Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

134results about How to "Strong production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

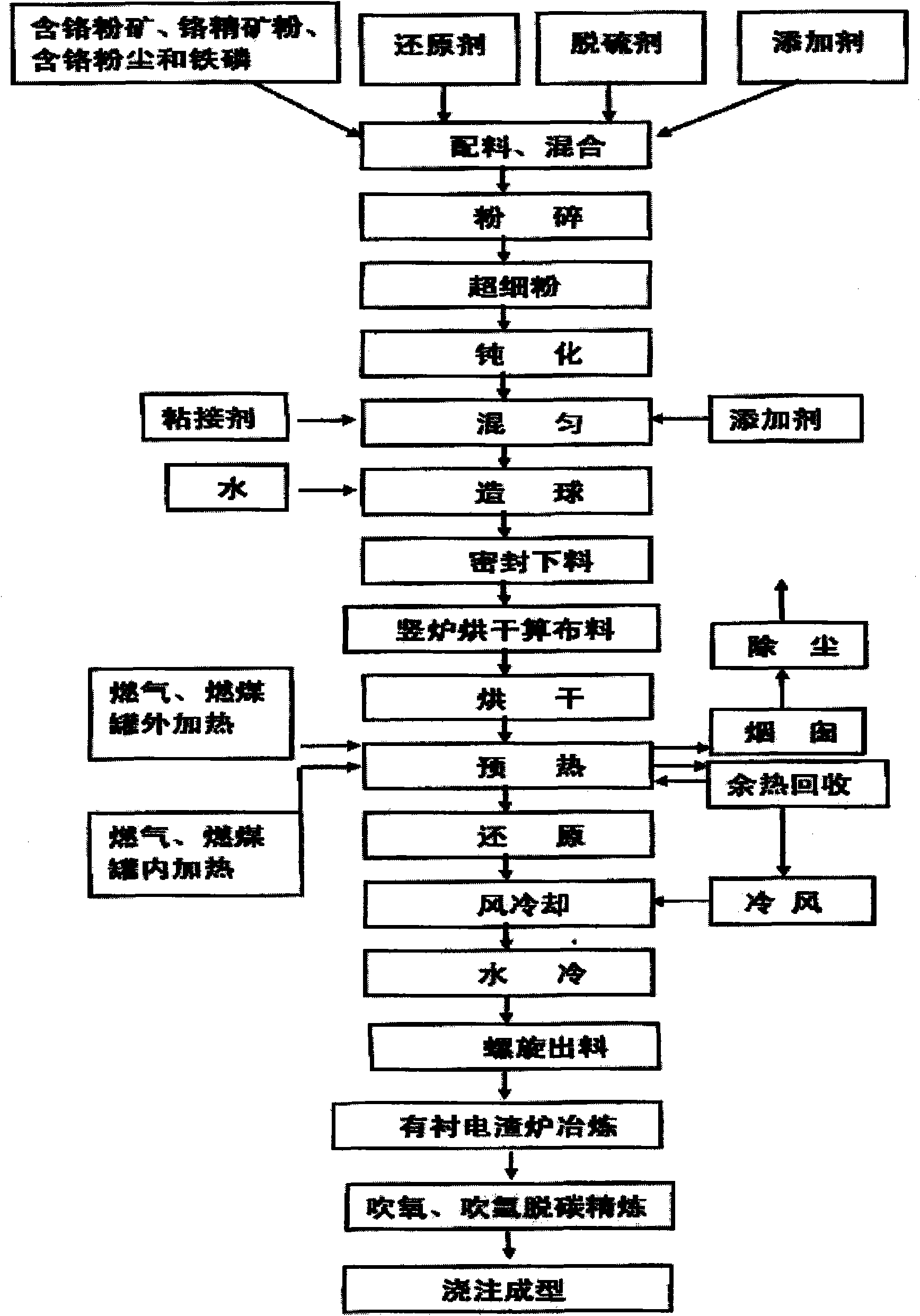

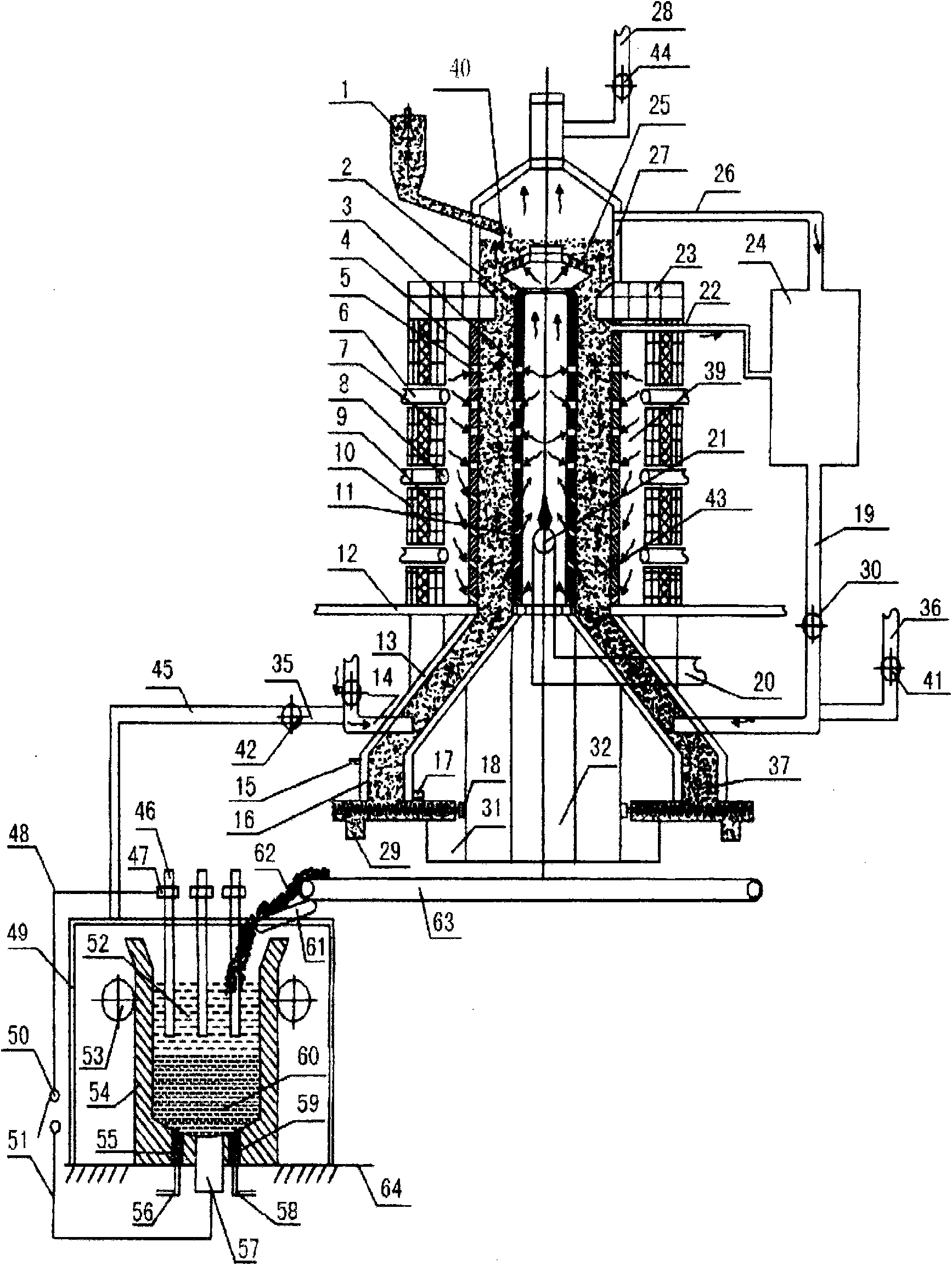

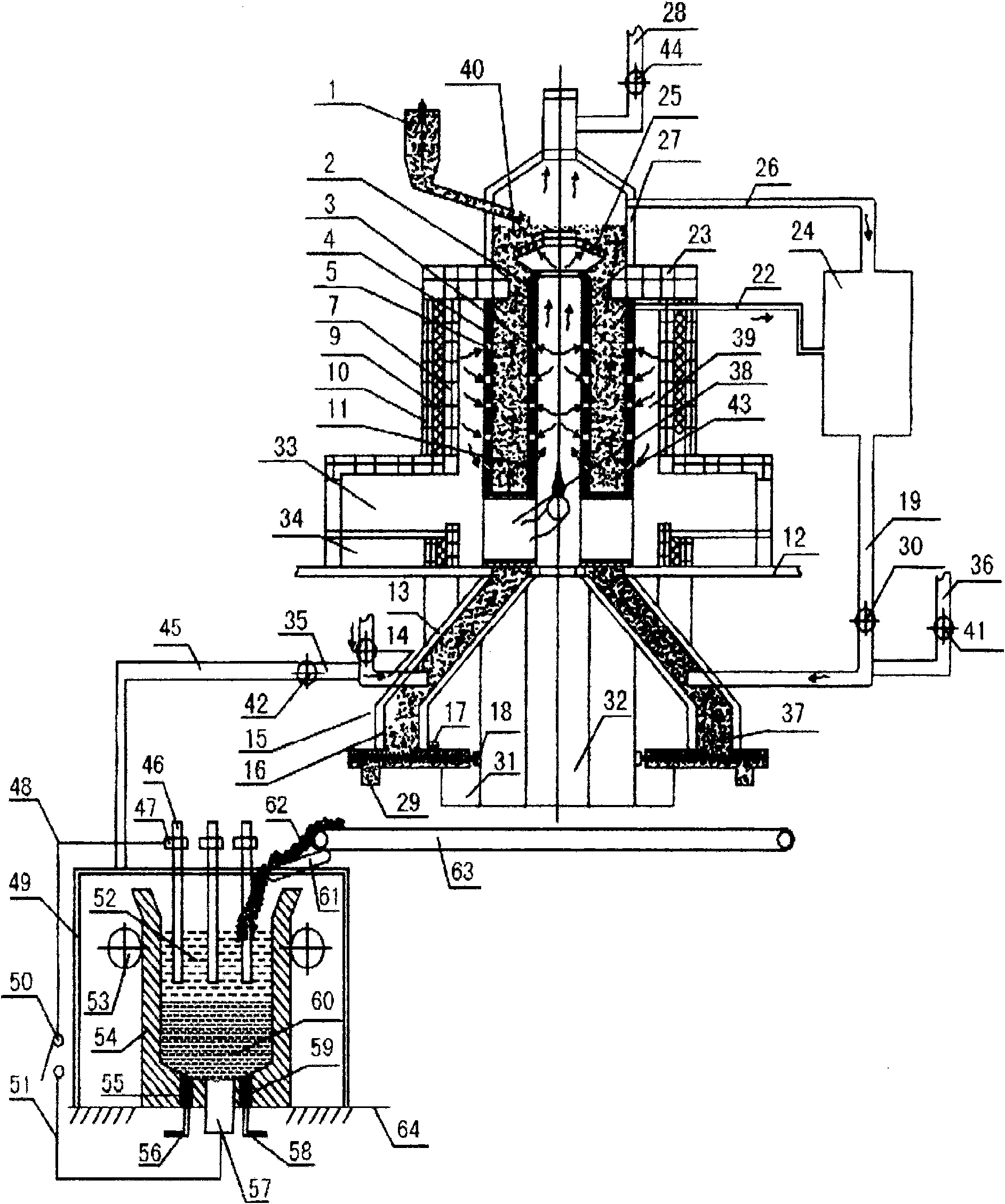

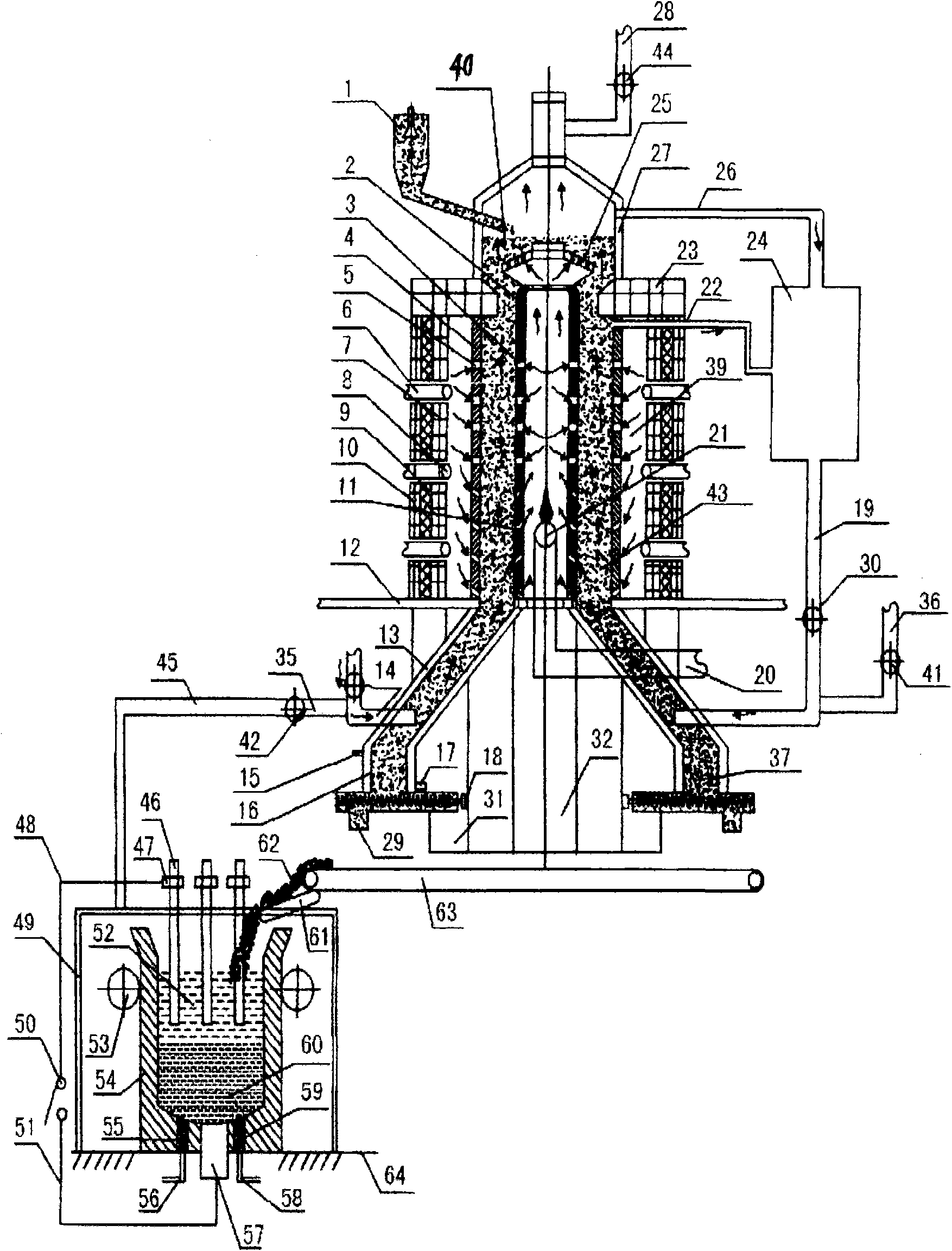

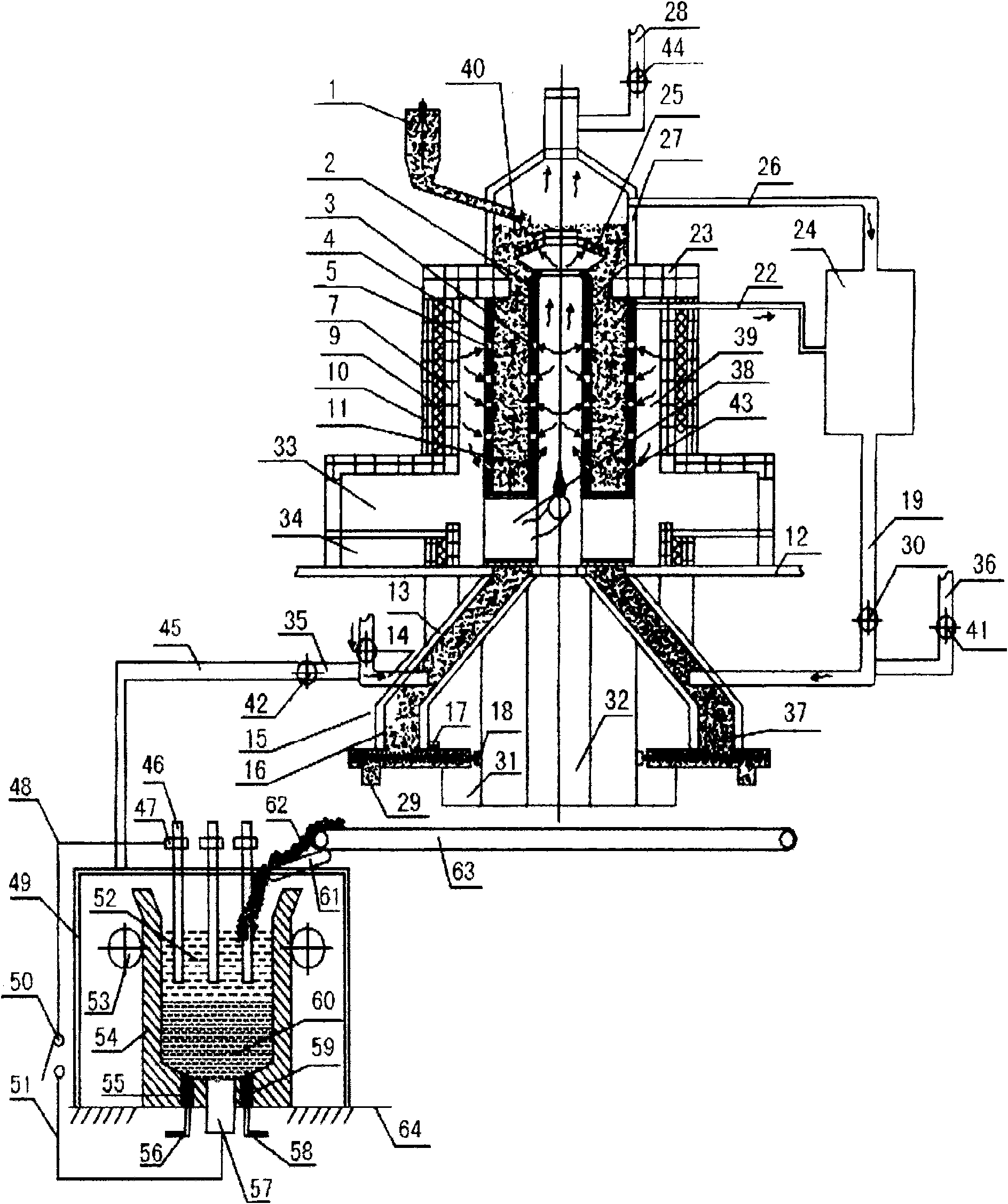

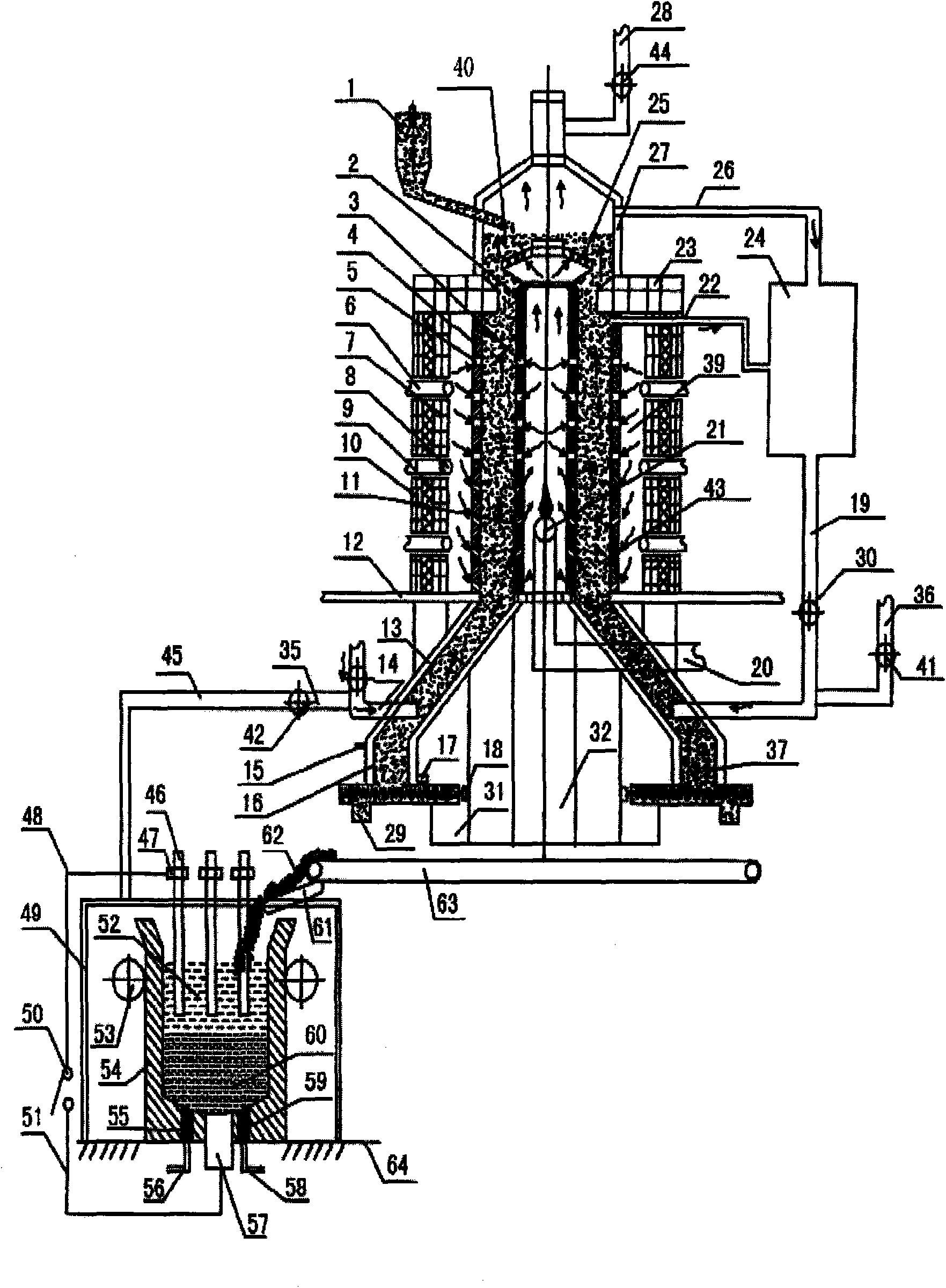

Process and device for smelting chromium irons and chromium-containing molten iron by using chromium ore powder

InactiveCN101538629AImprove applicabilityHigh recovery rateProcess efficiency improvementShaft furnaceUltra fineSolvent

The invention relates to a process and a device for smelting chromium irons and chromium-containing molten iron by using chromium ore powder, which belongs to metallurgical industry steel-making raw material. The process comprises the following steps: mixing chromium iron containing raw materials with reducing agent, solvent and catalyst to prepare ultra fine powder, mixing to make pelletizing materials, sending the pelletizing materials into a reducing furnace, obtaining chromium irons pellets after the reduction reaction, and directly adding reduced pellets into a lining electroslag furnace for being smelted into the chromium-iron alloy or the chromium-containing molten iron. The device comprises an internal-external heating vertical reducing furnace, a lining electroslag furnace and a residual heat recovery system. The invention has the advantages that: firstly, the reduction temperature is low, the speed is high, the energy consumption is reduced, the production cost is lowered, the production efficiency is high, and the uniformity of the quality is good; secondly, the degree of mechanization is high, the procedure is simple, the yield is large, the mass production can be performed; thirdly, the waste of raw materials is reduced, the environment pollution is lowered; fourthly, the source of raw materials adopting the chromium ore powder and chromium-containing waste, the cost is low; fifthly, the waste resource can be recycled so as to save the resource consumption; and sixthly, the high-temperature pellets are directly smelted by adopting the lining electroslag furnace, the heat efficiency is high, the energy consumption is low, the material purity is high and the quality is good, and the device is simple with less investment.

Owner:丁家伟

Manufacturing method of surface compressed plate

InactiveCN101664948AHigh densityHigh strengthWood compressionWood treatment detailsPolymer scienceVolumetric Mass Density

The invention relates to a manufacturing method of a surface compressed plate, in particular to solving the technical problem of providing a manufacturing method of a surface compressed plate featuring high surface layer density, high strength, low probability of deformation, simple technology, strong operability and lighter color. The technical scheme for solving the problem is as follows: the method comprises the following steps: (1) drying and controlling the water content between 20% and 30%; (2) rolling and controlling the compression ratio between 10% and 30%; (3) impregnating surface layer, namely soaking one or two sides of the plate into light-color water-soluble low molecular weight phenolic resin adhesives at a concentration of 10-25%; (4) softening by steam and controlling thesoftening temperature between 120 DEG C and 140 DEG C and time between 20min and 60min; and (5) compressing surface layer and controlling the compression ratio between 15% and 50%, the hot pressing temperature between 160 DEG C and 180 DEG C and the unit pressure between 1.5MPa and 4.5MPa. The method is suitable for such fields as furniture manufacturing, indoor decoration and the like.

