Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80 results about "Poly methyl pentene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer/carbon nanotube composites, methods of use and methods of synthesis thereof

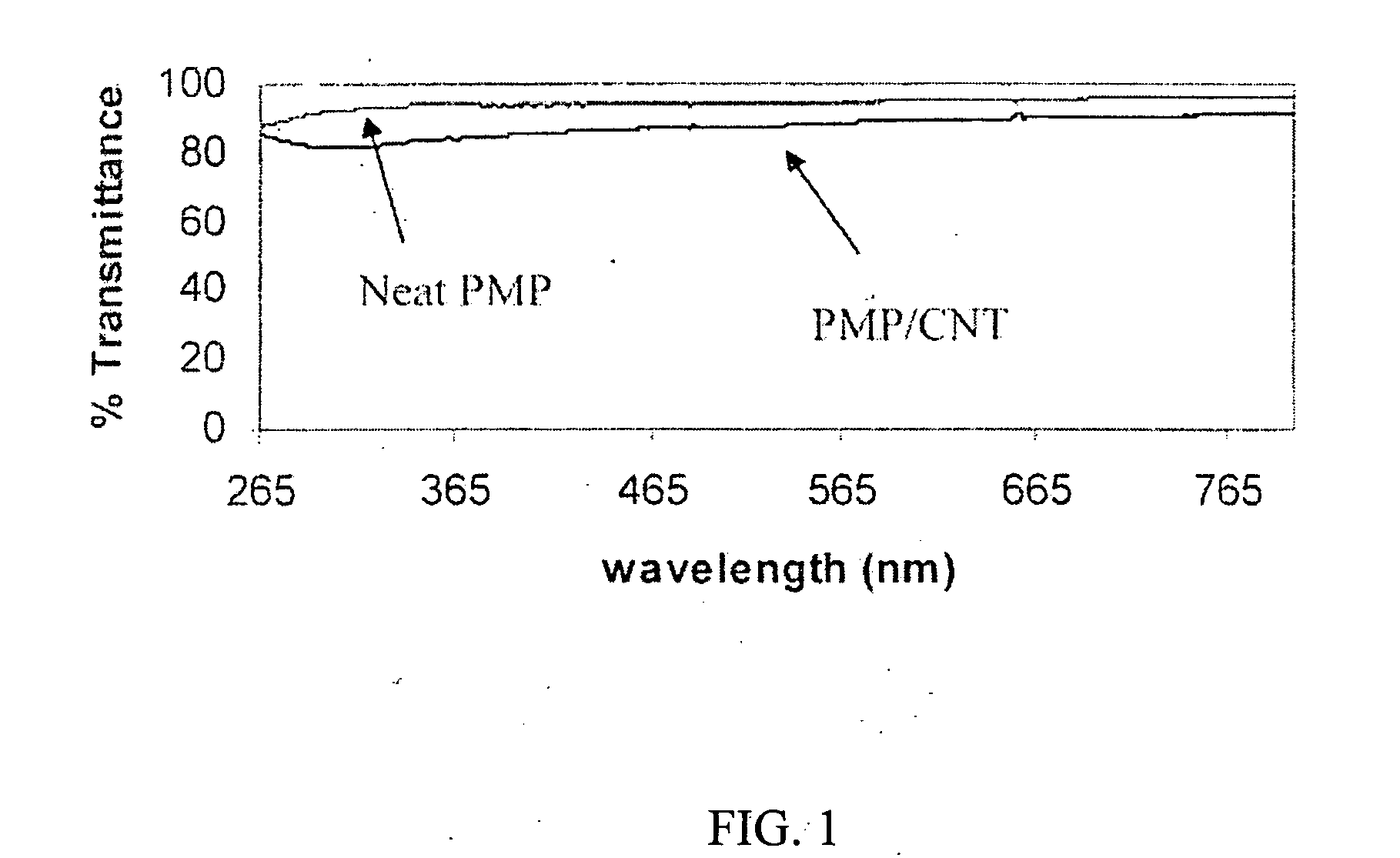

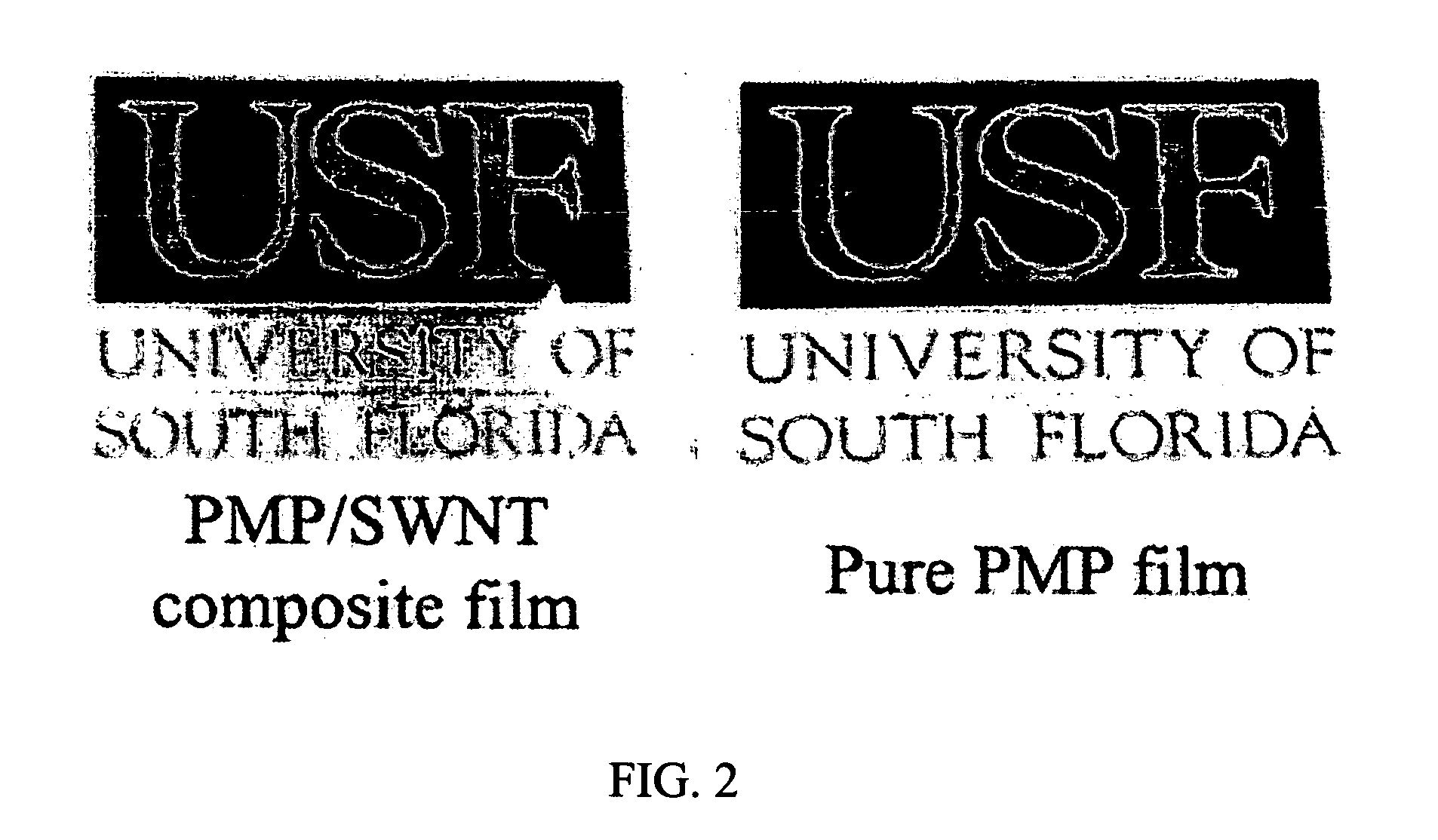

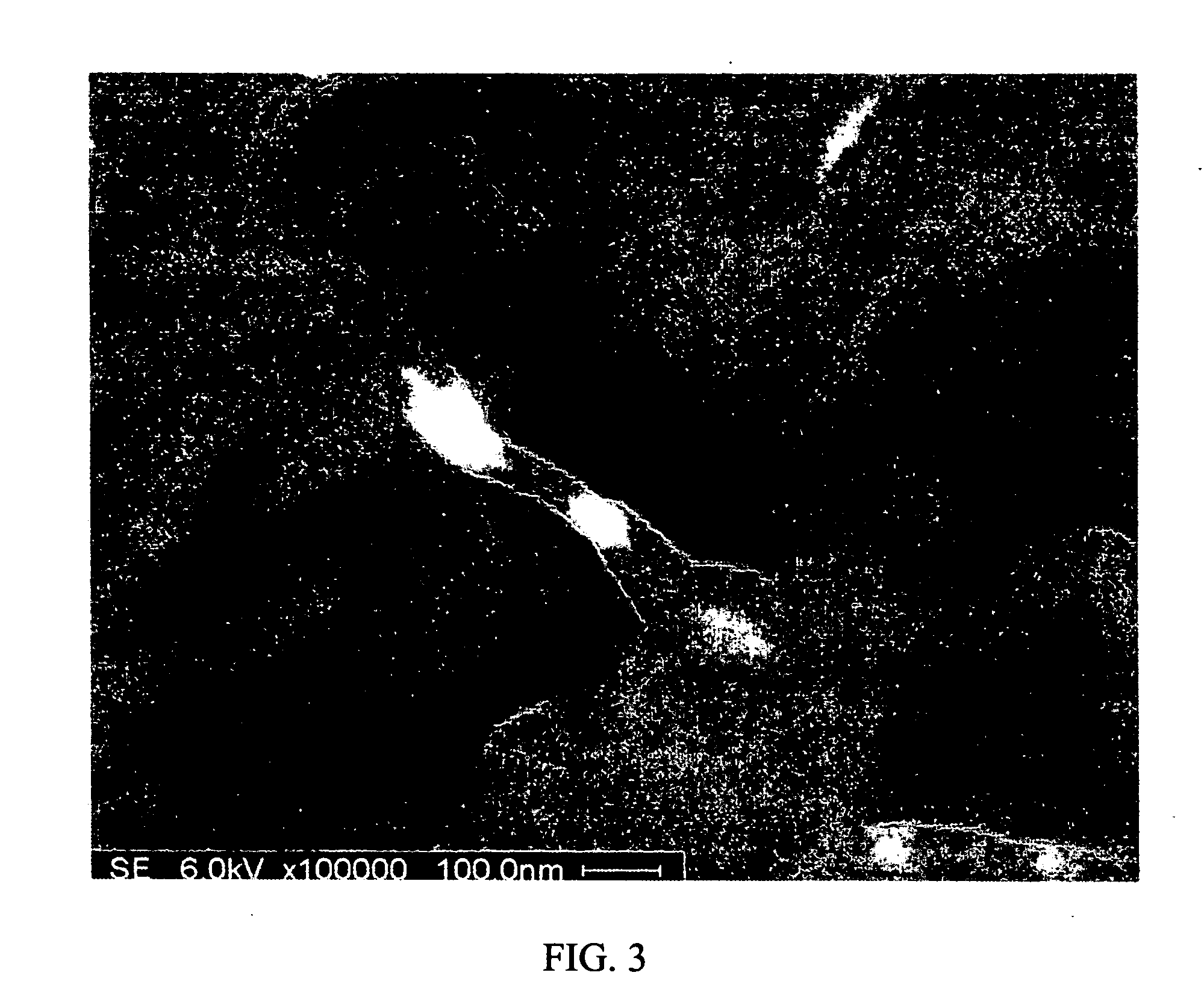

InactiveUS20050245667A1Good optical performanceMaintain transparencyMaterial nanotechnologyElectric discharge heatingPolymer scienceOrganic dye

Novel transparent composites composed of single wall carbon nanotubes incorporated into the matrix of a polymer are utilized in services wherein the composites are exposed to ionizing radiation, including galactic cosmic radiation. Accordingly, the composites are useful in deep space applications like space vehicles, space stations, personal equipment as well as applications in the biomedical arts and atom splitting research. The composites can be modified with organic dyes containing at least one phenyl ring and the resulting doped composite is useful as a radiation detector. The preferred polymer is poly(4-methyl-1-pentene).

Owner:UNIV OF SOUTH FLORIDA

Device for fresh-keeping packaging of bananas

InactiveCN102030151AReduce contentAutoregulationFruit and vegetables preservationLiving organism packagingPoly methyl penteneFilm material

