Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

199results about How to "Increase surface density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

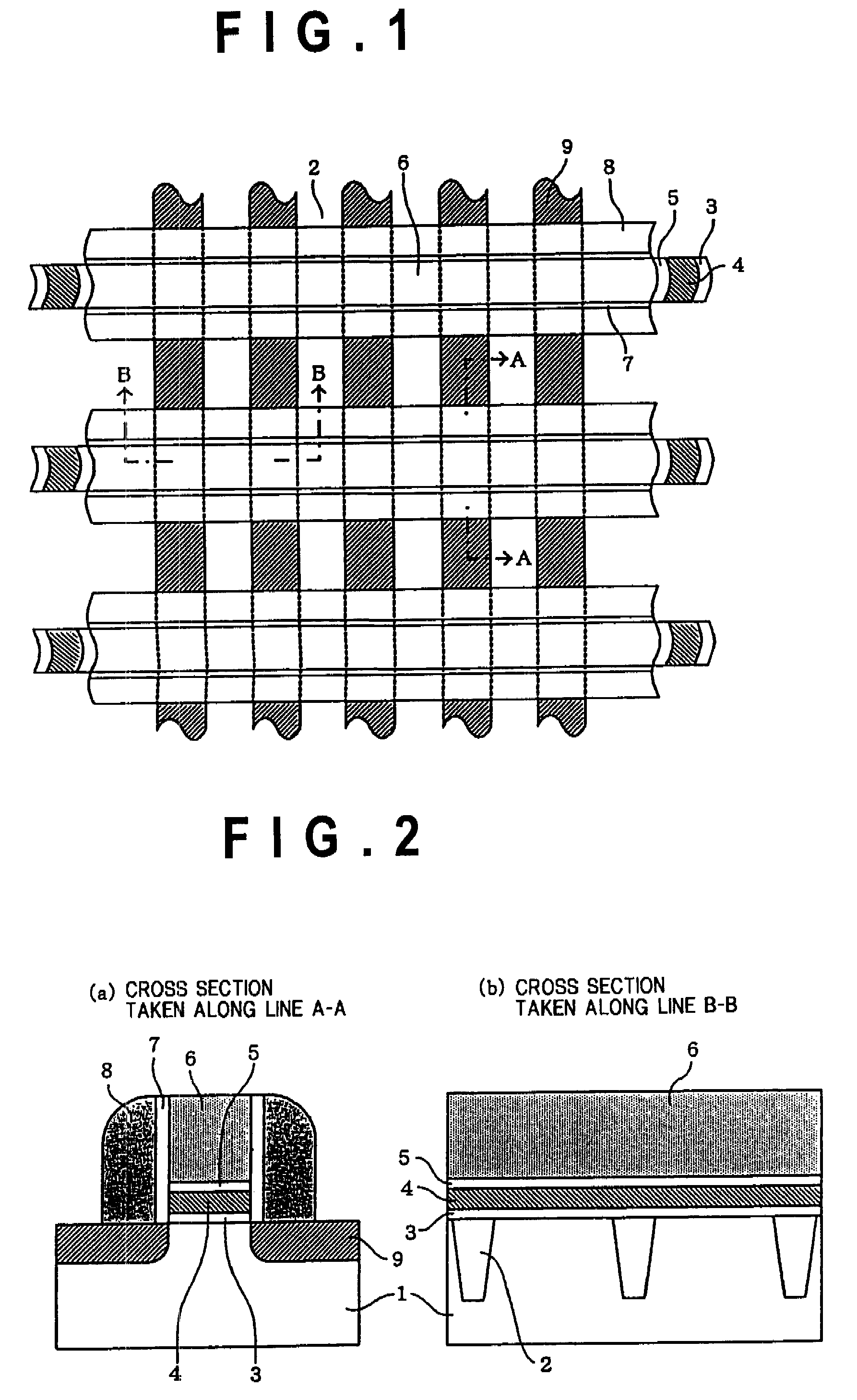

Perpendicular magnetic recording medium

InactiveUS7993765B2Increase surface densityPrevent degradationBase layers for recording layersRecord information storageCrystal structureMetallic materials