Owner:ZHEJIANG FORESTRY UNIVERSITY

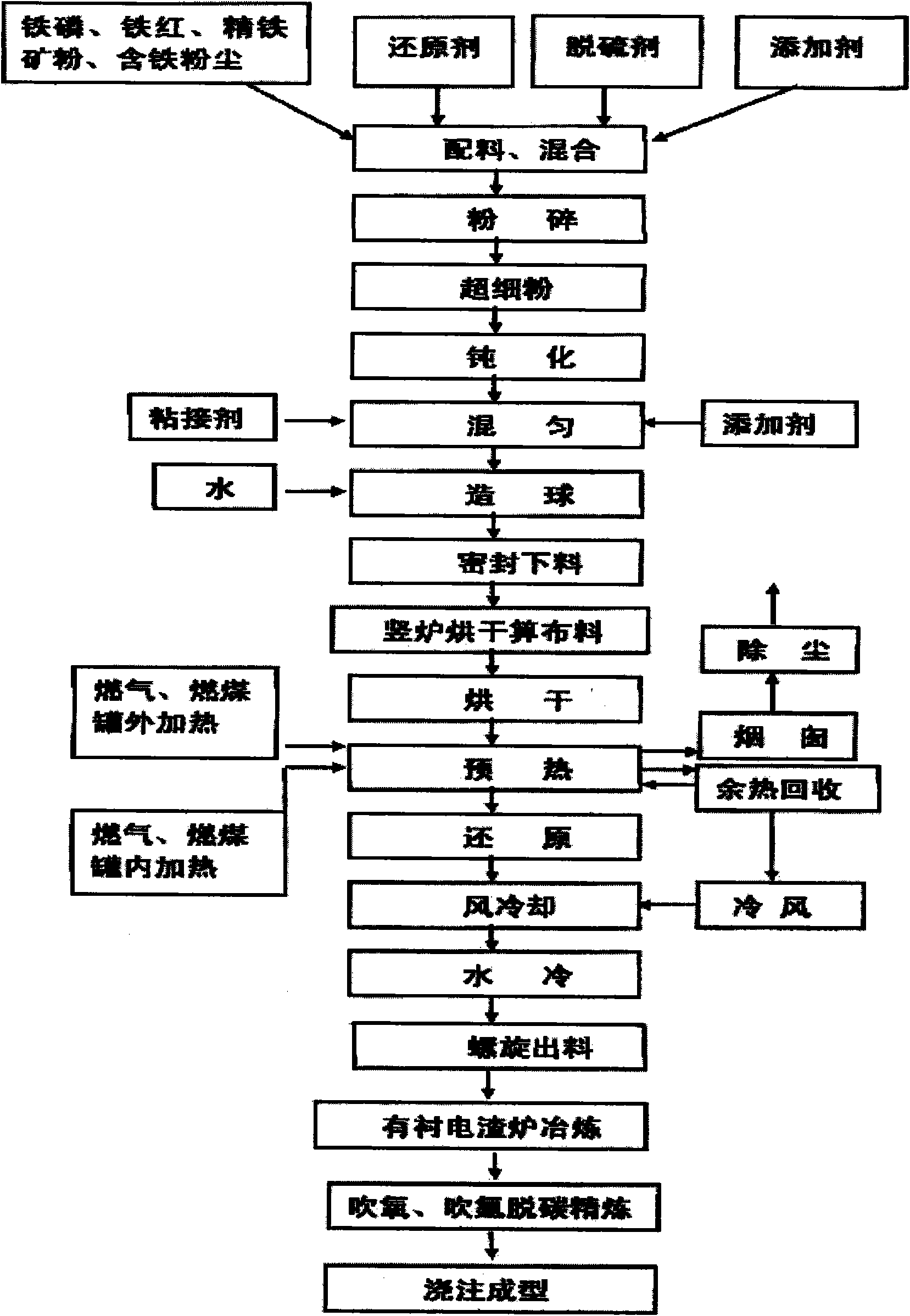

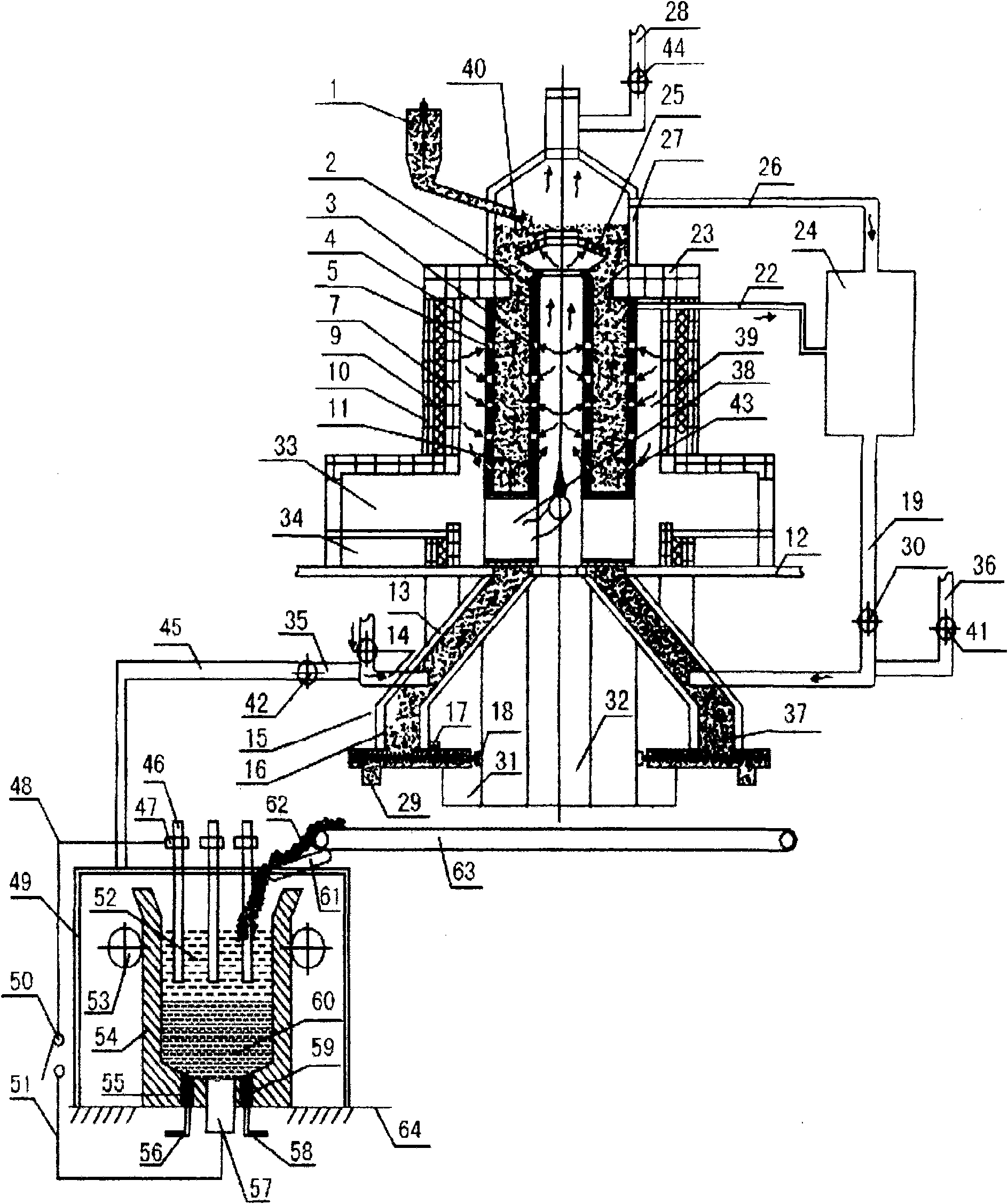

Smelting process and device of pure iron

InactiveCN101538634AImprove applicabilityHigh recovery rateShaft furnaceProcess efficiency improvementUltra fineSolvent

The invention relates to a smelting process and a device of pure iron, belonging to metallurgical industry steel-making raw material. The process comprises the following steps: mixing iron-containing raw materials with reducing agent, solvent and catalyst to prepare ultra fine powder, mixing to make pelletizing materials, sending the prepared pelletizing materials into a reducing furnace, obtaining metallic pellets after the reduction reaction, and directly adding the reduced pellets into a lining electroslag furnace for being smelted into pure iron. The device comprises an internal-external heating vertical reducing furnace, a lining electroslag furnace and a residual heat recovery system. The invention has the advantages that: firstly, the reduction temperature is low, the speed is high, the energy consumption is reduced, the production cost is lowered, the production efficiency is high, and the uniformity of the quality is good; secondly, the degree of mechanization is high, the procedure is simple, the yield is large, the mass production can be performed; thirdly, the waste of raw materials is reduced, the environment pollution is lowered; fourthly, the source of raw materials adopting iron ore concentrate powder and iron-containing metallurgical waste, the cost is low; fifthly, the waste resource can be recycled so as to save the resource consumption; and sixthly, the high-temperature pellets are directly smelted by adopting the lining electroslag furnace, the heat efficiency is high, the energy consumption is low, the material purity is high and the quality is good, and the device is simple with less investment.

Owner:丁家伟 +1

Alcohol-group coating for V-method casting and preparation method thereof

The invention discloses an alcohol-group coating for V-method casting, wherein the coating is powdery or granulous and is formed by blending 100 parts of fire-resistant powder and 10-14 parts of composite sizing agent by weight. Meanwhile, the invention further discloses a method for preparing the alcohol-group coating for V-method casting. Compared with the prior art, the costing disclosed by the invention is powdery or granulous, so that the advantages of convenience and safety in transportation are achieved; the packaging cost is low because barrels are not required for package; the transportation cost is low because the phenomenon of sediment hardening does not occur during the transportation so as not to result in material scrap; meanwhile, the coating further has the advantages that the adhesion and bond strength of a coating layer is high, the capability of resisting metal fluid machinery and thermal shock is strong, the drying time is short, the production efficiency is high, and the sand cohesiveness resistance is excellent.