The invention relates to a device for fresh-keeping packaging of bananas. The device consists of an outer packaging box and an inner packaging film. The packaging box is generally made of a cardboard with air vents on the walls, and an independent gas buffer environment is formed between the packaging film and the outside of the packaging box and enables air exchange between the outside and the inside of the packaging film. The packaging film material used by the device is poly(4-methyl-1-pentene) film containing an ethylene absorption-decomposition agent. The film has high gas-and-vapor transmission rate, which is about 10 times of that of an ordinary PE film, and the film is capable of absorbing and decomposing the ethylene gas produced in the banana metabolism. The content control of the carbon dioxide and the ethylene greatly delays the respiratory peak of the bananas, thus achieving the purpose of fresh-keeping.

Owner:NAT ENG AN TECH RES CENT FOR PRESERVATION OF AGRI PROD TIANJIN

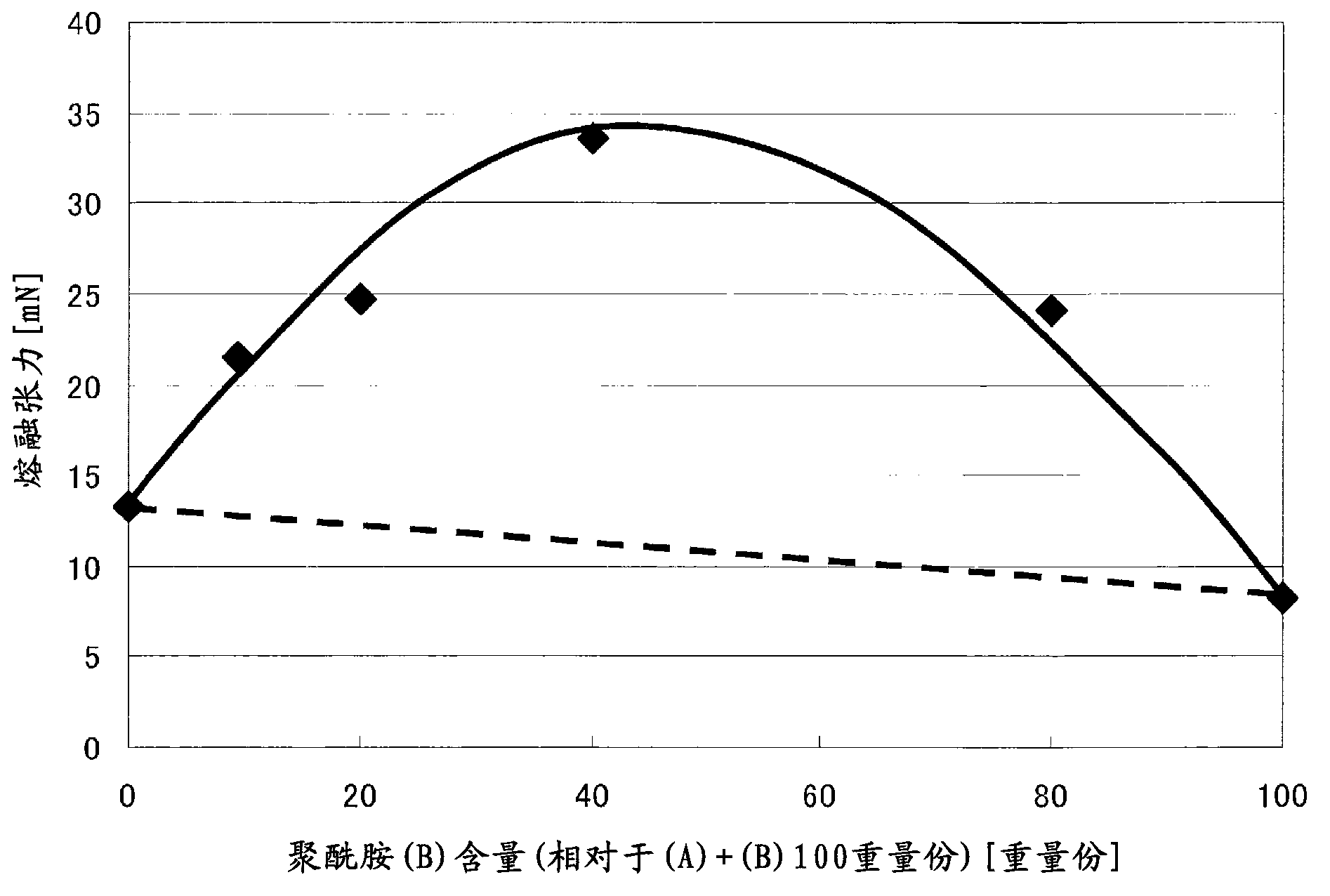

Poly-4-methyl-1-pentene based resin composition and molded products obtained from the composition

InactiveCN103189442ASmall water absorptionImprove tensile propertiesSynthetic resin layered productsThin material handlingPolyamide4-Methyl-1-pentene