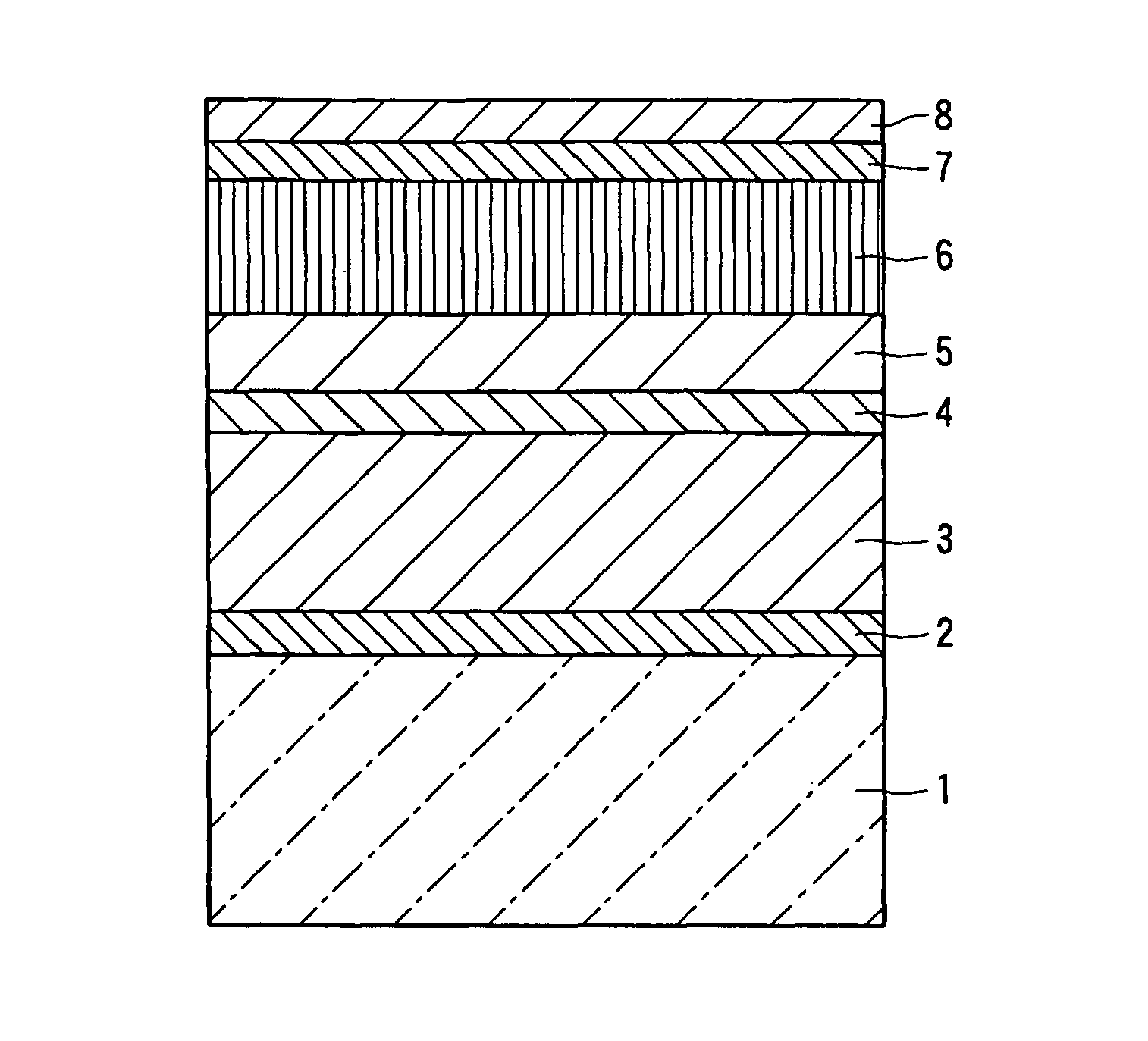

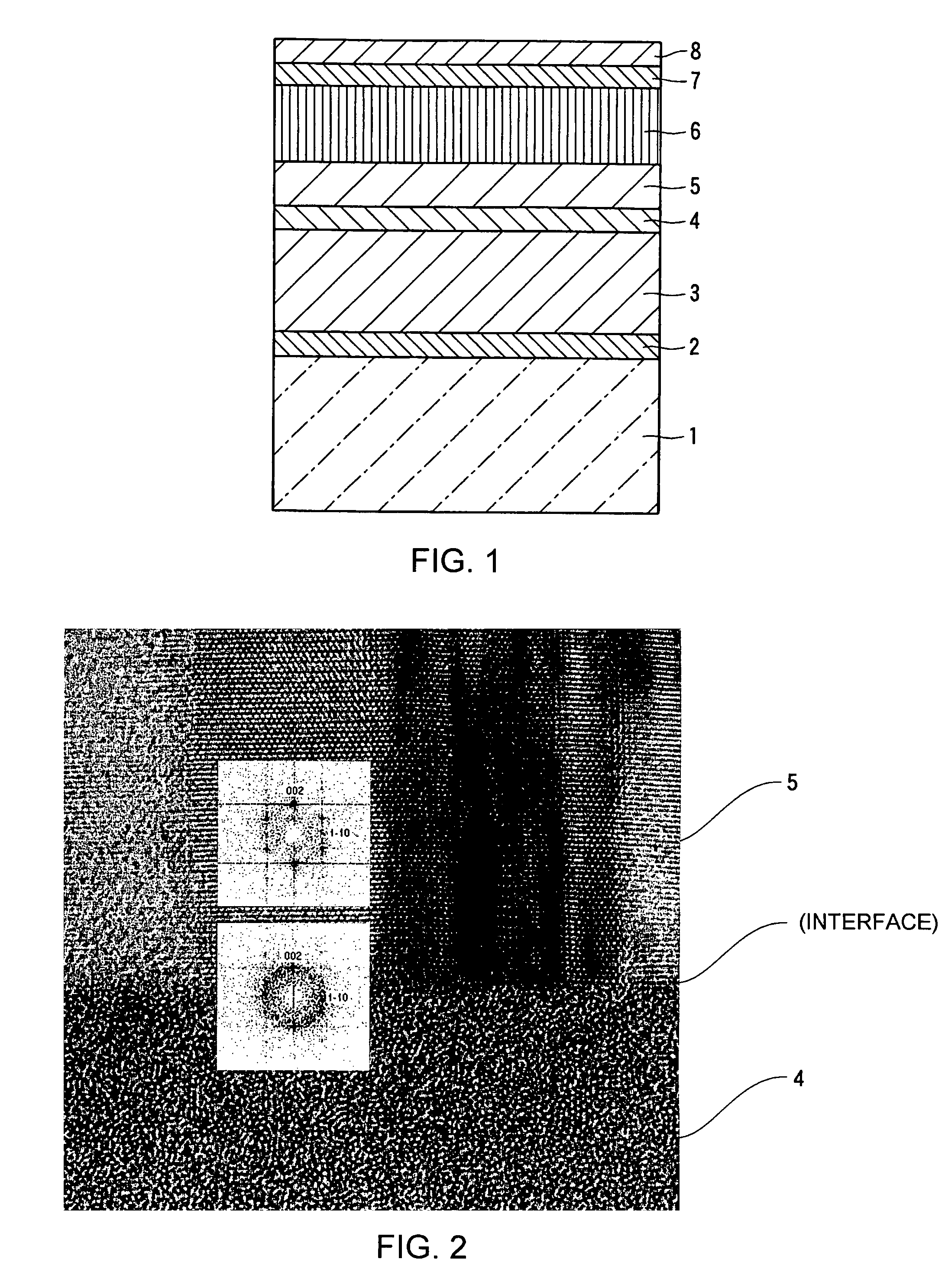

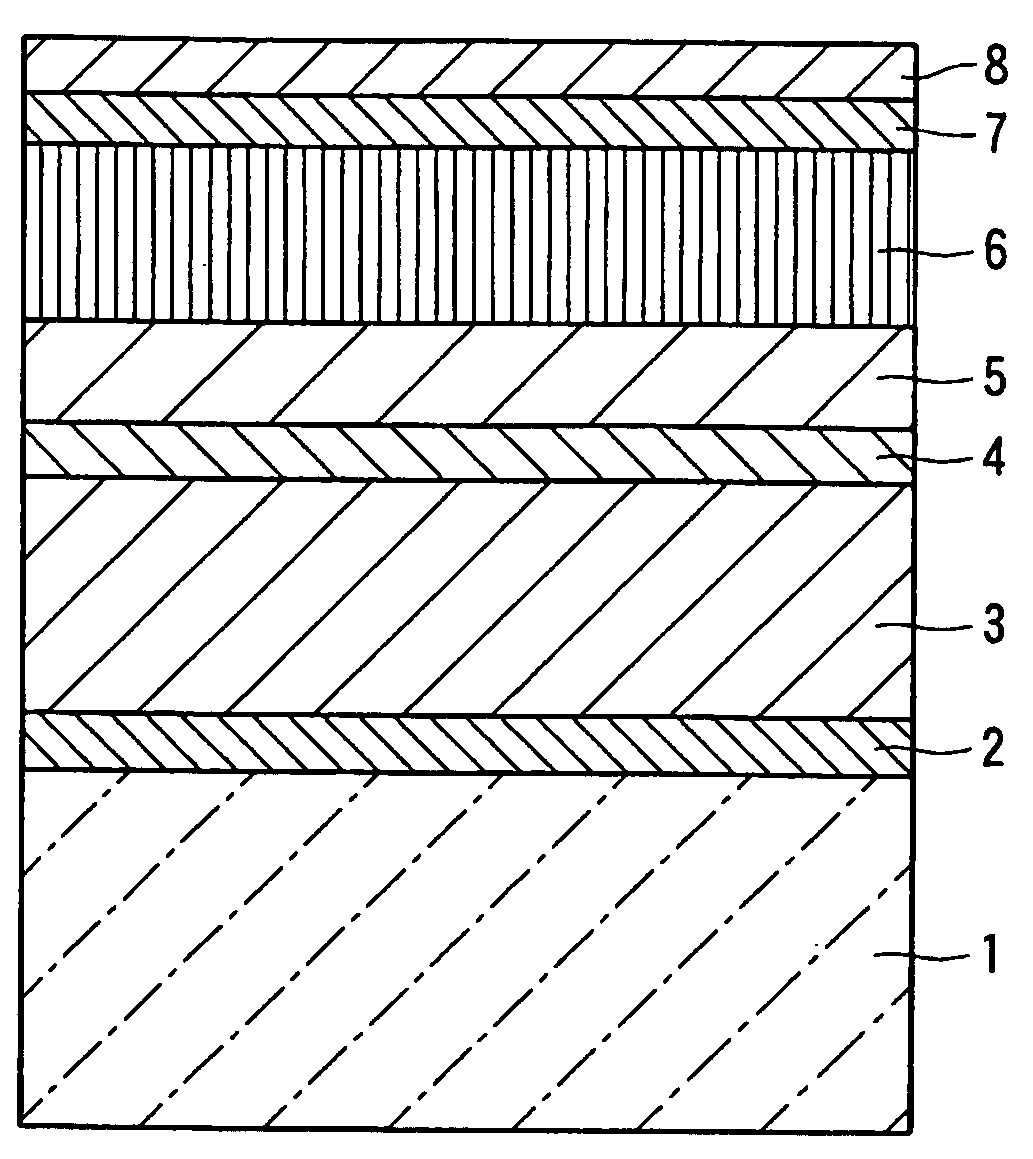

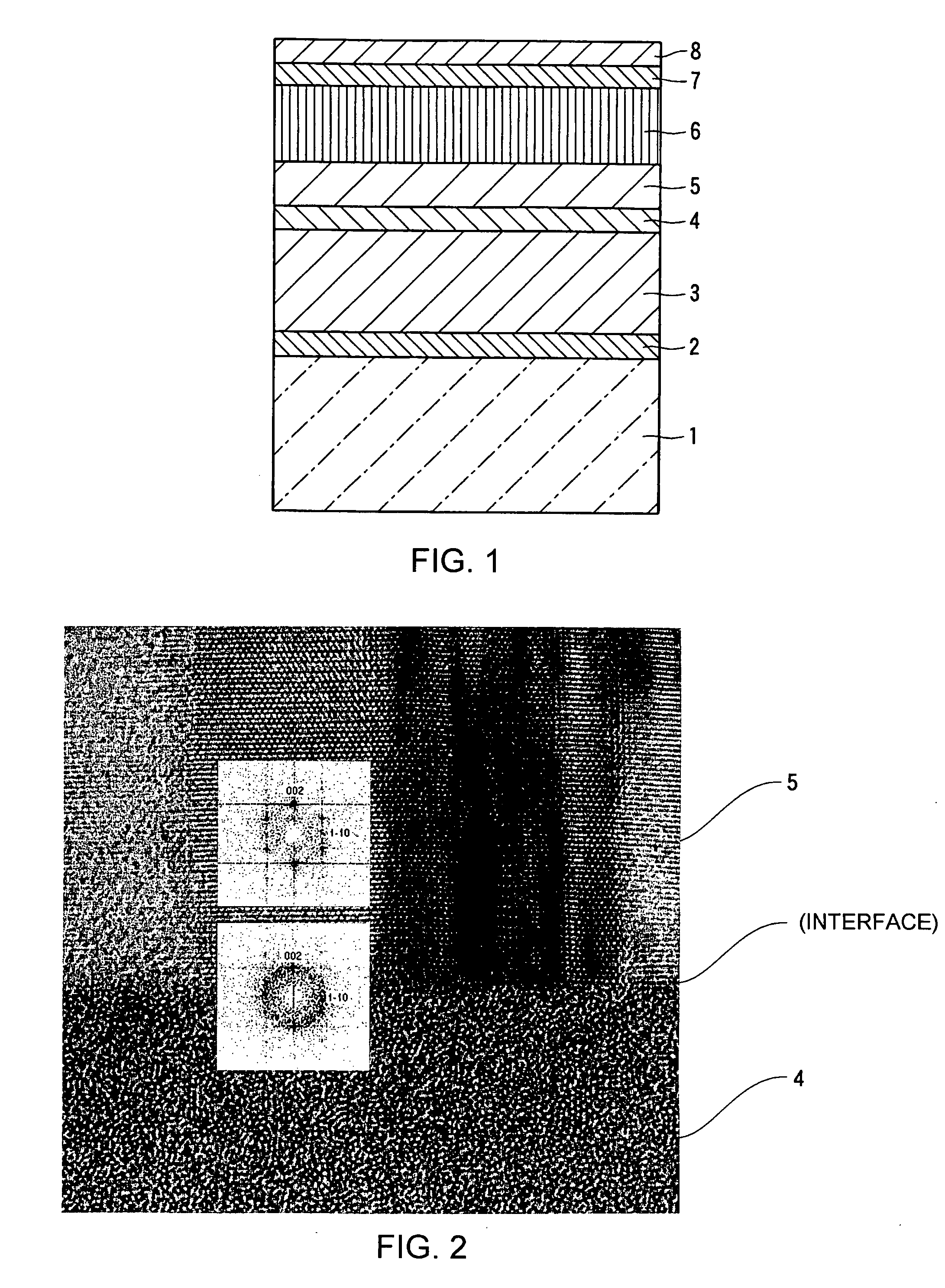

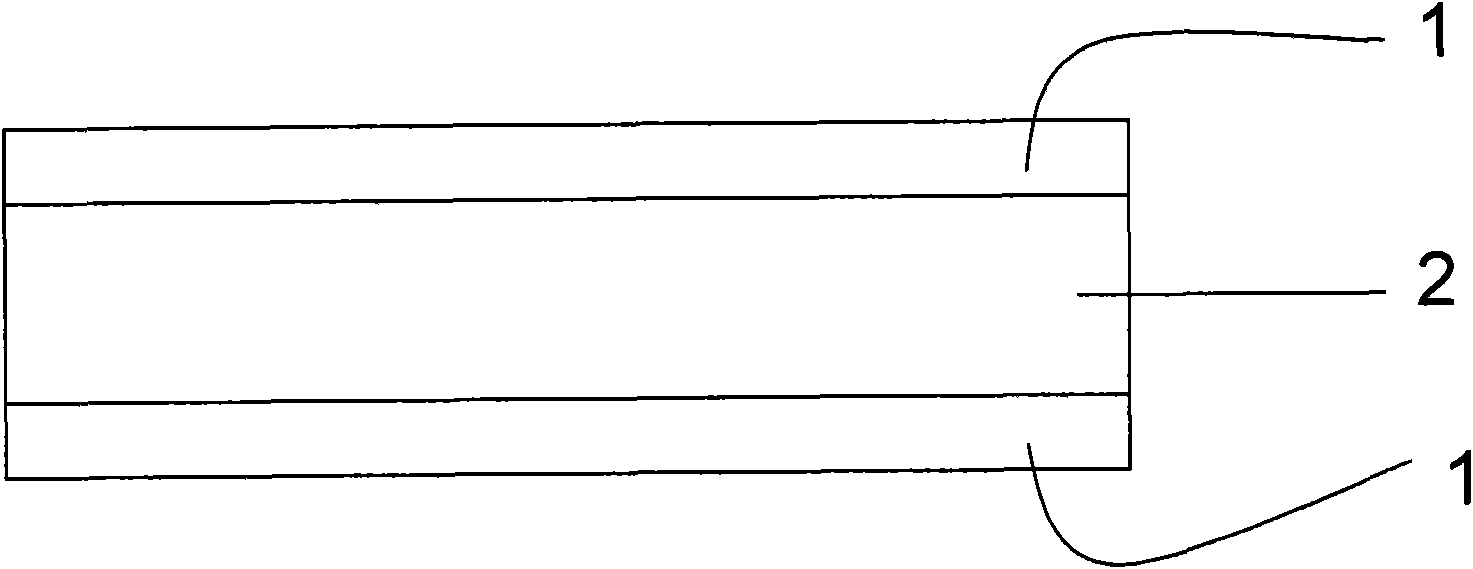

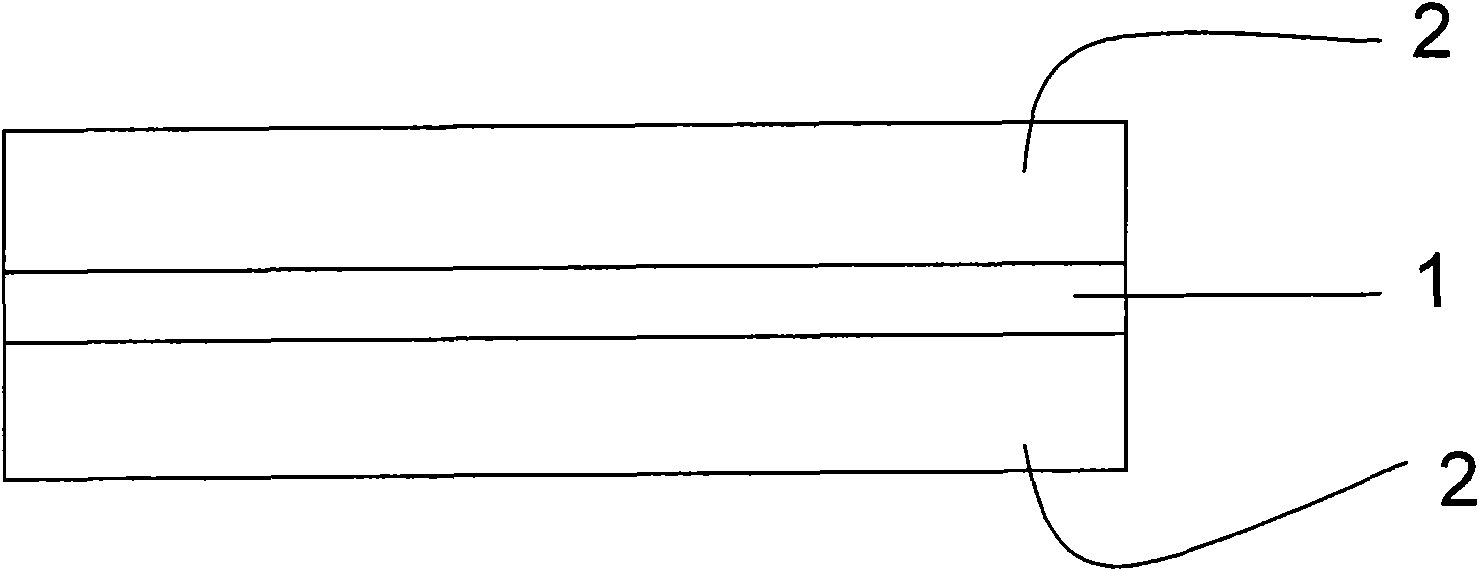

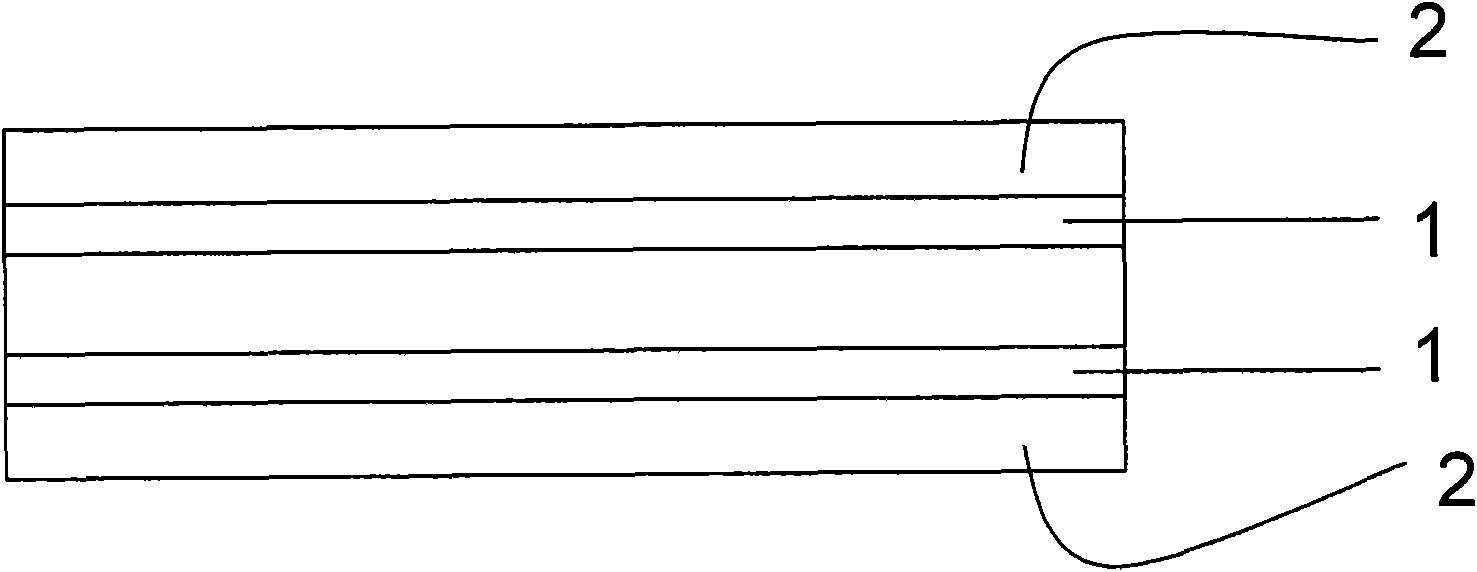

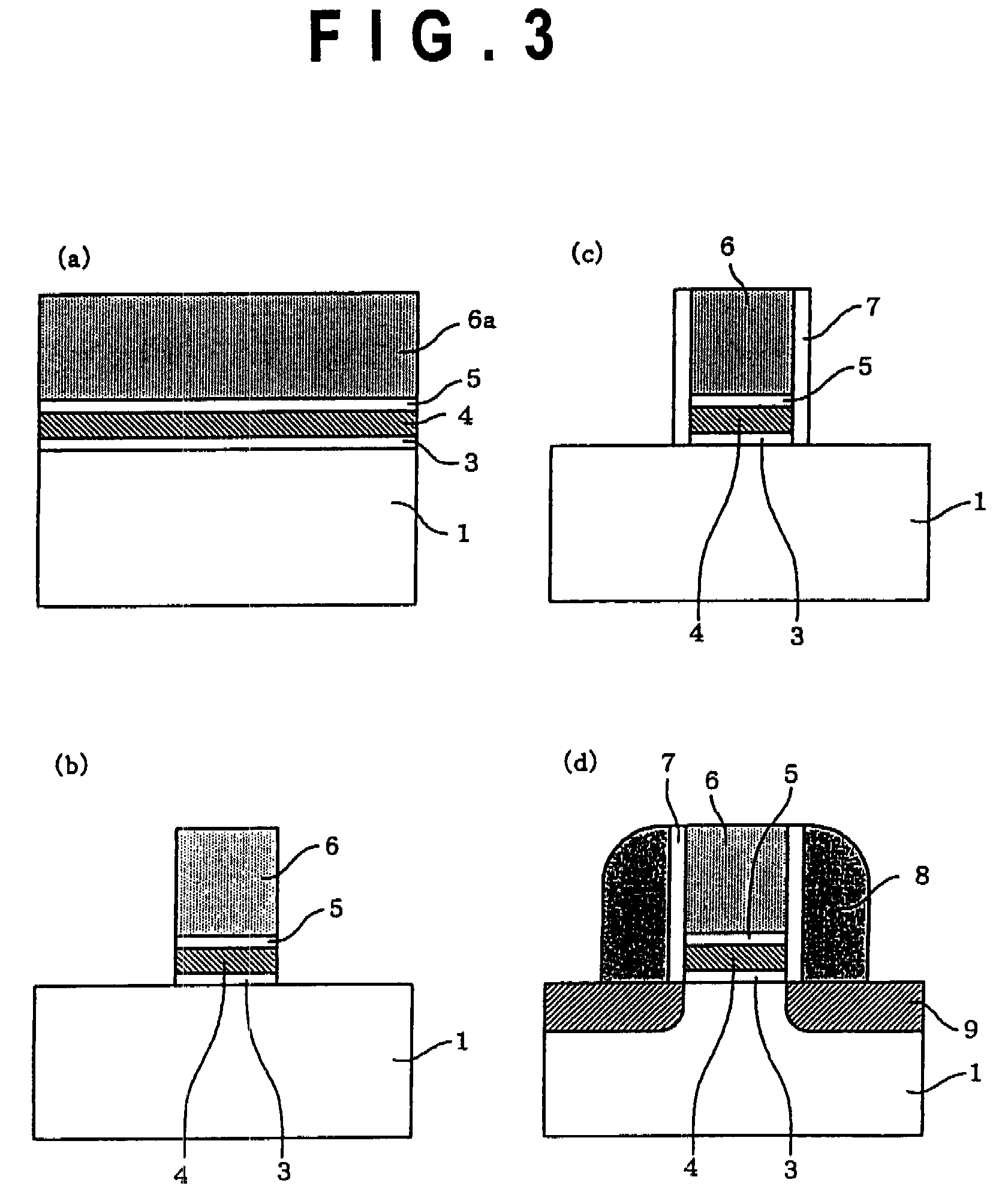

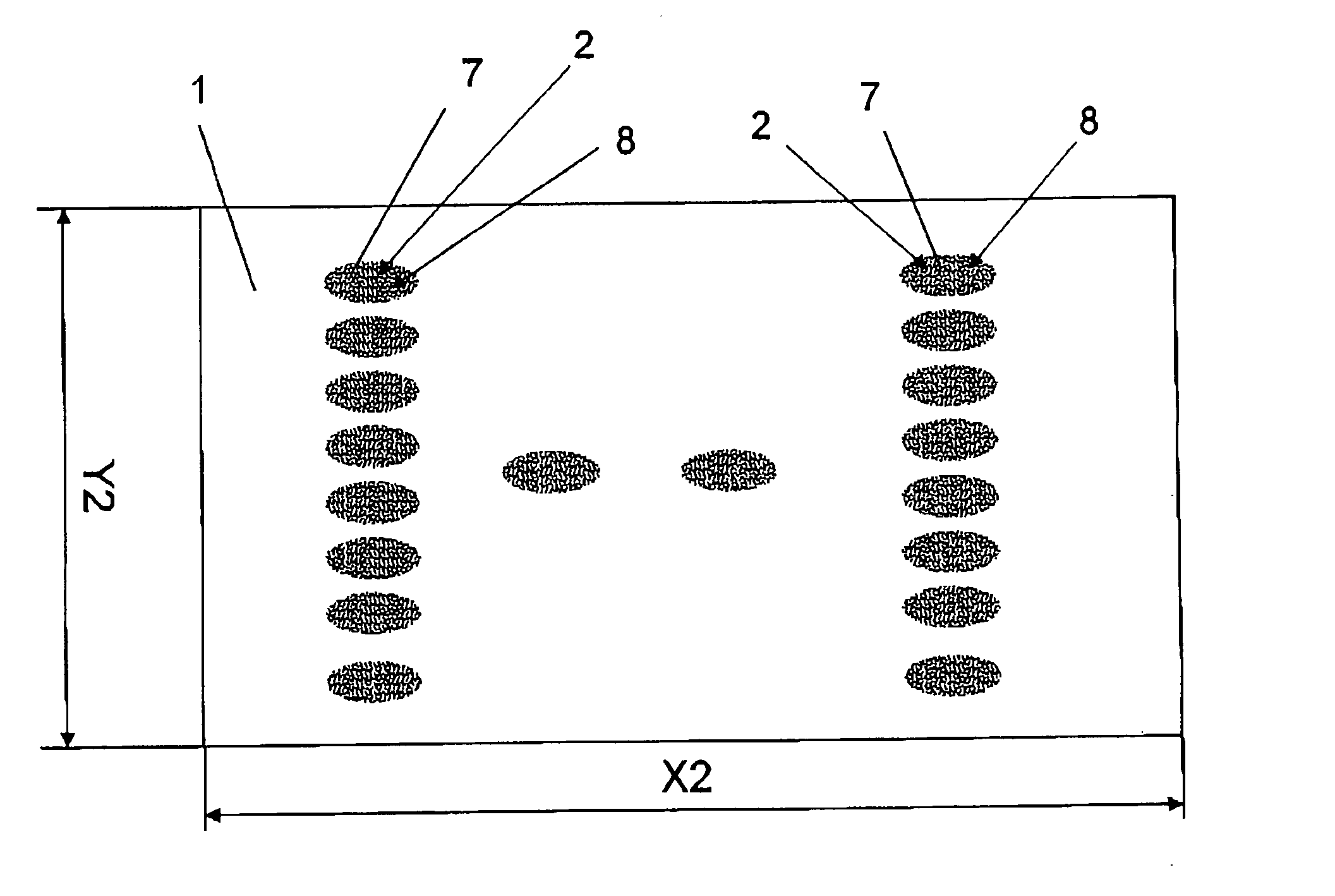

In a perpendicular magnetic recording medium which includes a substrate (1) of a nonmagnetic material, first and second nonmagnetic underlayers (4 and 5) formed on the substrate, and a perpendicular magnetic recording layer (6) formed on the first and the second nonmagnetic underlayers, the first nonmagnetic underlayer is made of an amorphous nonmagnetic metal material containing a metal element which forms a face-centered cubic (fcc) crystal structure by a simple substance. The second nonmagnetic underlayer is formed on the first nonmagnetic underlayer in contact with the first nonmagnetic underlayer and made of a nonmagnetic material containing a hexagonal close packed structure. The perpendicular magnetic recording layer is formed on the second nonmagnetic underlayer in contact with the second nonmagnetic layer.

Owner:WESTERN DIGITAL TECH INC

Perpendicular magnetic recording medium

InactiveUS20050019608A1Increase surface densityPrevent degradationBase layers for recording layersRecord information storageMetallic materialsCrystal structure

In a perpendicular magnetic recording medium which includes a substrate (1) of a nonmagnetic material, first and second nonmagnetic underlayers (4 and 5) formed on the substrate, and a perpendicular magnetic recording layer (6) formed on the first and the second nonmagnetic underlayers, the first nonmagnetic underlayer is made of an amorphous nonmagnetic metal material containing a metal element which forms a face-centered cubic (fcc) crystal structure by a simple substance. The second nonmagnetic underlayer is formed on the first nonmagnetic underlayer in contact with the first nonmagnetic underlayer and made of a nonmagnetic material containing a hexagonal close packed structure. The perpendicular magnetic recording layer is formed on the second nonmagnetic underlayer in contact with the second nonmagnetic layer.

