Preparation method of rare earth modified pressure-sensitive material

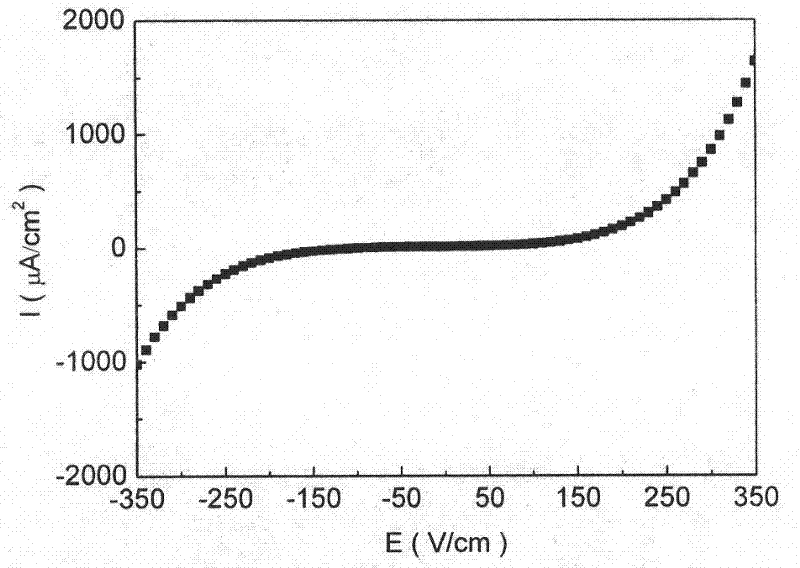

A pressure-sensitive material, rare earth modification technology, applied in the field of preparation of CaCu3Ti4O12-based pressure-sensitive materials, can solve problems such as poor performance and large leakage current, and achieve the effect of improving pressure-sensitive characteristics and reducing leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