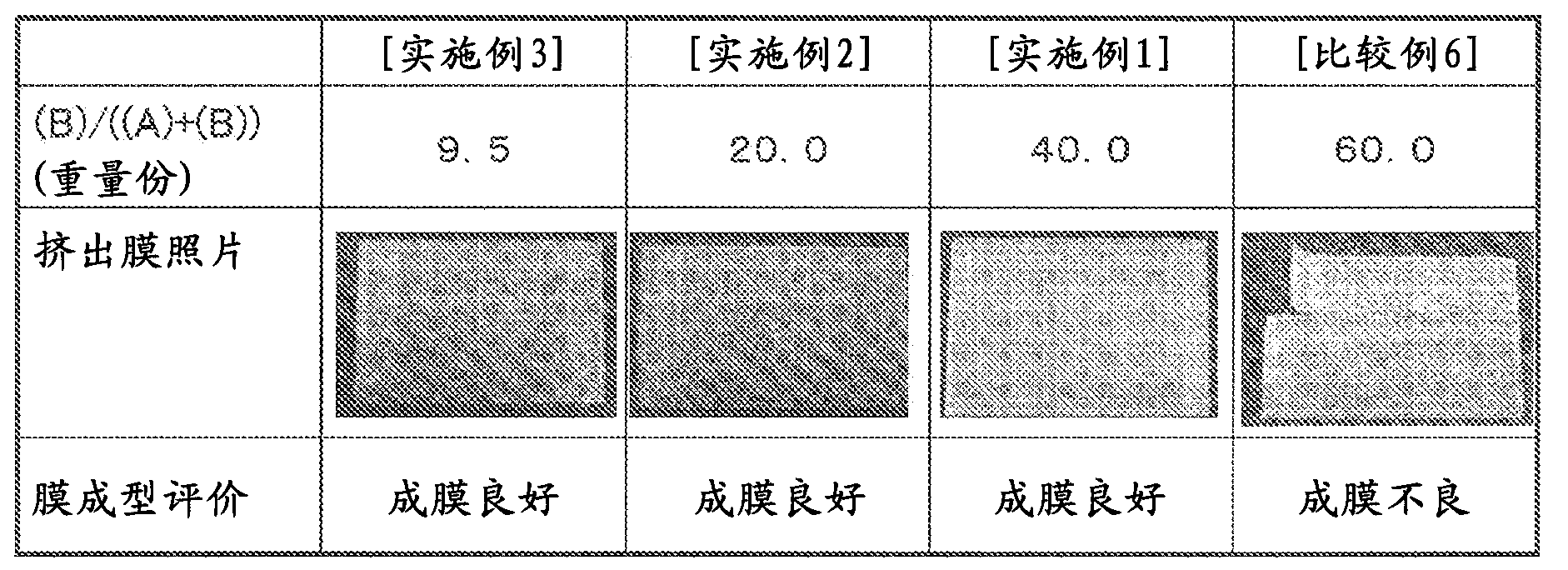

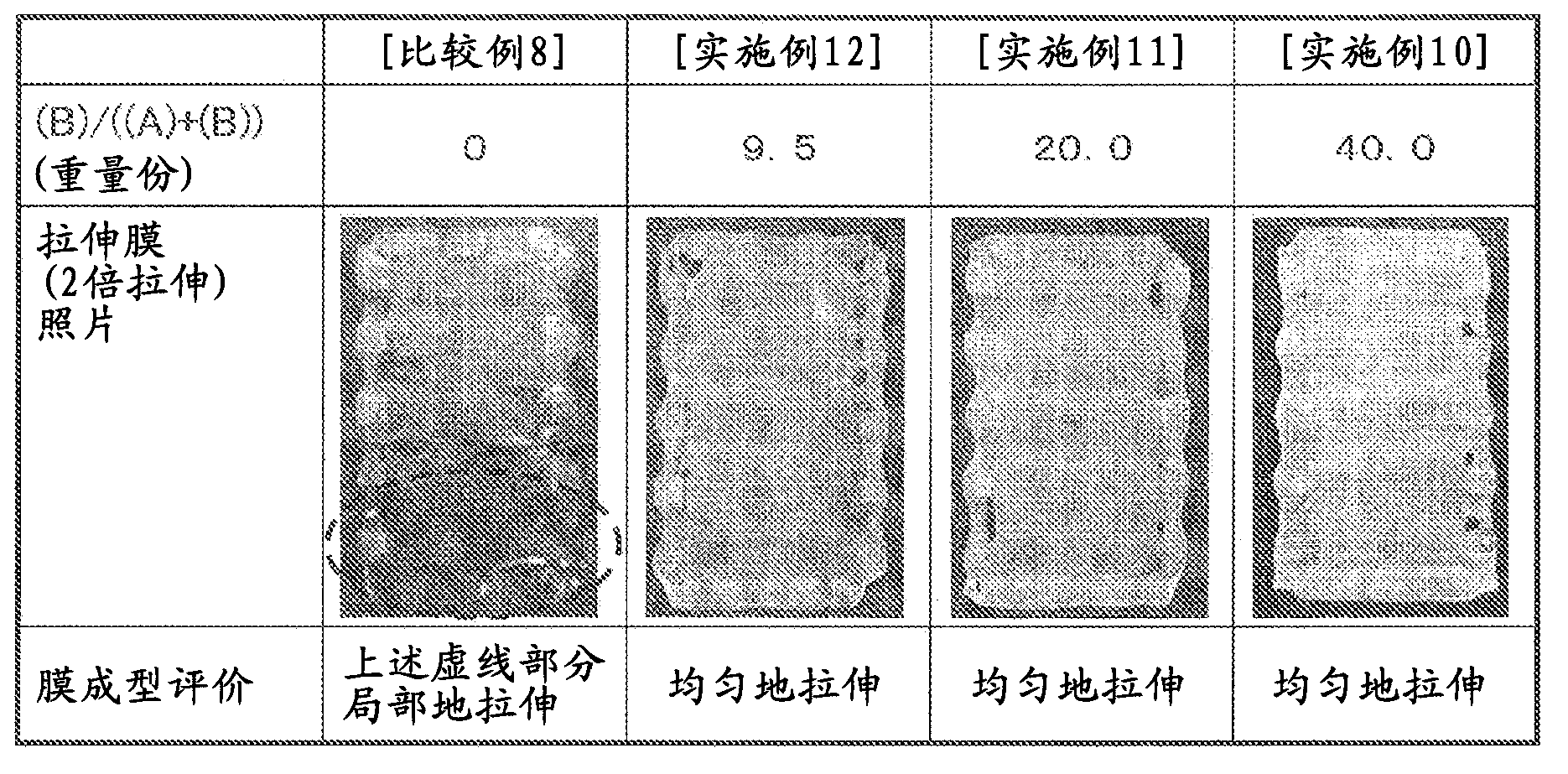

To provide a poly-4-methyl-1-pentene based resin composition which exhibits improved film strength and improved moldability into various molded products while keeping the mold release properties and low water absorbency inherent in poly-4-methyl-1-pentene, and to provide molded products thereof. [Solution] The problem is solved by a poly-4-methyl-1-pentene based resin composition obtained by incorporating 0.1 to 30 parts by weight of a modified poly-4-methyl-1-pentene (C) prepared by grafting a monomer that contains an ethylenic unsaturated bond with 50 to 99 parts by weight of poly-4-methyl-1-pentene (A) and 1 to 50 parts by weight of a polyamide (B) (with the proviso that the sum of (A) and (B) is 100 parts by weight).

Owner:MITSUI CHEM INC

Environment-friendly tensile high-temperature-resistant control cable material and preparation method thereof

InactiveCN102911409AReasonable formulaEasy to prepareInsulated cablesInsulated conductorsPolycaprolactoneHexanoic acid

The invention discloses an environment-friendly tensile high-temperature-resistant control cable material and a preparation method thereof. The cable material is composed of a mixture A and a mixture B, wherein the mixture A comprises, by weight, 30-40 parts of nitrile rubber, 20-30 parts of silicon rubber, 10-20 parts of polyacrylate, 10-20 parts of poly(styrene-butadiene-styrene), 1-3 parts of semi-reinforcing carbon black, 40-60 parts of modified nano-powder, 1-3 parts of insoluble sulfur, 1.5-2.5 parts of methyltrimethoxysilane, 1-3 parts of zinc stearate, 3-4 parts of antioxidant 1035, 1-3 parts of bi-texanol, 10-20 parts of magnesium hydroxide and 1-3 parts of dioctyl phthalate; the mixture B comprises, by weight, 30-50 parts of nitrile rubber, 20-40 parts of silicon rubber, 20-30 parts of polyacrylate, 0.3-0.5 part of poly(4-methyl-1-pentene) , 2-4 parts of antiager RD, 5-10 parts of polycaprolactone, 2-3 part of crosslinking agents TAIC, 1-3 part of chlorinated paraffin, 5-8 parts of ammonium dihydrogen phosphate and 1-3 parts of isooctyl thioglycolate dimethyl tin. The preparation method is simple, the composite formula is reasonable, the performance of the cable material is improved greatly, thermal resistance, aging resistance and wear resistance of the cable material are good, expansion deformation under high temperature is small, secondary vulcanization is facilitated, and the cable material is low-smoke, flame-retardant, environment-friendly and safe.