Owner:WESTERN DIGITAL TECH INC

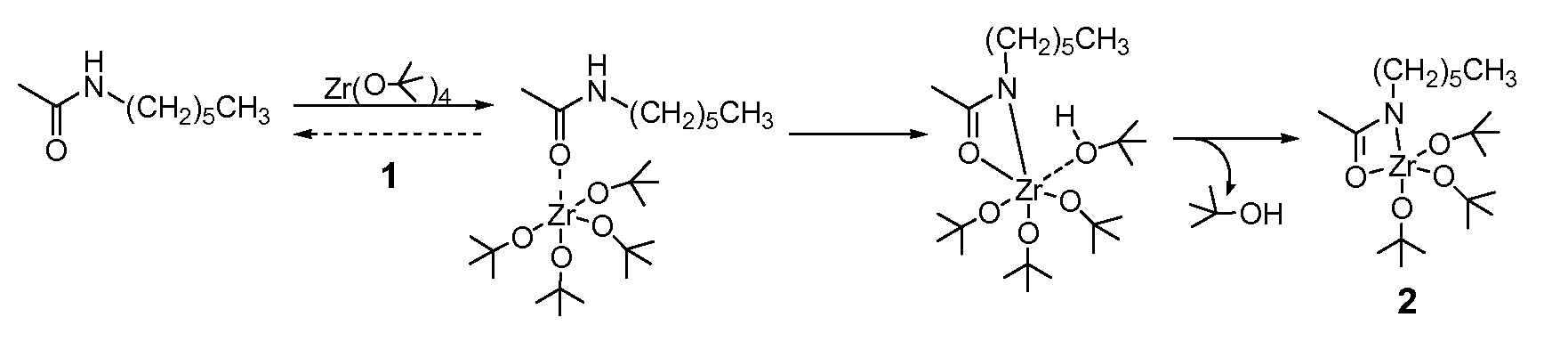

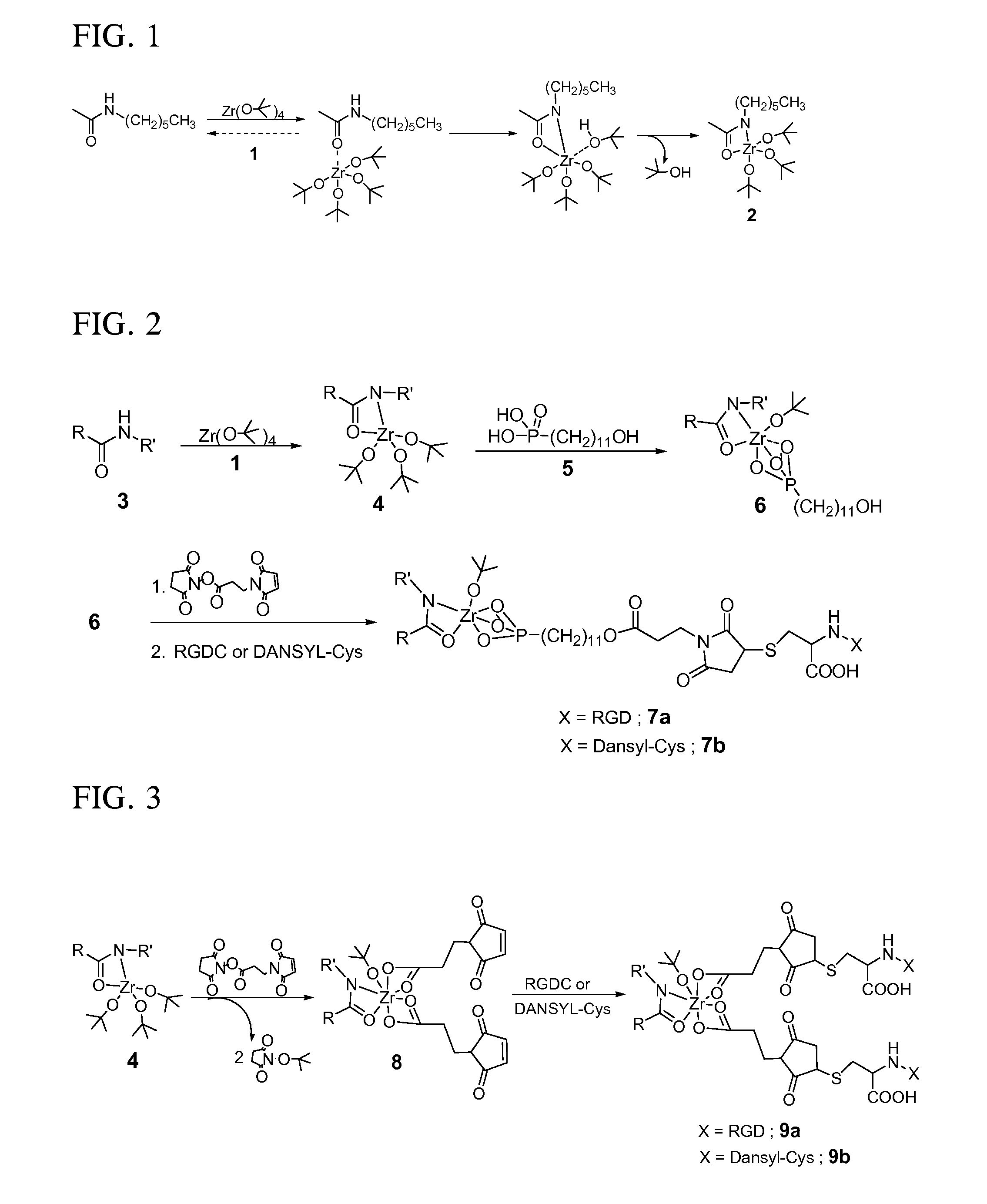

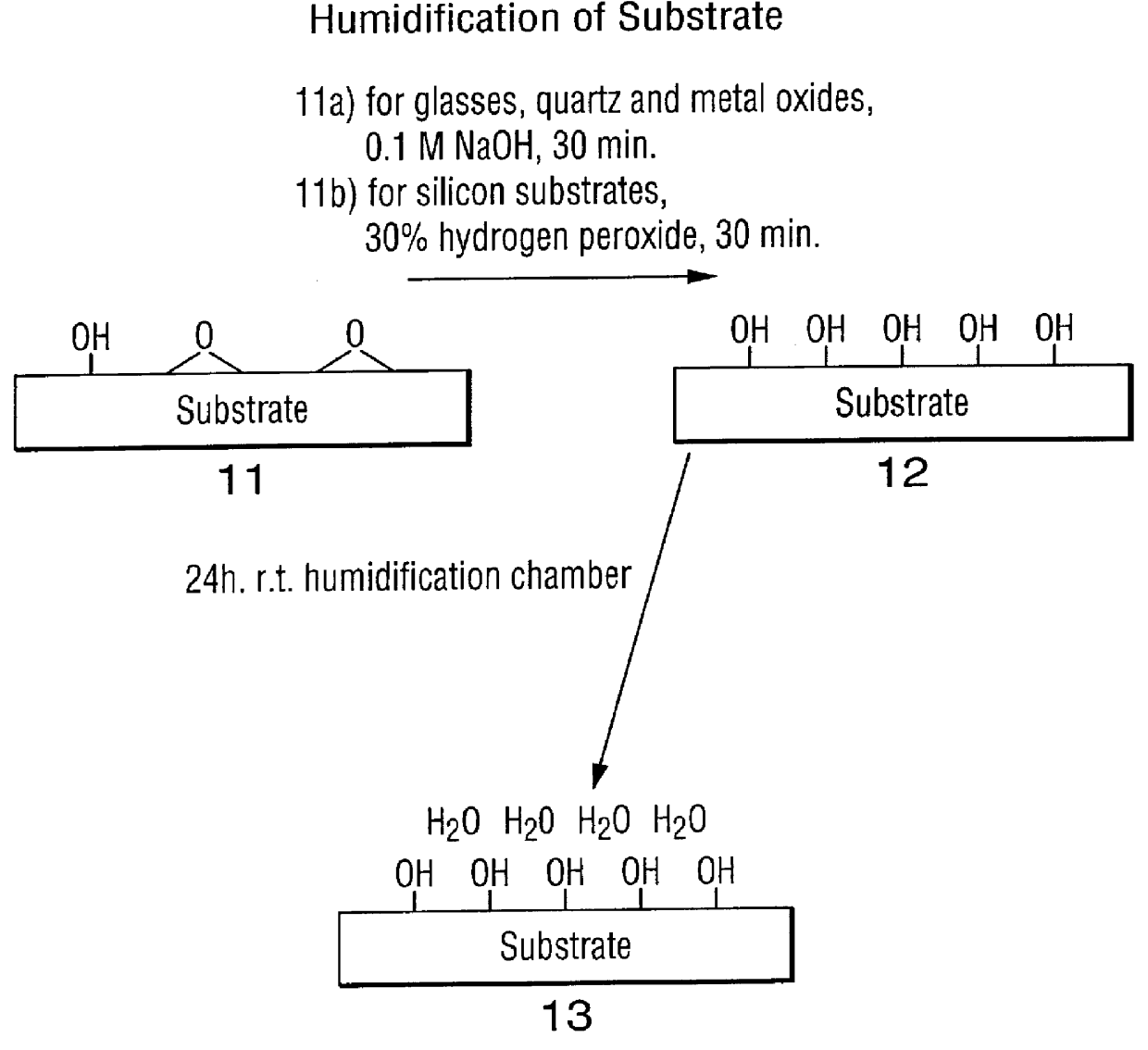

High-yield activation of polymer surfaces for covalent attachment of molecules

InactiveUS20070196663A1High yieldMild reaction conditionsSurgeryPretreated surfacesPolymeric surfaceBiological activation

Polymer surfaces coated with organometallic layers, wherein the organometallic layers and polymer surfaces have functional groups that react to bond the organometallic layer to the polymer surface with organometallic functional groups remaining unreacted for the subsequent covalent attachment of organic overlayers. Coating methods and coated articles are also disclosed.

Owner:THE TRUSTEES FOR PRINCETON UNIV

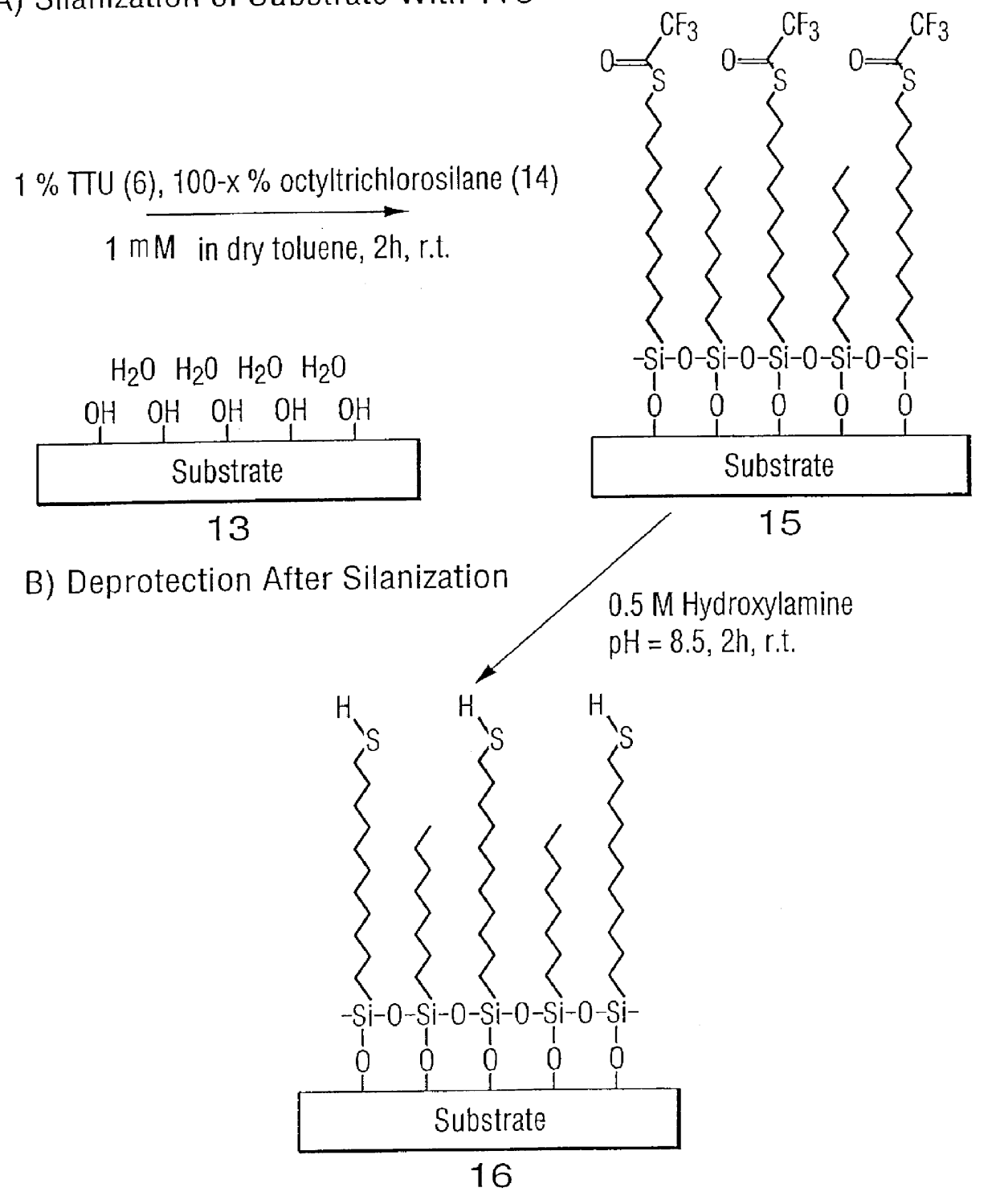

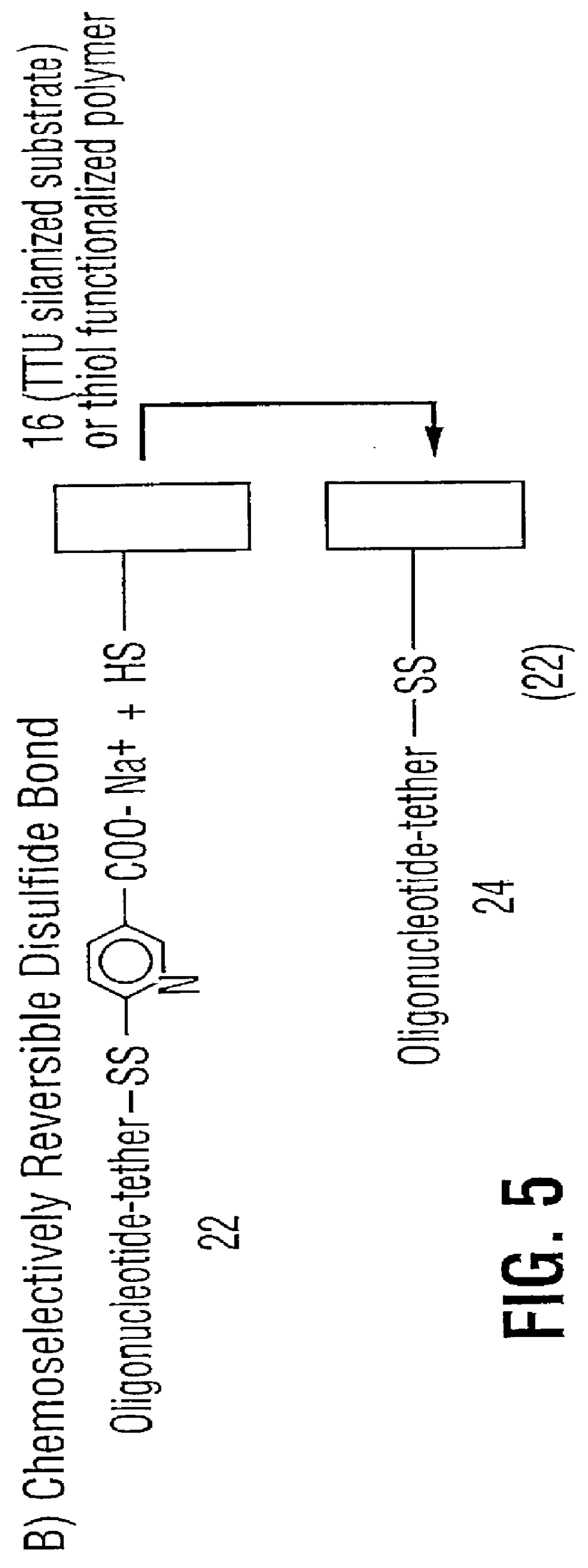

High surface density covalent immobilization of oligonucleotide monolayers

InactiveUS6159695AIncrease surface densityHigh sensitivityBioreactor/fermenter combinationsMaterial nanotechnologySilanesHigh surface

Oligonucleotides and other biomolecules are immobilized in high density on solid substrates through covalent forces using either a permanent thioether bond, or a chemoselectively reversible disulfide bond to a surface thiol. Substrates which have hydroxyl groups on their surfaces can be first silanized with a trichlorosilane containing 2-20 carbon atoms in its hydrocarbon backbone, terminating in a protected thiol group. The oligonucleotides or other biomolecules are first connected to a tether consisting of a hydrocarbon or polyether chain of 2-20 units in length which terminates in a thiol group. This thiol may be further modified with a halobenzylic-bifunctional water soluble reagent which allows the conjugate to be immobilized onto the surface thiol group by a permanent thioether bond. Alternatively, the oligonucleotide-tether-thiol group can be converted to a pyridyldisulfide functionality which attaches to the surface thiol by a chemoselectively reversible disulfide bond. The permanently bound oligonucleotides are immobilized in high density compared to other types of thiol functionalized silane surface and to the avidin-biotin method.

Owner:SENSORCHEM INT

Preparation method of high-performance anti-corrosion repairing mortar

A preparation method of high-performance anti-corrosion repairing mortar including following components, by weight: 150-250 parts of cement, 280-725 parts of quartz sand, 50-200 parts of mineral powder, 50-150 parts of fly ash, 0-50 parts of silicon ash, 5-10 parts of barium nitrate, 0.1-1 part of an early strength agent, 1-4 parts of PP fibers, 0.5-20 parts of latex powder, 0.5-5 parts of cellulose ether, 0.5-2 parts of a water repellent agent, 0.001-0.1 parts of an air entraining agent, 0.1-2 parts of a water reducing agent, 0-1 part of a defoaming agent, and 100-250 parts of water. The invention, aiming to the characteristic of sulphate attack and the performance requirement of repairing mortar, discloses the repairing mortar which can repair the surface of damaged concrete with a protective film formed thereon to prevent the concrete form being corroded again. The repairing mortar is good in construction performance, can be used for coating the surface of the damaged concrete or filling damaged positions of the concrete. The repairing mortar is high in bonding strength and strength, is good in anti-permeability and flexibility, is simple in preparation process, is especially suitable for repairing the concrete subjected to sulphate attack, is great in market prospect and is good in practicability.

