Vanadate upconversion material fluorescent powder, and preparation method and application thereof

A conversion material and vanadate technology, which is applied in luminescent materials, chemical instruments and methods, and the use of gas discharge lamps, etc., can solve the problems of color coordinate drift of mixed white light, UV pollution of LED chips, etc., and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

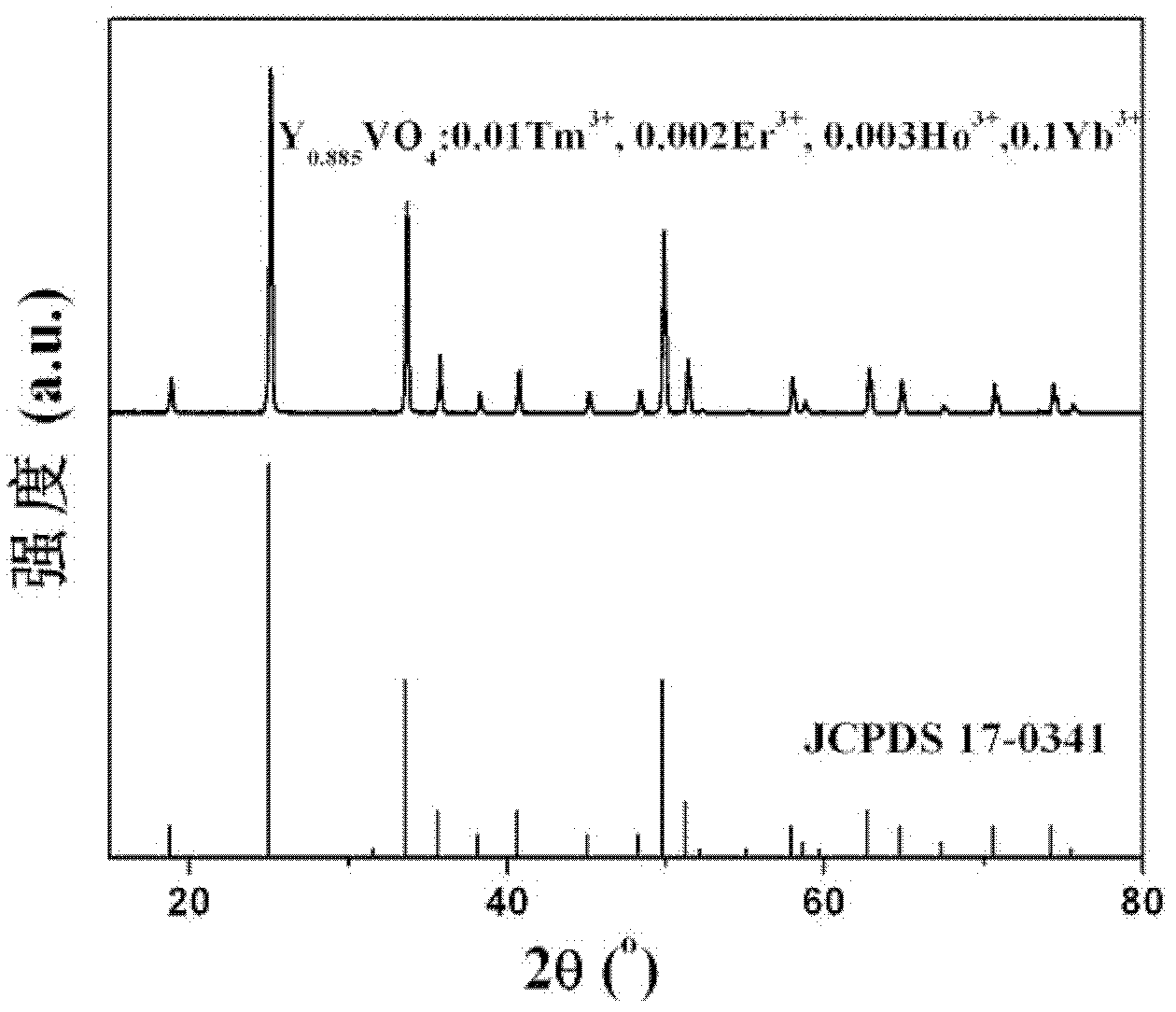

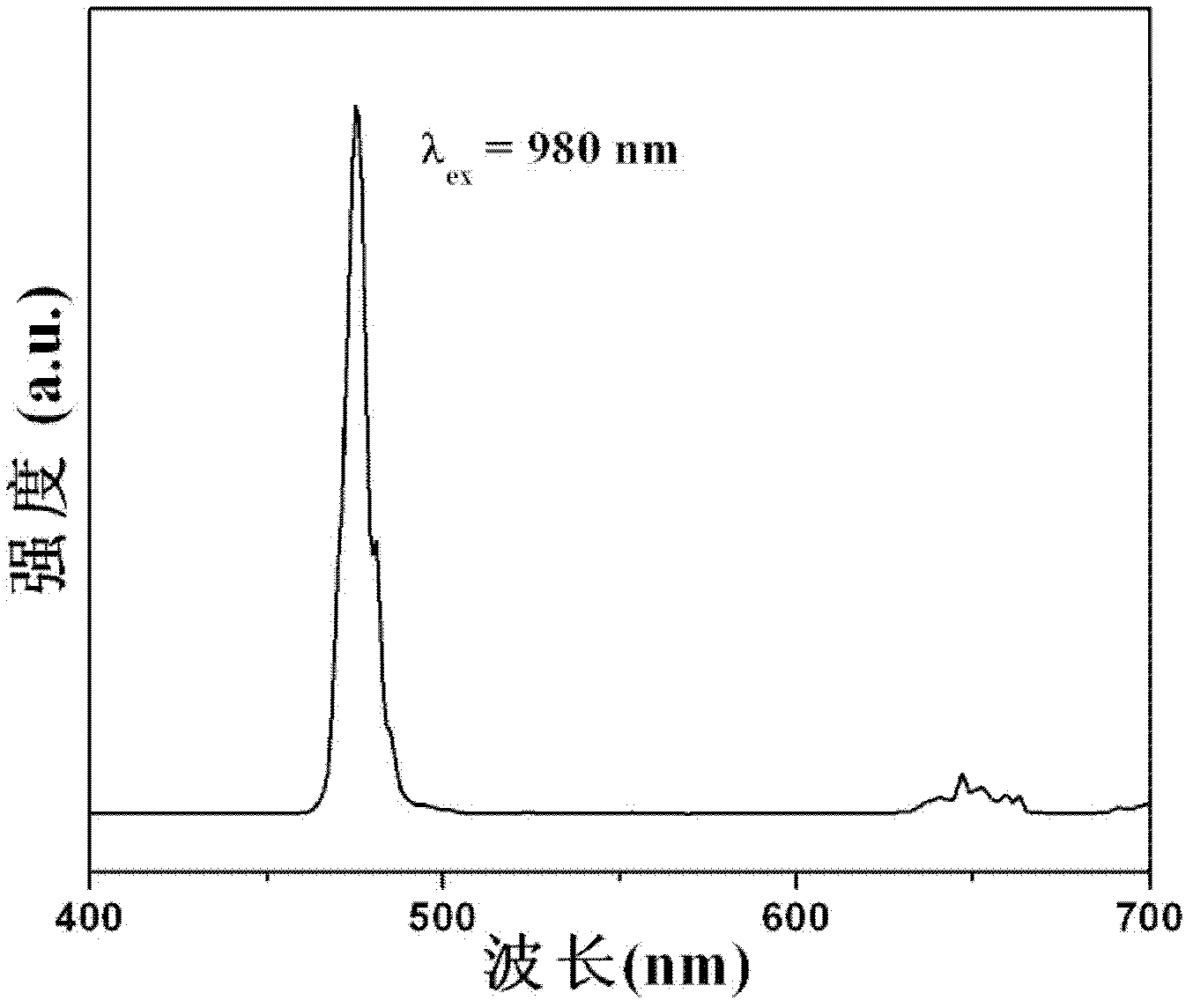

[0019] Example 1: Y 0.89 VO 4 :0.01Tm 3+ / 0.1Yb 3+ Phosphor powder preparation

[0020] Weigh yttrium oxide (YVO 4 )0.5036g, vanadium pentoxide (V 2 o 5 )0.4547g, thulium oxide (Tm 2 o 3 ) 0.0096g, ytterbium oxide (Yb 2 o 3 ) 0.0985g, after grinding and mixing the above raw materials in an agate mortar, put them into a corundum crucible, pre-fire at 650°C (increase the temperature to 650°C at a constant speed of 1.5 hours), keep the temperature at 650°C for 6 hours, cool, take out and grind ; Then sinter at 1200°C for 3 hours (that is, heat up to 1200°C at a rate of 400°C / hour), and keep the temperature at 1200°C for 6 hours; after cooling, grind again, crush and sieve, and finally obtain the sample. The up-conversion spectrum of the sample under 980nm excitation with a power of 0.39mw is as follows figure 2 As shown, strong blue upconversion luminescence (0.1233, 0.1038) was observed.