Owner:沛县格桑电子有限公司

Poly(4-methyl-1-pentene) hollow fiber membrane with gradient pore structure and preparation method thereof

ActiveCN112403289AExtended diluent screeningExpand the scope of the filterSemi-permeable membranesNon solventPolymer science

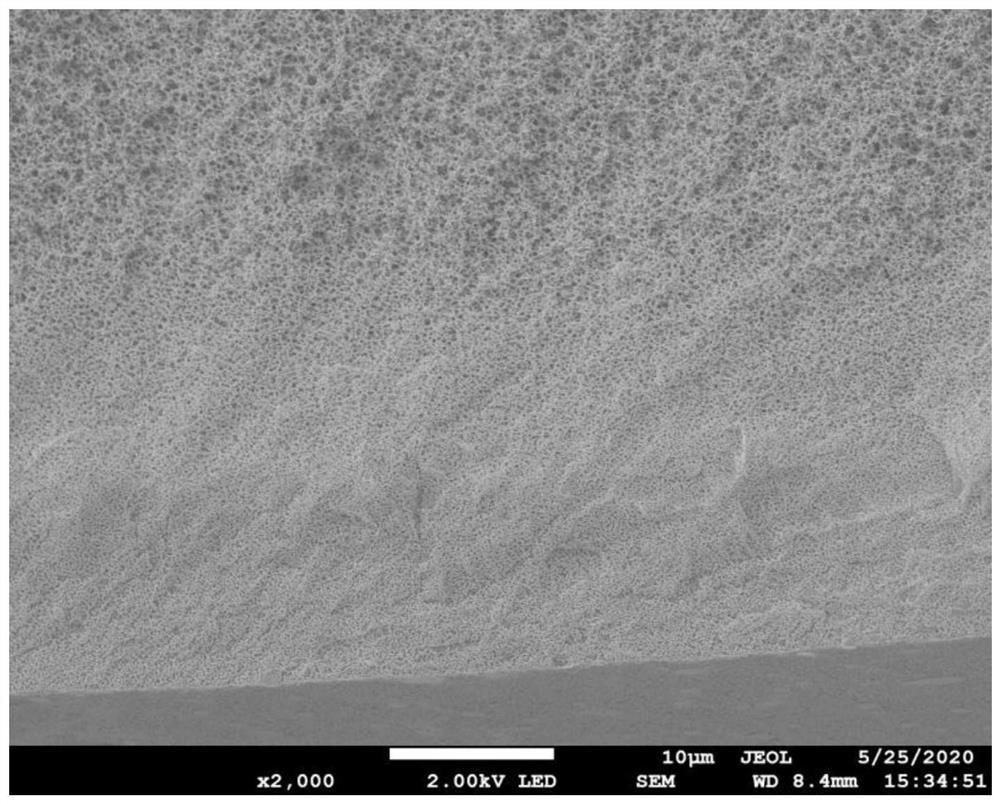

The invention provides a method for preparing a poly(4-methyl-1-pentene) hollow fiber membrane with a gradient pore structure through coupling of a thermally induced phase separation method and a non-solvent induced phase separation method. The method comprises the following steps: uniformly mixing poly(4-methyl-1-pentene) and a diluent at high temperature, and carrying out extrusion to realize one-shot molding; after the formed mixture passes through an air section, allowing the mixture to enter a cooling bath for cooling so as to realize thermally induced phase separation and non-solvent phase separation; and finally, extracting the diluent to obtain the hollow fiber membrane. The hollow fiber membrane prepared by the method provided by the invention has improved safety, and the thermally induced phase separation process and the non-solvent induced phase separation process in a poly(4-methyl-1-pentene) diluent system are easy to regulate and control, so the poly(4-methyl-1-pentene) membrane with better mechanical strength, gas permeability and plasma infiltration resistance is obtained. The invention also provides the poly(4-methyl-1-pentene) hollow fiber membrane and applicationthereof in the field of artificial membrane lungs.

Owner:TSINGHUA UNIV

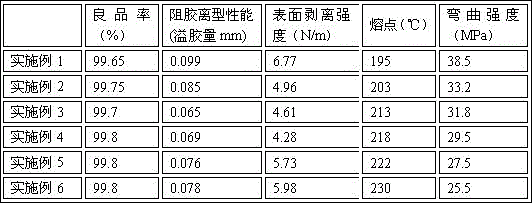

Flexible circuit board gum inhibition release paper release layer hot-melt resin composition, gum inhibition release paper and production method of gum inhibition release paper

ActiveCN105926362AHigh melting pointImprove surface peel strengthNon-fibrous pulp additionPaper coatingFlexible circuitsFlexural strength

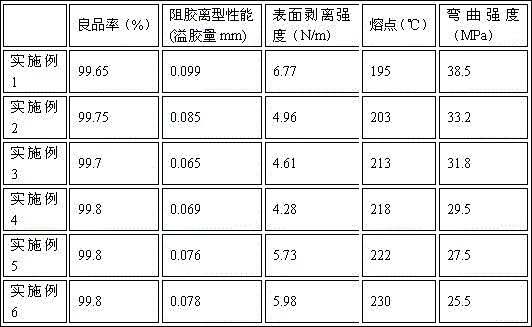

The invention discloses a flexible circuit board gum inhibition release paper release layer hot-melt resin composition, a gum inhibition release paper and a production method of the gum inhibition release paper. The hot-melt resin composition comprises, by mass, 5-30 parts of polypropylene, 60-85 parts of poly(4-methyl-1-pentene), 0-5 parts of polyethylene and 5-20 parts of polybutylene terephthalate; and the flexible circuit board gum inhibition release paper is formed through coating the surface of paper with the hot-melt resin composition in a hot melt manner and through carrying out high frequency corona to form surface micro-pores. Combination of hot-melt coating and high frequency corona micro-pore technologies changes the overflow amount of an adhesive in the hot pressing process of a flexible circuit board in order to improve the gum inhibition function, and modified resin is added to improve the melting point, the surface peeling strength and the bending strength of a release layer, so the yield is improved; the production method has the advantages of simplicity, easy process control and low cost; and the gum inhibition release paper has the advantages of excellent gum inhibition release performance, very low peeling strength, high temperature resistance and high bending strength.

Owner:ZHEJIANG KAREN SPECIALTY MATERIALS

Multi-component composite metal antirust paint and its preparation method

The invention discloses a multi-component composite metal antirust paint and its preparation method. The metal antirust paint is composed of the following raw materials, by weight, 32-35 parts of a polypropylene resin, 28-32 parts of a bisphenol A epoxy resin, 10-15 parts of a phenolic resin, 17-25 parts of modified meerschaum powder, 1.4-1.6 parts of 8-hydroxyquinoline, 20-25 parts of dibutyl phthalate, 0.6-0.8 parts of calcium lignin sulphonate, 0.4-0.8 parts of polybutylene terephthalate, 0.3-0.5 parts of poly-4-methyl-1-pentene, 1.1-1.3 parts of 4,4-methylene-bis(2,6-di-t-butylphenol), 2-5 parts of a modified styrene-acrylate emulsion, 1.5-1.7 parts of carboxymethyl cellulose sodium, 0.4-1.0 part of vinyltrisilane, 0.4-0.7 parts of sodium stearate and 1.0-1.5 parts of sodium dodecyl benzene sulfonate. The film of the metal antirust paint has the advantages of good adhesion, fast drying, good heat resistance, environmental protection and no pollution, and the modified meerschaum powder and the modified styrene-acrylate emulsion which are added to the raw materials improve the excellent performances of high-polymer materials in the raw materials and simultaneously increase the corrosion and heat resistances of the metal antirust paint; and the preparation method of the metal antirust paint has the advantages of simplicity, low cost and suitableness for large-scale production.

Owner:佛山市顺德区姿彩塑料粉末实业有限公司

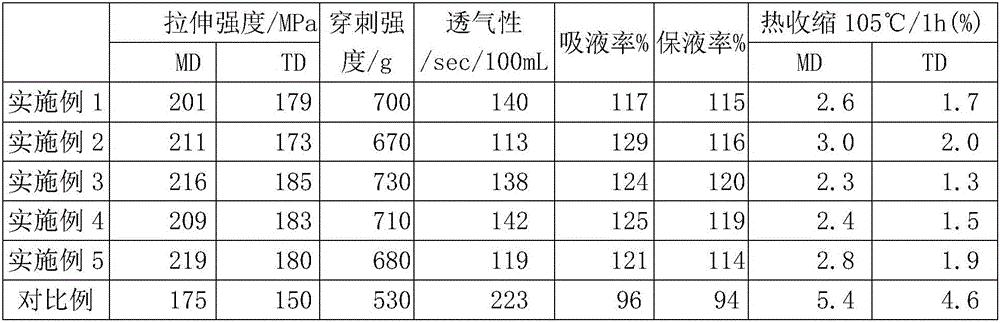

Poly(4-methyl-1-pentene) microporous membrane with high strength and high thermal stability and preparation method of poly(4-methyl-1-pentene) microporous membrane

ActiveCN106751043AImprove heat resistanceHigh mechanical strengthCell component detailsFlat articlesPolyolefinPolymer science

The invention discloses a poly(4-methyl-1-pentene) microporous membrane with high strength and high thermal stability and a preparation method of the poly(4-methyl-1-pentene) microporous membrane. The membrane is prepared from 25 to 50 parts of poly(4-methyl-1-pentene) resin, 0.05 to 1 part of antioxidant and 50 to 75 parts of diluent; the poly(4-methyl-1-pentene) microporous membrane is prepared by the following working procedures: mixing and melting; extrusion molding; biaxial stretching; extracting and drying; heat treatment setting and the like. Compared with a polyolefin membrane, the poly(4-methyl-1-pentene) microporous membrane disclosed by the invention has the advantages of high thermal resistance, high mechanical strength, high liquid absorbing and retaining rate and the like. The thermal shrinkage rate of the poly(4-methyl-1-pentene) microporous membrane prepared by the preparation method disclosed by the invention in an MD direction is not greater than 3.0 at 105DEG C / 1h, the thermal shrinkage rate of the poly(4-methyl-1-pentene) microporous membrane in a TD direction is not greater than 2.0, the MD tensile strength is greater than 200MPa, the TD tensile strength is greater than 170MPa, and the air permeability range is 150+ / -50 sec / 100mL.