Owner:潍坊德霖建材科技有限公司

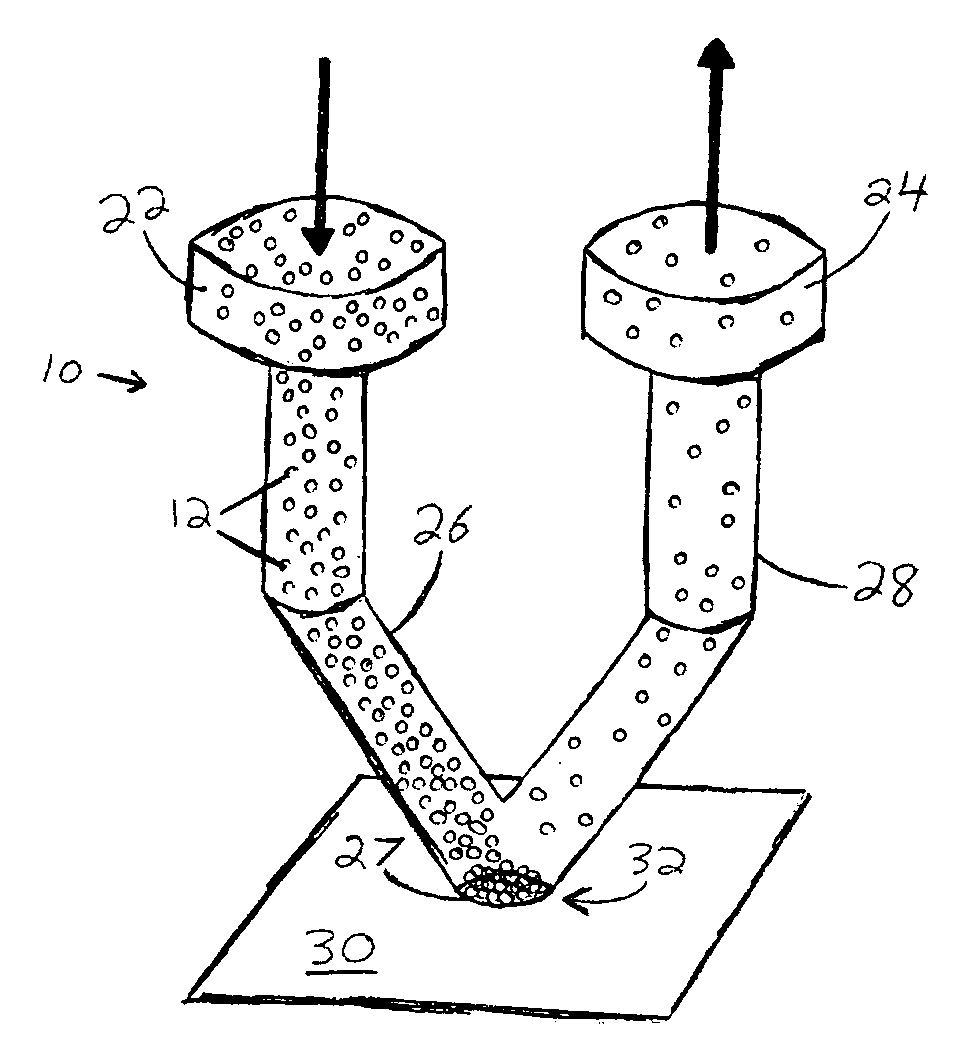

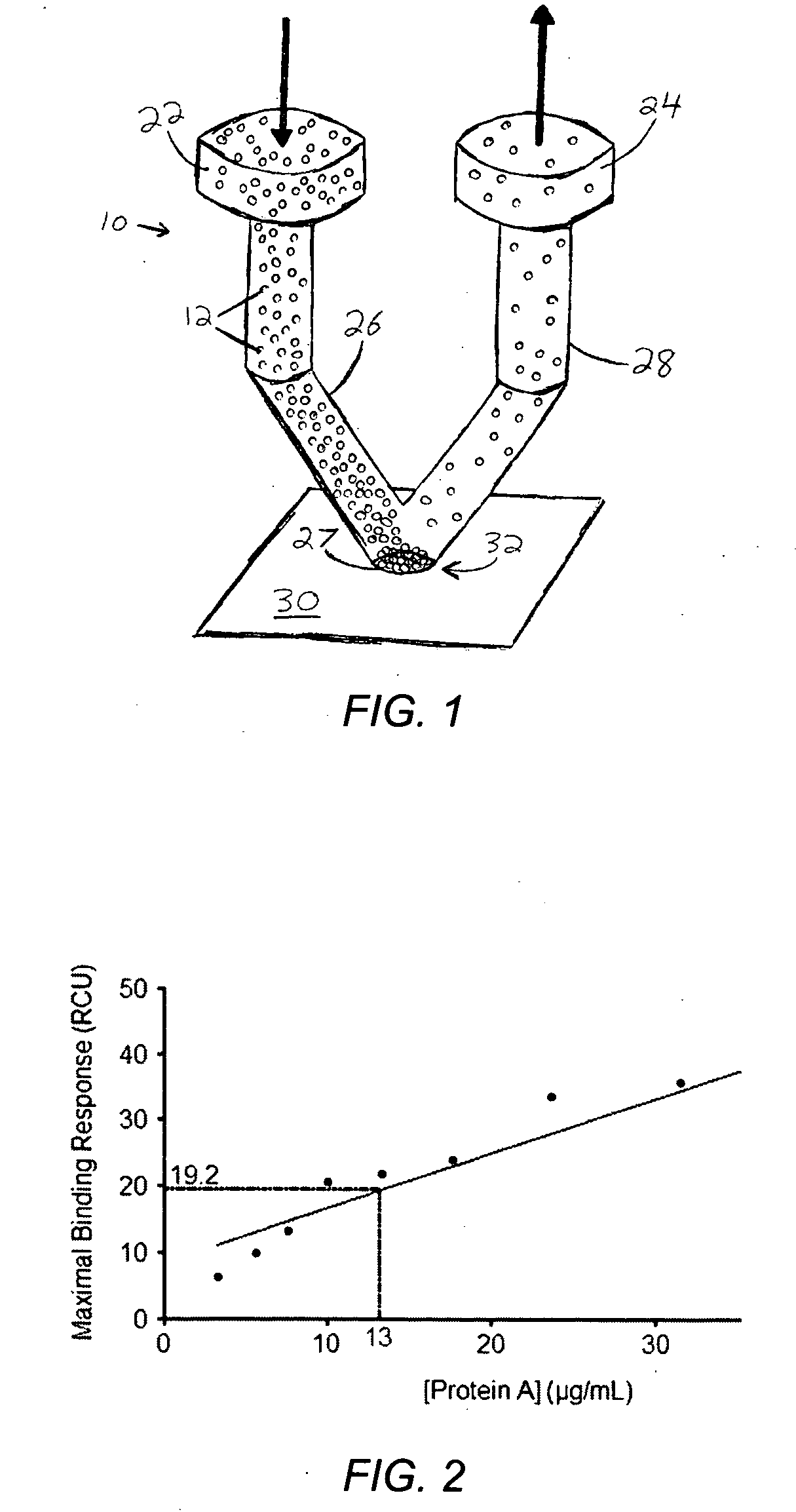

Microfluidic interface for highly parallel addressing of sensing arrays

ActiveUS20070231880A1Increase surface densityBioreactor/fermenter combinationsSequential/parallel process reactionsChemical substanceCompound (substance)

Disclosed is a spotter device and methods for the formation of microassays, biochips, biosensors, and cell cultures. The spotter may be used to deposit highly concentrated spots of protein or other materials on a microarray slide, wafer, or other surface. It may also be used to perform various chemistry steps on the same spots. The spotter increases the surface density of substances at each spot by directing a flow the desired substance (or a solution thereof) over the spot area until surface saturation is accomplished. The spotter may be loaded by well plate handling equipment. The spotter uses wells, microfluidic conduits, and orifices to deposit proteins, other biomolecules, or chemicals on a spot on a separate surface. Each orifice is connected to two wells via microconduits. When the spotter contacts a surface, a seal is formed between the orifices and the surface. The same or different substances may be flowed across each orifice. Any number of orifices may be incorporated into a spotter. The spotter is particularly useful for depositing proteins in high concentrations on a surface, since the spotter may be placed on a surface for an extended period of time.

Owner:UNIV OF UTAH RES FOUND

Method for densifying wood and densified wood

The invention discloses a method for densifying wood and densified wood manufactured by the same. The method comprises: sealing the cross section of wood by using a hydrophobic material, wherein the water content of the wood is less than 12 weight percent; coating softener on the surface and / or shallow layer of the sealed wood; and performing the hot pressing of the wood of which the cross section is sealed and which is coated with the softener at a temperature above the boiling point of the softener to densify the wood. The method for densifying wood can compress the wood to different extent according to needs. The method is simple and easy to operate, requires short time and simple equipment and makes product cost low. The densified wood manufactured by the method of the invention is greatly improved in surface density, hardness and wear resistance.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

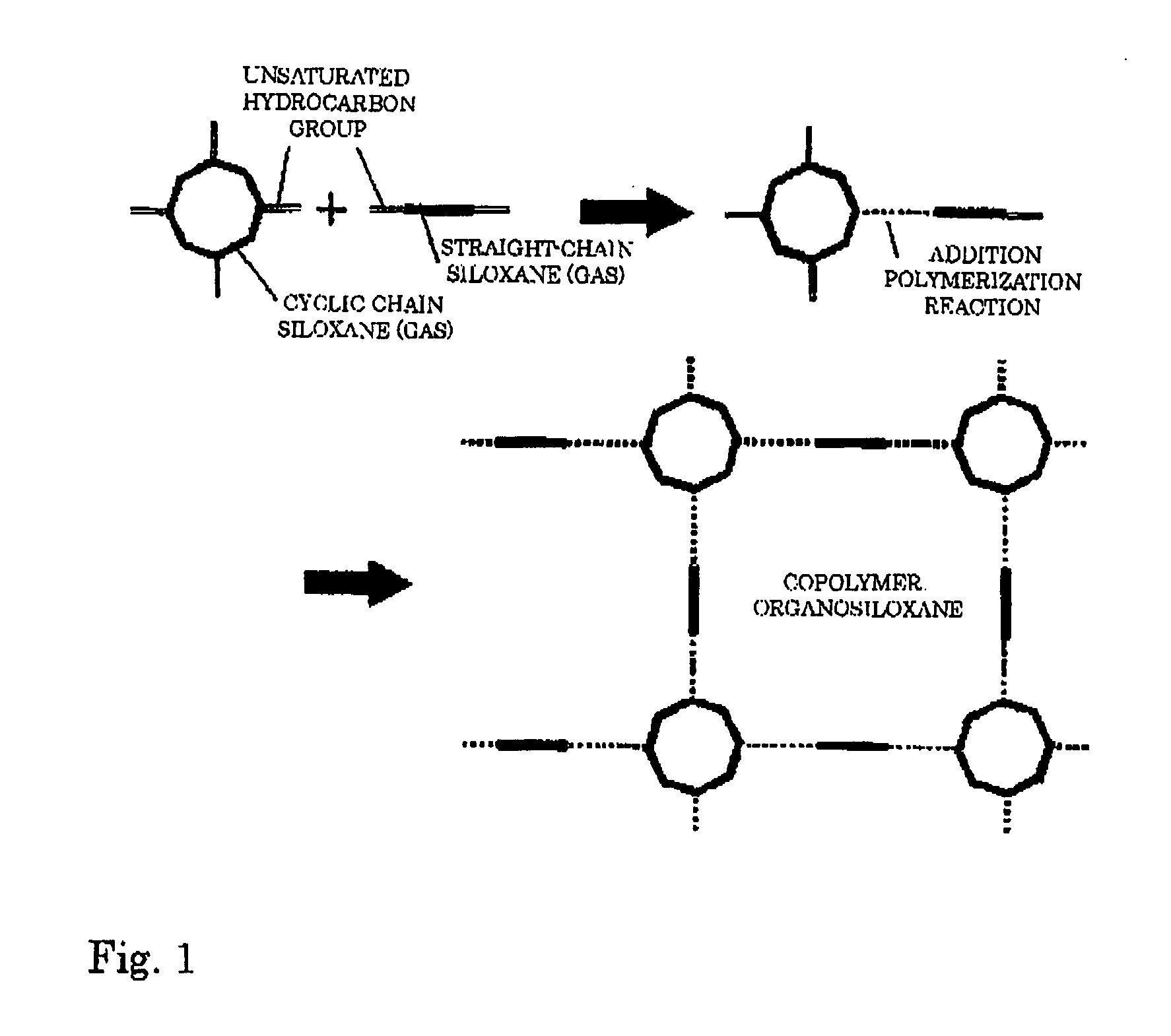

Organic siloxane copolymer film, method and deposition apparatus for producing same, and semiconductor device using such copolymer film

ActiveUS20050267253A1Improve film qualityHigh bridge densityVacuum evaporation coatingSputtering coatingDielectricCopper-wiring

An insulated organic copolymer is provided, having the excellent mechanical strength and deposition property at an interface contacting the lower base or the upper layer of the inorganic insulation film, and the effective dielectric constant is low as the whole film, which is suitable as the interlayer insulation film that separates the multi-layer copper wirings of the semiconductor device. The organosiloxane copolymer film is obtained by the polymerization of the cyclosiloxane and the straight-chain siloxane as the raw materials by the plasma excitation of both. At the interfaces contacting the inorganic insulation films, the interface layers having a film quality that is intricate and excellent in deposition property are prepared whereby the main component of the film composition is the straight-chain siloxane. The inner section of the copolymer film mixes the cyclosiloxane component having pores surrounded by the cyclosiloxane backbone and the straight-chain siloxane components, has the network structure layer relatively suppressing the density, and has the composition changing in the thickness direction whereby the multi-layer wirings embedding the copper thin film is formed.

