Poly-4-methyl-1-pentene based resin composition and molded products obtained from the composition

A resin composition, pentene-based technology, used in synthetic resin layered products, layered products, transportation and packaging, etc., can solve the problem of no improvement in formability, and achieve the effect of improving stretchability and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

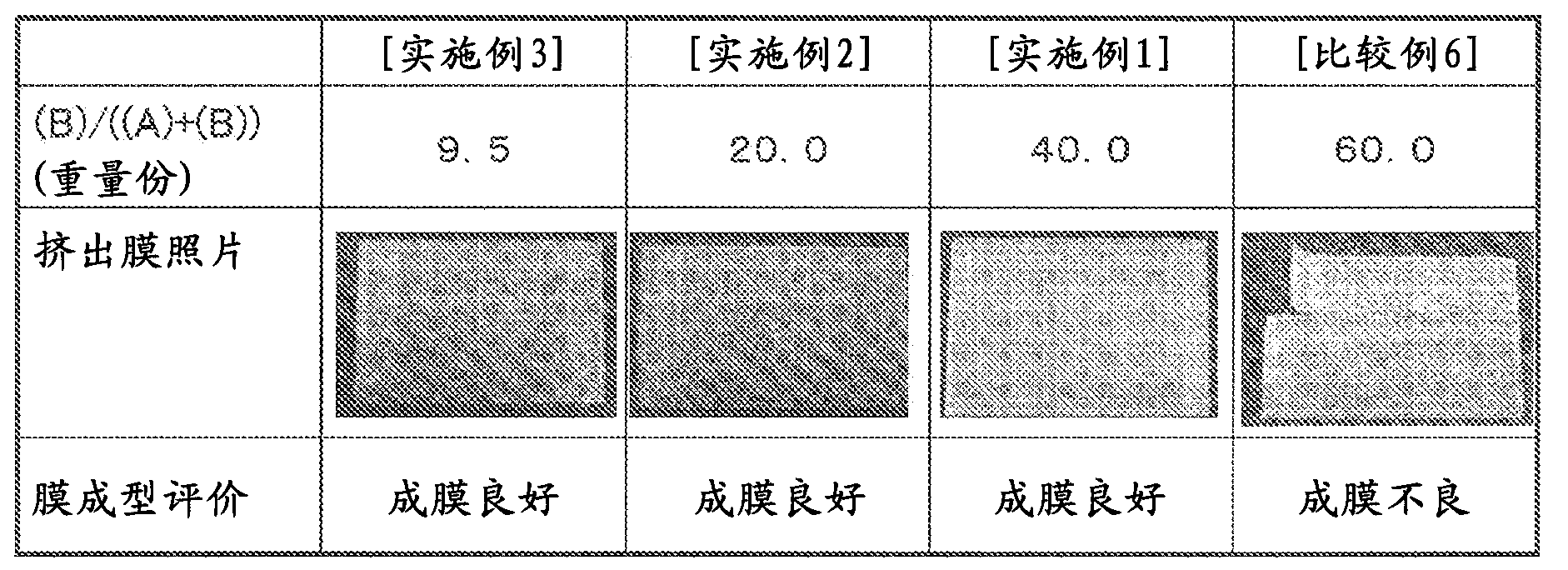

Embodiment 1~9、 comparative example 1~7

[0226] As poly-4-methyl-1-pentene (A), Mitsui Chemicals, Inc. MX002 (MFR (260°C, 5 kg load) 26 g / 10 minutes, melting point (Tm) 224°C) or RT18 (MFR (260°C, 5kg load) 20g / 10 minutes, melting point (Tm) 235°C).

[0227] In addition, as the polyamide (B), CM1041LO (PA6, MFR (260° C., 5 kg load) 13 g / 10 minutes, melting point (Tm) 225° C.) manufactured by Toray Corporation was used.

[0228] In Examples 1 to 9 and Comparative Examples 1 to 7, the poly-4-methyl-1-pentene (A) and polyamide (B) described in Table 1 or Table 2 and polyamide (B) synthesized in Production Example 1 were used. Modified poly-4-methyl-1-pentene (C) was used in the compounding amount recorded in Table 1 or Table 2, respectively, using a twin-screw extruder (manufactured by Technovel Co., Ltd., KZW-15, screw diameter 15mm, L / D=30, temperature 270° C., rotation speed 200 rpm) were melt-kneaded to obtain a resin composition.

[0229] Next, using a 30-ton injection molding machine (Nex30) manufactured by Toy...