Owner:HEFEI XINGYUAN NEW ENERGY MATERIAL CO LTD

Poly 4-methyl-1-pentene hollow fiber membrane and preparation method thereof

PendingCN112337322AEasy to operateThe preparation process is easy to be continuousSemi-permeable membranesDispersed particle separationPolymer scienceSpinning

The invention provides a preparation method of a poly 4-methyl-1-pentene hollow fiber membrane. The preparation method comprises the following steps: by using a thermally induced phase separation method, controlling the mixing temperature of 4-methyl-1-pentene resin and a diluent to obtain a homogeneous solution, co-extruding the homogeneous solution serving as a spinning solution and a core solution, and carrying out solid-liquid phase separation in a coagulating bath through an air layer. The pore diameter and porosity of the hollow fiber membrane can be controlled by controlling the temperature of the coagulating bath, and finally, the diluent is removed by soaking so that the poly 4-methyl-1-pentene hollow fiber membrane with uniform pore diameter distribution is obtained. The result of the embodiment shows that the porosity of the support layer in the poly 4-methyl-1-pentene hollow fiber membrane provided by the invention is 37%, the pore size distribution is 20-200nm, the O2 transmission coefficient of the hollow fiber membrane is 142 Barrer, the N2 transmission coefficient is 156 Barrer, and the CO2 transmission coefficient is 138 Barrer.

Owner:TIANJIN POLYTECHNIC UNIV

Metal antirust paint treating modified diatomite as filler, and its preparation method

InactiveCN102977664AImprove adhesionDry fastAnti-corrosive paintsPolyester coatingsPolymer scienceMeth-

The invention discloses a metal antirust paint treating modified diatomite as a filler, and its preparation method. The metal antirust paint comprises the following raw materials, by weight, 28-32 parts of a water-soluble phenolic resin, 22-25 parts of water-soluble polyester, 14-16 parts of the modified diatomite, 4-6 parts of a pure acrylic emulsion, 1.2-1.5 parts of octylamine, 14-16 parts of polycaprolactone, 0.4-0.6 parts of glycerol monostearate, 0.7-0.9 parts of polybutylene terephthalate, 0.6-0.8 parts of poly-4-methyl-1-pentene, 0.5-0.7 parts of zinc dialkyl dithiophosphate, 1-2 parts of 2,6-di-t-butyl-p-cresol, 3.5-5.5 parts of a modified acrylic emulsion, 0.8-1.5 parts of chitosan, 0.9-1.1 parts of vinylsilane, and 1.2-1.5 parts of polyoxyethylene ether type acrylate. The film of the metal antirust paint has the advantages of good adhesion, fast drying, good heat resistance, environmental protection and no pollution, and the modified diatomite and the modified acrylic emulsion added to the raw materials improve the excellent performances of high-polymer materials in the raw materials and simultaneously increase the corrosion resistance and the heat resistance of the metal antirust paint; and the preparation method has the advantages of simplicity, low cost and suitableness for large-scale production.

Owner:TONGLING MINGCHENG FOUNDRY

High-toughness automobile sealing strip

InactiveCN104844871AHigh strengthImprove toughnessDiethylene glycol monobutyl etherChlorinated paraffins

The invention discloses a high-toughness automobile sealing strip, which is prepared from the following raw materials in parts by weight: 9 to 15 parts of neoprene, 3 to 6 parts of a rare earth modifier, 4 to 9 parts of white carbon black, 3 to 10 parts of chlorinated paraffin, 1 to 5 parts of an accelerator, 6 to 11 parts of nitrile-butadiene rubber, 3 to 8 parts of sulfur powder, 9 to 14 parts of benzyl trimethyl ammonium tribromide, 6 to 9 parts of diethylene glycol monobutyl ether, 2 to 7 parts of tetrahydrofuran, 6 to 11 parts of 3-propargyl chloride, 3.5 to 8 parts of zinc stearate, 6 to 10 parts of poly-4-methyl-1-pentene, 7 to 10 parts of thermoplastic resin, 3 to 9 parts of dimethylsilicone fluid, 6 to 12 parts of butadiene styrene rubber and 2 to 9 parts of an accelerator. The automobile sealing strip has the beneficial effects of strong strength, high toughness, capability of well achieving a sealing effect and good soundproof and waterproof effects.

Owner:青岛千帆高新技术有限公司

Preparation method of poly-4-methylpentene nanosheet composite film

The invention discloses a poly-4-methylpentene nanosheet composite film which is characterized by being prepared from the following raw materials in parts by weight: 40-55 parts of poly-4-methyl-1-pentene, 10-15 parts of amino-terminated hyperbranched polybenzimidazole, 3-6 parts of a surface-modified graphene nanosheet / ceramic nanosheet composite, 1-3 parts of allyl glycidyl ether and 0.5-1.5 parts of N-[4-cyan-3-(trifluoromethyl) phenyl] methyl epoxy acrylamide. The invention also discloses a preparation method of the poly-4-methylpentene nanosheet composite film. The poly-4-methylpentene nanosheet composite film is small in dielectric loss, large in dielectric constant, good in thermal stability, high in breakdown field strength, good in flexibility, small in mass and easy to process.

Owner:苏州市新广益电子股份有限公司

Zirconia loaded metal antirust paint and its preparation method

InactiveCN102977666AImprove adhesionDry fastConjugated diene hydrocarbon coatingsAnti-corrosive paintsPolymer scienceMeth-

The invention discloses a zirconia loaded metal antirust paint and its preparation method. The metal antirust paint comprises the following raw materials, by weight, 35-40 parts of an epoxy resin, 15-20 parts of a polytetrafluoroethylene resin, 23-28 parts of modified nanometer argil, 9-11 parts of zirconia, 8-10 parts of a butadiene-styrene latex, 1.3-1.8 parts of a tallow amine, 15-20 parts of polycaprolactone, 0.7-0.9 parts of glycerol monostearate, 0.4-0.6 parts of polybutylene terephthalate, 0.7-0.9 parts of poly-4-methyl-1-pentene, 0.4-0.6 parts of salicylic acid, 0.5-1.0 part of an oxidant 168, 3-5 parts of a modified styrene-acrylate emulsion, 0.8-1.2 parts of polyacrylic acid, 0.6-1.2 parts of vinyl-tri(beta-methoxyethoxy)silane, and 1.0-1.2 parts of fatty alcohol polyoxyethylene ether. The film of the metal antirust paint has the advantages of good adhesion, fast drying, good heat resistance, environmental protection and no pollution, the modified nanometer argil and the modified styrene-acrylate emulsion which are added into the raw materials improve the excellent performances of high-polymer materials in the raw materials, and simultaneously increase the corrosion and heat resistances of the metal antirust paint, and the preparation method has the advantages of simplicity, low cost and suitableness for large-scale production.

Owner:TONGLING MINGCHENG FOUNDRY

Poly (4-methyl-1-pentene) hollow fiber alloy membrane as well as preparation method and application thereof

ActiveCN113398773AStable mechanical propertiesDoes not affect gas permeabilitySemi-permeable membranesOther blood circulation devicesHollow fibreFiber

The invention provides a poly (4-methyl-1-pentene) hollow fiber alloy membrane as well as a preparation method and application thereof. The poly (4-methyl-1-pentene) hollow fiber alloy membrane comprises 100 parts by weight of poly (4-methyl-1-pentene) and 0.1-50 parts by weight of a fluorine-containing polymer. The poly (4-methyl-1-pentene) hollow fiber alloy membrane provided by the invention not only has excellent mechanical strength and gas permeability, but also has excellent oleophobicity and blood compatibility, and can be used in a membrane oxygenator and an in-vitro membrane lung oxygenation system.

Owner:TSINGHUA UNIV

Poly(4-methyl-1-pentene) hollow fiber membrane and preparation method thereof

PendingCN113546525AImprove toughnessImprove gas permeabilityMembranesSemi-permeable membranesDibutyl sebacateVegetable oil

The invention discloses a poly(4-methyl-1-pentene) hollow fiber membrane and a preparation method thereof, belonging to the technical field of polymer separation membranes. The hollow fiber membrane is prepared by adopting a thermally induced phase separation method, and a diluent used in the preparation process consists of a good solvent and a poor solvent of poly(4-methyl-1-pentene), wherein the good solvent is composed of one or more selected from dibutyl sebacate, behenic acid, hydrogenated vegetable oil and trioctyl trimellitate, and the poor solvent is composed of one or more selected from glycerin, linseed oil, tea oil and palm oil. According to the invention, a preparation process is simple, required equipment is simple, operability is high, large-scale production is easy, the prepared hollow fiber membrane is high in toughness, the pore structure, the inner diameter and the outer diameter of the prepared hollow fiber membrane can be adjusted, and the obtained hollow fiber membrane is particularly suitable for an oxygen neutralizer of ECMO.