Owner:GK BRIDGE 1

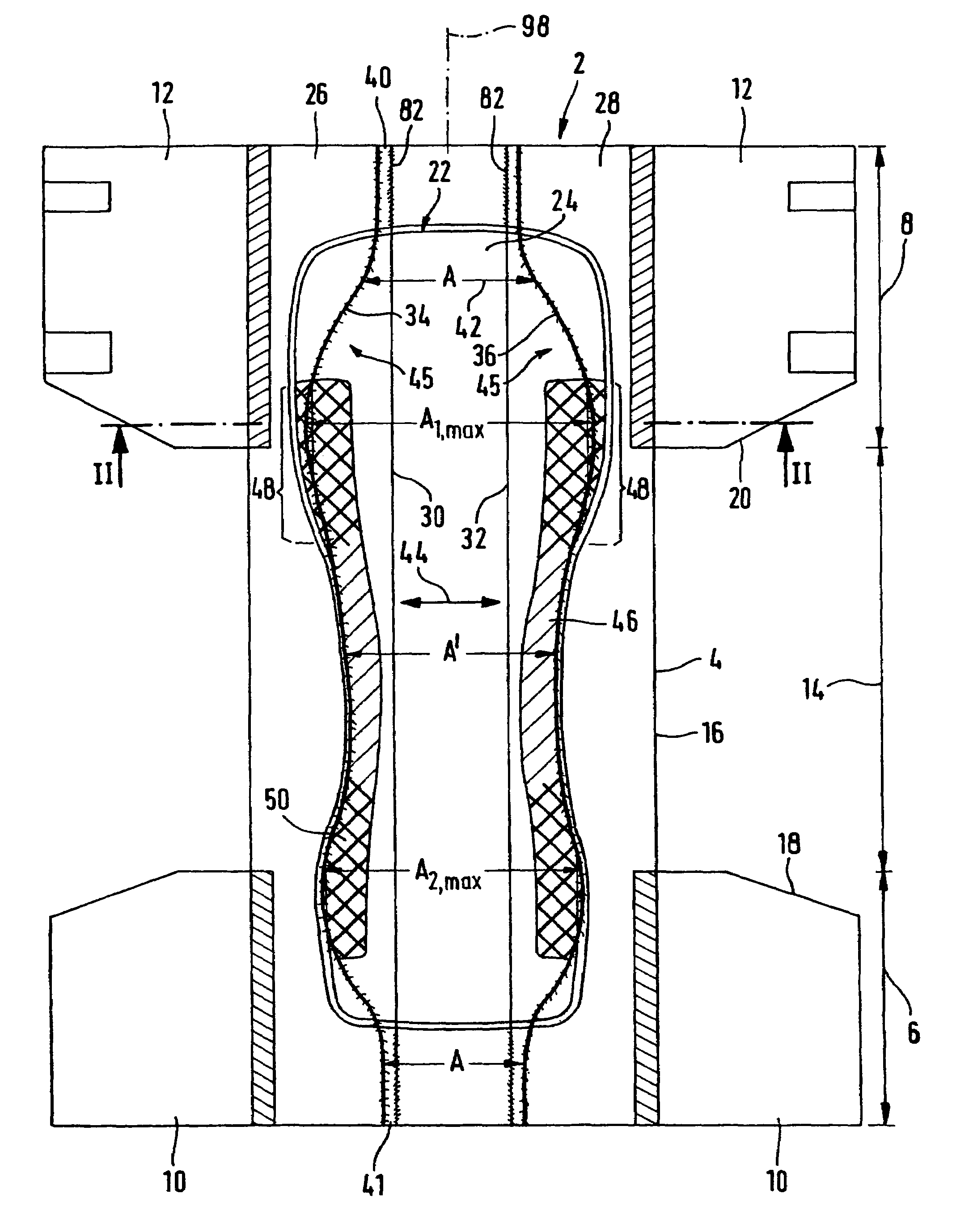

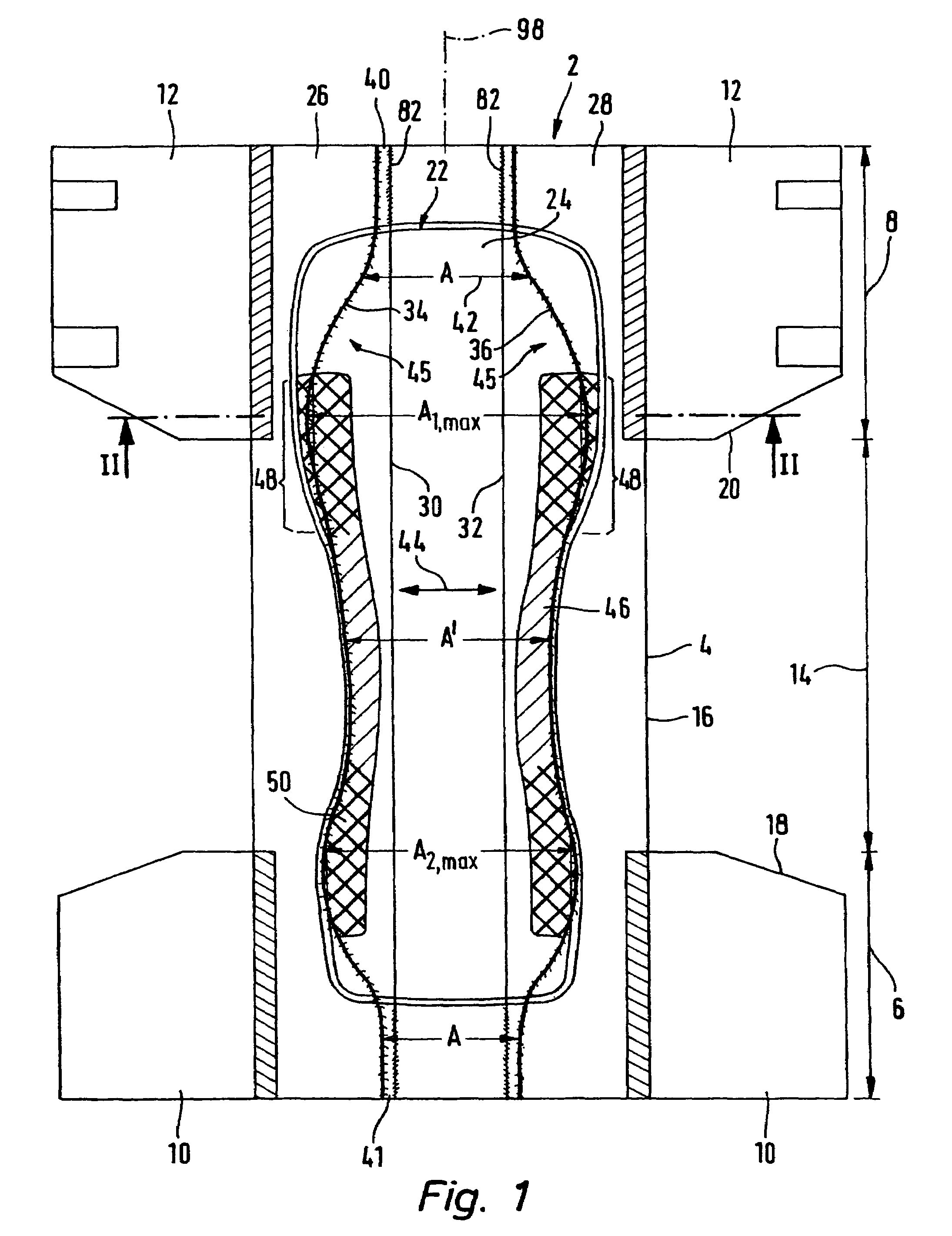

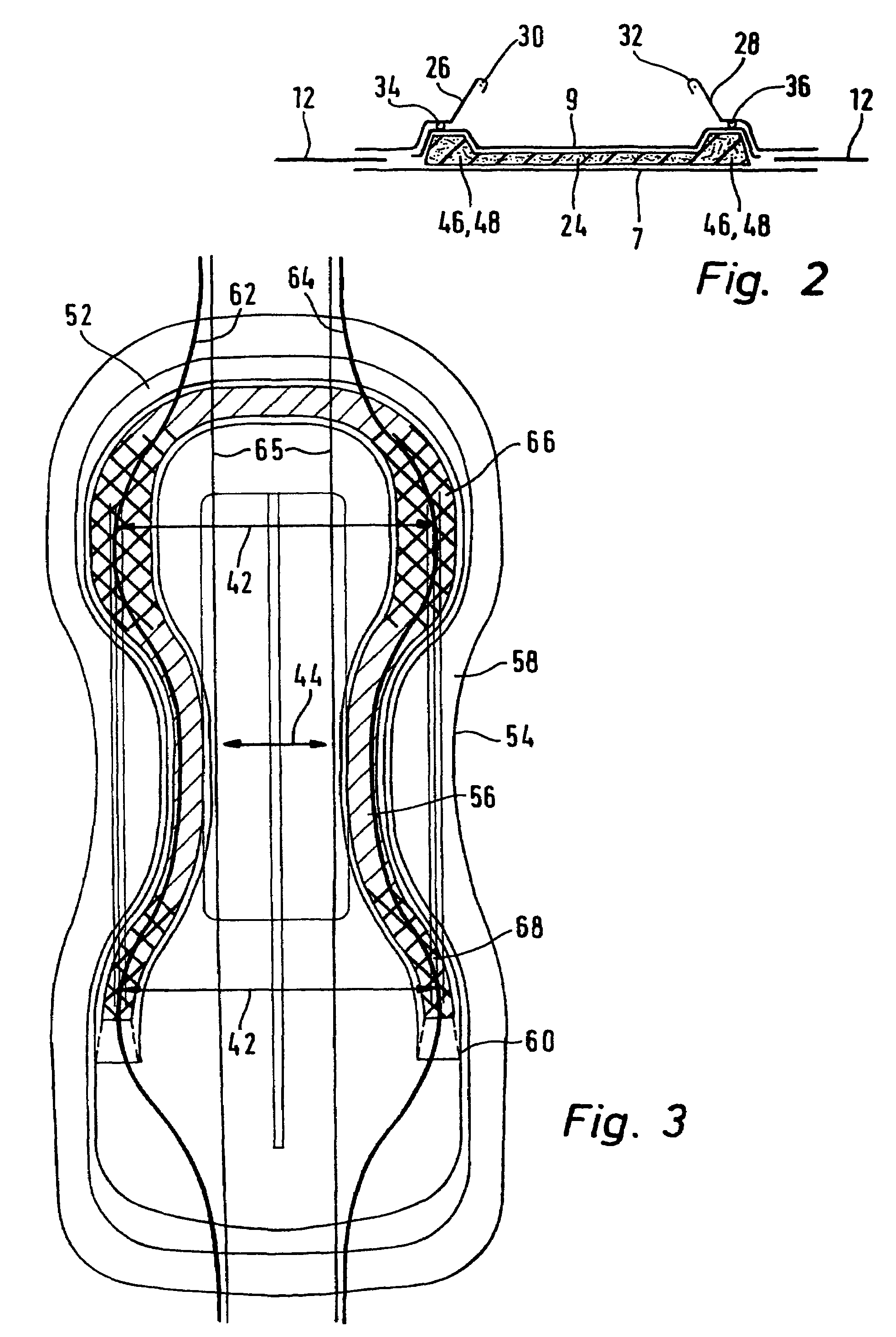

Single-use hygiene article

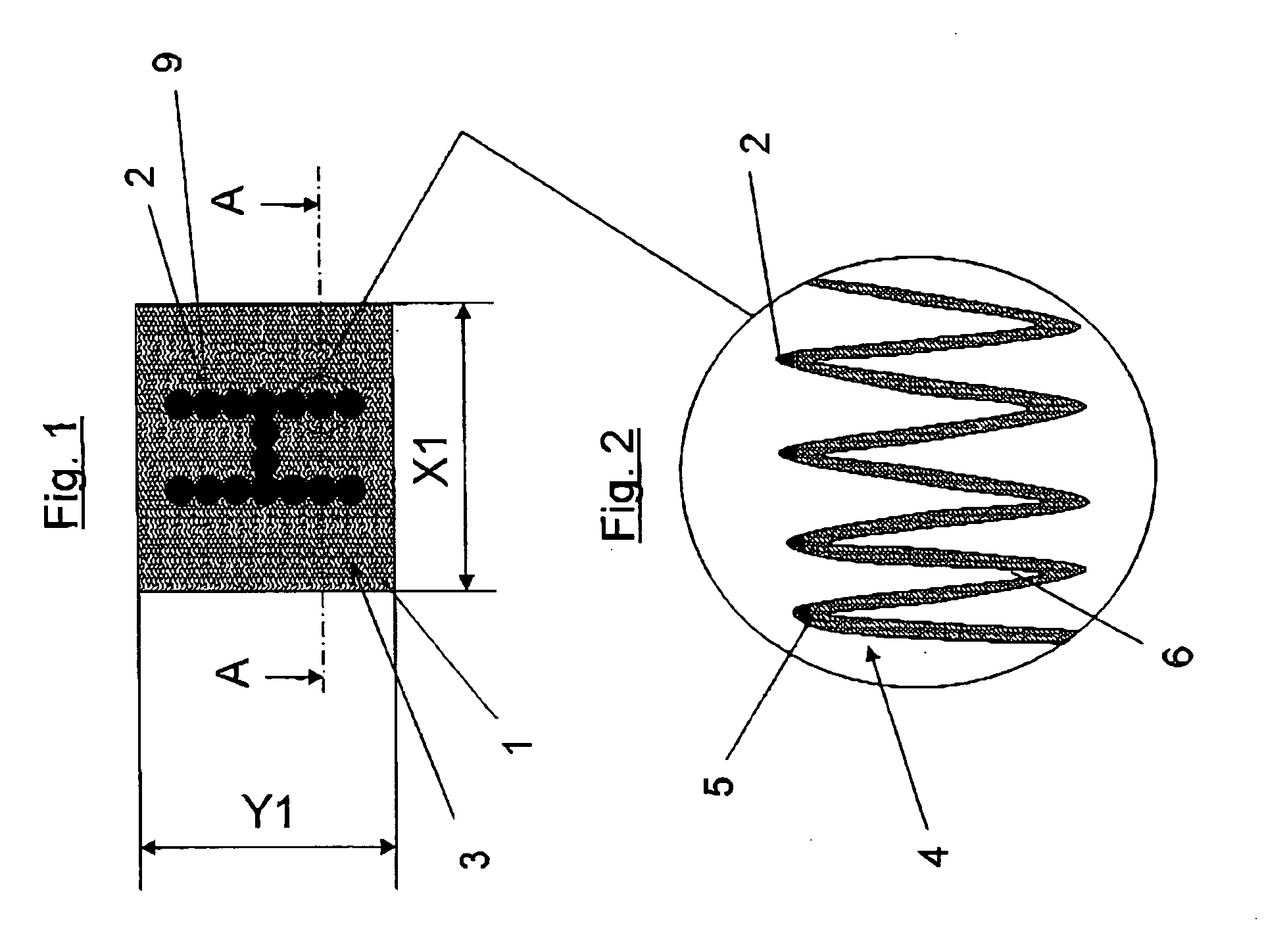

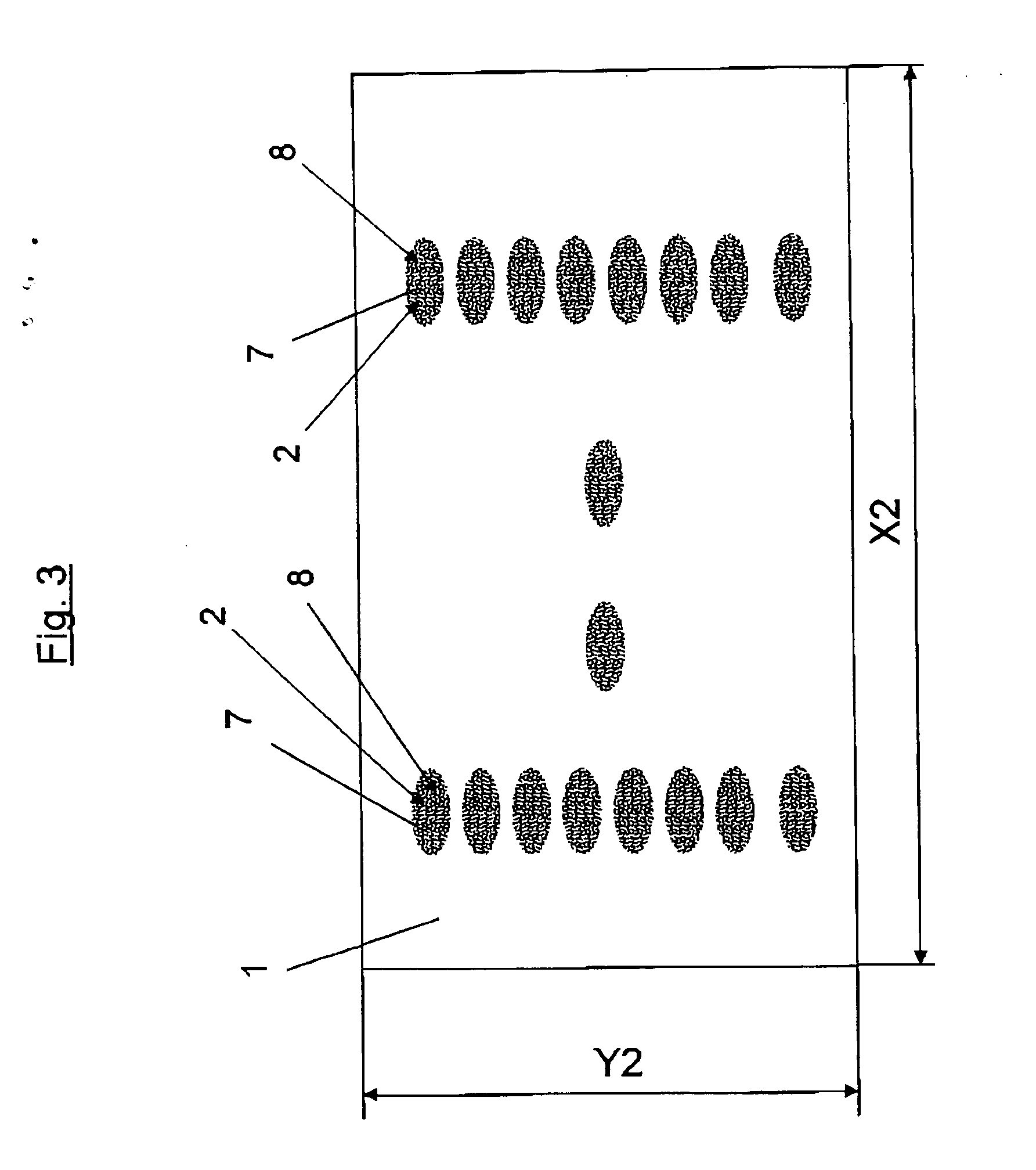

InactiveUS7482505B2Improved and reliable liquid retention propertyIncrease surface densitySanitary towelsBaby linensMedicineAbsorbent material

The invention relates to a single use hygiene article, comprising an absorbing body layer (24, 60, 70), which serves to store body fluids and which can also contain superabsorbent materials, and comprising standing cuff elements (26, 28), which extend in an essentially longitudinal direction, form a lateral leakage barrier and which are attached to the body-facing side of the article at least along a cuff base line (34, 36; 62, 64; 76, 78). The cuff elements (26, 28) are guided with variable distances between the cuff base lines (34, 36; 62, 64; 76, 78). The aim of the invention is to improve the absorption characteristics of the hygiene article. Towards this end, the article is designed in such a manner that the absorbing body layer (24, 60, 70) comprises, in a transversal direction (44) of the hygiene article up to the lateral edges (16) and / or in a longitudinal direction (38) up to at least one longitudinal end (40), an increasing mass per unit area of an absorbent material of this layer. In addition, the area (46, 56, 74) of the greater mass per unit area has at least one partial area (48, 66) in which the distance (42) of the cuff base lines (34, 36; 62, 64; 76, 78) from one another is greater that outside this partial area (48, 50, 66, 68).

