Pneumatic flotation machine with mechanical stirring

A technology of mechanical stirring and flotation machine, applied in the direction of flotation, solid separation, etc., can solve the problems of low processing capacity, large volume, large consumption of medicine, etc., to achieve enhanced processing capacity, save plant area, and reduce power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

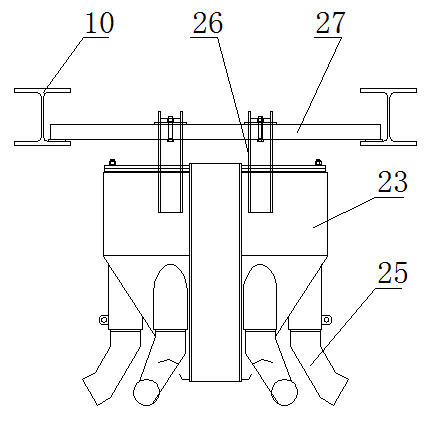

[0039] Such as figure 1 The air-compressed mechanical agitation flotation machine shown includes a cylindrical tank body flotation chamber 1, and a foam product concentration chute 2 is installed on the outer side of the upper end of the flotation chamber 1. The foam product concentration chute 2 has an annular cavity , the upper end of the flotation chamber 1 is provided with a foam product collection chute 3 connected to the cavity of the foam product concentration chute 2; the bottom surface of the foam product concentration chute 2 is an inclined plane, which is convenient for the concentration of the foam product, and the lowest point of the bottom surface is in contact with the clean coal Pipelines (not shown in the figure) are connected and used to transport clean coal outward. In the flotation chamber 1, there is a hollow shaft 6 connected with the driving device 5. The upper part of the hollow shaft 6 is fixed on the support 9 above the foam product concentration chut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com