Owner:NINGBO CANGHAI NEW MATERIALS DEV

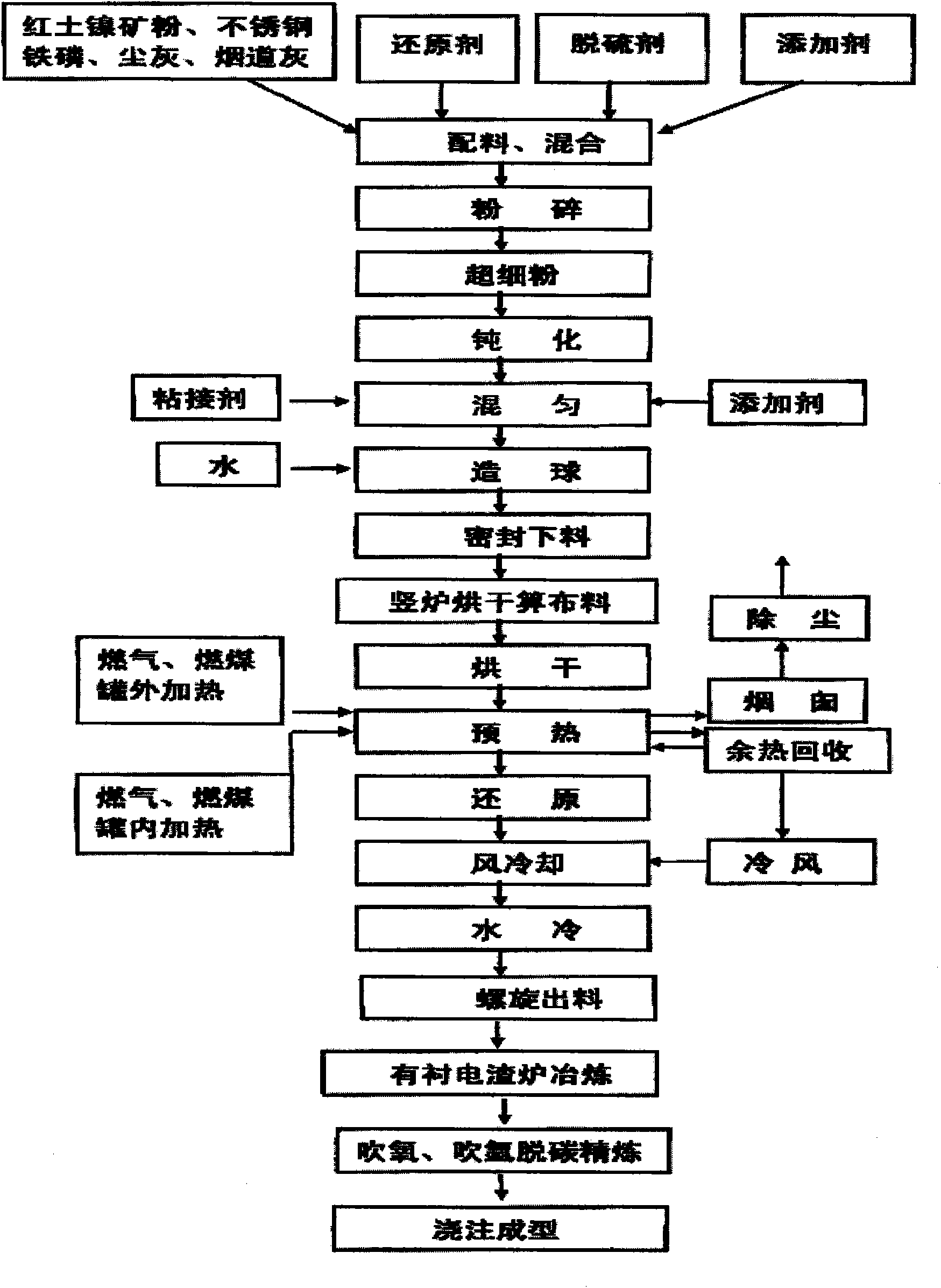

Process and device for smelting ferronickel and nickel-containing molten iron by using lower-nickel materials

InactiveCN101538631AImprove applicabilityHigh recovery rateShaft furnaceSolventMetallurgical industry

The invention relates to a process and a device for smelting ferronickel and nickel-containing molten iron by using lower-nickel materials, which belongs to metallurgical industry steel-making raw material. The process comprises the following steps: mixing ferro nickel containing raw materials with reducing agent, solvent and catalyst to prepare ultra fine powder, mixing to make pelletizing materials, sending the pelletizing materials into a reducing furnace, obtaining chromium irons pellets after the reduction reaction, and directly adding reduced pellets into an lining electroslag furnace for being smelted into ferro nickel alloy or the nickel-containing molten iron. The device comprises an internal-external heating vertical reducing furnace, a lining electroslag furnace and a residual heat recovery system. The invention has the advantages that: firstly, the reduction temperature is low, the speed is high, the energy consumption is reduced, the production cost is lowered, the production efficiency is high, and the uniformity of the quality is good; secondly, the degree of mechanization is high, the procedure is simple, the yield is large, the mass production can be performed; thirdly, the waste of raw materials is reduced, the environment pollution is lowered; fourthly, the source of raw materials adopting nickel oxide ore or nickel-containing waste, the cost is low; fifthly, the waste resource can be recycled so as to save the resource consumption; and sixthly, the high-temperature pellets are directly smelted by adopting the lining electroslag furnace, the heat efficiency is high, the energy consumption is low, the material purity is high and the quality is good, and the device is simple with less investment.

Owner:丁家伟

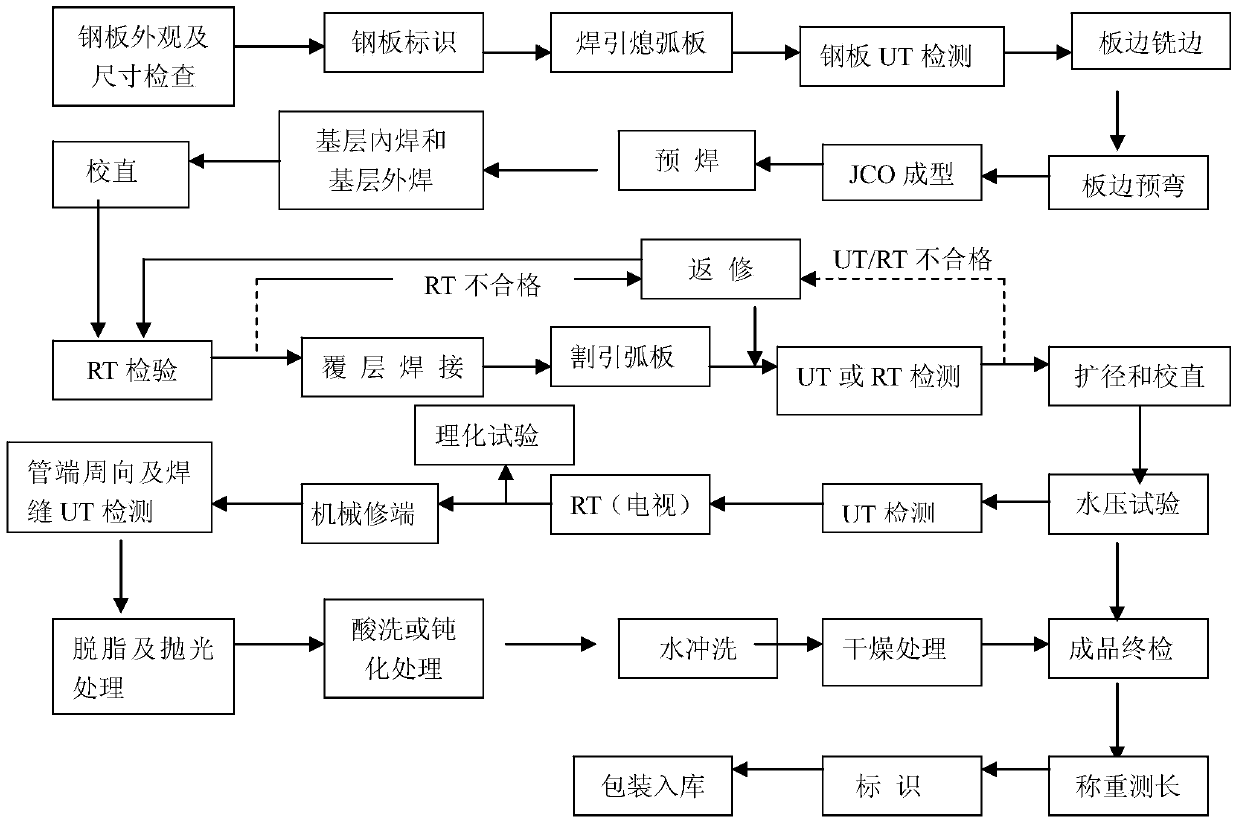

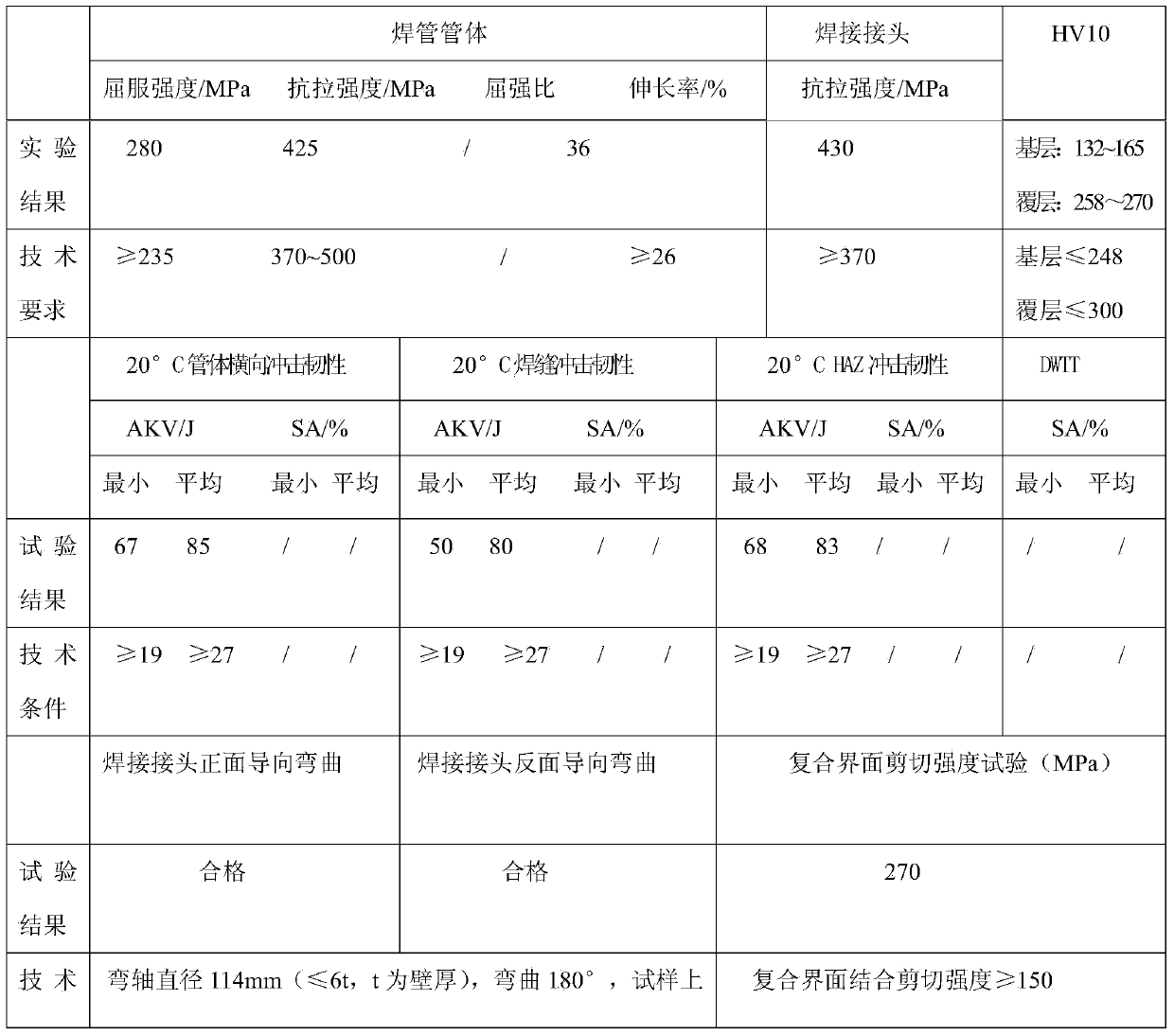

Corrosion-resistant metallurgical composite bimetal longitudinal submerged-arc welded steel pipe and method for manufacturing same

ActiveCN103722346AHigh strengthStrong integrityArc welding apparatusMetal rolling arrangementsSteel tubeSteel plates

The invention provides a corrosion-resistant composite bimetal longitudinal submerged-arc welded steel pipe and a method for manufacturing the same. The method includes steps of (1), manufacturing bimetal composite steel plates by a hot rolling process; (2), carrying out edge milling, pre-bending, JCO forming and pre-welding on the bimetal composite steel plates manufactured in the step (1); (3), welding weld joints of a steel pipe by a submerged-arc welding process, particularly, welding a carbon steel layer of a base layer at first when the weld joints are welded, and then welding metal of a clad layer of a corrosion-resistant layer. The steel pipe is obtained after JCO forming and pre-welding are carried out on the bimetal composite steel plates. The corrosion-resistant composite bimetal longitudinal submerged-arc welded steel pipe and the method have the advantages that the corrosion-resistant metallurgical composite bimetal longitudinal submerged-arc welded steel pipe is manufactured by a hot rolling metallurgical composite bimetal steel plate and JCOE pipe manufacturing process and the efficient automatic submerged-arc welding process, double layers of metal of the steel pipe can be metallurgically combined with each other, and accordingly the steel pipe is high in strength, integrity and corrosion resistance; the JCOE pipe manufacturing process is adopted, so that the steel pipe is high in mechanical degree, production efficiency and overall dimensional accuracy, and steel pipes with the lengths of 12 meters can be produced by the method.

Owner:江苏玉龙钢管科技有限公司

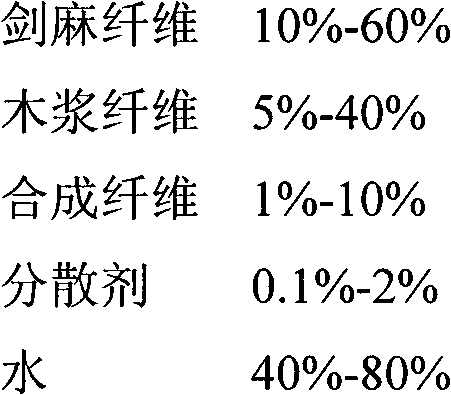

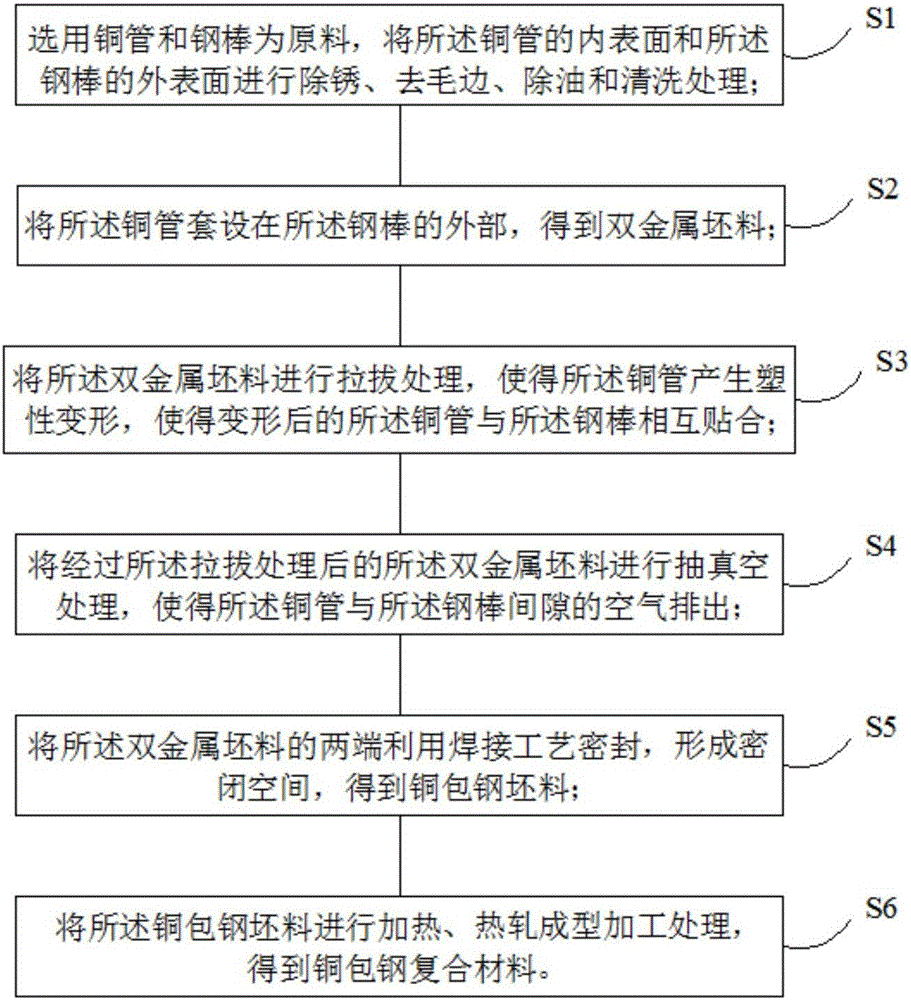

Manufacture method of sisal fiber wet nonwoven fabric

InactiveCN103374852AIncrease elasticityStrong production efficiencyNon-woody plant/crop pulpSynthetic cellulose fibresPapermakingSisal fiber

The invention relates to a manufacture method of a sisal fiber wet nonwoven fabric. According to the manufacture method, the sisal fiber wet nonwoven fabric is mainly prepared from reproducible and naturally degradable sisal fibers and wood in the presence of a small amount of chemical fibers by a wet papermaking process. Mainly aiming at the disadvantages that the chemical fiber nonwoven fabric is difficult to degrade, the invention discloses a sisal fiber nonwoven fabric having the characteristics of simple formula, environmental friendliness and easiness in process operation.