Owner:TSINGHUA UNIV

Poly4-methyl-1-pentene/silicone rubber thermoplastic elastomer, preparation and application thereof

ActiveCN111777821AEffective combination of performance characteristicsIncrease productivityElastomerPolymer science

The invention discloses a poly4-methyl-1-pentene / silicone rubber thermoplastic elastomer. The thermoplastic elastomer is prepared from the following raw materials: poly4-methyl-1-pentene, silicone rubber, a vulcanizing agent, filler, a structure control agent and hydrogen-containing silicone oil. The invention also discloses a preparation method of the poly4-methyl-1-pentene / silicone rubber thermoplastic elastomer. The poly4-methyl-1-pentene with high heat resistance is adopted and subjected to dynamic vulcanization processing with silicone rubber in a melt blending state, and the poly4-methyl-1-pentene / silicone rubber thermoplastic elastomer is prepared. The thermoplastic elastomer has high heat resistance, high release property, weather resistance and chemical resistance, is suitable fora release film in a flexible printed circuit board production process, and can also be widely applied to the fields of electronics, food, medical treatment and the like.

Owner:拓烯科技(衢州)有限公司

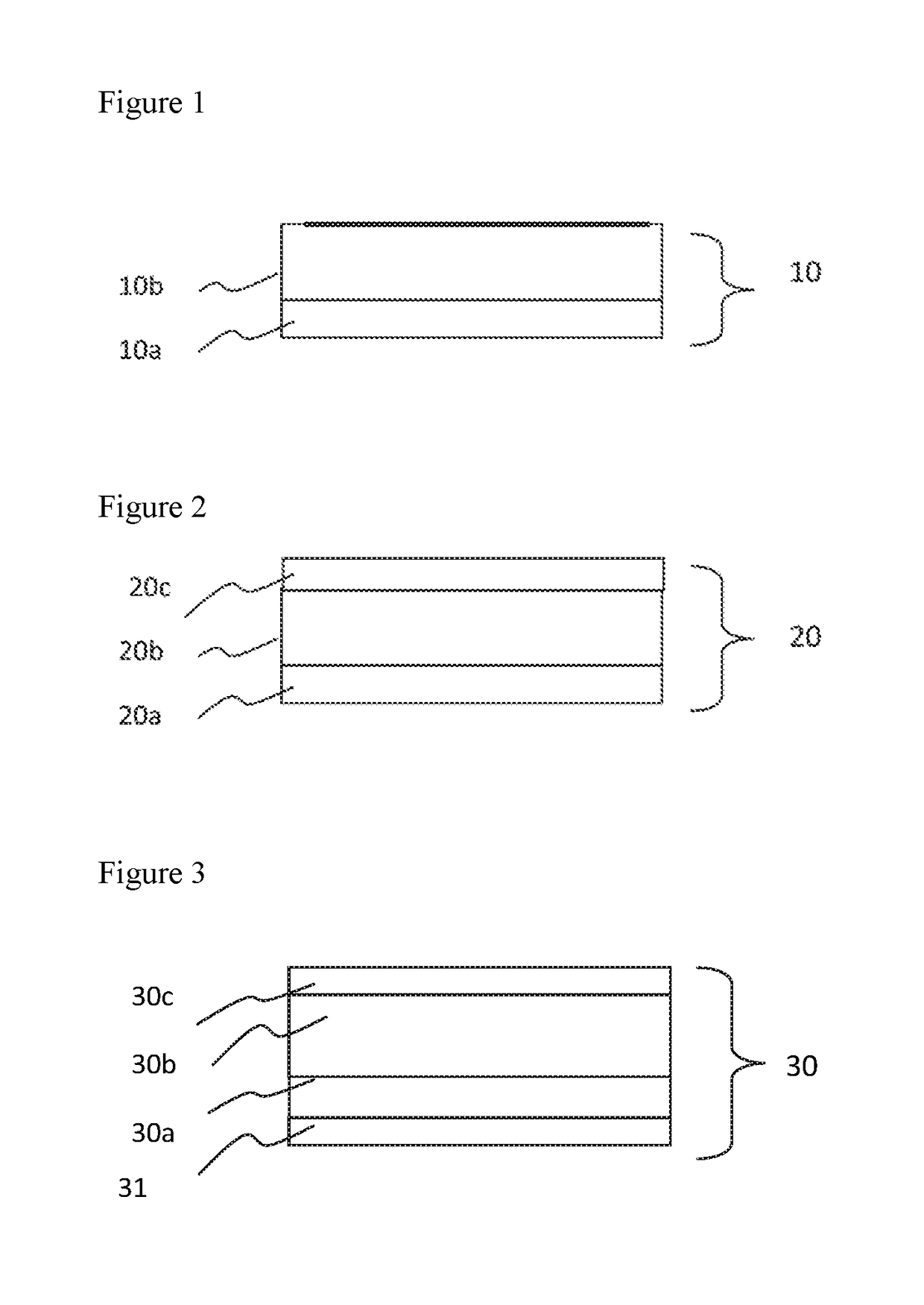

Three-layer composite release film for 3D printing process and preparation method of three-layer composite release film

ActiveCN114603955ARelease stabilityHigh mechanical strengthManufacturing platforms/substratesSynthetic resin layered productsPolymer scienceButanediol

The invention discloses a three-layer composite release film for a 3D printing process and a preparation method of the three-layer composite release film. The three-layer composite release film comprises a layer B and layers A arranged on the two sides of the layer B, the component of the layer A is poly (4-methyl-1-pentene); the component of the layer B is long-chain branch modified poly (4-methyl-1-pentene); the ratio of the total mass of the layer A to the mass of the layer B is 10: (1-5); the preparation method of the long-chain branch modified poly (4-methyl-1-pentene) comprises the following steps: mixing poly (4-methyl-1-pentene), a grafting monomer and an initiator, and carrying out melt extrusion to obtain the long-chain branch modified poly (4-methyl-1-pentene), and the grafting monomer comprises 1, 4-butanediol diacrylate and maleic anhydride. According to the invention, the poly (4-methyl-1-pentene) and the long-chain-chain modified poly (4-methyl-1-pentene) are respectively used as the surface layer and the middle layer, so that the prepared release film has excellent release property under the condition that a release agent is not added, and the film is high in light transmittance and good in mechanical property and can meet the use requirements in the 3D printing process.

Owner:NINGBO CHANGYANG TECH

Monoaxially or biaxially oriented polyolefin release film

A release film including a monoaxially or biaxially oriented multilayer polyolefin-based film having a crystallizable polyolefin core film layer and at least one coextruded skin layer having a poly-4-methyl-1-pentene composition blended with an olefin copolymer elastomer modifier. The film's release surface has a peeling force value of 1500 g / inch or less and a 60° angle surface gloss of below 50 gloss units (GU). An embodiment is a film structure having (a) a metal transfer carrier film having polyolefin as described above and (b) a coated metal layer having a metal layer and a coating layer, wherein the coating layer lies between the metal layer and the metal transfer carrier film, wherein the metal transfer carrier film is configured to allow transfer of the coated metal layer onto a substrate, so that after transfer of the coated metal layer onto the substrate, the coating layer is located on top of the substrate.

Owner:TORAY PLASTICS AMERICA

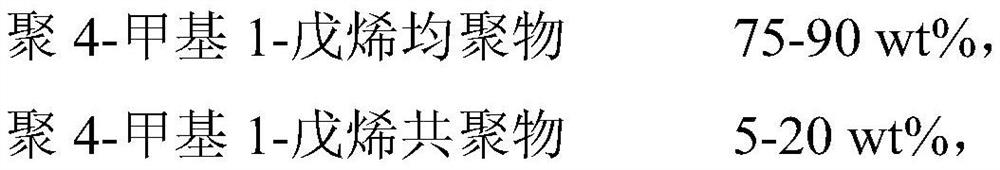

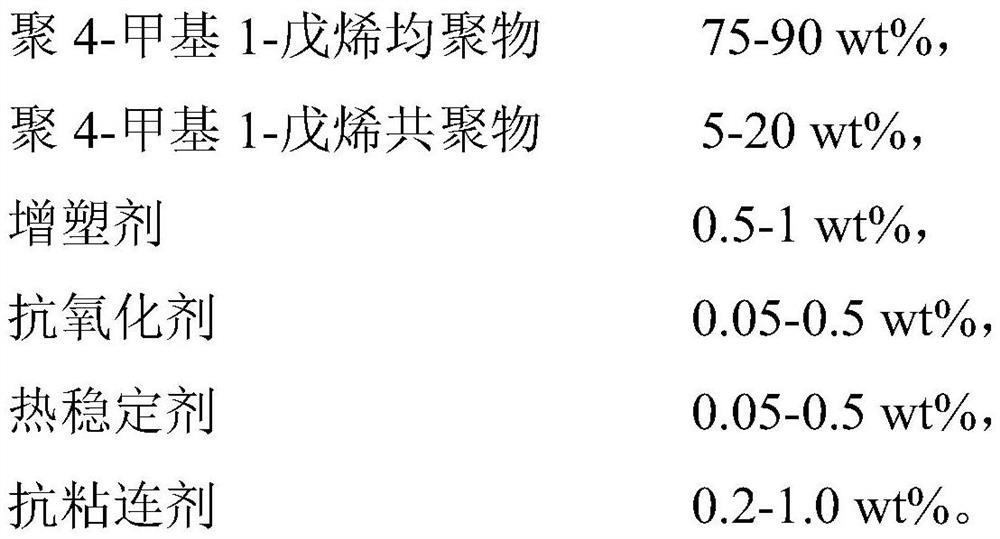

Biaxially oriented poly (4-methyl-1-pentene) film and preparation method thereof

The invention relates to a biaxially oriented poly (4-methyl-1-pentene) film and a preparation method thereof, and particularly belongs to the technical field of high polymer materials. The film belongs to crystalline olefin resin, and is high in heat resistance, the melting point reaches up to 240 DEG C, and the working temperature can reach 140-160 DEG C. According to the preparation method of the poly (4-methyl-1-pentene) film, by setting temperature parameters of all sections in a production line, main factors influencing crystallization, stretching orientation and shaping processes of poly (4-methyl-1-pentene) molecules are controlled, and it is guaranteed that the product performance suitable for capacitor films is obtained; in the processing course, poly (4-methyl-1-pentene) resin with the optimal molecular weight is selected, the crystallization degree of the film is controlled and material degradation is prevented according to the temperature and stretching ratio suitable forprocessing, and the biaxially oriented poly (4-methyl-1-pentene) film which is resistant to high temperature and good in thickness uniformity is continuously produced.