Owner:PAUL HARTMANN AG

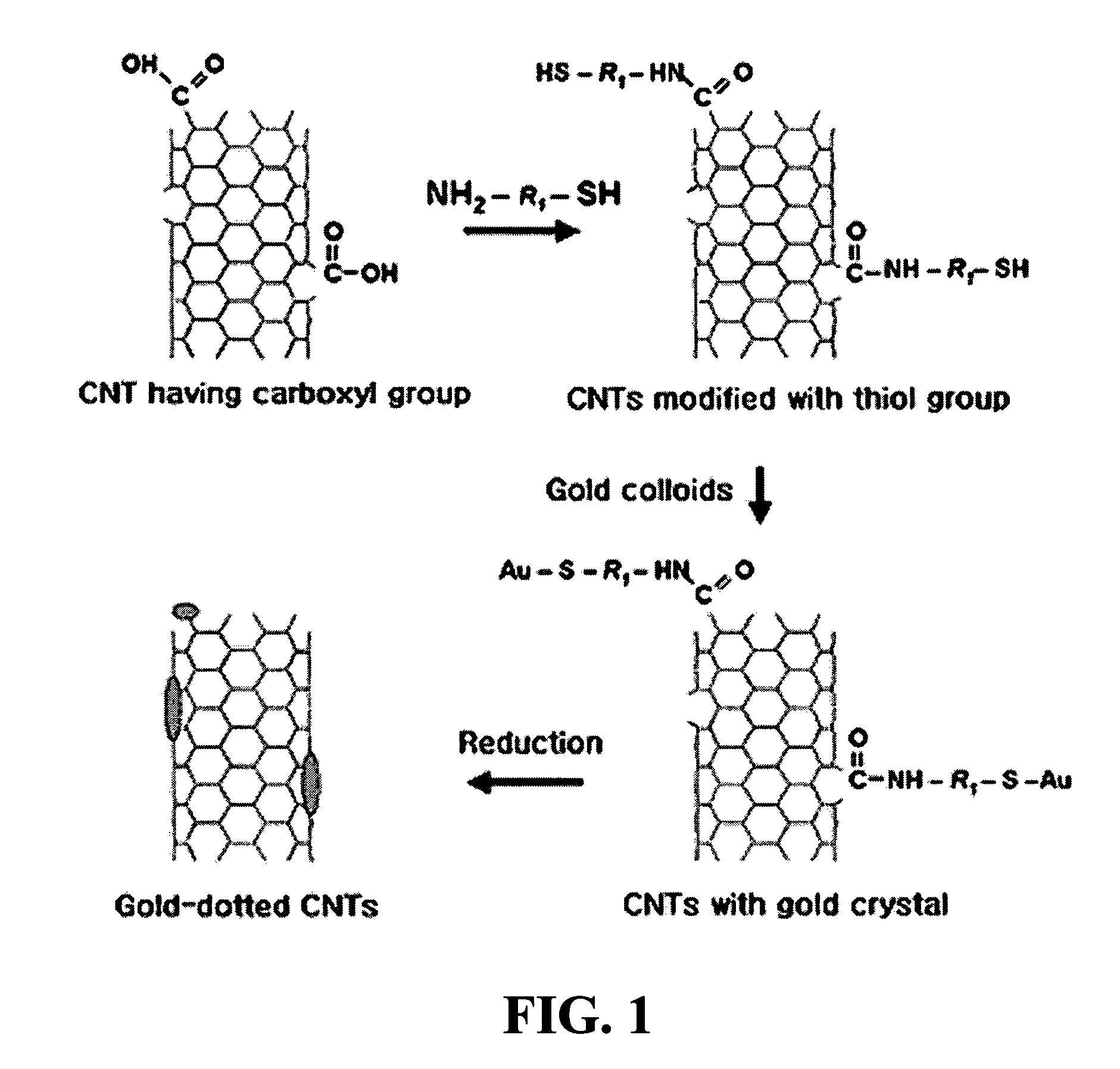

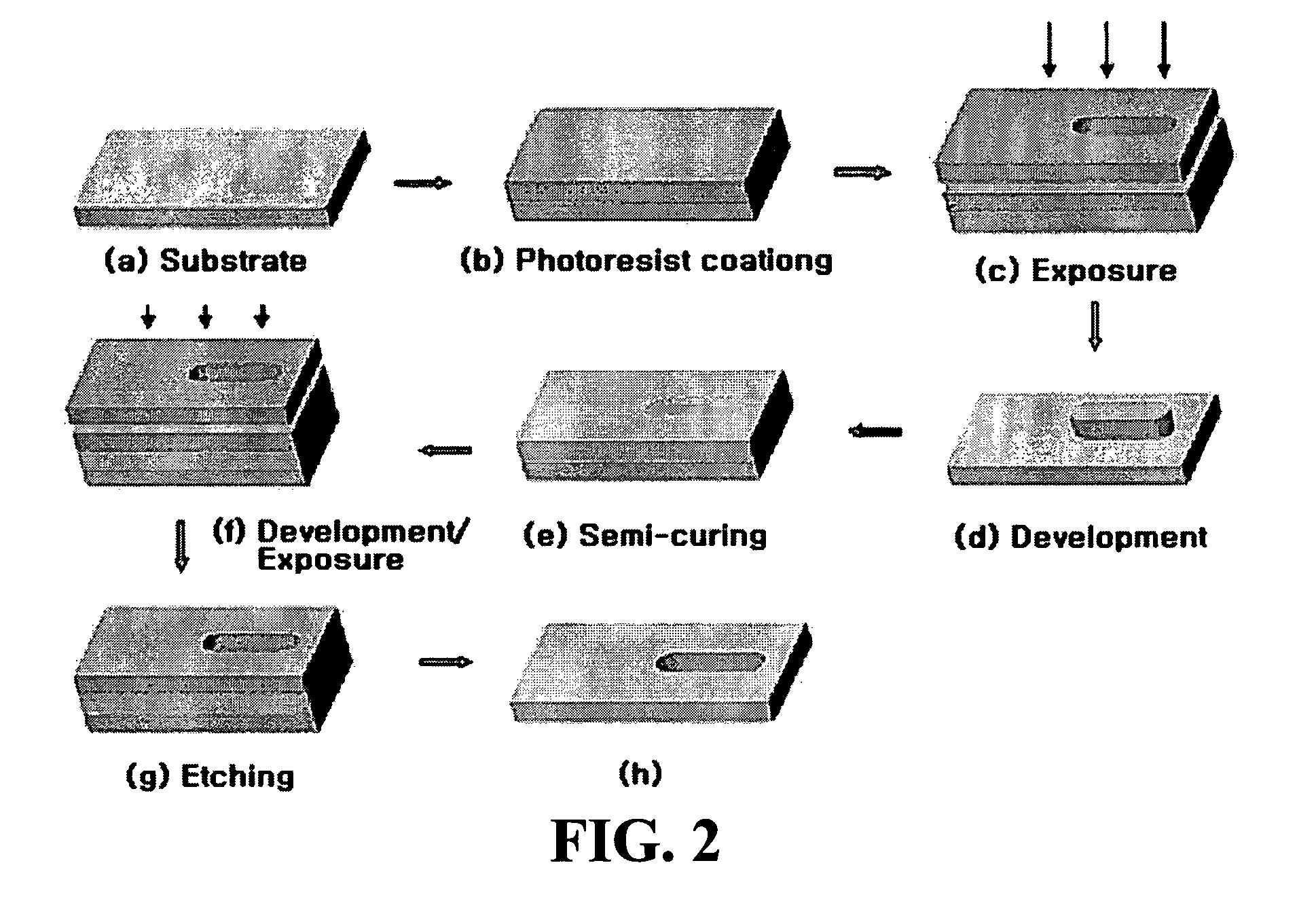

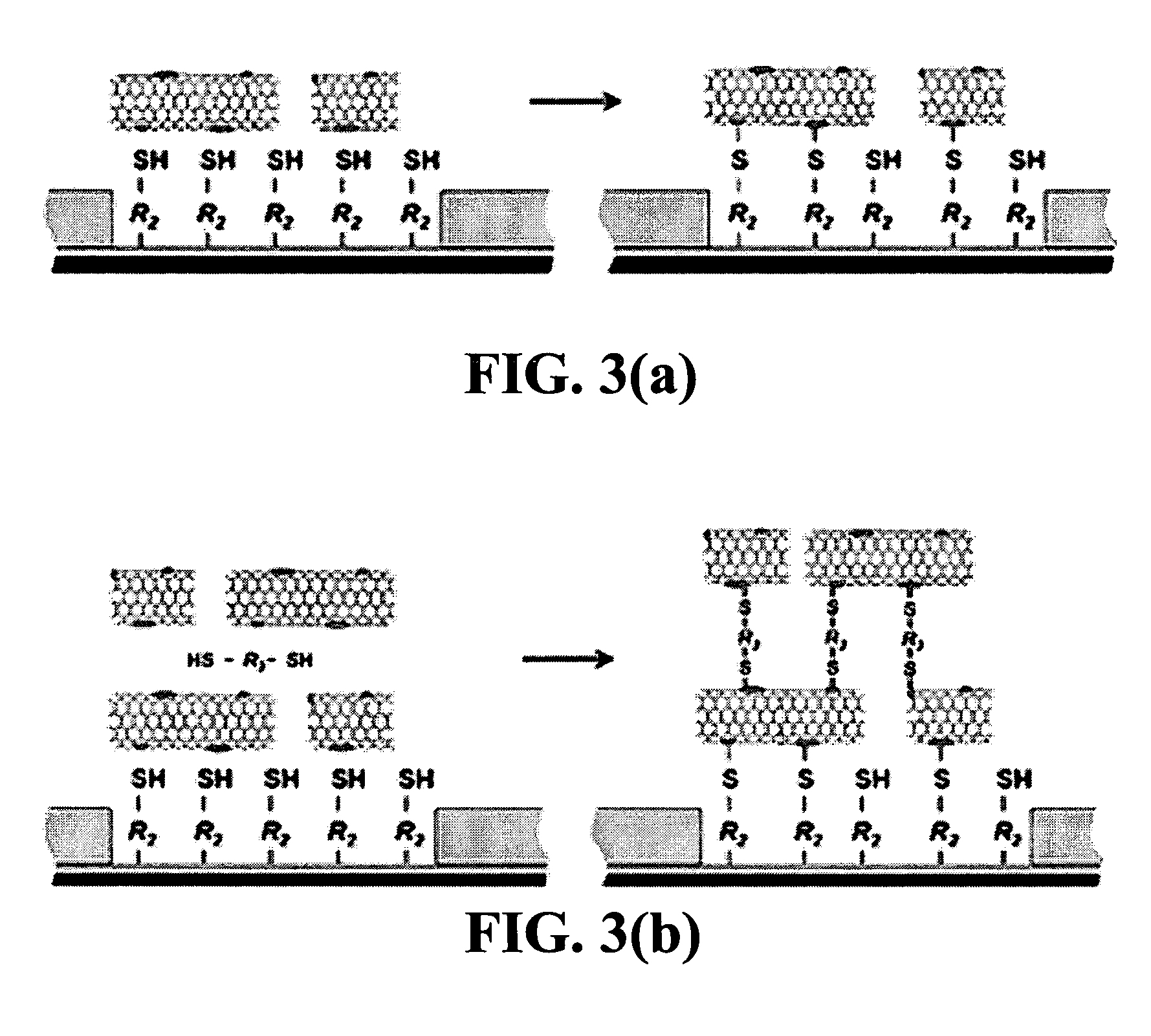

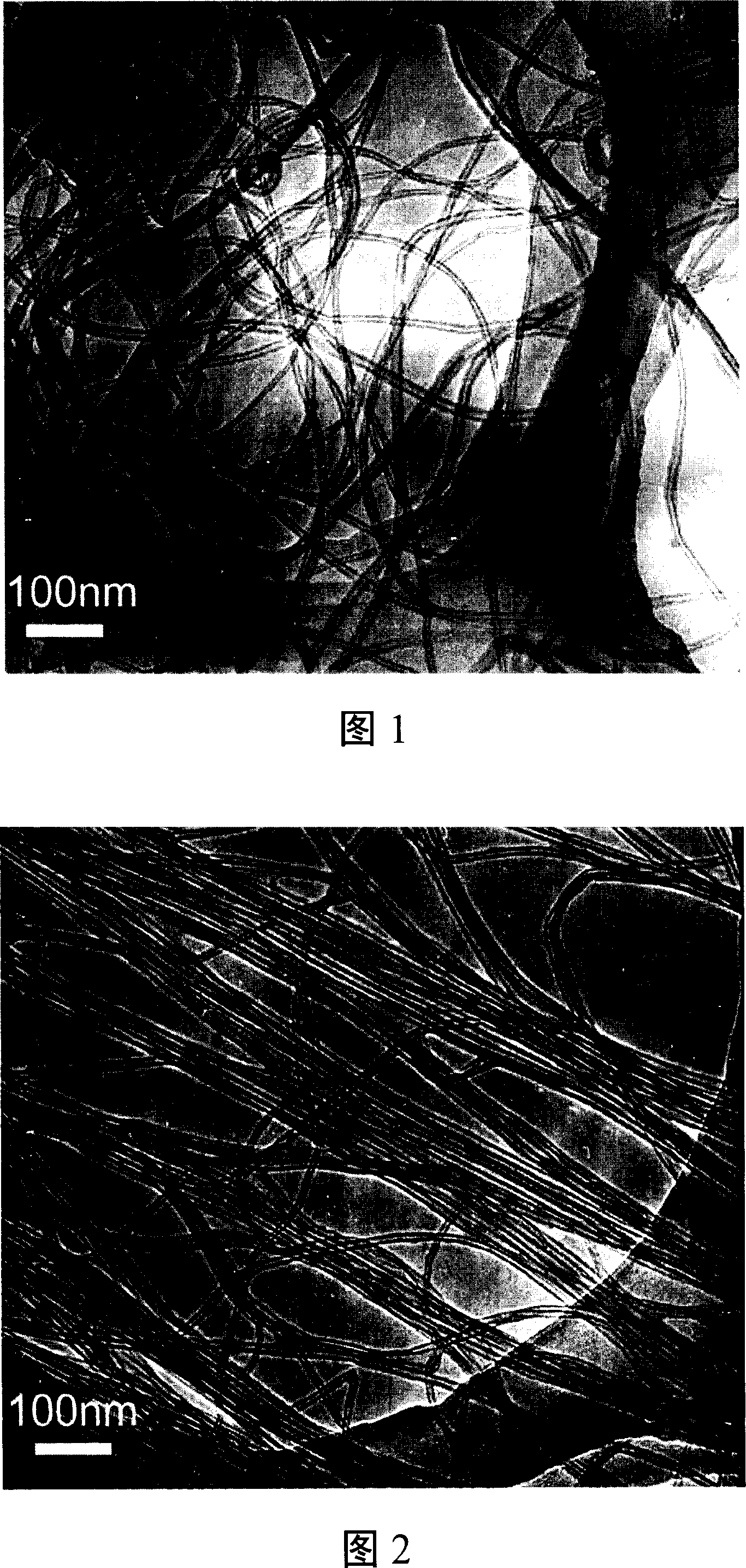

Conductive carbon nanotubes dotted with metal and method for fabricating a biosensor using the same

InactiveUS7670831B2Increase surface densityImprove conductivityMaterial nanotechnologyBioreactor/fermenter combinationsSource materialCarbon nanotube

Conductive carbon nanotubes (CNTs) obtained by dotting carboxylated CNTs with metal nanocrystals by chemical functional groups, are described, as well as a method for fabricating a pattern or film of the conductive CNTs which involves repeatedly depositing conductive CNTs on a substrate to achieve high surface density. A biosensor is described, in which bioreceptors that bind to target biomolecules are selectively attached to conductive CNTs or a conductive CNT pattern or film. By use of the conductive biosensor, various target biomaterials that bind or react with the bioreceptors can be precisely measured directly or by electrochemical signals at large amounts in one step. Additionally, the biosensor can be used for an electrical detection method capable of providing precise measurement results even with a small amount of source material.

