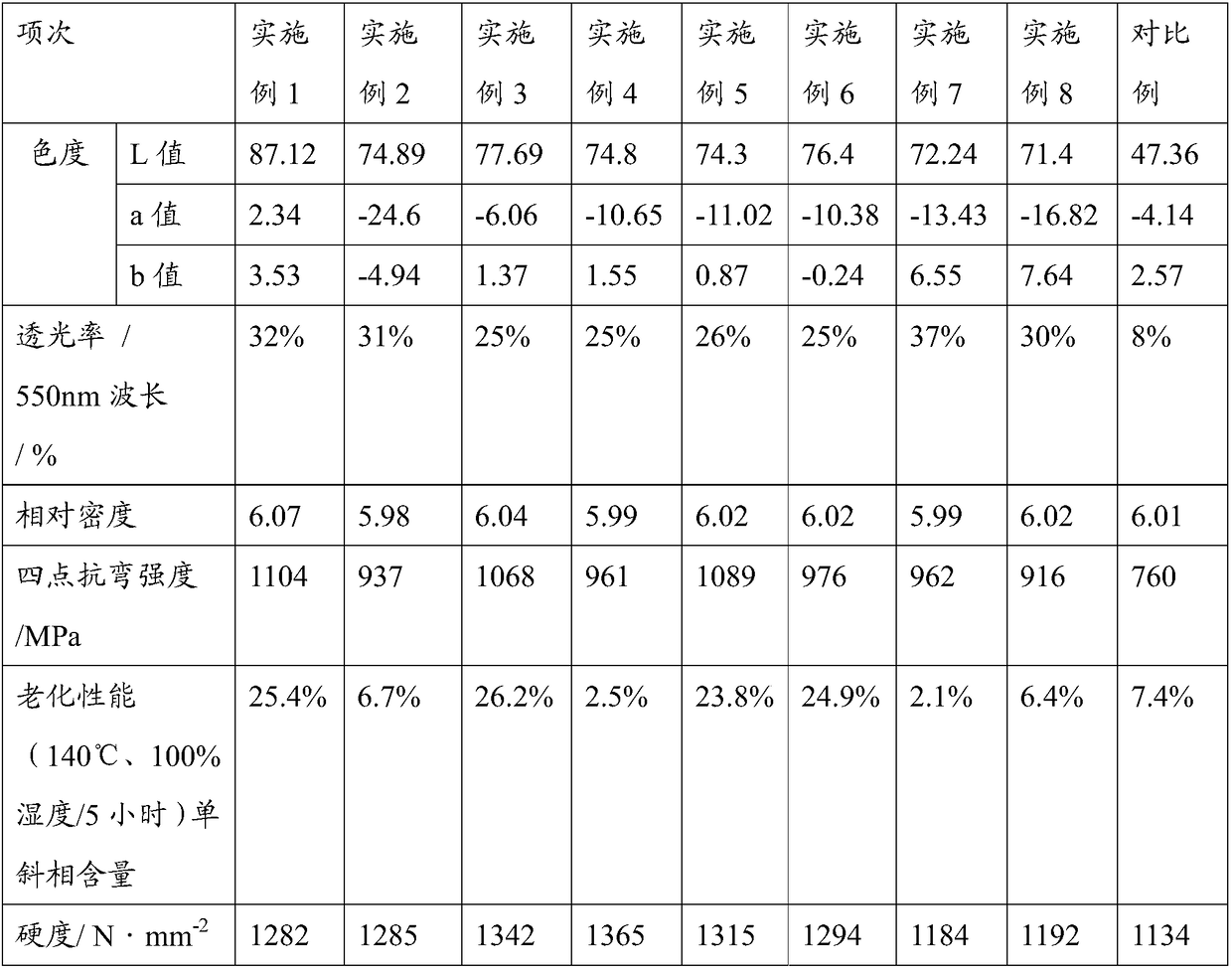

Examples

preparation example Construction

[0038] The preparation method of above-mentioned zirconia ceramics, comprises the following steps:

[0039] Step S110, providing a zirconia ceramic raw material composition.

[0040] In one embodiment, the zirconia ceramic raw material composition is obtained by thoroughly grinding and mixing the raw materials of the zirconia ceramic main body material and the toning composition. Further, the grinding can be sand milling or ball milling. Furthermore, the ball milling is wet ball milling or dry ball milling.

[0041] In one embodiment, the toning composition is obtained by mixing a salt solution corresponding to each raw material with an alkali solution to carry out a precipitation reaction to obtain a precipitate and calcining it. Grinding and mixing the ceramic zirconia ceramic main body material and the toning composition thoroughly to obtain a zirconia ceramic raw material composition. Further, the alkali solution is sodium hydroxide solution. The salt solution is at le...

Embodiment 1

[0051] Get 98.999 parts of zirconia ceramic body material (containing 2.5% Y 2 o 3 , with a specific surface area of 18m 2 / g), add 0.001 part of CuO, 0.34 part of Al 2 o 3 , 0.01 part of CoO, 0.12 part of CeO2, 0.43 part of MgO, fully mixed and dispersed with a ball mill, dried the zirconia ceramic raw material composition, and granulated to obtain master batches. Use 100MPa cold isostatic pressing to form a flat plate, then raise the temperature to 1360°C at a rate of 2°C / min, and keep it warm for 1.5h to obtain zirconia ceramics.

Embodiment 2

[0053] Get 92.95 parts of zirconia ceramic host material (Y containing 7.85% mass fraction 2 o 3 , with a specific surface area of 12m 2 / g), add 5.0 parts of CuO, 0.48 parts of Al 2 o 3 , 0.96 Nd 2 o 3 , 0.66 parts of CaO were dispersed by wet ball milling, and dried to obtain a zirconia ceramic raw material composition. The zirconia ceramic raw material composition is mixed with polypropylene resin, stearic acid and common paraffin at 170° C. for 3 hours to obtain a premixture. The content of polypropylene resin in the premixture is 6%, and the content of stearic acid is 1.5% %, the content of ordinary paraffin is 7%. The premix is injection molded. Raise the temperature at 0.1°C / min to 200°C, 0.4°C / min from 200°C to 400°C, hold at 400°C for 2 hours to remove the glue, and then rise to 1360°C at 2°C / min for 1.5 hours to obtain zirconia ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com