Embodiment 2

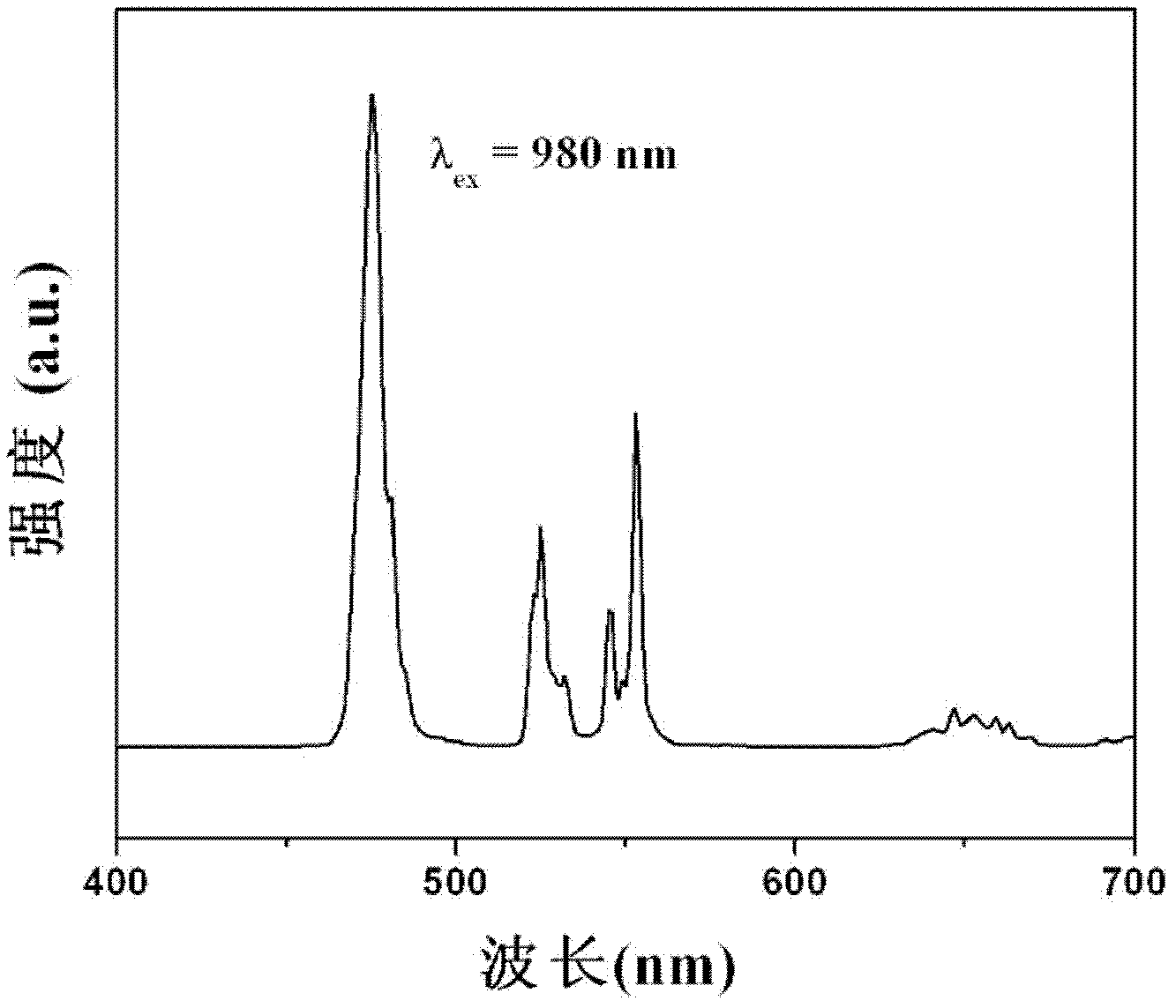

[0021] Example 2: Y 0.888 VO 4 :0.01Tm 3+ / 0.002Er 3+ / 0.1Yb 3+ Phosphor powder preparation

[0022] Weigh yttrium oxide (YVO 4 )0.5069g, vanadium pentoxide (V 2 o 5 )0.4547g, thulium oxide (Tm 2 o 3 ) 0.0096g, erbium oxide (Er 2 o 3 ) 0.0019g, ytterbium oxide (Yb 2 o 3 ) 0.0985g, after grinding and mixing the above raw materials in an agate mortar, put them into a corundum crucible, pre-fire at 650°C (increase the temperature to 650°C at a constant speed of 1.5 hours), keep the temperature at 650°C for 6 hours; cool, take out and grind ; Sinter at 1200°C for 3 hours (that is, heat up to 1200°C at a rate of 400°C / hour), and keep the temperature at 1200°C for 6 hours; after cooling, grind again evenly, crush and sieve, and finally obtain the sample. The up-conversion spectrum of the sample under 980nm excitation with a power of 0.39mw is as follows image 3 As shown, strong green upconversion luminescence (0.2450, 0.7276) was observed.

Embodiment 3

[0023] Example 3: Y 0.887 VO 4 :0.01Tm 3+ / 0.003Ho 3+ / 0.1Yb 3+ Phosphor powder preparation

[0024] Weigh yttrium oxide (YVO 4 )0.5069g, vanadium pentoxide (V 2 o 5 )0.4547g, thulium oxide (Tm 2 o 3 ) 0.0096g, holmium oxide (Ho 2 o 3 ) 0.0029g, ytterbium oxide (Yb 2 o 3 ) 0.0985g, after grinding and mixing the above raw materials in an agate mortar, put them into a corundum crucible, pre-fire at 650°C (increase the temperature to 650°C at a constant speed of 1.5 hours), keep the temperature at 650°C for 6 hours; cool, take out and grind ; Sinter at 1200°C for 3 hours (that is, heat up to 1200°C at a rate of 400°C / hour), and keep the temperature at 1200°C for 6 hours; after cooling, grind again evenly, crush and sieve, and finally obtain the sample. The up-conversion spectrum of the sample under 980nm excitation with a power of 0.39mw is as follows Figure 4 As shown, a strong pink upconversion luminescence (0.3403, 0.2408) was observed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com