Owner:GUANGDONG PAPER IND RES INST

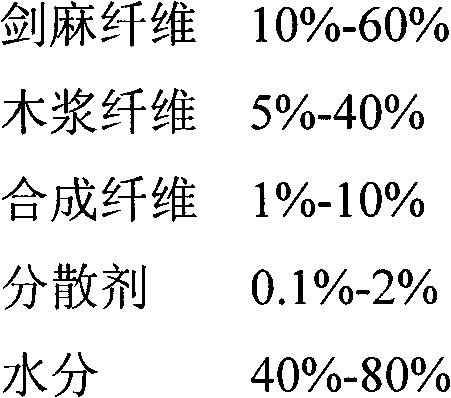

Hot work bending technology for spatial hyperbolic circular tube

The invention discloses a hot work bending technology for a spatial hyperbolic circular tube. The hot work bending technology comprises the following steps of: 1) discharging a steel tube, processing a groove, and determining a charging size of the steel tube according to a design drawing and a processing technology requirement in consideration of the length of a straight tube and a length of an unfolded bent part; 2) bending and forming a bent tube, namely manufacturing a bent tube fixture frame, bending and forming the steel tube, and measuring the bent tube; and 3) correcting the bent tube by one or more of the following methods: flame correction, flame and outer force jack correction and planeness flame correction. By the technology, a die is not required; the forming quality of the bent tube is high; the tube bending capacity is high; the technology has the characteristics of high production efficiency and low labor intensity; and a specially-shaped steel tube can be ingeniously bent and processed.

Owner:YINGDU BRIDGE STEEL STRUCTURE ENG

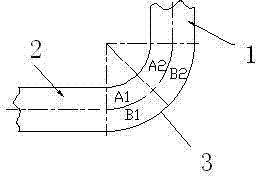

Method for preparing copper-clad steel composite material

InactiveCN106448932AImprove bindingGreat combination depthSingle bars/rods/wires/strips conductorsCable/conductor manufactureUltimate tensile strengthCopper-clad steel

The invention discloses a method for preparing a copper-clad steel composite material. The method comprises the following steps: performing treatment of rust removal, burr removal, oil removal and washing on the inner surface of a copper tube and the outer surface of a steel rod; sleeving the copper tube on the steel rod so as to obtain a double-metal blank; performing pull-drawing treatment on the double-metal blank so as to cause plastic deformation to the copper tube and clue the copper tube to the steel rod; performing vacuuming treatment on the double-metal blank so as to discharge air in the gap between the copper tube and the steel rod; sealing two ends of the double-metal blank by using a welding process so as to form a sealed space and thus obtain a copper-clad steel blank; performing treatment of heating and hot-rolling molding on the copper-clad steel blank, thereby obtaining the copper-clad steel composite material. According to the method disclosed by the invention, as procedures of vacuum sleeving, hot-rolling molding and the like are implemented, the copper tube and the steel rod can be mutually combined in a vacuum environment, then the copper-clad steel composite material can be prepared, and the method has the advantages of being high in combination strength, yield and capacity, adjustable in thickness of a copper layer, high in production efficiency, good in corrosion resistance and the like.

Owner:HUNAN 3T NEW MATERIAL

Integral moisture-retention cigarette case adopting annular opposed die cutting wrapping composite and manufacturing method of integral moisture-retention cigarette case

ActiveCN106672373AEasy accessSolve the shortcomings of high cost and waste of resourcesContainers for flexible articlesPackaging cigaretteMoisture retentionEngineering

The invention discloses an integral moisture-retention cigarette case adopting an annular opposed die cutting wrapping composite. The case structurally comprises a content, a paper inner frame and a wrapping composite material from inside to outside sequentially. A manufacturing method of the integral moisture-retention cigarette case comprises the following steps that A1, the paper inner frame wraps cigarettes and is made into a packaging inner container for standby application; and A2, the wrapping composite is folded and molded to wrap the packaging inner container, and then fixed in an adhesion mode or a local heat-sealing mode, so that the integral cigarette case is manufactured. The moisture-retention cigarette case adopting the annular opposed die cutting wrapping composite has the beneficial effects that the structure is concise; in the repeated opening and closing process, influence of the external temperature and humidity can be effectively prevented, destructive packaging protection is provided, the annular opposed die cutting wrapping composite replaces multiple materials of existing cigarette cases, and the opening process is smooth and convenient; the wrapping composite is good in printing adaptivity and excellent in processing resistance; and the moisture-retention cigarette case has the functions of damp prevention, moisture retention, fragrance retention, bacteria resistance and bacteriostasis, counterfeiting and copying are difficult, national tax erosion is effectively reduced, and the national economic benefits are protected effectively.

Owner:CHINA TOBACCO YUNNAN IND

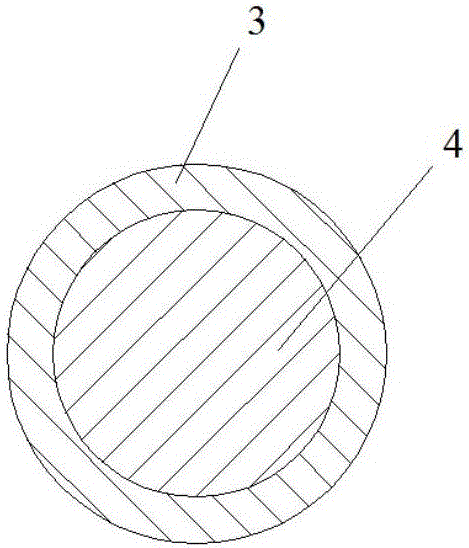

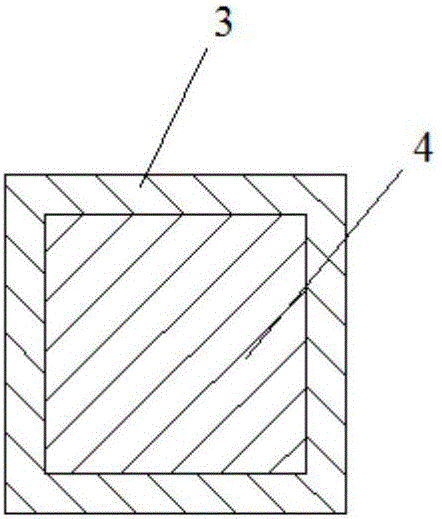

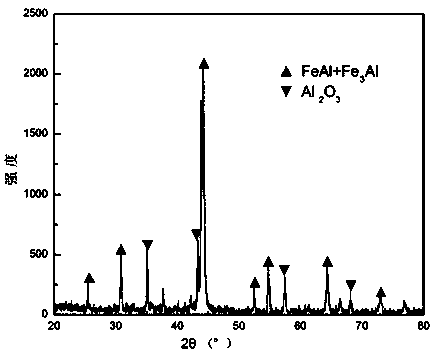

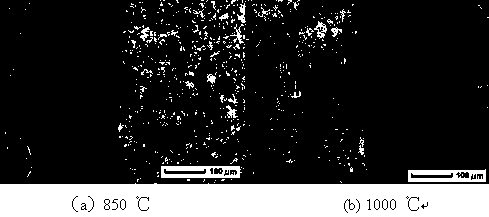

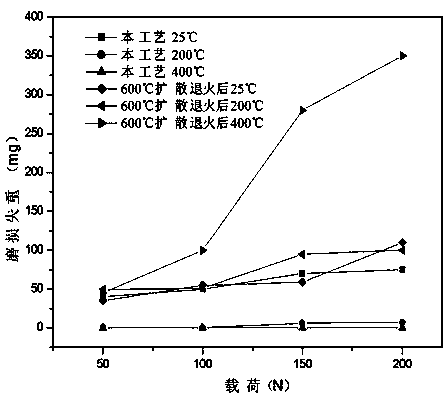

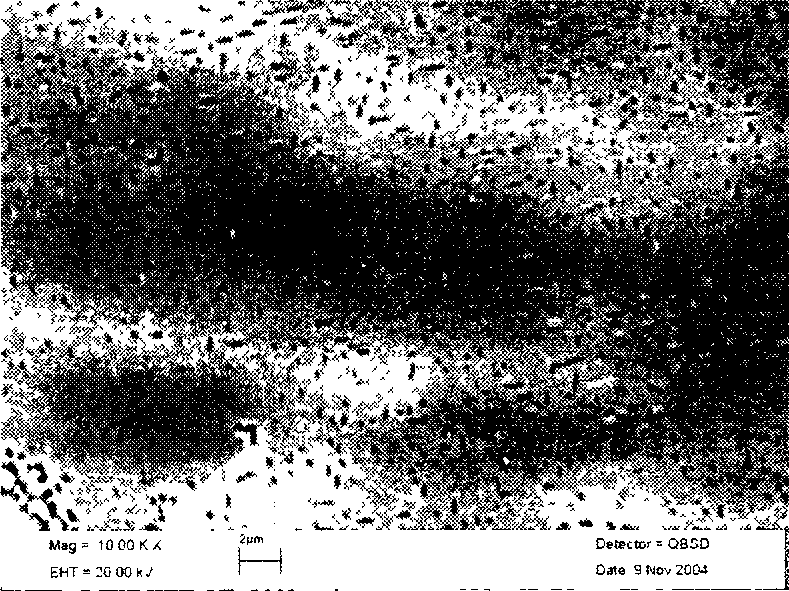

Preparation method of high-temperature wear-resistant coating on surface of steel piece

ActiveCN103628013AImprove corrosion resistanceImprove high temperature resistanceHot-dipping/immersion processesWear resistantWear resistance

The invention relates to the technical field of steel piece surface treatment, and in particular relates to a preparation method of a high-temperature wear-resistant coating on the surface of a steel piece. According to the preparation method, a composite coating of a Fe-Al intermetallic compound and a little Al2O3 is obtained through liquid dip aluminum plating and subsequent compound dispersion treatment. The process flow of the preparation method comprises pretreatment (alkali cleaning, acid pickling and assisted plating), dip aluminum plating and dispersion treatment, wherein the dip aluminum plating is carried out for 1-10 minutes in liquid aluminum at a temperature ranging from 720 DEG C to 800 DEG C; and compound dispersion annealing which is carried out in a protective atmosphere or in vacuum at a temperature ranging from 850 DEG C to 1100 DEG C for 1-5 hours, and in air at a temperature ranging from 400 DEG C to 600 DEG C for 20-30 minutes. The temperature and the time of the dispersion treatment are adjusted so that composite wear-resistant coatings containing the intermetallic compound and a little Al2O3 and are different in thickness can be obtained. The preparation method has the characteristics of simple and convenient process, low cost, high coating binding force, excellent high-temperature wear resistance and the like, and thus can be widely applied to surface strengthening of high-temperature wear resisting steel pieces.

Owner:东台市溱东科技发展有限公司 +1

Collagen fiber base cloth production line

InactiveCN103255579AStrong degree of automationHigh degree of automationNon-woven fabricsProduction lineViscose

The invention discloses a collagen fiber base cloth production line which comprises a viscose coming machine, a viscose lapping machine, viscose air current lapping machines, a first needling or spunlace machine, a first pressing presser, a second pressing presser, a second needling or spunlace machine, a third needling or spunlace machine, a third pressing presser and a drier. Turning rollers of a first group of fiber networks are arranged between the first pressing presser and the second pressing presser, turning rollers of a second group of fiber networks are arranged between the second pressing presser and the third pressing presser, and the turning rollers of the second group of the fiber networks are arranged below the turning rollers of the first group of the fiber networks. Leather-imitation base cloth produced in the production line has a texture of genuine leather, and meanwhile has the effects of being high in strength, strong in durability and low in cost. The production line has the advantages of being high in automation degree, high in production efficiency, safe, reliable and stable in produced product quality and the like.

Owner:JIANGYIN JUNHUA TEXTILE TECH

Ferrite antibacterial stainless steel for low-chrome copper-containing dishware and manufacturing method thereof

ActiveCN1827824AExcellent long-lasting antibacterial effectLow content of alloying elementsTemperature control deviceHeat treatment process controlPre treatmentChromium

Disclosed is a ferrite antibacterial stainless steel for low-chrome copper-containing dishware and manufacturing method, wherein the stainless steel matrix comprises (by wt%) Cr 12.0-14.0%, Cu 0.70-2.20%, C <=0.08-0.15, the preparing process comprises pre-processing melted iron, passing through composite revolving furnace, vacuum oxygen decarbonization furnace, refined-smelting ladle furnace, continuous plate blank casting, casting blank annealing, tandem rolling, and annealing in a bell-type furnace.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Lignin phenolic resin environment-friendly plate

ActiveCN106476367AIncrease surface densityHigh strengthConjugated diene hydrocarbon coatingsNatural rubber coatingsOperabilityMoisture resistance

The invention relates to a lignin phenolic resin environment-friendly plate and belongs to the technical field of building materials. The environment-friendly plate comprises an upper coating, an upper plate, a middle coating, a lower plate and a lower coating sequentially arranged from top to bottom. The lignin phenolic resin environment-friendly plate is high in surface layer density, high in strength, less prone to deformation, simple in production process, high in production efficiency, definite in process parameter, high in operability and capable of directly serving as a material for furniture and indoor decoration, has the advantages of high anti-seismic performance, flame retardance, low smoke, nontoxicity, water resistance, moisture resistance, corrosion resistance, resistance to high temperature, insulativity, light weight, quickness in mounting, antiaging resistance and wear resistance and is pollution-free, safe, environment-friendly and long in service life, and artificial forest soft wood does not need to be treated in a sealed container.

Owner:ANHUI GEYI CYCLIC ECONOMY IND PARK

Pure-natural multi-effect biogas slurry compound fertilizer and production method

InactiveCN105622275AGrowth inhibitionMulti-energy efficiencyBioloigcal waste fertilisersWaste based fuelAgricultural engineeringEnvironmental engineering

The invention provides a pure-natural multi-effect biogas slurry compound fertilizer and relates to the technical field of waste recycling and liquid fertilizers. The used raw materials and the manufacturing technology belong to the biological fermentation and phytoextraction biological technology field. The problems that the efficacy of organic fertilizers is single, the fertilizer efficiency is slow, the application labor cost is high, and the heavy metal content is difficult to control can be solved, purified concentrated biogas slurry is taken as a substrate, a plant extract is taken as an additive, the matching is scientific, balanced fertilizer supplement, soil improving, bacteria resisting and insect killing and weed inhibition are completed by one time, and the application market of the biogas slurry concentrated solution is opened; maximum reduction of the usage amount of the fertilizer and pesticide becomes possible; forceful guarantee is provided for production of pollution-free and green organic products; powerful support is provided for saving the labor cost and improving intensive agriculture and industrialization level.