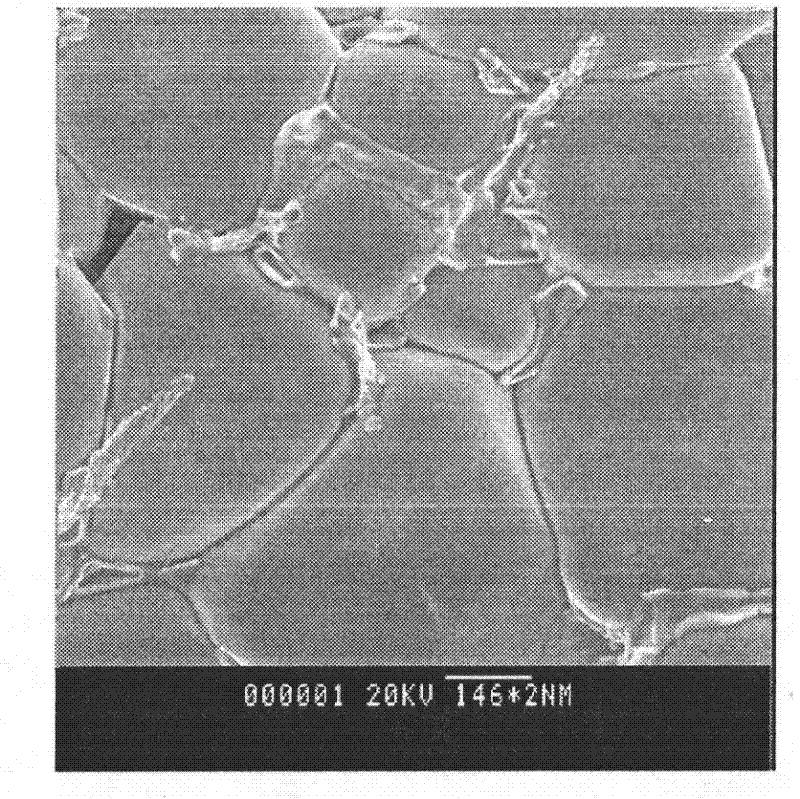

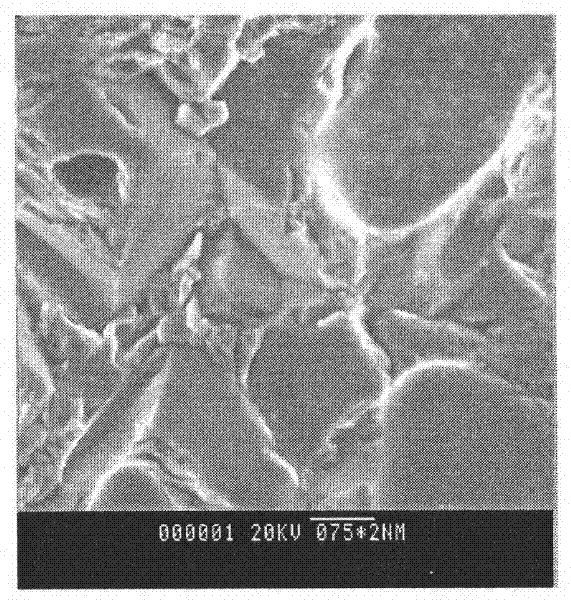

[0016] CaCu 3 Ti 4 o 12 The powder is sieved, and lanthanum oxide is added, and the total mass added is CaCu 3 Ti 4 o 12 0.01% of the powder mass; put the prepared material into a ball mill for mixing, the ball / material mass ratio is 9, and the material of the ball is zirconia. Add deionized water with a mass ratio of 23% of raw materials, polyacrylic acid ammonia dispersant with a mass ratio of 1.5%, and polyvinyl alcohol binder with a mass ratio of 6%, and mix them uniformly for 2 hours to form a slurry with a ball milling speed of 200 revolutions per minute, using airflow spray granulation to obtain powder particles with an average particle diameter of 0.3 mm; put the prepared powder particles into a press, and press a disc under a pressure of 300 MPa; put the disc into the furnace For medium debinding, the heating rate is 45°C / h at 25-500°C, 180°C / h at 500-800°C, and kept at 270°C, 360°C, 500°C and 800°C for 1 hour, and then cooled with the furnace ;Put the obtained ...

Embodiment 2

[0018] CaCu 3 Ti 4 o 12 The powder is sieved, adding lanthanum oxide and europium oxide, the mass ratio is 1:1, and the total mass added is CaCu 3 Ti 4 o 12 3% of the mass of the powder; put the prepared material into a ball mill for mixing, the ball / material mass ratio is 8, and the material of the ball is zirconia. Add deionized water with a mass ratio of 20% of raw materials, polyacrylic acid ammonia dispersant with a mass ratio of 1.8%, and polyvinyl alcohol binder with a mass ratio of 8%, and mix them uniformly for 2 hours to form a slurry with a ball milling speed of 200 revolutions per minute, using airflow spray granulation to obtain powder particles with an average particle diameter of 0.1mm; put the prepared powder particles into a press, and press the discs under a pressure of 300MPa; put the discs into the furnace For medium debinding, the heating rate is 45°C / h at 25-500°C, 180°C / h at 500-800°C, and kept at 270°C, 360°C, 500°C and 800°C for 1 hour, and then c...

Embodiment 3

[0020] CaCu 3 Ti 4 o 12 The powder is sieved, and praseodymium oxide is added, and the total mass added is CaCu 3 Ti 4 o 12 9% of the mass of the powder; the prepared material is put into a ball mill for mixing, the ball / material mass ratio is 12, and the material of the ball is agate. Add deionized water with a mass ratio of 30% of the raw materials, a polyacrylic acid ammonia dispersant with a mass ratio of 2.8%, and a polyvinyl alcohol binder with a mass ratio of 10%, and mix them uniformly for 3 hours to form a slurry with a ball milling speed of 300 Turn per minute, use airflow spray granulation to obtain powder particles with an average particle diameter of 0.03 mm; put the prepared powder particles into a press, and press the disc under a pressure of 400MPa; put the disc into the furnace For medium debinding, the heating rate is 35°C / h at 25-500°C, 130°C / h at 500-800°C, and kept at 270°C, 360°C, 500°C and 800°C for 2 hours, then cooled with the furnace ;Put the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle diameter | aaaaa | aaaaa |

| Average particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com