Owner:ANHUI TONGFENG ELECTRONICS

Dyeable fiber as well as preparation method and application of dyeable fiber

InactiveCN103668549AGood resistance to ironingImprove featuresConjugated synthetic polymer artificial filamentsYarnPolyamide

The invention provides a dyeable fiber as well as a preparation method and the application of the dyeable fiber. The fiber is an alloy fiber which at least contains a component A and a component B, wherein the component A is poly-4-methylpentene-1, and the component B is one or more of polyester, modified copolyester, polyamide and polylactic acid. The preparation method of the dyeable fiber comprises the following steps: blending the component A and the component B after the component A and the component B are dried, and performing melt spinning on the blended materials. The obtained dyeable fiber has certain dyeability, and meanwhile, high light weight property is also kept; the dyeable fiber is a dyeable lightweight fully oriented yarn, and can also be a curling dyeable lightweight yarn with elasticity; the dyeable fiber can also be made into braided fabric.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

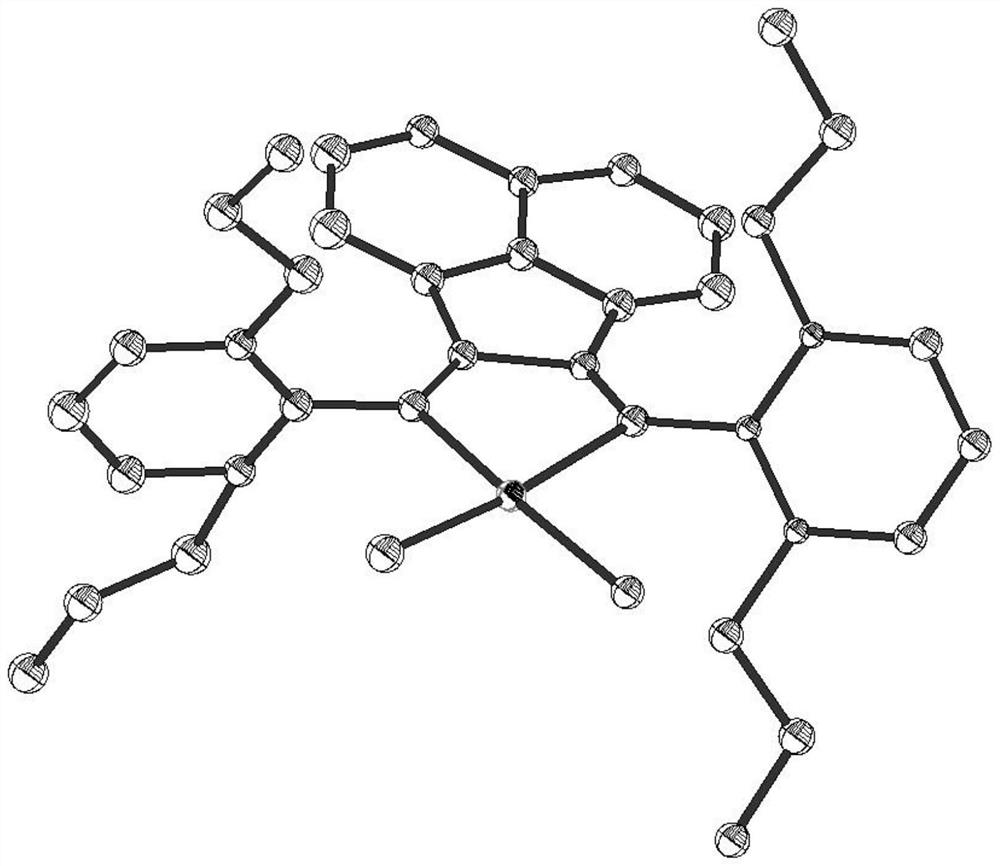

Complex for preparing highly branched poly (4-methyl-1-pentene) material and preparation method thereof

InactiveCN112745355ARegulating the degree of branchingRegulating Molecular WeightGroup 8/9/10/18 element organic compoundsPolymer scienceDiimine

The invention discloses a complex for preparing a highly branched poly (4-methyl-1-pentene) material and a preparation method of the complex. When the diimine palladium complex is applied to 4-methyl-1-pentene polymerization, the reaction condition is mild, and the polymerization reaction does not need to be carried out under harsh anhydrous and anaerobic conditions; according to the present invention, the propyl group is introduced to the ortho-position of the imine nitrogen atom aromatic ring, so that the dynamic steric hindrance can be provided for the complex during the catalytic polymerization process so as to finely adjust the space environment of the Pd catalytic activity center, regulate the branching degree and the molecular weight of the polymer, and obtain the highly branched poly 4-methyl-1-pentene;.

Owner:张洪胜

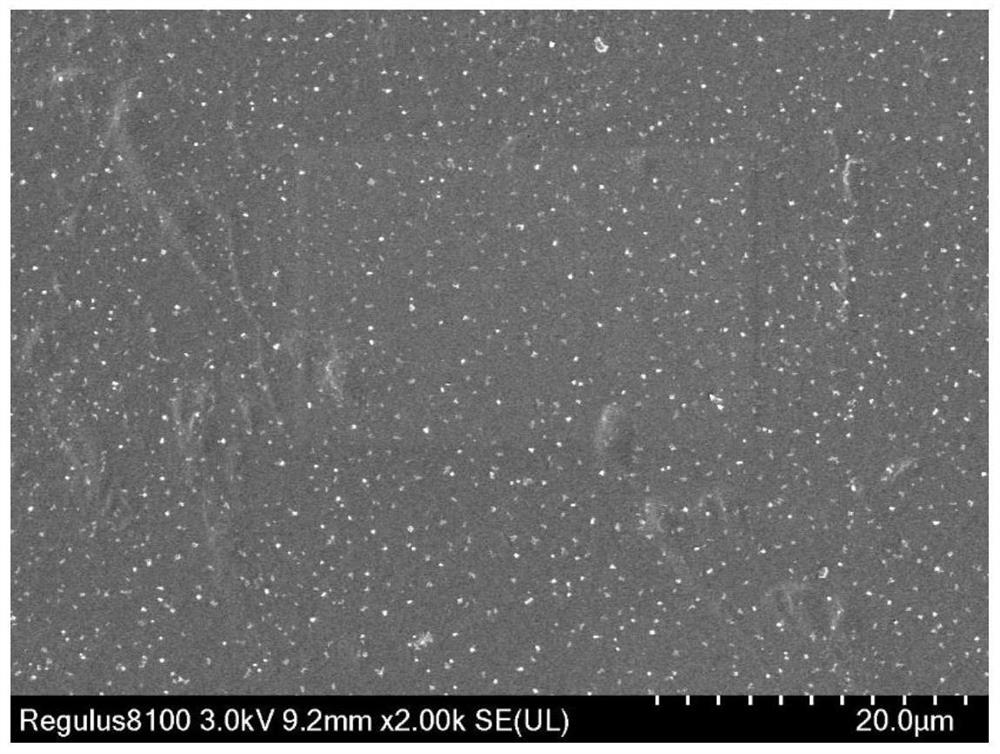

Stretchable radiation cooling adhesive tape as well as preparation method and application thereof

ActiveCN113025219ALow priceEasy to prepareFilm/foil adhesivesChemical industryPolymer scienceSilicone tape

The invention discloses a stretchable radiation cooling adhesive tape as well as a preparation method and application thereof, and belongs to the field of nano materials and application, namely poly (4-methyl-1-pentene) doped with titanium dioxide nano particles and dioctyl phthalate is used as a cooling layer of the adhesive tape, and nitrile rubber is used as a bonding layer of the adhesive tape. The adhesive tape is prepared by adopting a blade coating technology, the method is simple, and large-size continuous preparation can be realized. The adhesive tape prepared by the invention has high stretchability, relatively strong adhesive property and good waterproof performance. The adhesive tape can be used for cooling electronic equipment, and experimental results show that the adhesive tape prepared by the invention can realize the highest 9.3 K sub-environment cooling, and the surface temperature of a mobile phone can be reduced by 25.1 K.