Owner:朱青春

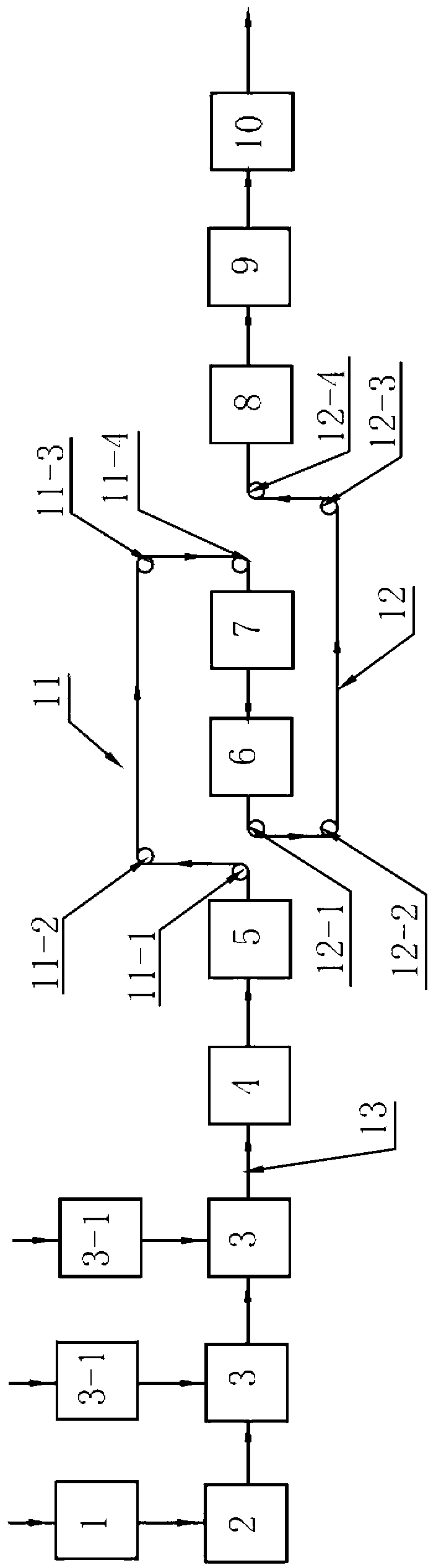

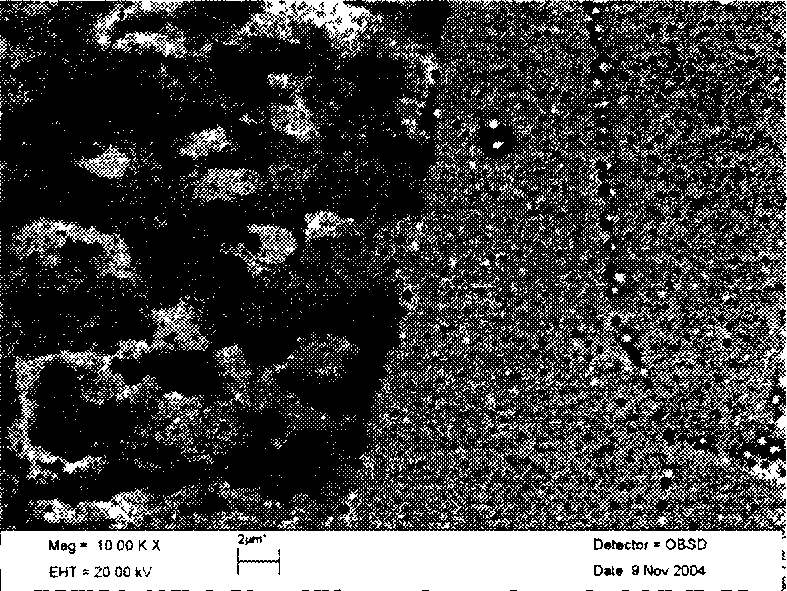

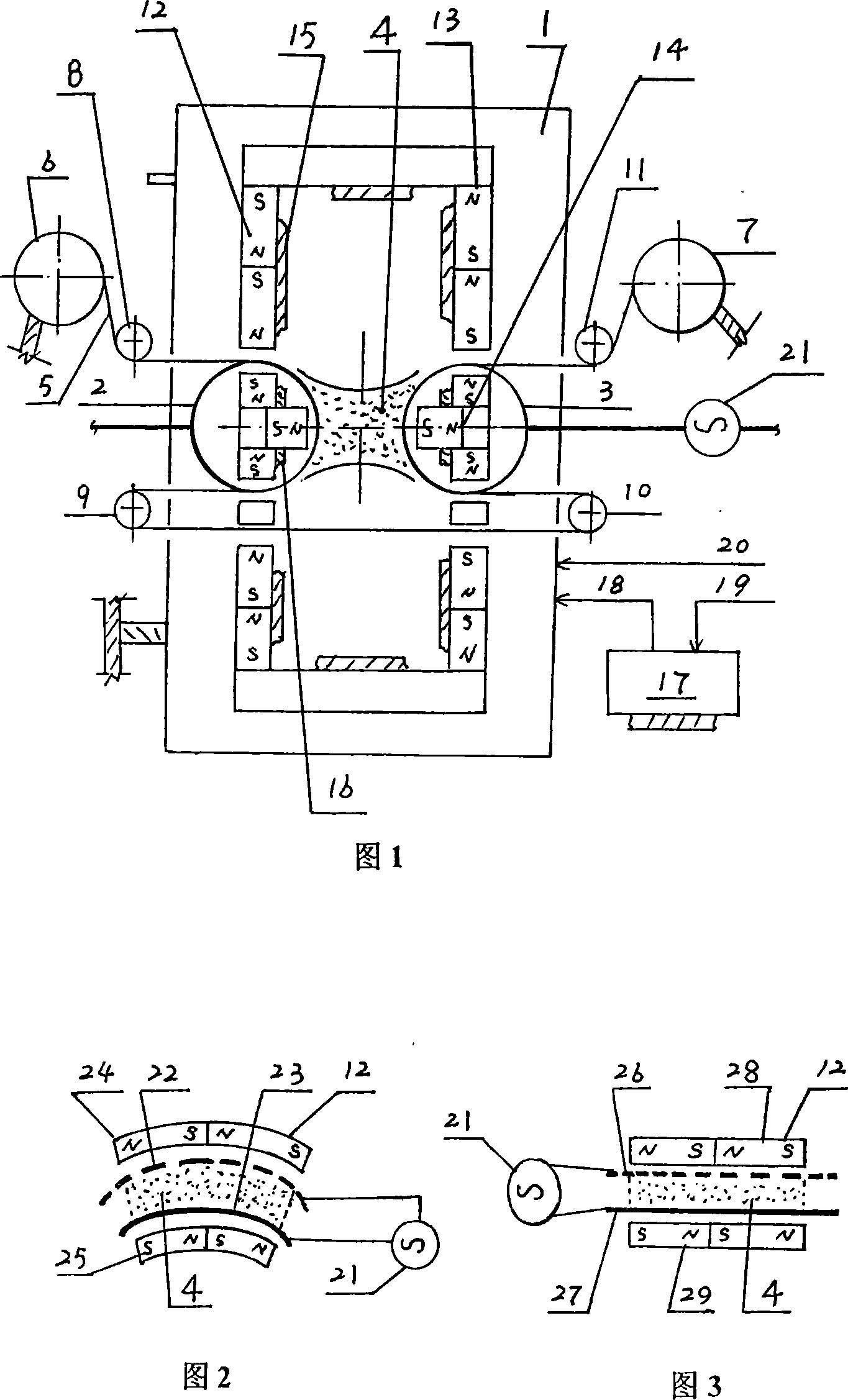

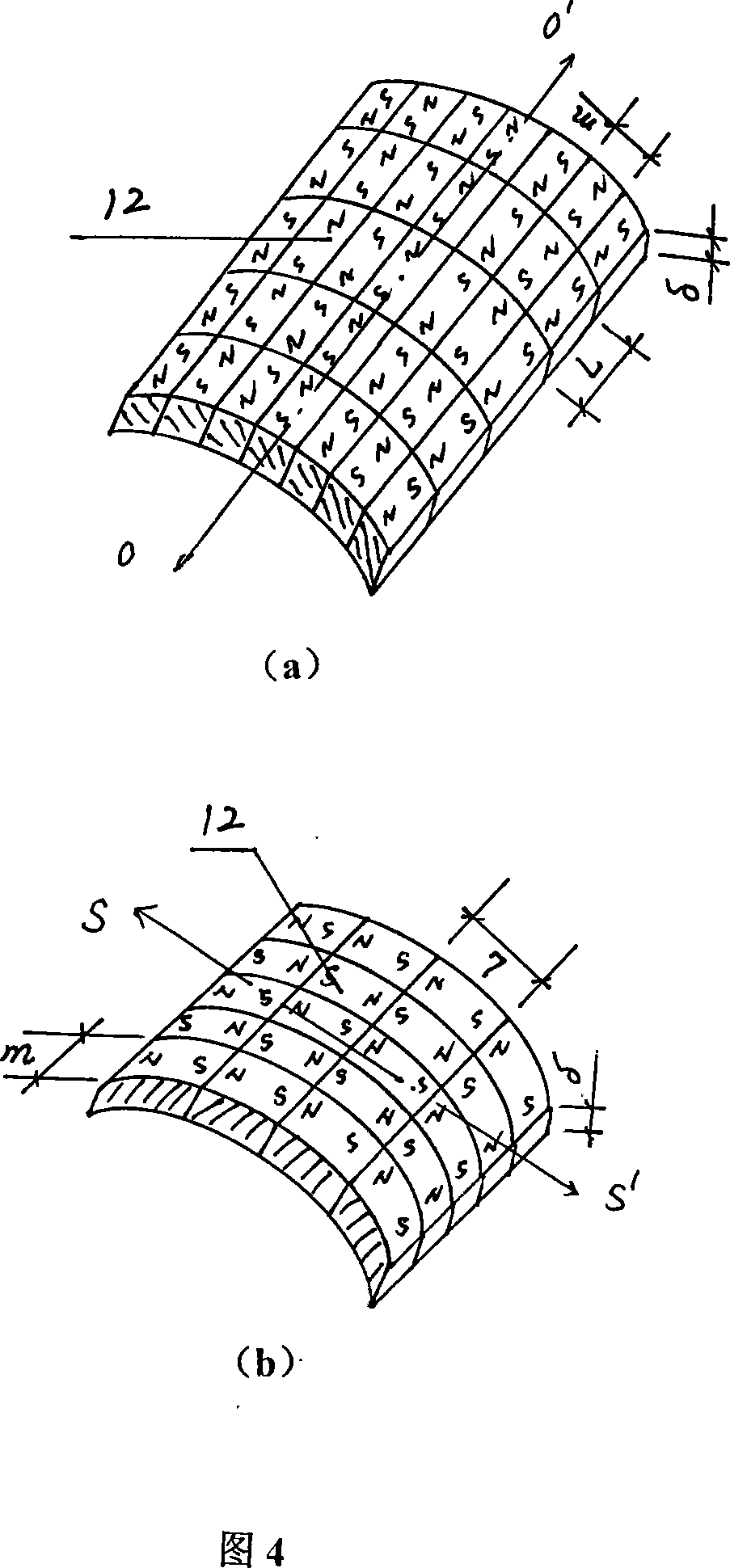

Nano thin film with separation and protection function and manufacturing method thereof

InactiveCN101126148AImprove corrosion resistanceImprove continuityVacuum evaporation coatingSputtering coatingWater vaporVolumetric Mass Density

The invention relates to a nano film with the function of obstructing and protection and the manufacturing method belonging to the technical field of protective film and manufacturing method, aiming at improving the performance of protective film; with the plasma device which is provided with a magnetic field strengthening device, the plasma chemical vapor deposition and the gas of organic silicone chemistry as the working gas, the nano film is manufactured on the parent metal surface by depositing and converging with a thickness of 1 to 1000nm, a transmission rate of oxygen less than 50ml / cm2 / 24h and a transmission rate of water vapor less than 10g / m2 / 24h. The magnetic field strengthening device is magnet assembly(12) made of permanent magnets, consisting of an outside and inside magnet assembly(13),(14) which are respectively corresponding to a left and a right roll electrode(2),(3), and the magnetic field strengthening device can increase the density of the plasma in the plasma area; the nano film has high density, great obstructing performance, uneasy breaking-off and corrosion resistance, being widely applicable as the protective layer for food, drug package and functional apparatus; the manufacturing method is suitable for the production line of continuous coiling based on the parent metal.

Owner:BEIJING BEIYIN EAST ORIENT NEW MATERIALS TECH

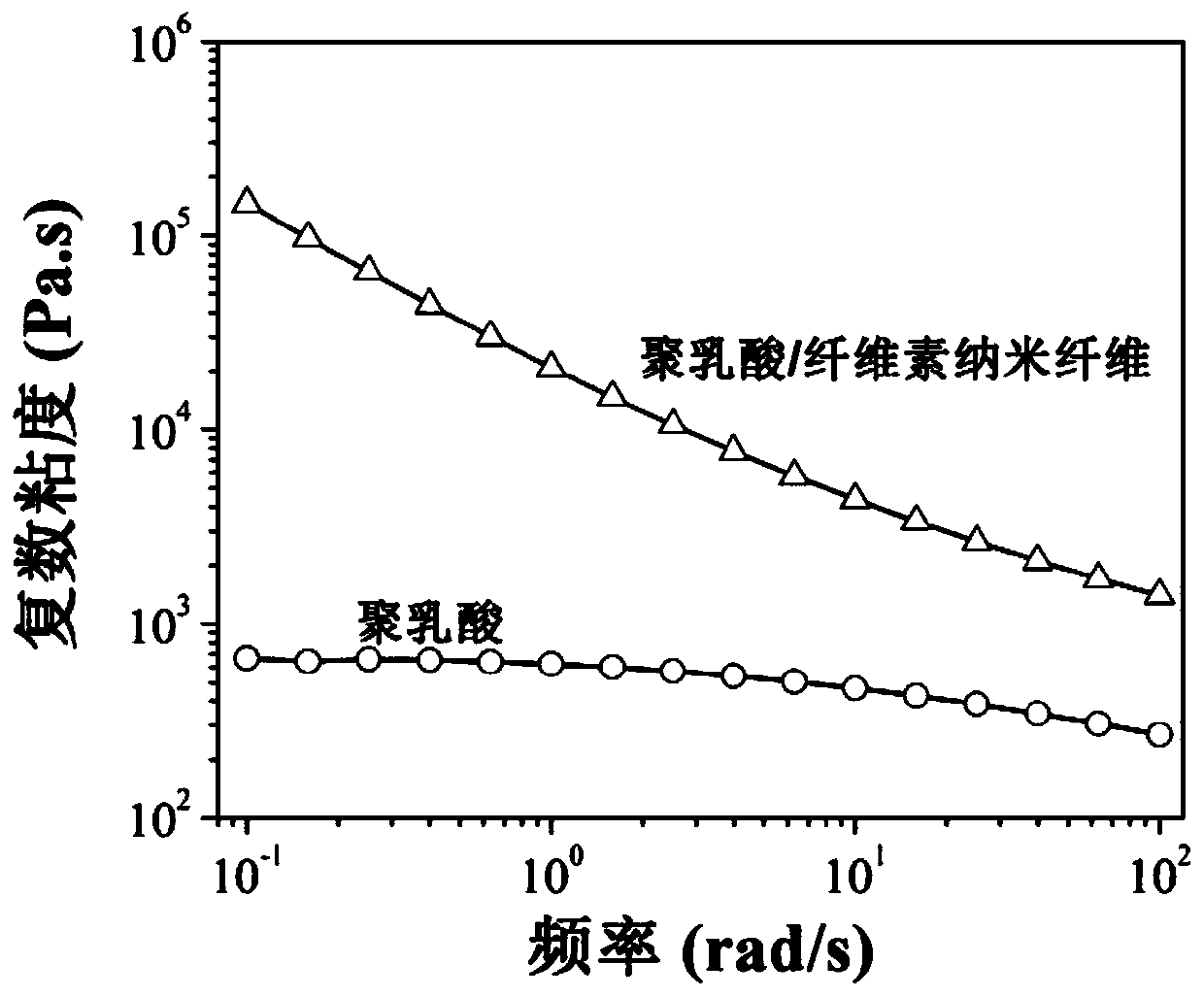

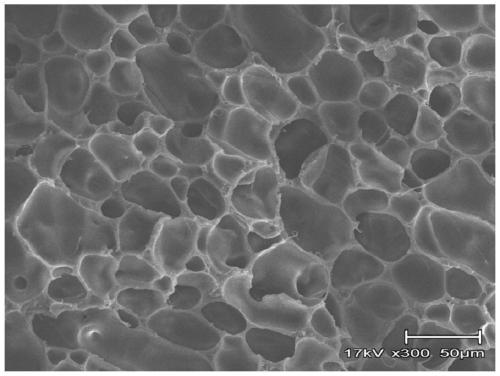

Supercritical fluid injection molding foaming polylactic acid foam material and preparation method thereof

ActiveCN111286070AIncrease cell densityHigh crystallinityLayered productsCellulose pulp after-treatment modificationCelluloseFoaming agent

The invention discloses a supercritical fluid injection molding foaming polylactic acid foam material and a preparation method thereof. The light high-strength polylactic acid foam material is prepared by modifying biological filler cellulose nanofibers, and the crystallization property and melt property of the polylactic acid material are improved by using the cellulose nanofibers as a nucleatingagent. The prepared cellulose nanofiber modified polylactic acid composite material is uniformly mixed with a supercritical fluid foaming agent in a microcellular foaming injection molding machine, and microcellular injection foaming molding is carried out through a mold opening and closing foaming device to obtain the full-bio-based polylactic acid foaming material. The microcellular foaming cellulose nanofiber / polylactic acid composite material which is uniform in cell size, high in cell density and good in performance is prepared, and the preparation method has the outstanding advantages of being high in production efficiency, high in operability, stable, reliable, easy for industrial production and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Production technology for manufacturing soft layer sound insulation pad and hard layer sound insulation pad by utilizing high-temperature steam

InactiveCN103317811AStrong penetrating powerImprove sound insulationLaminationLamination apparatusTemperature controlWater vapor

The invention relates to a production technology for manufacturing a soft layer sound insulation pad and hard layer sound insulation pad by utilizing high-temperature steam. The production technology comprises the following steps of: a raw material paving step, a compression forming step, a cooling customization step and a water cutter cutting step, wherein the temperature of an upper module is controlled at 140 DEG C-160 DEG C in compression forming, the temperature of a lower module is controlled at 160 DEG C-180 DEG C, and mould closing is carried out for compression forming; after the mould closing is carried out for 10-20 seconds, the upper module is vacuumized, the vacuumizing time is controlled within 10-20 seconds, and after the vacuumizing of the upper module is finished, water vapor the temperature is introduced into the upper module so as to carry out heating forming on a material, wherein the temperature of the water vapor is 140-180 DEG C and the pressure of the water vapor is 9-11MPa, the water vapor is discharged through the lower module, and the introducing time of the water vapor is controlled within 15-20 seconds, according to the production technology provided by the invention, high-temperature and high-pressure water vapor is adopted, the water vapor penetrating power is high, the heat transfer effect is good, a film is fully melted, soft and hard layers are firmly cohered, the soft layer sound insulation pad and the hard layer sound insulation pad manufactured by the technology provided by the invention have good sound insulation property.