Owner:KOREA ADVANCED INST OF SCI & TECH

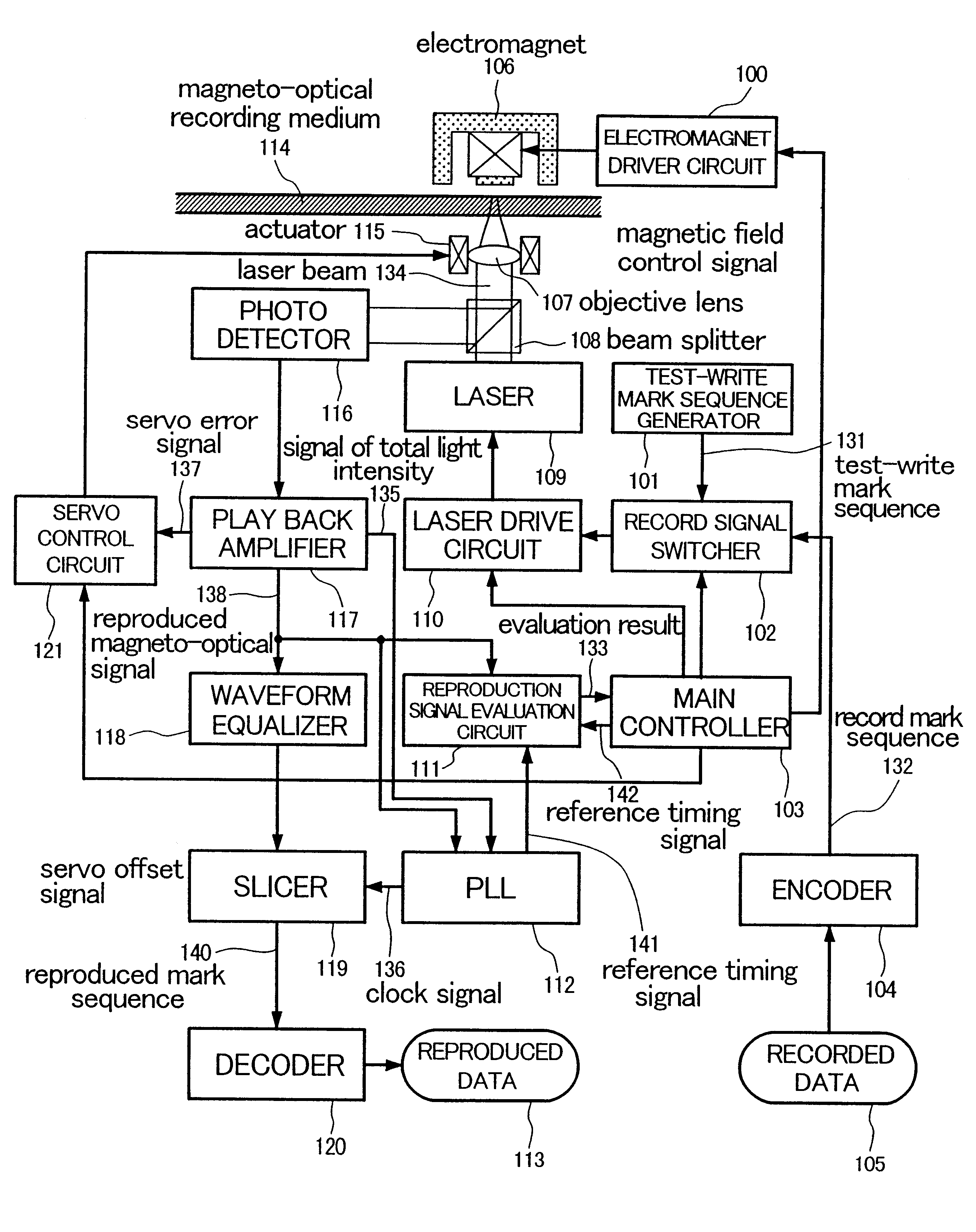

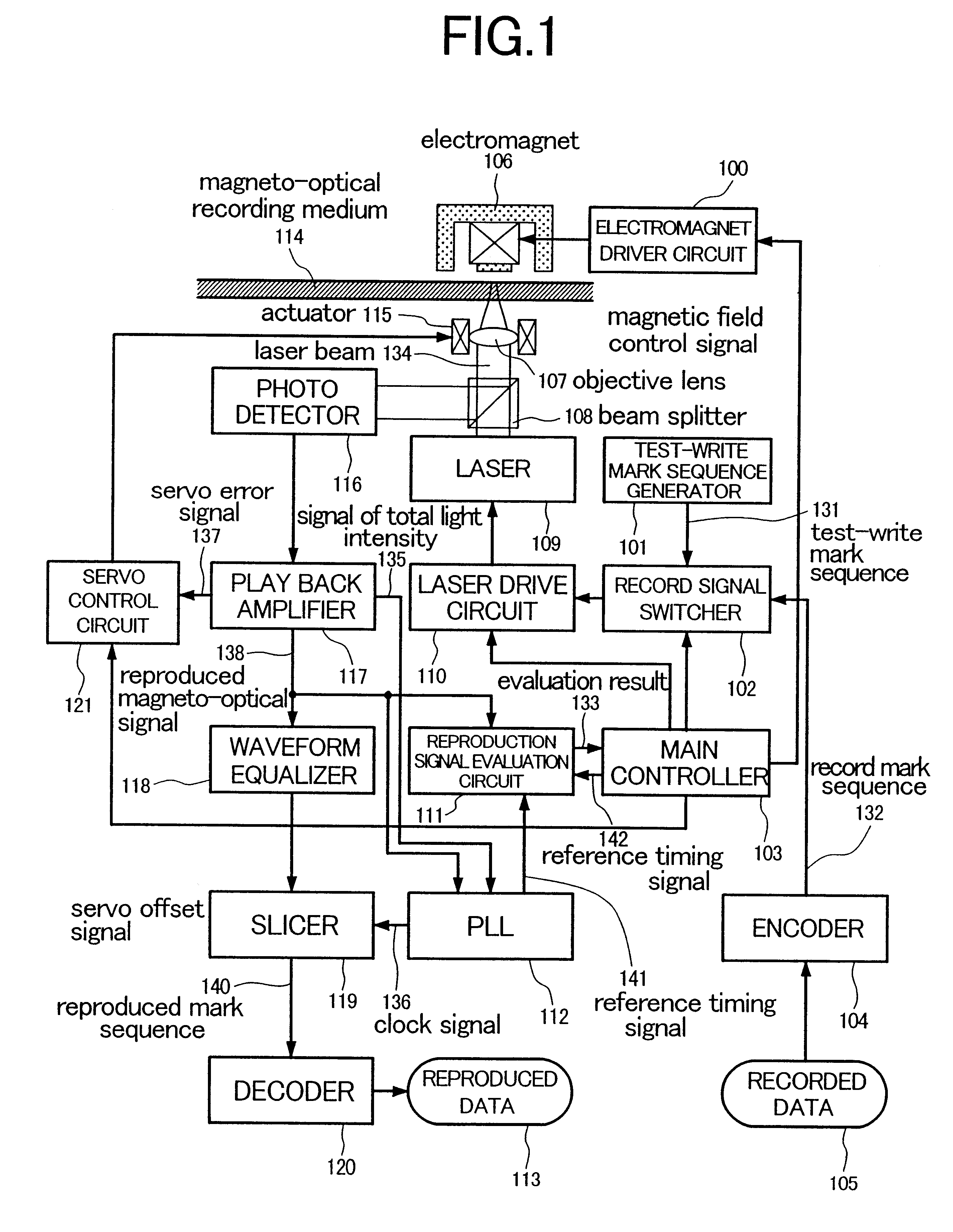

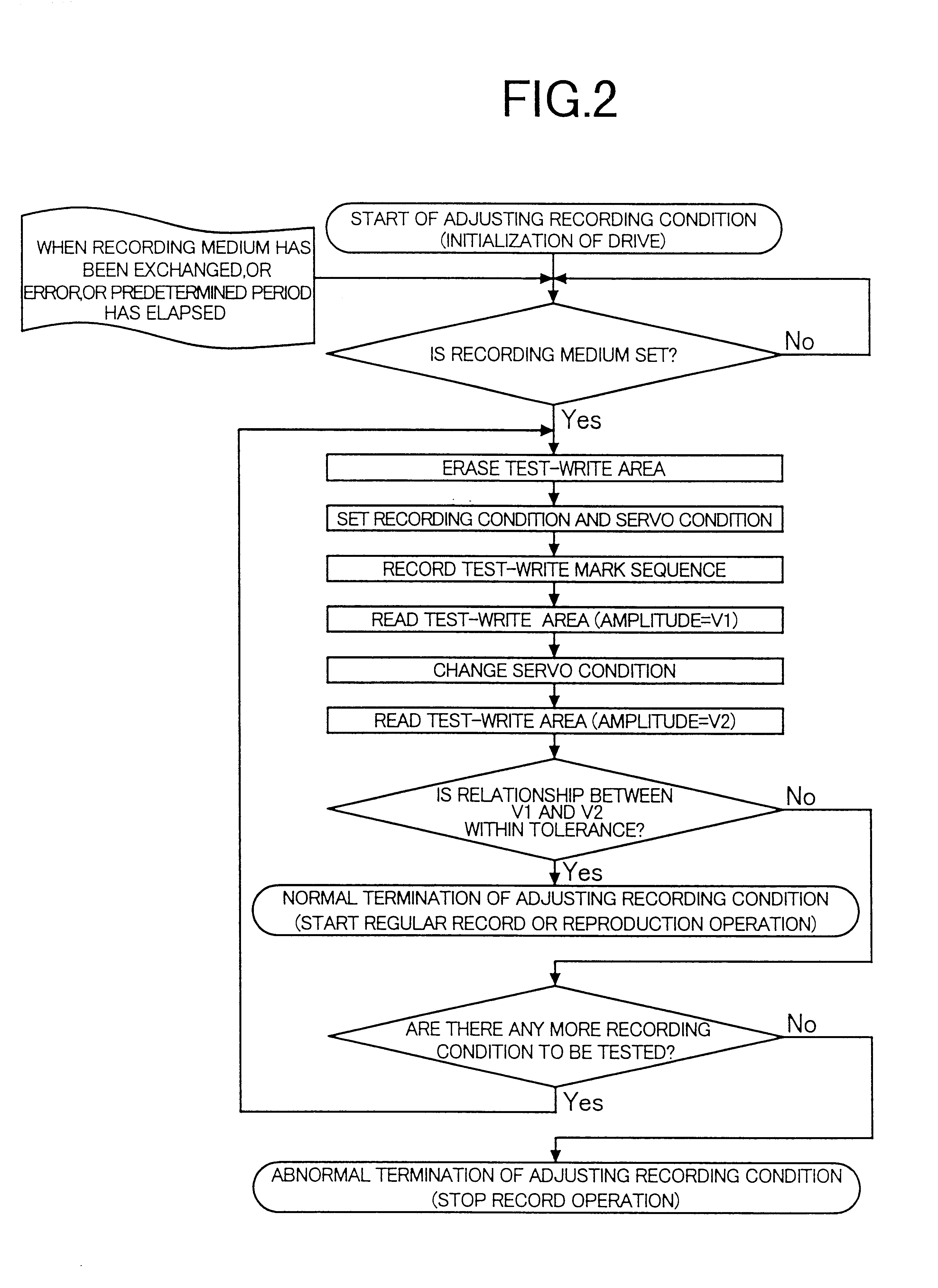

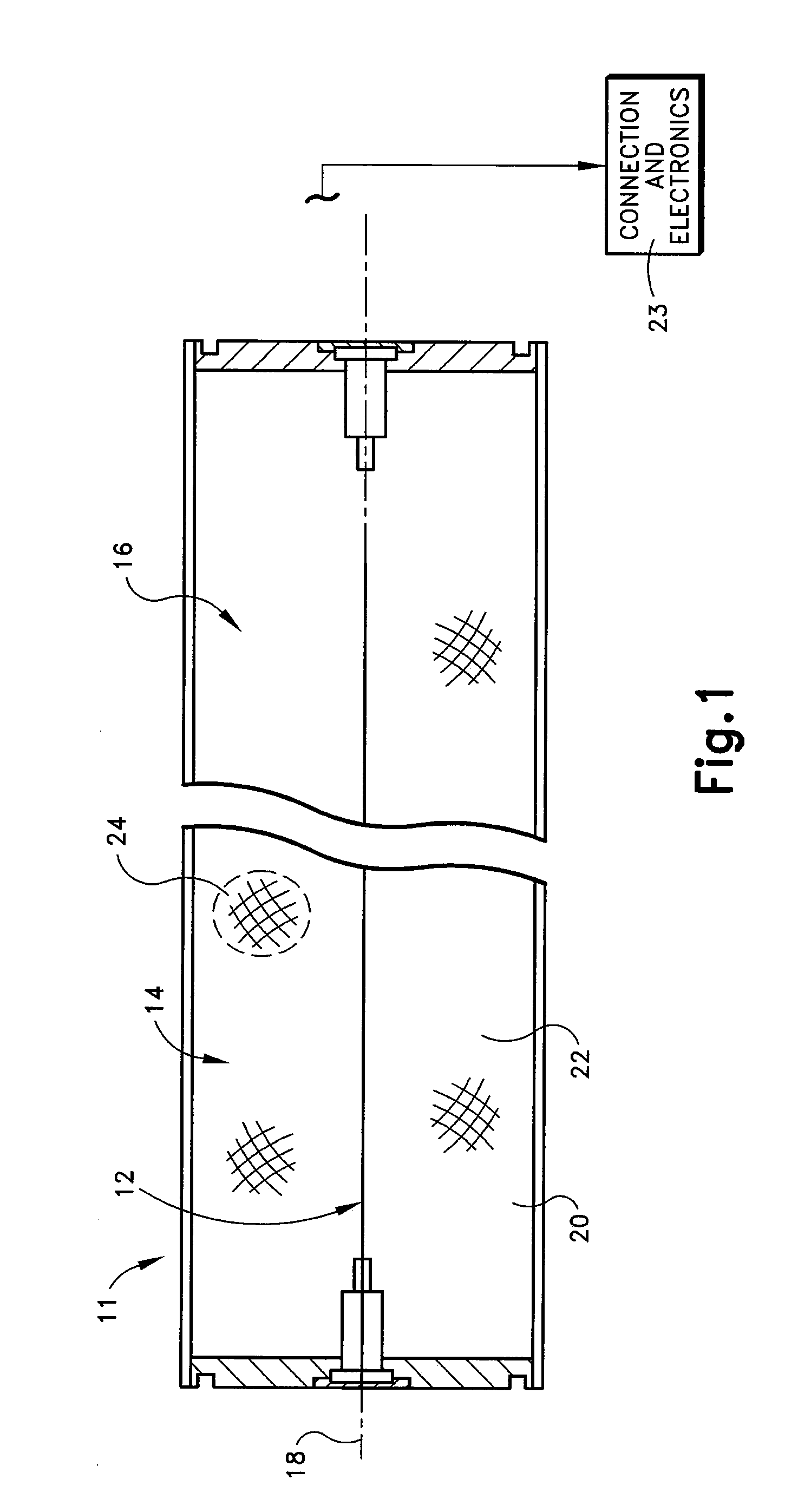

Information recording apparatus

InactiveUS6678220B1Variation of the mark shapeReduce variationOptical beam sourcesRecord information storagePosition controlIrradiation

An information recording apparatus includes an energy generation device for generating recording energy; a position control device for controlling a position of irradiation on the recording medium with an output of the energy generation device; a drive device for driving the energy generation device; a switching device for switching information based on user data and test information to supply the two kinds of information selectively to the drive device; a reading device for reading the marks recorded on the recording medium; an evaluation device for evaluating a reproduced signal obtained by the reading device; and a recording condition control device for controlling a recording condition on the basis of an evaluation result obtained by the evaluation device, wherein, when the marks used for recording the test information are to be reproduced, controlling operation of the position control device is changed to be different from that used for recording the test information.

Owner:HITACHI CONSUMER ELECTRONICS CORP

Preparation method of colored surface compressive plate

InactiveCN101664949ARich textureHigh surface densityWood treatment detailsWood mortising machinesWater contentWater soluble

The invention relates to a preparation method of a colored surface compressive plate, in particular to solving the technical problem of providing a manufacturing method of a colored surface compressive plate featuring high surface layer density, dimensional stability, strong operability and diverse colors which are close to the colors of natural precious wood. The technical scheme for solving theproblem is as follows: the method comprises the following steps: (1) drying and controlling the water content between 8% and 15%; (2) notching surface layer and controlling the width of grooves between 0.5mm and 1.0mm; (3) dipping dye, namely soaking part of the surface layer with notches of the plate into water-soluble dye solution at concentration of 0.5-2.0% for impregnation; (4) softening andcontrolling the softening temperature between 120 DEG C and 140 DEG C; (5) compressing surface and controlling the compression ratio between 15% and 50%, the hot pressing temperature between 160 DEG Cand 180 DEG C and the unit pressure between 1.5MPa and 4.5MPa; and (6) setting. The method is suitable for such fields as furniture manufacturing, indoor decoration and the like.

Owner:ZHEJIANG FORESTRY UNIVERSITY

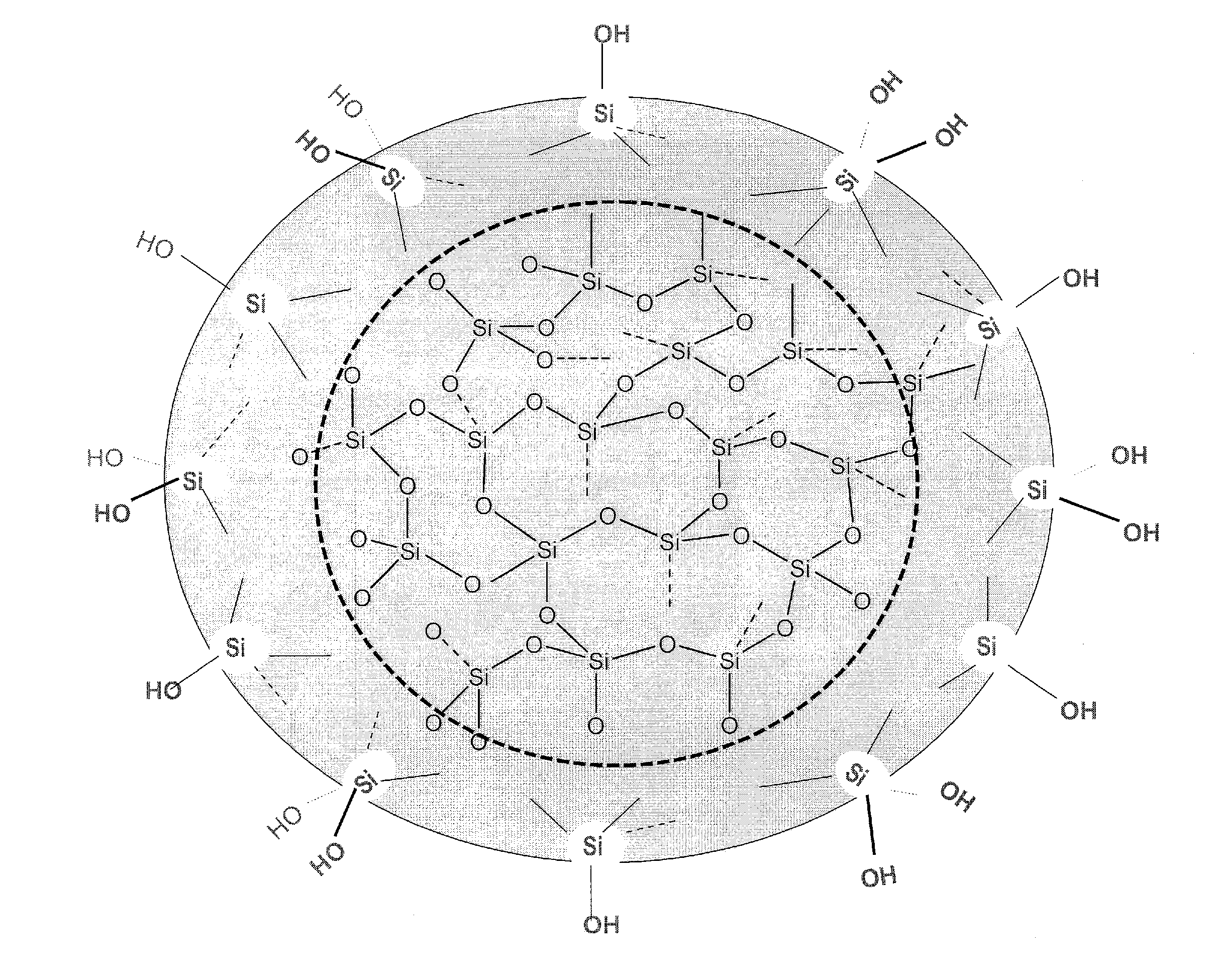

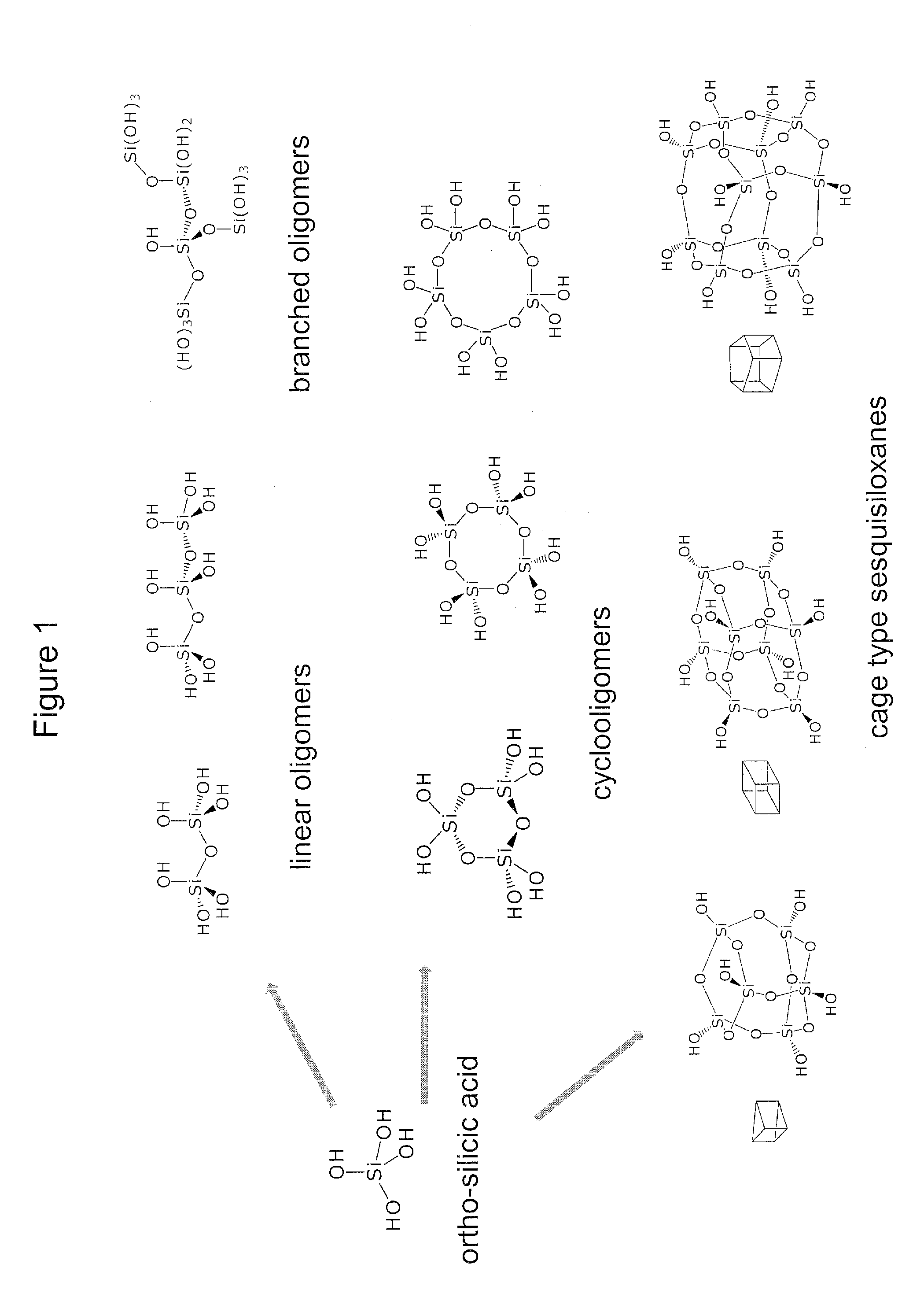

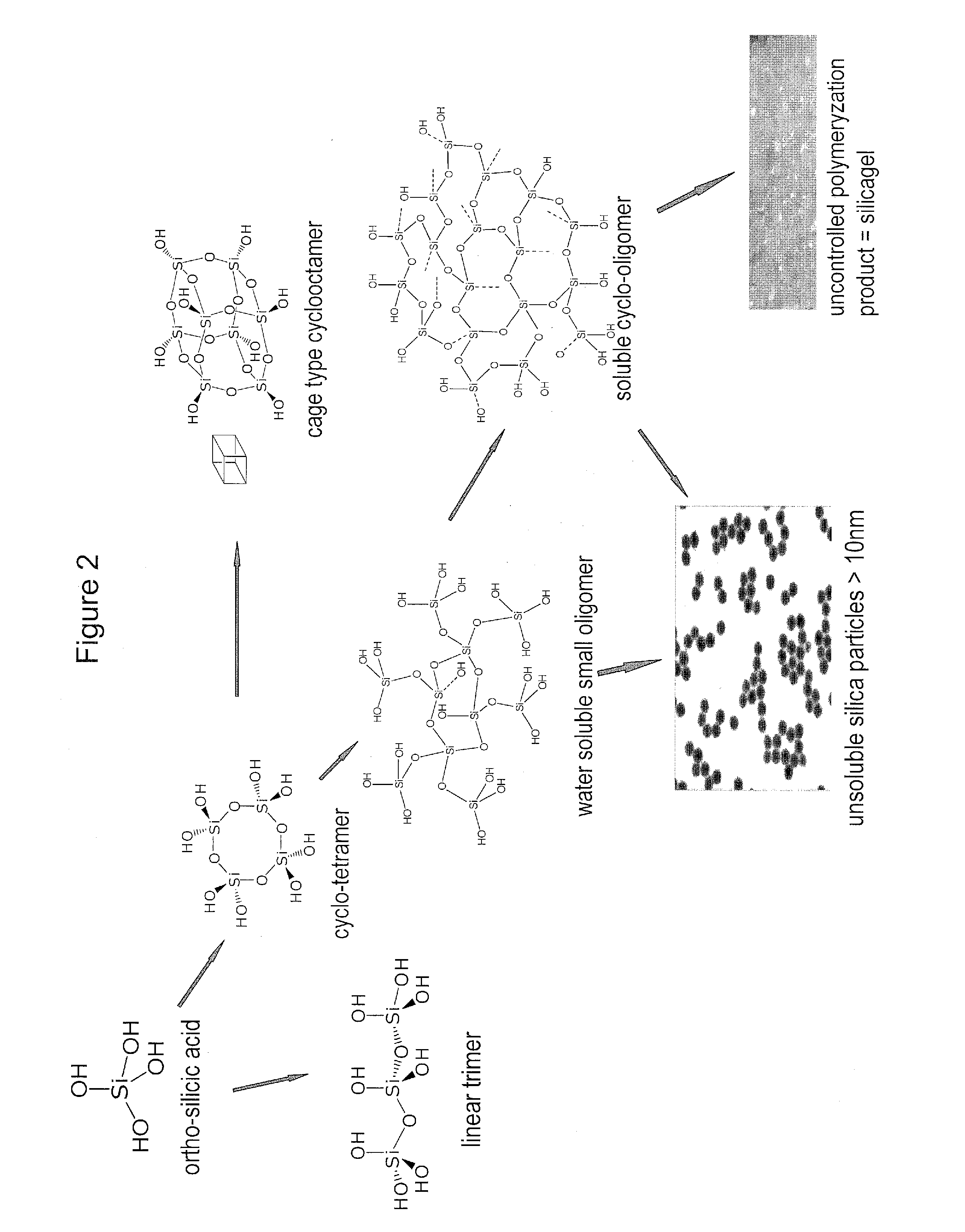

Biologically active silicic acid

The present invention relates to low-molar mass condensed derivatives of silicic acid of sub-nano particle size characterised by particular structure and specific biological activities. Preparation methods and applications are presented for the here disclosed sub-nano silicic acid (SNSA) which interact with bio-molecules and modify significantly their structure and biological function. Preferred field of application of the inventive silicic acid derivatives is to modulate the structure and biological function of proteins particularly of those involved in reversible phosphorylation within biological signal transduction or membrane transport processes. Structure of the substances, methods for the preparation and stabilization, as well as pharmaceutical compositions comprising the substances and methods of application in the prevention, diagnosis and therapy of diseases are disclosed.