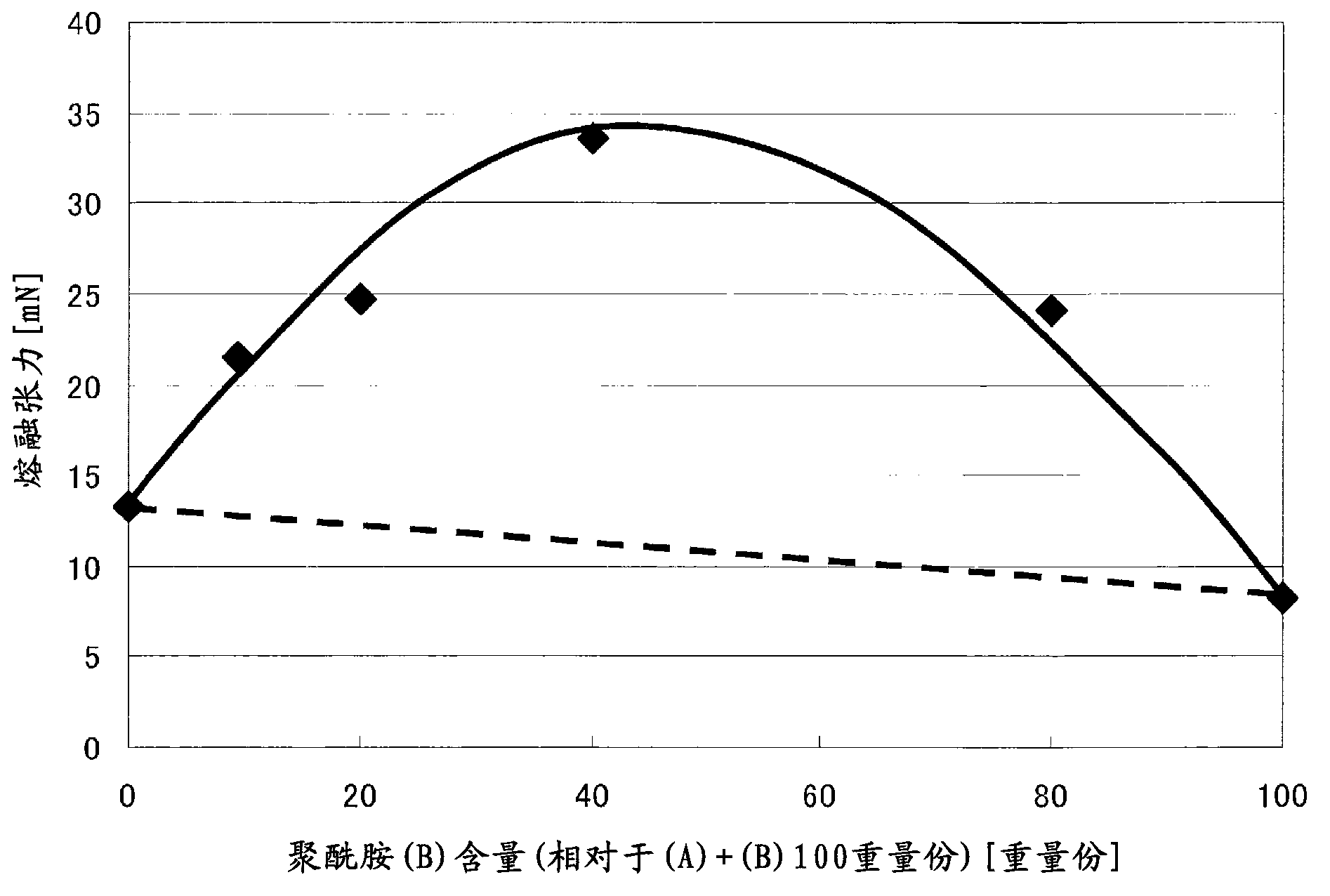

Embodiment 10~18、 comparative example 8 and 9

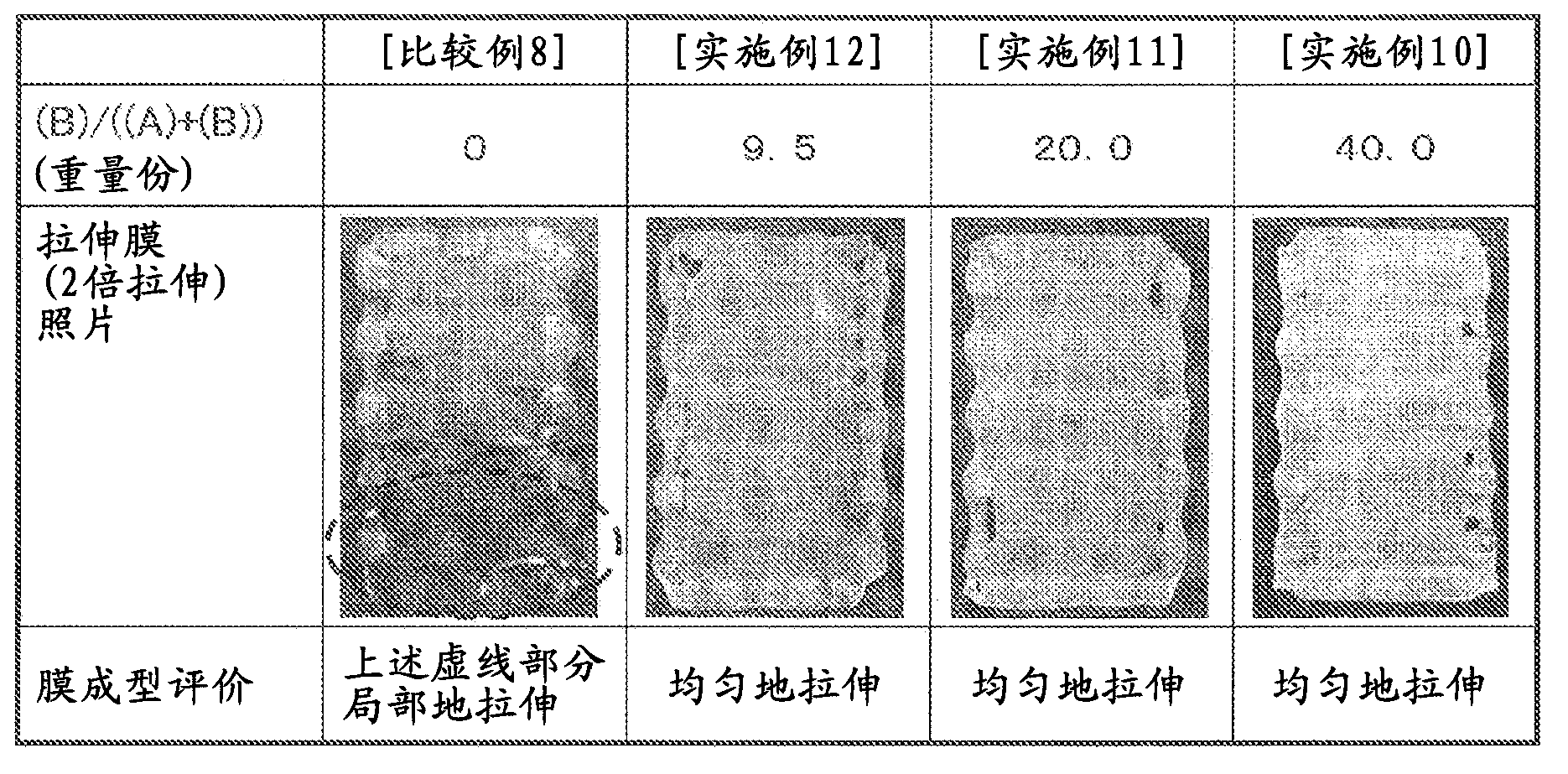

[0247]Take 70×70 mm from the extruded films obtained in Examples 1-3, 7-9 and Comparative Examples 3 and 4, and specify in the MD direction of the extruded films at a stretching temperature of 100° C. and a stretching speed of 2 mm / sec. Uniaxial stretching at a certain ratio (Imoto Manufacturing Co., Ltd., automatic biaxial stretching device, IMC-18BD type), after stretching, the temperature is raised to 200 ° C, and heat setting is carried out for 10 minutes in the stretched state to obtain the specified Stretch film with stretch ratio.

[0248] Tables 3 and 4 show the values of the predetermined stretch ratios and the results of the tensile tests of the obtained stretched films. In addition, regarding Examples 10 to 12 and Comparative Example 8, digital images related to the state of stretch molding of the stretched film due to the content of the polyamide (B) are shown in image 3 middle.

[0249] [table 3]

[0250] table 3

[0251] (A) / ((A)+(B)):(A) content relativ...

Embodiment 19~21、 comparative example 10 and 11

[0261] Using the resin compositions of the above-mentioned Examples 1-3 and Comparative Examples 3 and 5, an inflation film molding machine (manufactured by Thermoplastics Industry Co., Ltd., 20mmΦ inflation film manufacturing device) was used, and the temperature of the barrel and the die was both 270°C. , traction speed 2.5m / min, inflation ratio 2.0-2.5 for blown film forming. Table 5 shows the film shape, film thickness and tensile test physical properties of the obtained inflation film. In addition, regarding Examples 19 to 21 and Comparative Example 10, digital images related to the molded state of the inflation film are shown in Figure 4 middle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com