Owner:WUXI GISSING AUTO PARTS CO LTD

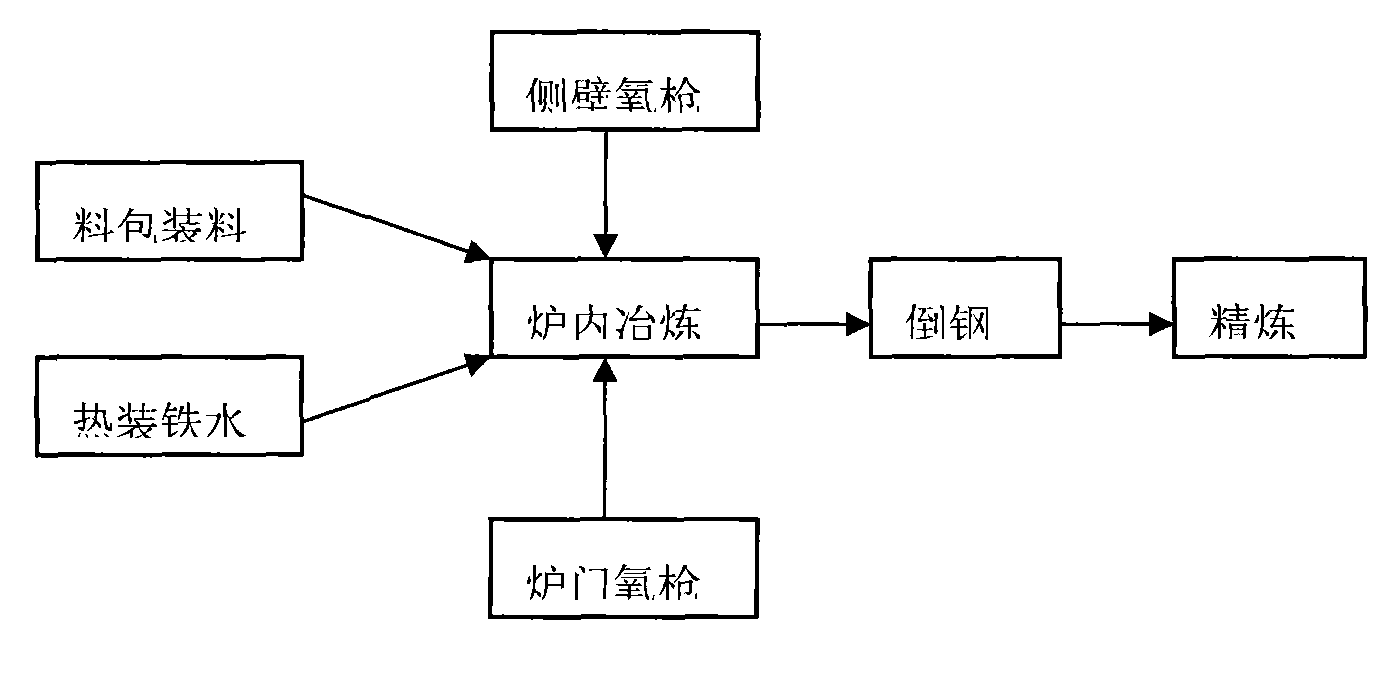

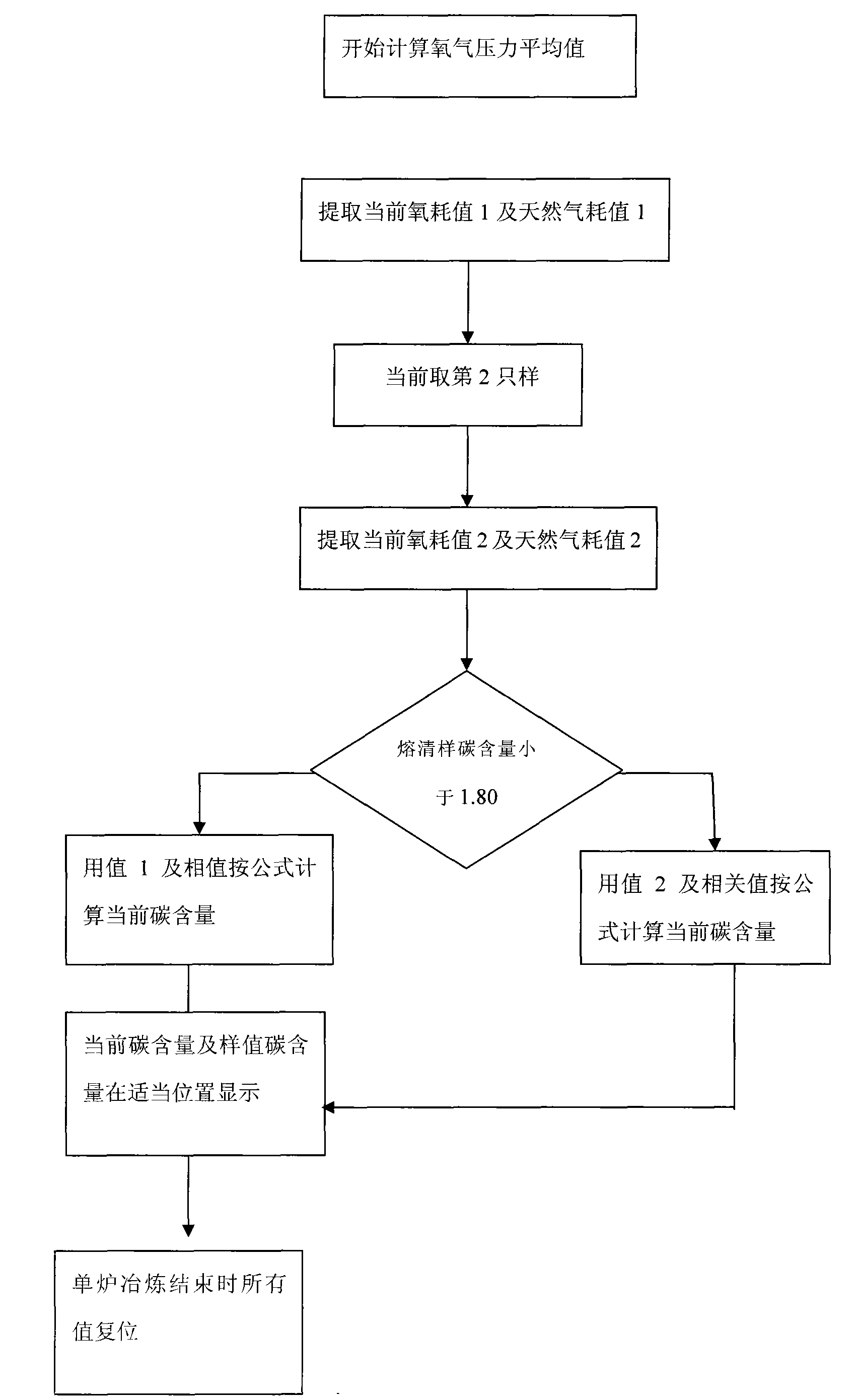

Method for continuously measuring carbon content of molten steel in electric steelmaking furnace

ActiveCN101592650AStrong production efficiencyIncrease productivityTesting metalsSteelmakingMathematical model

The invention discloses a method for continuously measuring carbon content of molten steel in an electric steelmaking furnace and belongs to the technical field of metallurgical steelmaking. The method utilizes a common gas flowmeter, a programmable controller (PLC) and a computer system to measure relevant parameter values for calculating the carbon content, carries out the continuous calculation on the carbon content of the molten steel through a mathematical model, continuously displays the current carbon content of the molten steel in a user interface and carbon contents of other samples after a melting down sample is obtained by calculation and other relevant parameters so as to realize real-time online forecasting of the carbon content of the molten steel. The invention relates to asimple service method and is not influenced by furnace capacity, material situation, configuration of decarbonization equipment and has high forecasting precision of the carbon content of the molten steel; and the method makes a judgment on the current carbon content of the molten steel in the electric steelmaking furnace with high accuracy, saves the steelmaking time and improves the production efficiency of steelmaking.

Owner:SHAGANG GROUP

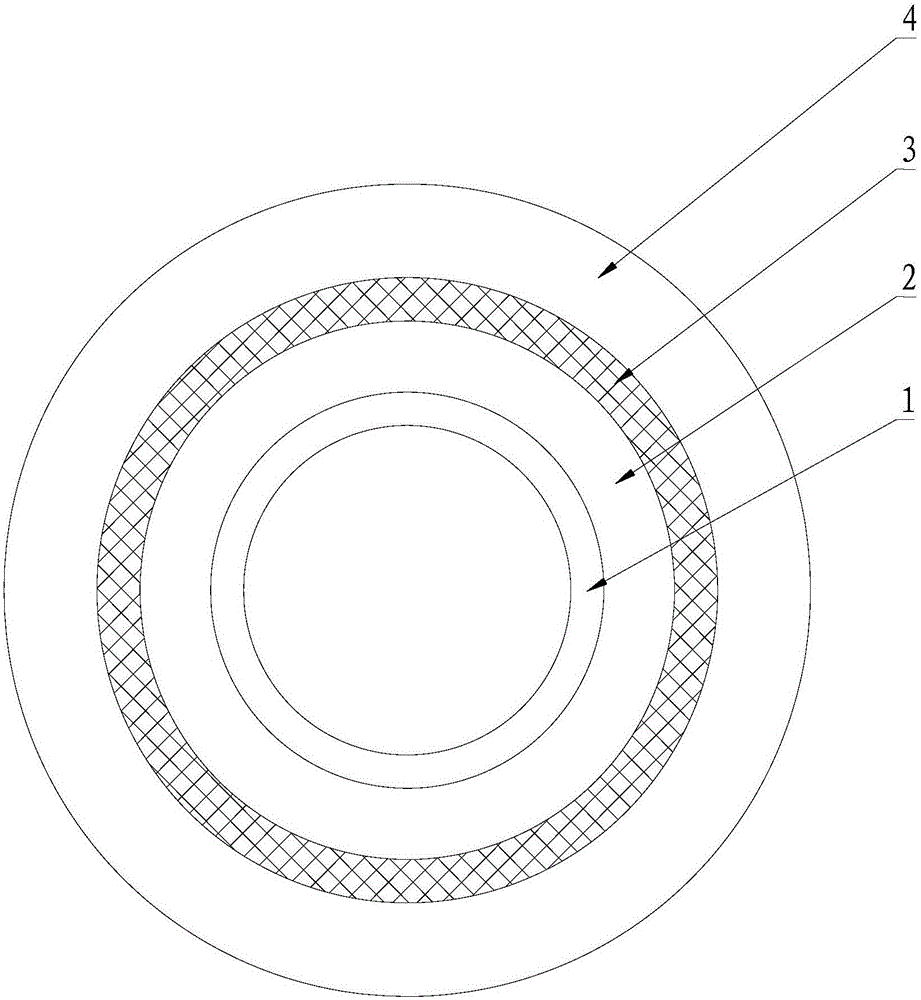

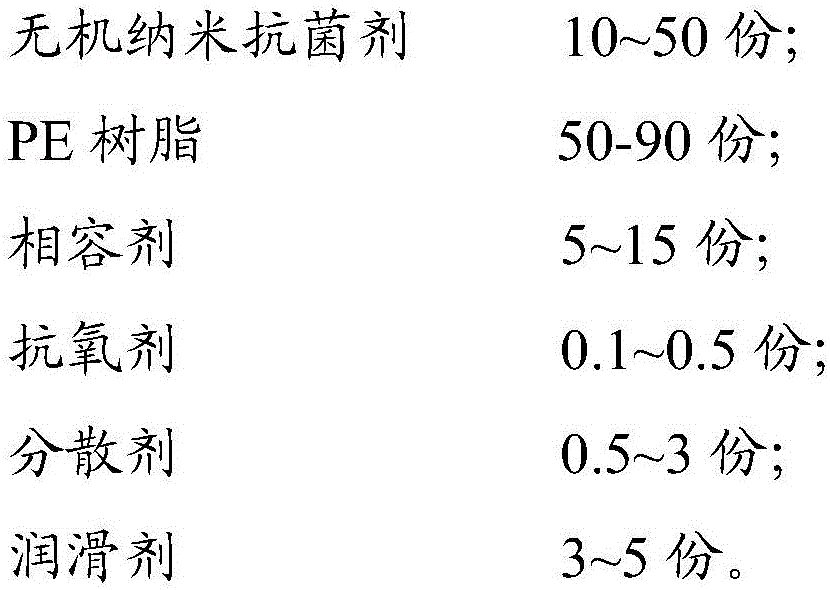

Steel band reinforced antibacterial PE (polyethylene) water supply pipe and preparation method thereof

InactiveCN106674700ACorrosion resistantExtended service lifeService pipe systemsWater mainsWater leakageHot melt

The invention relates to a steel band reinforced antibacterial PE (polyethylene) water supply pipe and a preparation method thereof. The steel band reinforced antibacterial PE water supply pipe sequentially comprises an antibacterial layer, an inner PE layer, a steel band layer and an outer PE layer from interior to exterior. The preparation method comprises the following steps of precoating the steel band layer with the inner PE layer; respectively extruding the antibacterial layer and the outer PE layer to the inner side and the outer side of the steel band layer precoated with the inner PE layer. The steel band reinforced antibacterial PE water supply pipe has the characteristics that the strength is high, the corrosion-resistant property is realized, the service life is long, the environment-friendly and sanitation effects are realized, the pollution is avoided, the connection property is firm and reliable, the sealing property is strong, the water leakage is avoided, the blasting is avoided, and the like; the preparation method of the steel band reinforced antibacterial PE water supply pipe has the advantages that the steel band reinforced antibacterial PE water supply pipe with the characteristics can be prepared; the antibacterial layer, the inner PE layer and the outer PE layer are co-extruded to the steel band layer, and all the layers can be melted to form a firm non-disengaging whole structure, so that the use of hot melt glue is avoided.

Owner:福建晟扬管道科技有限公司

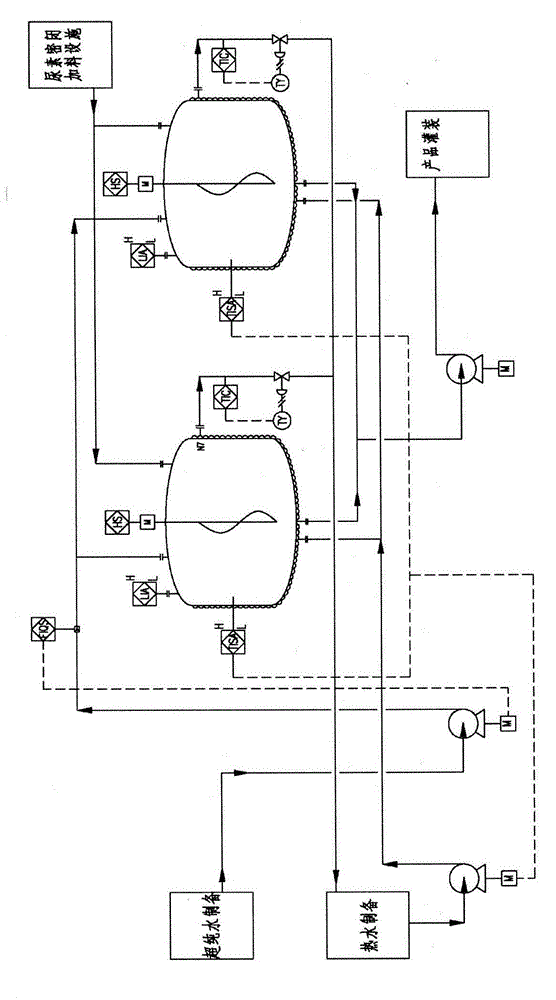

Preparation method and preparation equipment of Adblue solution

InactiveCN104437148AHigh activityStrong YieldRotary stirring mixersDispersed particle separationPhysical chemistryEnergy source

The core part of a preparation method of the Adblue solution is the preparation method of the urea solution; the method comprises the step of dissolving urea crystal in super-pure water to prepare the Adblue solution with the concentration of 31.8-33.3%. The preparation method of the Adblue solution adopts the way of preparing the Adblue solution under forcible mixing and heating condition. The continuous production is realized by using two blending kettles, wherein one of the blending kettles is started and the other is standby. The method is simple in operation, continuous in production, high in production efficiency, high in yield, and capable of saving energy source, and the produced urea solution is strong in activity.

Owner:CHINA NAT ENERGY REFINING & CHEM ENG CO LTD

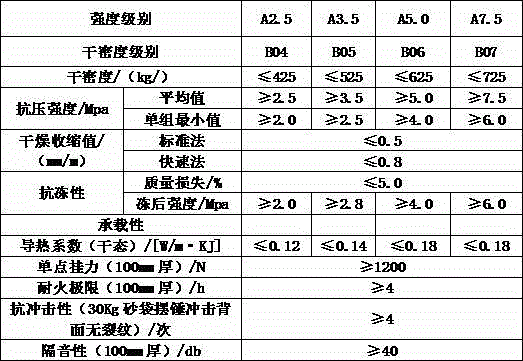

Light-weight porous partition plate

The invention discloses a light-weight porous partition plate. A hollow fiber reinforced cement concrete partition plate, an autoclaved aerated concrete partition plate and the like are mainly available in the market at present and these partition plates have respective advantages and defects. Making a comprehensive survey, novel building partition plates which are available in the existing market are prepared by filling with industrial waste residues or pure concrete and cement and all have the problems of instable structure, nonuniform pores, low porosity, high heat conduction coefficient, poor fireproof property, frangibility and the like due to the limitations on the aspects of the formulas and technical processes of the novel building partition plates. The light-weight porous partition plate disclosed by the invention is prepared from coal gangue, slag, coal ash 0, an exciting agent, a foam stabilizer, a foaming agent and water, has the advantages of uniform pores, low heat conduction coefficient, good sound insulation effect, light weight, low cost, environmental friendliness in production and the like and can effectively overcome the critical defects of the traditional partition plates. Because the product utilizes industrial solid wastes as raw materials and the production of the product is environmental-friendly, the utilization ratio of the industrial solid wastes is enhanced and the social environment can be effectively protected.