Owner:NANKAI UNIV

Poly(4-methyl-1-pentene) hollow fiber membrane applied to ECMO, and preparation method thereof

PendingCN113144909AStable structureEasy to controlSemi-permeable membranesOther blood circulation devicesRubber materialPolymer science

The invention relates to a preparation method of a hollow fiber membrane, and concretely relates to a poly(4-methyl-1-pentene) hollow fiber membrane applied to ECMO, and a preparation method thereof. According to the method for preparing the poly(4-methyl-1-pentene) porous membrane by adopting the melt extrusion method, the poly(4-methyl-1-pentene) hollow fiber membrane with different membrane pore forms is prepared from poly(4-methyl-1-pentene) and different types of diluents in the production process of the method. According to the principle of film forming, after poly(4-methyl-1-pentene) powder and a diluent are mixed, the mixture is subjected to double-screw melting and then stretched, extruded and molded through a spinning nozzle, the poly(4-methyl-1-pentene) hollow fiber membrane is prepared through two-step cold and hot stretching, rubber material coating is conducted through a deposition tank, a compact layer is formed on the surface of the hollow fiber film, and the diluent is extracted to generate different membrane pore forms and porous structures, so that the poly(4-methyl-1-pentene) composite hollow fiber membrane with certain pore size distribution, good microporous structure and anti-leakage function is obtained.

Owner:NANJING UNIV OF TECH

Acid-and-alkali-resistant automobile rubber hose

An acid-and-alkali-resistant automobile rubber hose is prepared from raw materials in parts by weight as follows: 6-14 parts of blast furnace slag micro-powder, 4-9 parts of fast extruding furnace black N550, 3-9 parts of carnauba wax, 4-7 parts of a friction property modifier, 2-6 parts of aluminum oxide, 3-6 parts of graphite, 4-9 parts of acetyl triethyl citrate, 1-3 parts of black soil, 3-9 parts of talc powder, 1-5 parts of a coupling agent, 4-9 parts of polyolefin elastomers, 3-6 parts of polypropylene resin, 4-10 parts of poly(4-methyl-1-pentene) and 6-14 parts of vinyl trimethoxy silane. The automobile rubber hose has the benefits as follows: the wear-resistant automobile rubber hose has good wear resistance and acid and alkali resistance, is long in service life and well guarantees the normal work of an automobile.

Owner:青岛海蓝海洋复合功能材料科技有限公司

Metal antirust paint containing modified acrylic emulsion, and its preparation method

The invention discloses a metal antirust paint containing a modified acrylic emulsion, and its preparation method. The metal antirust paint comprises the following raw materials, by weight, 35-37 parts of a modified water-soluble phenolic resin, 25-30 parts of a polyimide resin, 15-17 parts of modified styrene, 9-11 parts of a silicate, 1.7-1.9 parts of phenylnaphthylamine, 18-20 parts of polycaprolactone, 0.3-0.5 parts of chlorinated paraffin, 0.5-0.7 parts of polybutylene terephthalate, 0.9-1.1 parts of poly-4-methyl-1-pentene, 1.3-1.8 parts of an antioxidant DSTP, 3-4 parts of the modified acrylic emulsion, 1.1-1.4 parts of urea, 1.4-1.6 parts of tetraisopropyl di(dioctylphosphate) titanate, 0.6-0.8 parts of isooctyl thioglycolate dimethyl tin and 1.3-1.8 parts of .polyoxyethylene ether acrylate. The film of the metal antirust paint has the advantages of good adhesion, fast drying, good heat resistance, environmental protection and no pollution, the modified water-soluble phenolic resin, the modified styrene and the modified acrylic emulsion which are added to the raw materials improve the excellent performances of high-polymer materials in the raw materials and simultaneously increase the corrosion resistance and the heat resistance of the metal antirust paint, and the preparation method has the advantages of simplicity, low cost and suitableness for large-scale production.

Owner:佛山市晶茂科技有限公司

Pearlescent polyamide film and preparation method thereof

ActiveCN111572138AReduce adhesionReduce usageSynthetic resin layered productsDomestic containersMasterbatchPolymer science

The invention provides a pearlescent polyamide film and a preparation method thereof. The pearlescent polyamide film sequentially comprises an upper surface layer, a core layer and a lower surface layer from top to bottom. The core layer is prepared from the following components in parts by mass: 70 to 90 parts of polyamide resin; and 15 to 35 parts of pearlescent master batch. The pearlescent master batch is prepared from 55 to 85 parts of polyamide resin, 20 to 30 parts of barium sulfate, 5 to 15 parts of copolymer containing poly (4-methyl-1-pentene) structural units and 0.1 to 1 part of hyperdispersant. The upper surface layer and the lower surface layer are anti-adhesion layers and are composed of 100 parts of polyamide resin and 3-5 parts of anti-adhesion master batch. The pearlescent polyamide film prepared by the invention has soft and pleasant pearlescent luster and better shading property, has the advantages of high tensile strength and better oxygen barrier property, and canbe widely applied to products such as food and gift packages.

Owner:厦门长塑实业有限公司

High-transparency modified polyolefin material and preparation method thereof

The invention discloses a high-transparency modified polyolefin material and a preparation method thereof. The high-transparency modified polyolefin material is prepared from 65-85 parts of poly(4-methyl-1-pentene), 7-15 parts of polyisobutene, 3-10 parts of ethylene propylene rubber, 0.1 part of a vulcanizing agent, 0.2 part of butylated hydroxytoluene, 5-10 parts of basic magnesium carbonate, 0.5 part of an antioxidant and 0.2 part of a dispersing agent. According to the high-transparency modified polyolefin material provided by the invention, the crystalline material poly(4-methyl-1-pentene) with an excellent light transmission effect is selected as a base material, so that the dimensional stability of the disclosed material at a relatively high temperature is ensured; the high-molecular-weight polyisobutene and the micro-crosslinked low-molecular-weight ethylene propylene diene monomer are used as toughening agents, and the basic magnesium carbonate with a special optical refractive index is used as a filling substance, so that the toughness and rigidity of the disclosed material are improved, and the influence on the overall transparency of the disclosed material is avoided tothe greatest extent.

Owner:HEFEI GENIUS NEW MATERIALS

Rubber composition for tire

The invention discloses a rubber composition for tires. The rubber composition comprises the following components in parts by weight: 8-15 parts of butadiene rubber, 3-9 parts of zinc stearate, 4-6 parts of silicon dioxide, 3-9 parts of sodium acetate, 2-6 parts of ammonium polyphosphate, 5-10 parts of poly-4-methyl-1-amylene, 5-10 parts of an active agent, 2-7 parts of a peroxide vulcanization agent, 1-5 parts of zinc oxide, 3-6 parts of a vulcanization promoting agent TT, 1-3 parts of a filling agent, 4-9 parts of kieselguhr and 1-4 parts of a silane coupling agent. The rubber composition for tires has the beneficial effects of good wearing resistance, good strength and high acid-alkali resistance and oxidation property.

Owner:QINGDAO MEIJIALONG PACKAGING MACHINERY

Packaging plastic film containing nylon PA66

The invention relates to a packaging plastic film containing nylon PA66. The packaging plastic film containing nylon PA66 is prepared from the following raw materials in parts by weight: 10-12 parts of nylon PA66, 40-45 parts of LDPE (low-density polyethylene), 20-25 parts of a homogeneous ethylene / alpha-olefin copolymer, 10-15 parts of SG-1 type polyvinyl chloride, 3.5-5.5 parts of epoxy cottonseed oil, 2.2-3.5 parts polyethylene wax powder, 1-2 parts of distearoyl isopropoxy aluminate, 8-12 parts of modified diatomite, 1-1.5 parts of polyisobutylene, 1-2 parts of poly-4-methyl-1-pentene, 0.5-0.7 part of magnesium oxide, 0.7-1.2 parts of aluminum oxide, 0.8-1.2 parts of nano clay, 0.8-1.5 parts of tree ash, 0.9-1.4 parts of glycerol triacetate, 1-1.8 parts of chlorinated paraffin, 0.8-1.6 parts of calcium stearate, 0.5-1 part of methyltrimethoxysilane, 1-2 parts of ferrocene and 1-2 parts of modified sepiolite powder. The nylon PA66 containing packaging plastic film provided by the invention has good barrier properties and air tightness and excellent pressure resistance and impact resistance and also has the characteristics of high heat sealing strength and good heat sealing performance.

Owner:TIANJIN KAIXUAN PLASTIC PROD

Hollow fiber heterogeneous membrane as well as preparation method and application thereof

PendingCN114749036ALittle impact on main body performanceEasy to makeSemi-permeable membranesMembranesFiberPolymer science

The invention discloses a hollow fiber heterogeneous membrane as well as a preparation method and application thereof. The oxygenated membrane is prepared by taking poly-4-methyl-1-pentene as a membrane material and dioctyl phthalate as a diluent through a thermally induced phase separation method. The preparation method comprises the following steps: blending an amphiphilic block copolymer in a membrane casting solution, extruding the uniformly mixed membrane casting solution through a spinning nozzle, performing phase separation and curing in a cooling water bath, spontaneously enriching a hydrophilic chain segment to the surface of the membrane, anchoring a polymer matrix by a hydrophobic segment, and realizing in-situ surface modification of the membrane. And subsequently, extracting, drying and the like to obtain the heterogeneous PMP oxygenation membrane with a hydrophilic surface and a hydrophobic main body. The method has the advantages of simplicity in operation, high controllability, capability of realizing one-step modification and the like. When the prepared modified membrane is applied to in-vitro membrane oxygenation, the blood compatibility of the membrane is obviously improved, and meanwhile, the original high gas permeability of the PMP membrane is still kept.

Owner:TIANJIN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com