Owner:广西启利新材料科技股份有限公司

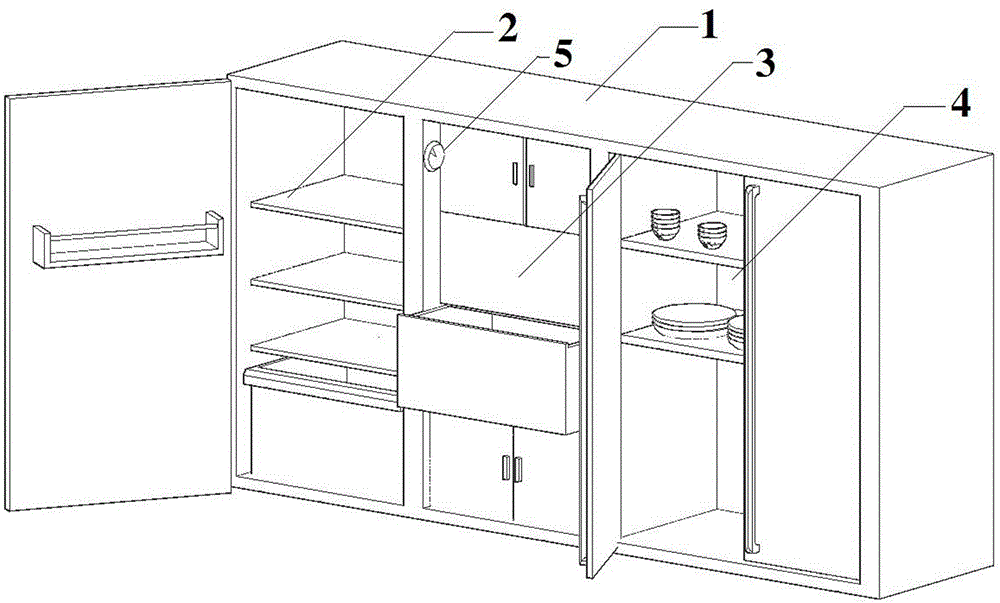

Novel sheet material and application thereof

InactiveCN104029261AHigh densityHigh strengthWood compressionWood treatment detailsWater contentWater soluble

The invention relates to a novel sheet material and application thereof. The objective of the invention is to provide manufacturing and application of the novel sheet material with the advantages of high surface density, great lightness, uneasy deformability, simple process, good controllability and a shallow color. Manufacturing of the novel sheet material comprises the following steps: (1) drying, wherein water content is controlled to be 20 to 30%; (2) rolling, wherein a compression ratio is controlled to be 10 to 30%; (3) surface impregnation: a step of soaking one or two surfaces of the sheet material in a light-color water-soluble low-molecular-weight phenolic resin glue with a concentration of 10 to 25%; (4) steam softening, wherein softening temperature is controlled to be 120 to 140 DEG C, and softening time is 20 to 60 min; and (5) surface compaction, wherein a compression ratio is controlled to be 15 to 50%, a hot pressing temperature is 160 to 180 DEG C and unit pressure is 1.5 to 4.5 MPa. The novel sheet material can be applied both to a kitchen cabinet with adjustable temperature and in fields like furniture manufacturing and interior decoration.

Owner:ZHANGWU MEISHUO FURNITURE PLATE R & D CO LTD

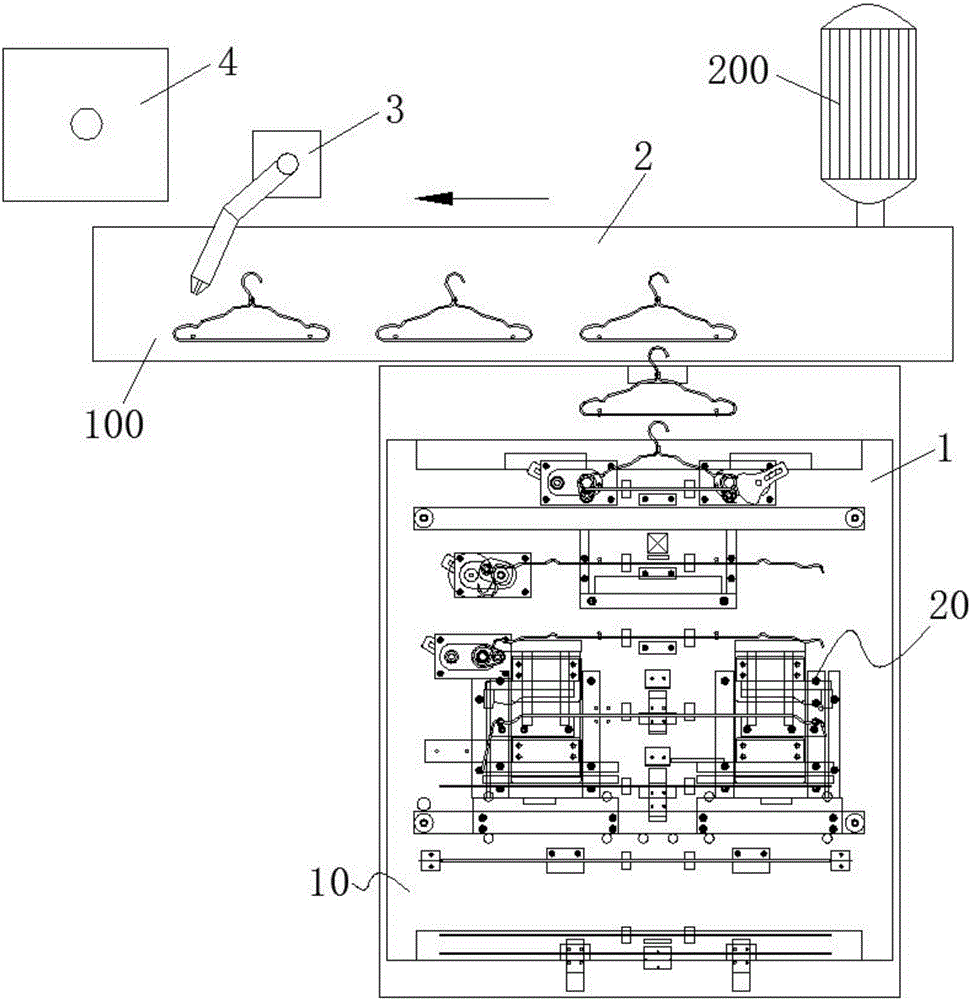

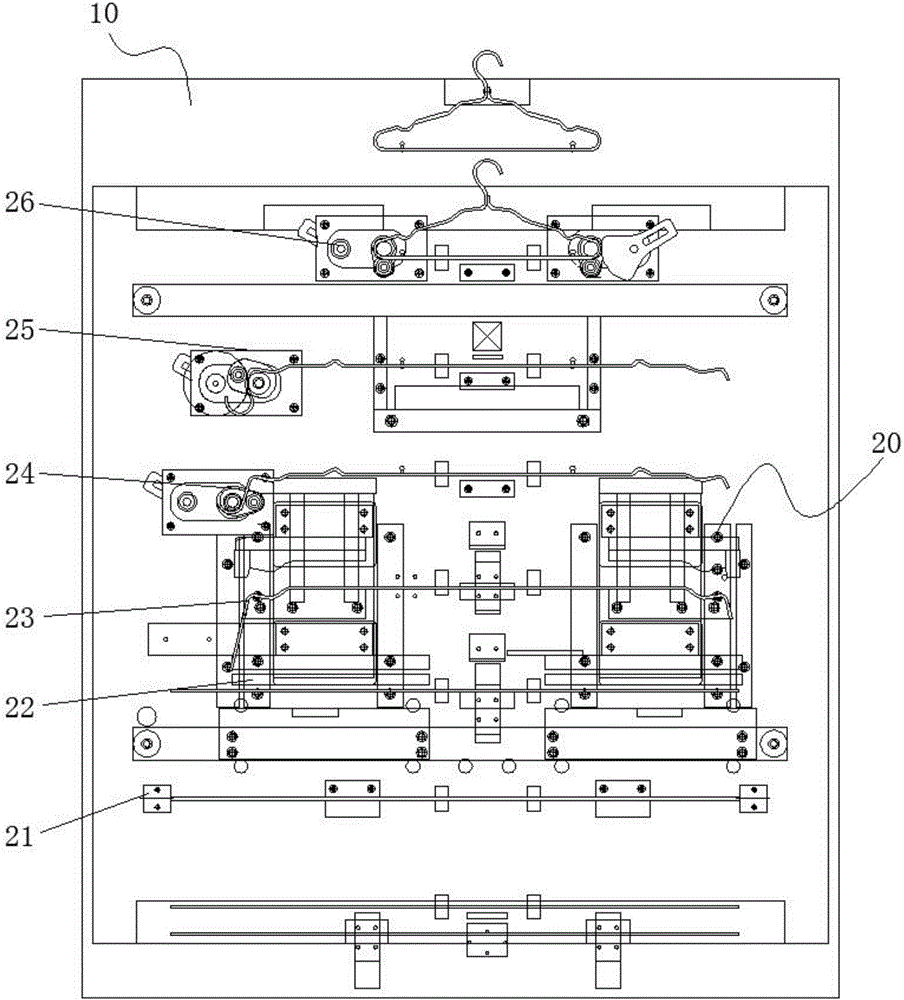

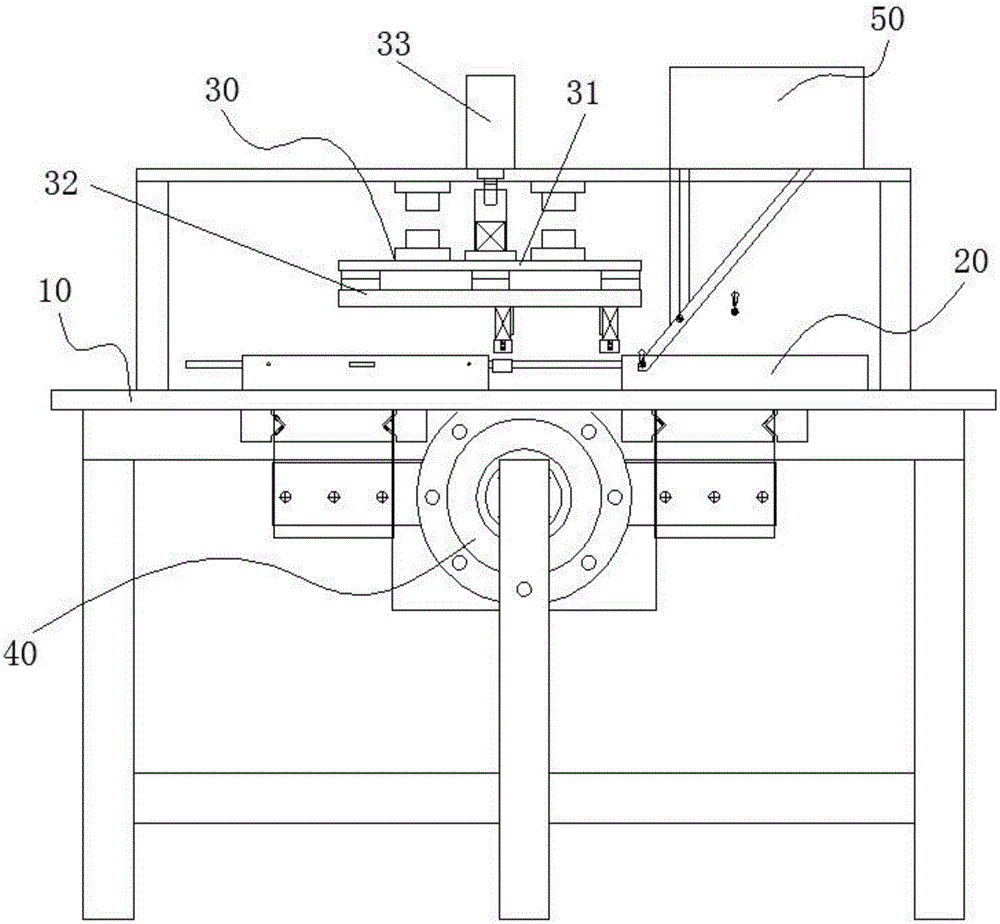

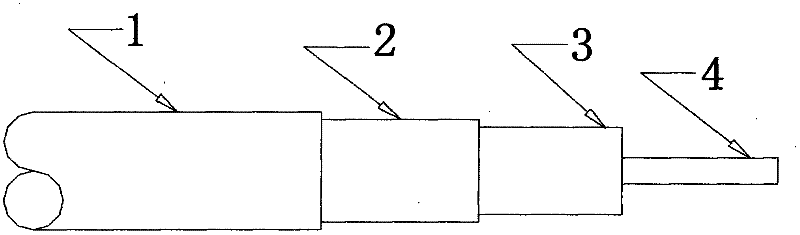

Automatic hanger machining device

ActiveCN105964840ASatisfy productionIncrease the level of automationWire articlesWork in processEngineering

The invention discloses an automatic hanger machining device. The automatic hanger machining device comprises a bending forming machine, a conveying mechanism, an automatic picking machine and a stapling machine. The conveying mechanism is arranged between the bending forming machine and the automatic picking machine. The stapling machine is arranged on one side of the automatic picking machine. The bending forming machine is used for bending raw materials to form semi-finished hangers. The conveying mechanism is used for conveying the semi-finished hangers to the position of the automatic picking machine from the bending forming machine. The automatic picking machine is used for picking up the semi-finished hangers on the conveying mechanism and placing the semi-finished hangers on the stapling machine to be stapled. According to the automatic hanger machining device, due to the fact that the bending forming machine, the conveying mechanism, the automatic picking machine and the stapling machine are arranged, integrated hanger producing and machining are achieved, complex hanger production can be achieved, the automation level of the automatic hanger machining device is high, and the production efficiency is obviously improved.

Owner:台山市万力达金属制品科技有限公司

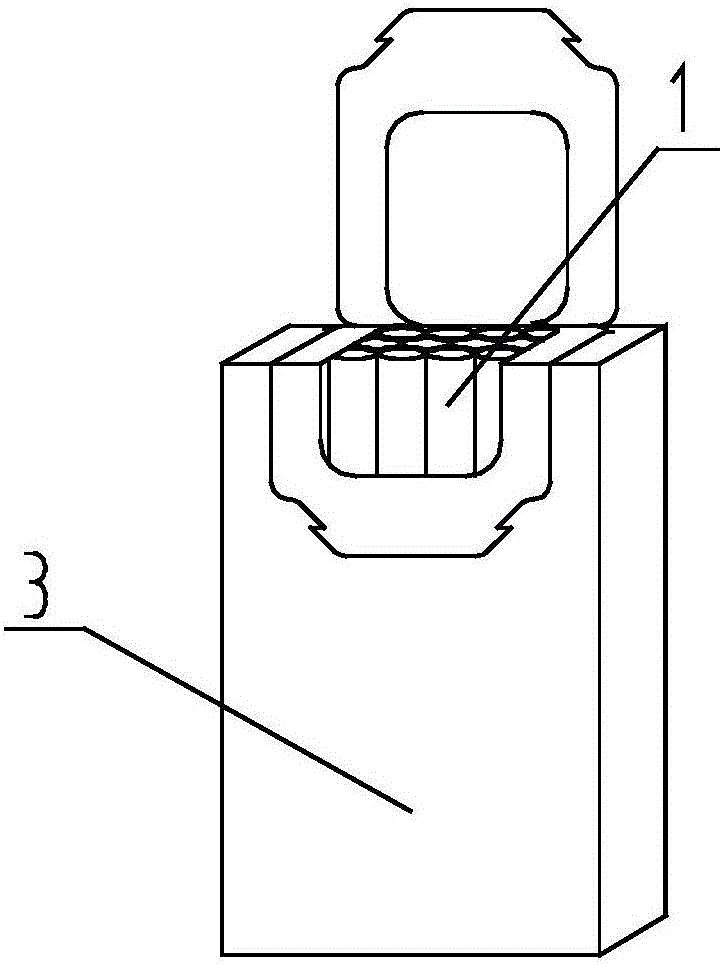

Preparation method for smelting electrodes

A preparation method for smelting electrodes comprises the following steps of firstly, providing strip-shaped raw materials which are used for preparing electrodes and qualified through surface inspection and distinguishing the strip-shaped raw materials according to lengths; secondly, arranging the distinguished raw materials in forming dies of corresponding specifications according to the principle that the raw materials of large lengths are arranged on the periphery and the raw materials of small lengths are arranged inside to enable the raw materials to be formed into columnar raw materials; and thirdly, after the columnar raw materials are fastened through a fastening device, bundling the columnar raw materials with metal strips to enable the columnar raw materials to be formed into the smelting electrodes. According to the preparation method, strip-shaped scraps of plates, tubes, rods and the like produced during machining of metal are used as raw materials, so that the strip-shaped scraps are formed in a column shape through simple steps and formed into the smelting electrodes in a metal strip bundling mode, the preparation method replaces a conventional welding method to prepare electrodes, metallurgical defects of oxide and nitride inclusion brought in during electrode preparation through the conventional welding method can be effectively overcome, and the requirement for smelting high-quality materials can be met.

Owner:BAOJI TITANIUM IND

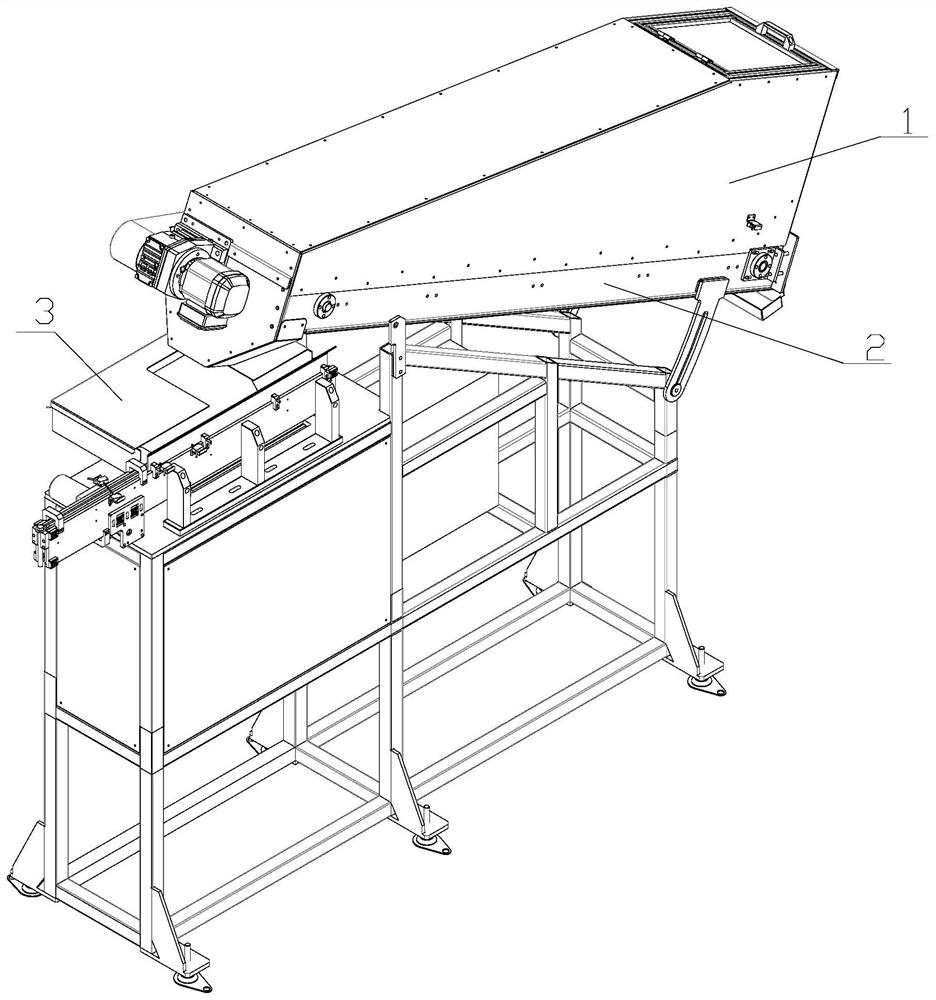

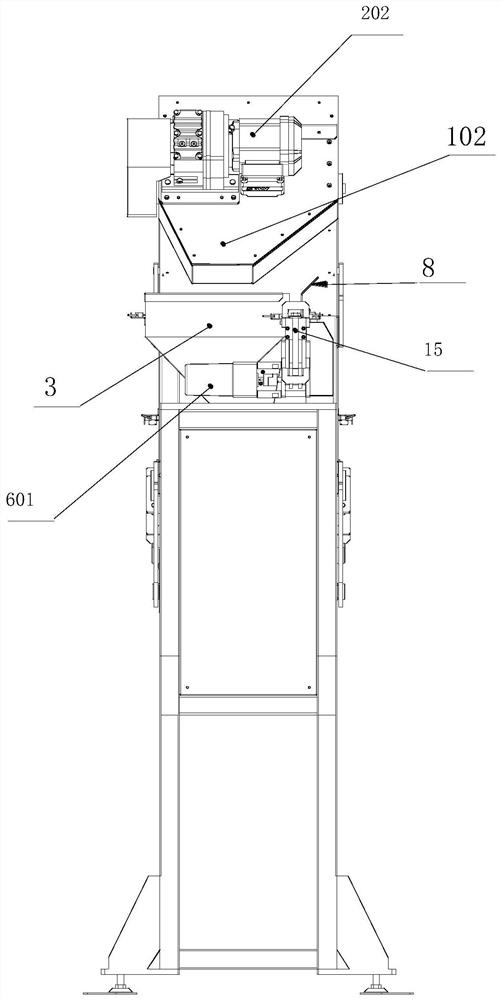

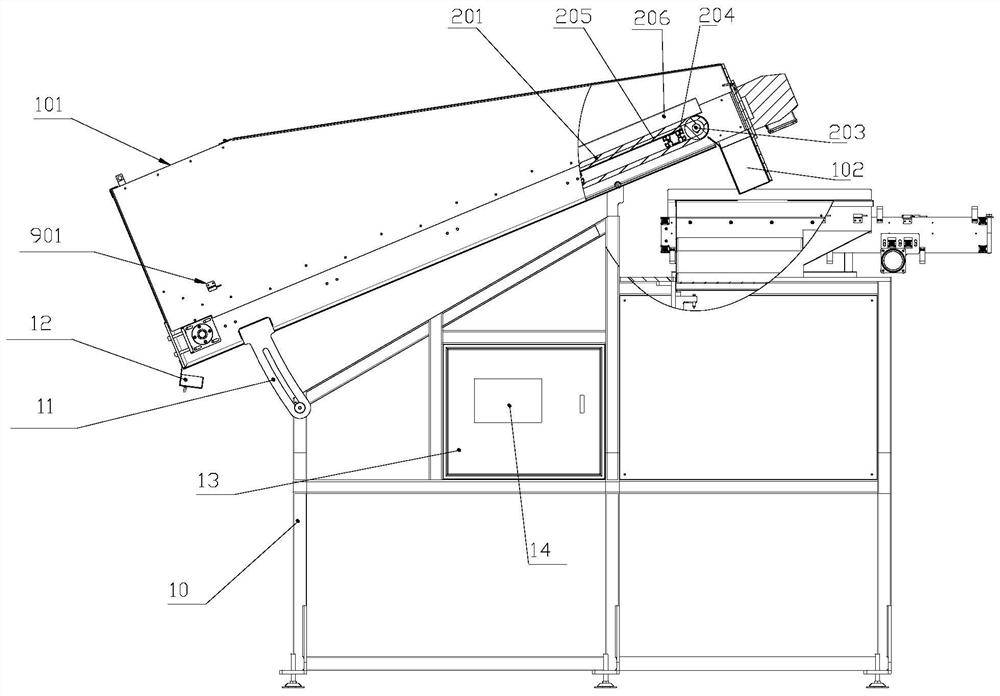

Ultra-long bolt column feeding device

The invention belongs to the technical field of bolt feeding equipment, and particularly relates to an ultra-long bolt column feeding device. The ultra-long bolt column feeding device comprises a lifting unit, a hoisting unit and a column feeding unit, wherein the lifting unit comprises a large stock bin and a chain lifting unit obliquely arranged at the bottom of the large stock bin, the chain lifting unit comprises a plurality of chains, one end of each chain is positioned at the lower end of a bin door, and the other end of each chain is positioned at the front end of a material falling barrel; the hoisting unit comprises a small stock bin and a pneumatic hoisting unit, and the pneumatic hoisting unit comprises a stepped hoisting carriage; and the column feeding unit is arranged on theouter side of the position, at one end of the stepped hoisting carriage, of the small stock bin, and comprises two horizontally-moving supporting strips which are arranged in parallel and a supportingstrip driving unit, bolts are hoisted to the horizontally-moving supporting strips from the stepped hoisting carriage, and under the driving of the supporting strip driving unit, the bolts are movedto the ends along with the horizontally-moving supporting strips. The feeding device replaces a traditional feeding mode of an electromagnetic vibration disc and original various feeding equipment ofthe ultra-long screws, and the feeding and assembling efficiencies are improved.

Owner:沈阳金华精机制造有限公司

Elastic sound-absorbing cotton and preparation method thereof

InactiveCN103710866AImprove flatnessIncrease elasticitySynthetic resin layered productsSound producing devicesBoron nitrideEngineering

The invention discloses elastic sound-absorbing cotton composed of a top surface layer, a back surface layer and a cellucotton layer sandwiched between the top surface layer and the back surface layer. Both the top surface layer and the back surface layer are made of non-woven fabric materials. The elastic sound-absorbing cotton is characterized in that the non-woven fabric is composed of, by weight, 100 parts of isotactic polypropylene, 4-5 parts of calcium stearate, 2-3 parts of sodium chromate, 1-2 parts of sodium molybdate , 2-3 parts of sodium sulfate, 12-15 parts of dioctyl phthalate, 1-2 parts of dysprosium oxide, 1-2 parts of boron nitride, 12-15 parts of montmorillonoid, 10-12 parts of wheat straw, 3-4 parts of Cacumen biotae, 4-5 parts of Eclipta prostrata, 2-3 parts of kuh-seng, 1-2 parts of mastix and 4-5 parts of assistant, and is prepared by a melt blowing process. As the non-woven fabric is prepared by the melt blowing process, the method for preparing the elastic sound-absorbing cotton is simple, the raw materials of the elastic sound-absorbing cotton are environmentally friendly, cheap and easy to obtain, the elastic sound-absorbing cotton has the advantages of good evenness and excellent resilience, expanded function and application range as compared with the general sound-absorbing cotton, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

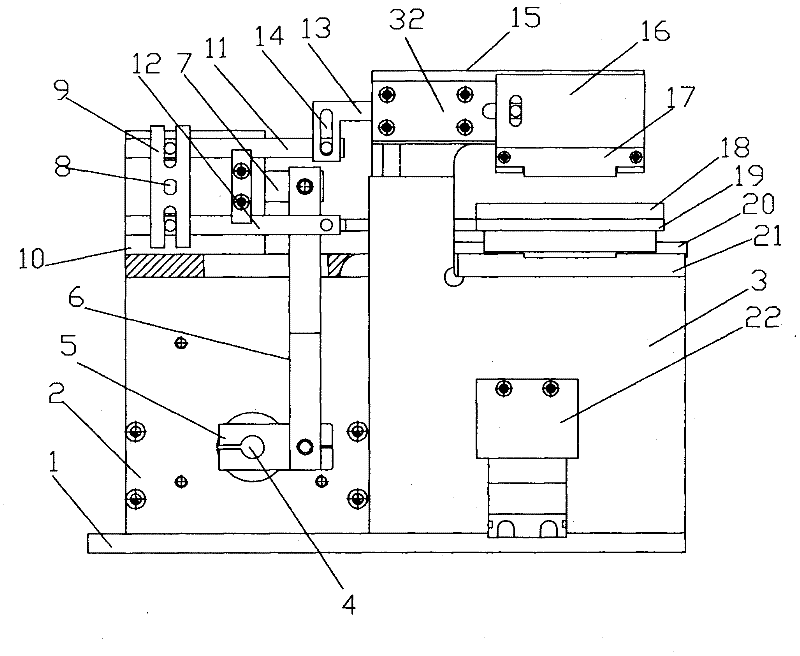

Coaxial cable stripping machine

InactiveCN102361267ASimple structureLow manufacturing costApparatus for removing/armouring cablesEngineeringCoaxial cable

The invention discloses a coaxial cable stripping machine, which comprises an upper sliding block and a lower twisting plate, wherein the upper sliding block is opposite to the lower twisting plate; a tool rest is arranged on the upper sliding block; blades are arranged on the tool rest; the upper sliding block and the lower twisting plate are connected with a swinging mechanism; the swinging mechanism can drive the upper sliding block and the lower twisting plate to move in opposite direction at a constant speed; the upper sliding block is also connected with a longitudinal driving mechanism; and the longitudinal driving mechanism can drive the upper sliding block to move up and down. The coaxial cable stripping machine is simple in structure, low in manufacturing cost and quite high in production efficiency; because the upper sliding block and the lower twisting plate move in the opposite direction at the constant speed and then twist each other, wire materials of the whole row can be subjected to skin cut-off operation at the same time; and because the upper sliding block can move up and down, a distance between the upper sliding block and the lower twisting plate can be adjusted. Therefore, the coaxial cable stripping machine can be applied to coaxial cables with various kinds of diameters, is high in universality and wide in application range, and can effectively meet requirements on production.

Owner:昆山市张浦镇双威机械厂

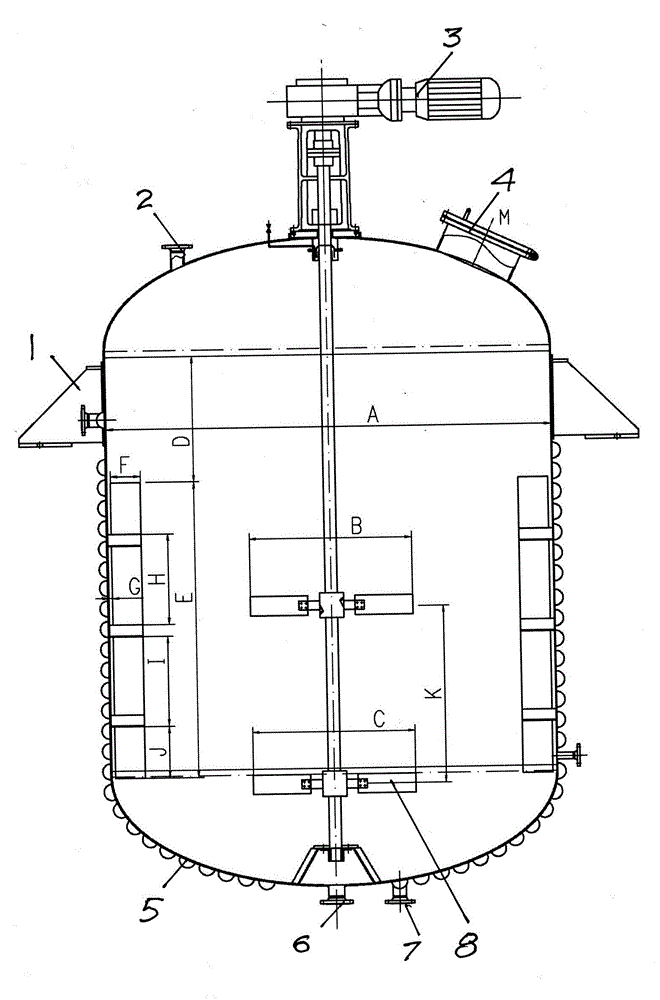

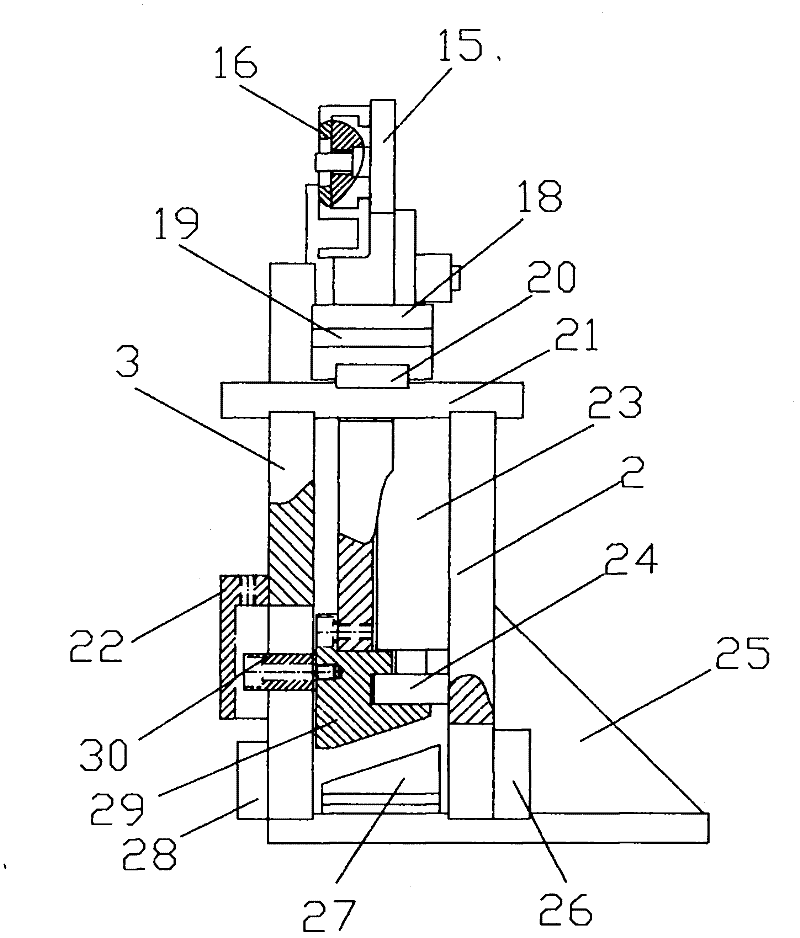

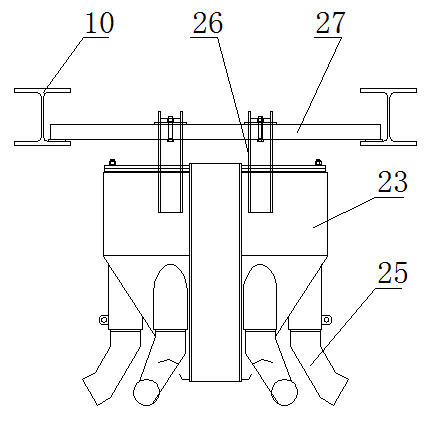

Pneumatic flotation machine with mechanical stirring

The invention discloses a pneumatic flotation machine with mechanical stirring, which comprises a cylindrical tank body flotation chamber, wherein a foam product collecting chute is closely fastened on the outer side of the upper end of the flotation chamber, and the outer side of the foam product collecting chute is connected with a concentrate pipe; a hollow shaft connected with a driving device is arranged in the flotation chamber, and the hollow shaft is fixed on the support through a bearing and bearing blocks, a bearing housing is arranged between the bearing blocks, an air inlet formedon the bearing housing is connected with an air inlet pipe, and an air inlet is formed on a hollow shaft corresponding to the bearing housing; the lower end of the hollow shaft is connected with a rotor which has an air outlet, and a stator is arranged on the outer side of the rotor; a feed tank is hoisted on the upper part of the flotation chamber, the feed tank is a tank body with an annular cavity, the annular tank body surrounds the outside of the hollow shaft, a feed inlet is formed on the upper part of the feed tank, and discharging nozzles are uniformly arranged on the lower part of the feed tank; and a tailing chamber is formed at the bottom part of the flotation chamber, and the tailing chamber is communicated with a tailing tank through a pipe. The machine is efficient, energy-saving and very adaptable and is long in service life and low in production cost.

Owner:张玮

Preparation method of surface compaction plate

ActiveCN107234692AHigh densityHigh strengthWood compressionWood treatment detailsSurface layerWood machining

The invention discloses a preparation method of a surface compaction plate. The preparation method comprises the following steps: (1) wood is processed into a plate with the thickness being 10-25mm, and is dried till the water ratio reaches 20-30wt%; (2) the dried plate is arranged between two compression rollers of a roller press for cross grain radial rolling, and the thickness compression ratio of the plate passing the compression rollers is controlled at 10-30%; (3) the plate after the rolling treatment is soaked in phenolic resin liquid for 1-10h; (4) the soaked plate is subjected to steam-injection softening treatment; and (5) the softened plate is arranged in a hot press for compression. According to the preparation method of the surface compaction plate, the produced plate is high in surface layer density and strength and is not prone to deform; a technology is simple, no treatment on man-made forest soft wood is required in a sealed container, and the production efficiency is high; processing parameters are definite and the operability is high; and the surface compaction plate is light in color, has excellent flame retardant and antibacterial properties, and can directly act as materials of furniture and interior decoration.

Owner:中山市海邦家具实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com