Owner:SINATUR

Anti-reflective film-plating liquid and preparation method thereof, photovoltaic glass and preparation method of photovoltaic glass, and solar cell module

ActiveCN104671672AReduce reflectivityLong-term stabilitySemiconductor devicesTotal solid contentPhysical chemistry

The invention provides an anti-reflective film-plating liquid comprising a dispersion type silica sol, a hollow silica sol, a linear sol, an additive and a solvent; with the total solid content of the anti-reflective film-plating liquid as a benchmark, the content of the dispersion type silica sol is 30-60 wt%, the content of the hollow silica sol is 30-60 wt%, and the content of the linear sol is 10-40 wt%; with the total mass of the anti-reflective film-plating liquid as a benchmark, the content of the additive is 0.2-2 wt%; the average particle size of the dispersion type silica sol is less than that of the hollow silica sol. The invention also provides a preparation method of the anti-reflective film-plating liquid, photovoltaic glass prepared from the anti-reflective film-plating liquid, a preparation method of the photovoltaic glass, and a solar cell module containing the photovoltaic glass. An anti-reflective film prepared by the anti-reflective film-plating liquid has high permeability improvement rate, good wear resistance, high pencil hardness and good salt fog performance.

Owner:BYD CO LTD

Preparation method of molybdenum-niobium alloy sputtering target

ActiveCN105441884AEasy to prepareSave raw materialsVacuum evaporation coatingSputtering coatingHot isostatic pressingSurface grinding

The invention discloses a preparation method of a molybdenum-niobium alloy sputtering target. The method comprises the following steps: (1) molybdenum powder and niobium powder are put in a mixing tank of a mixing machine for uniformly mixing to obtain mixed powder; (2) the cold isostatic pressing is performed for the mixed powder to obtain a slab; and the slab is pre-sintered under the vacuum or hydrogen atmosphere protection condition to obtain a molybdenum-niobium alloy prefabricated blank; (3) the surface of the molybdenum-niobium alloy prefabricated blank is turned and milled; and the hot isostatic pressing is performed to obtain a molybdenum-niobium alloy part; and (4) the mechanical processing and the surface grinding are performed for the molybdenum-niobium alloy part to obtain the molybdenum-niobium alloy sputtering target. The preparation method is simple in process, and saves raw materials; the introduction of impurity elements can be reduced in the preparation process; the prepared molybdenum-niobium alloy sputtering target is uniform in components, free of segregation and fine in grains; the theoretic density can reach above 99%; the oxygen mass content is lower than 500 ppm; and the requirements of the sputtering target can be preferably satisfied.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Neutron sensitivity by increasing boron surface area

ActiveUS20100258736A1Increase surface densityMaterial analysis by optical meansNeutron radiation measurementBoronNeutron

Owner:BAKER HUGHES INC

Surface treatment method of amorphous alloy

InactiveCN103993314AConsistent colorConsistent textureAnodisationSuperimposed coating processAluminum metalAluminium oxides

The invention relates to the technical field of amorphous alloy and in particular relates to a surface treatment method of amorphous alloy. The method comprises the following steps: 1, performing cold spraying, namely spraying an aluminum layer or an aluminum alloy layer to the surface of the amorphous alloy by adopting a cold spraying process to obtain a semi-finished product; 2, performing anodizing treatment, namely performing anodizing treatment on the aluminum layer or the aluminum alloy layer in the semi-finished product obtained in the step 1 to enable an aluminum oxide film to be formed on the surface the aluminum layer or the aluminum alloy layer to obtain a finished product. According to the method, the treated amorphous alloy product can be perfectly matched with an aluminum alloy product in appearance, and the appearance requirements of industrial design are met; moreover, compared with a PVD (physical vapor deposition) technology, the method has the characteristics that the appearance requirements can be well met on the basis of the advantage of low cost, and the application range of the amorphous alloy is greatly expanded.

Owner:WINTOP DONGGUAN INDAL TECH

Method for preparing carbon nano tube array

ActiveCN1978315AIncrease surface densityMaterial nanotechnologyAligned nanotubesComing outCarbon nanotube

Owner:BEIJING FUNATE INNOVATION TECH +1

A high-size special-shape carbon-based composite material member and a preparing method thereof

The invention relates to a high-size special-shape carbon-based composite material member and a preparing method thereof. The member includes, by mass, 20-35% of carbon fibers, 35-75% of pyrolytic carbon and 5-15% of SiC. The preparing method includes needling the continuous carbon fibers into a prefabricated blank the density of which is 0.4-0.55 g / cm<3> according to a required shape of the member; then fixing the inner and outer surfaces of the prefabricated blank by adopting a graphite mold; and then performing high-temperature thermal treatment, a first time of carbon deposition, demolding, coarse machining, a second time of carbon deposition, graphite processing, silicon vapor bathing and finish machining in order to obtain a finished product. According to the member and the method, a problem that high-size special-shape carbon-based composite material members are liable to deform in long-time standing processes and preparing processes is overcome, and the obtained product has advantages of good mechanical performance, a low thermal expansion coefficient, high thermal conductivity, good chemical stability, and the like, is suitable for industrial production, and can be applied in the field of aviation and aerospace, the field of communication and transportation, the field of biomedicine, and the like.

Owner:CENT SOUTH UNIV

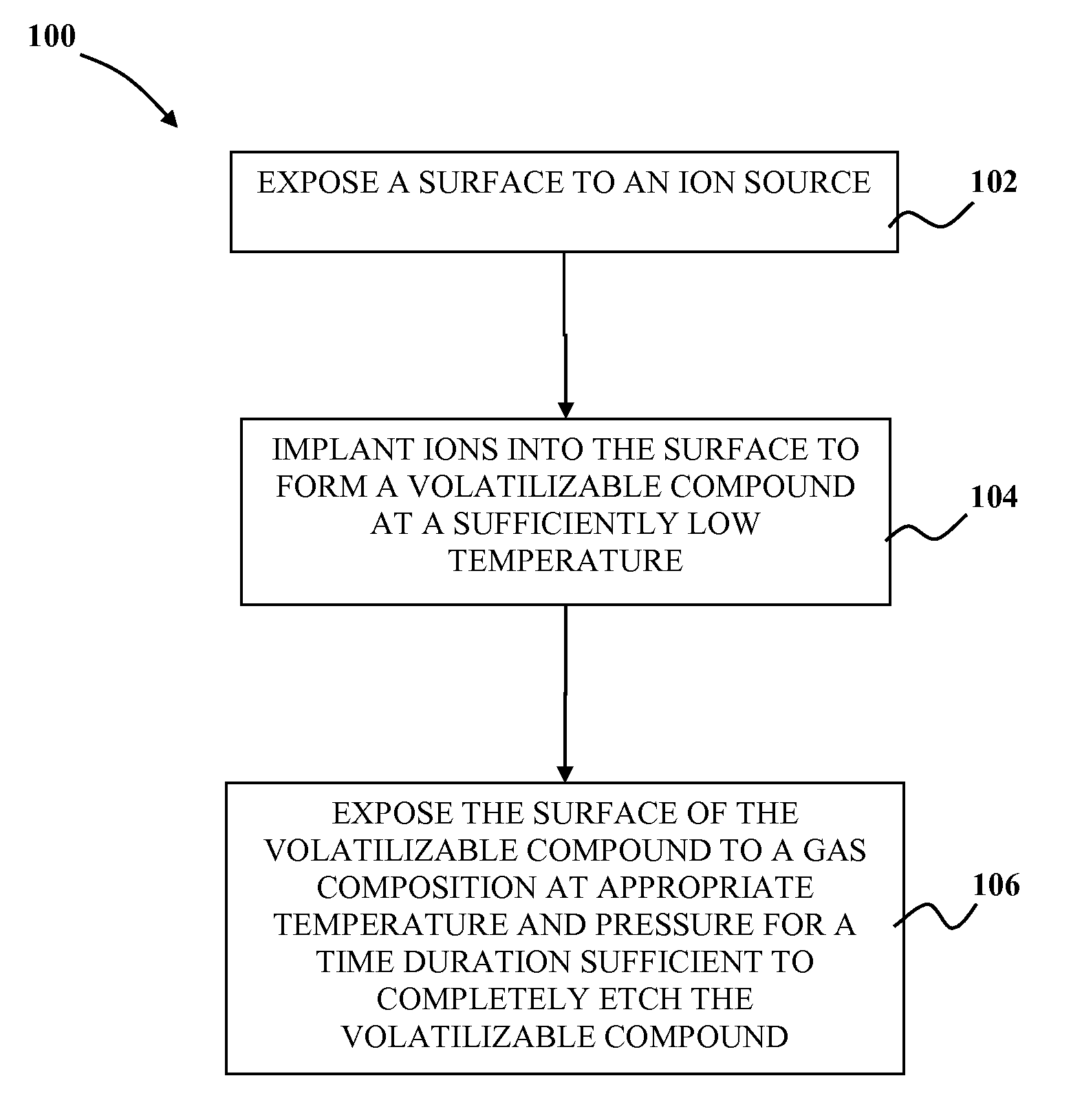

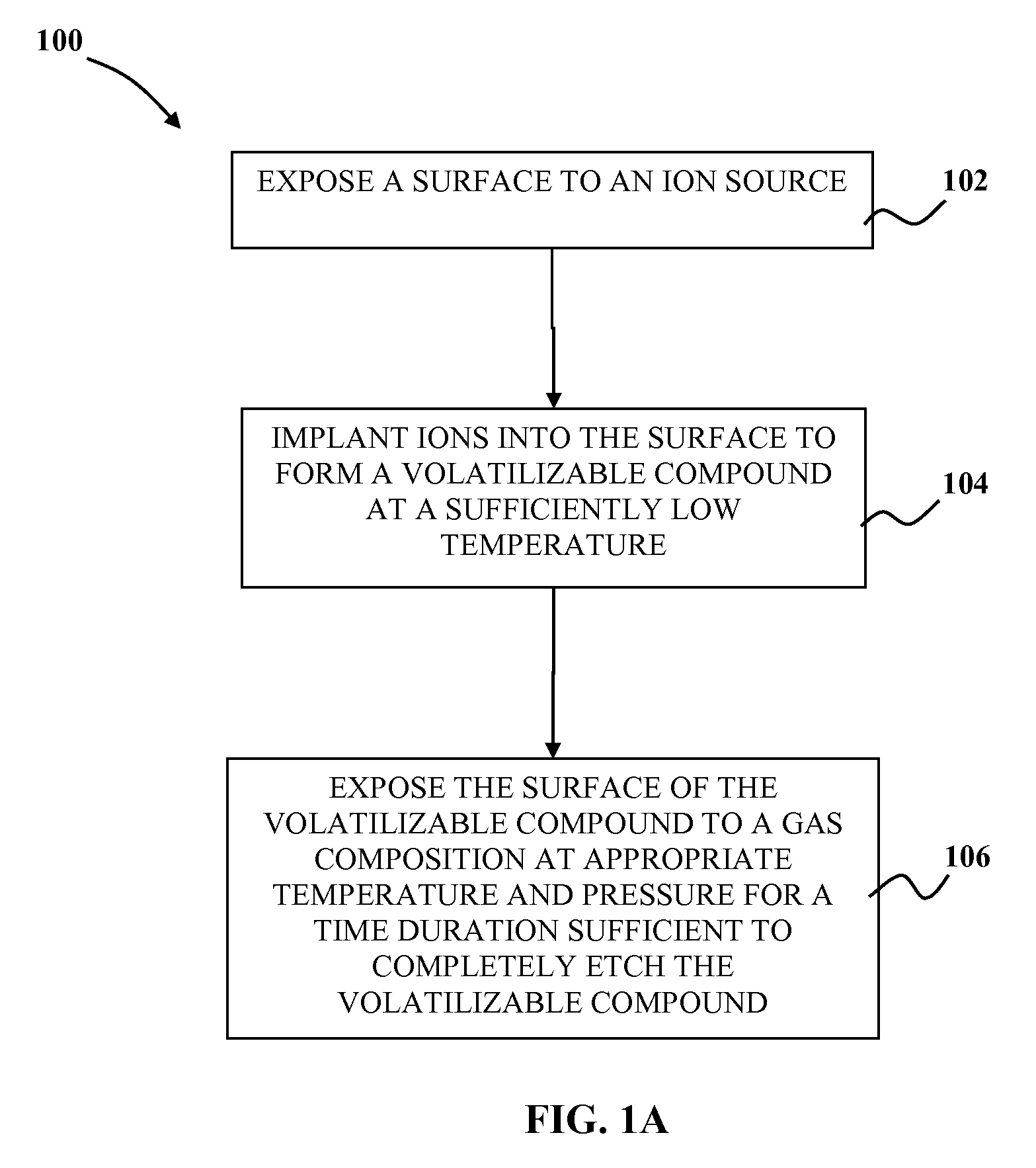

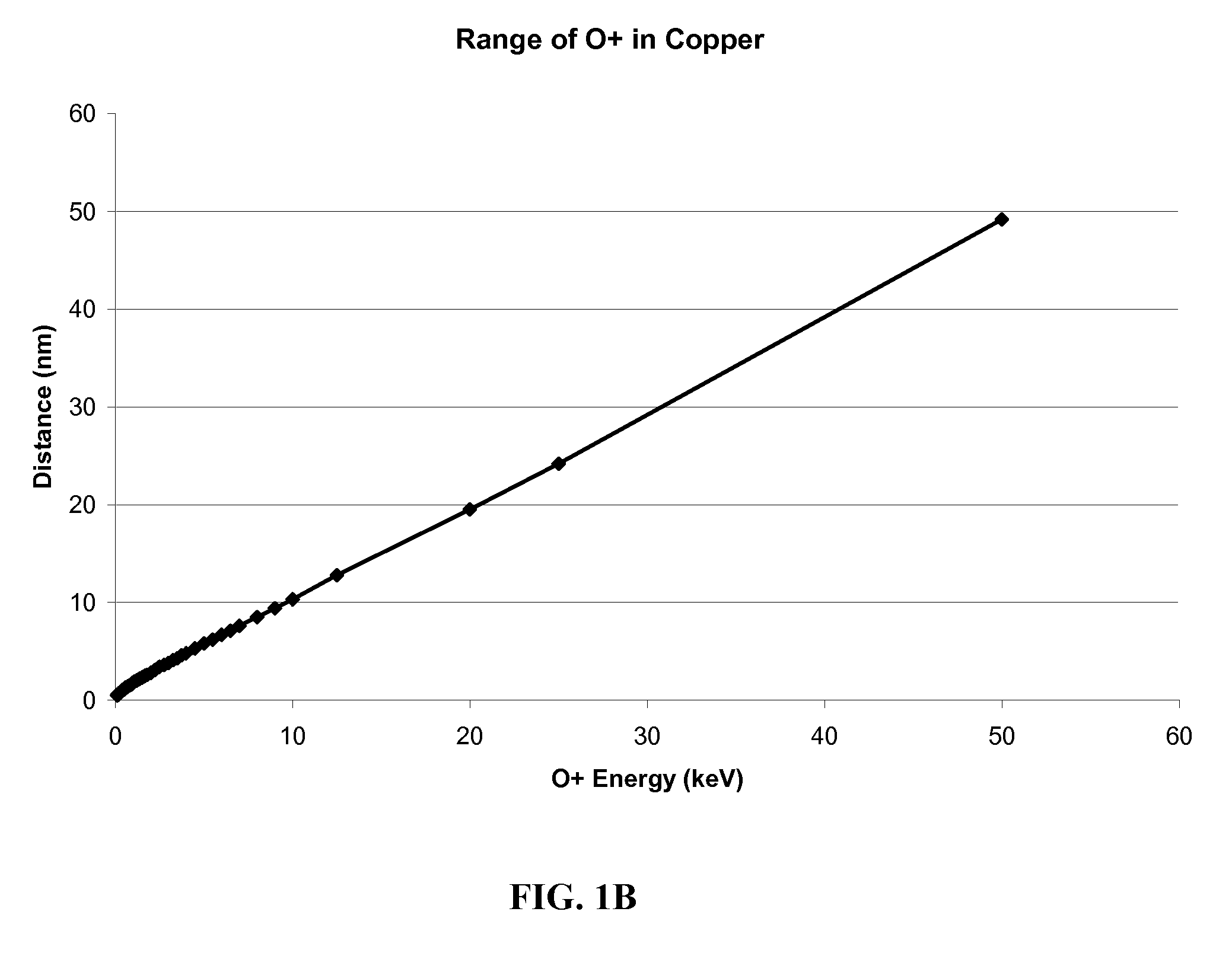

Use of ion implantation in chemical etching

InactiveUS20070264831A1Improve surface smoothnessIncreased injected energyElectric discharge tubesPhotomechanical apparatusGas compositionCompound (substance)

A method for controlling chemical dry etching to improve smoothness of an etched surface is disclosed. Ions are implanted into a surface to form a volatilizable compound at a temperature low enough to avoid, reduce, or eliminate formation of three-dimensional structures of the volatilizable compound that might create the roughness at an etched surface of the volatilizable compound. The ions are applied in a sufficient energy to penetrate to a predetermined depth of material that is to be removed from the surface in an etching cycle, and in a sufficient dosage to achieve full formation of the volatilizable compound. The surface of the volatilizable compound is exposed to a gas composition for a time duration sufficient to completely etch the volatilizable compound.

Owner:KLA TENCOR TECH CORP

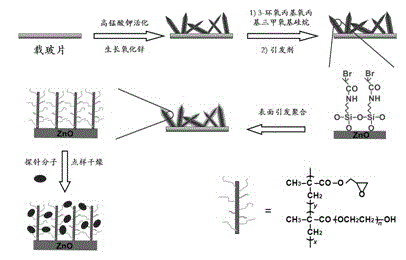

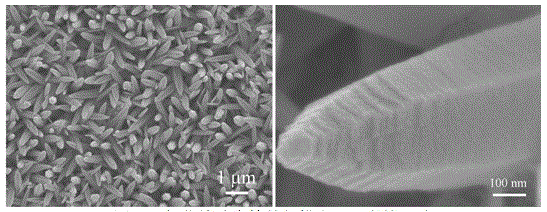

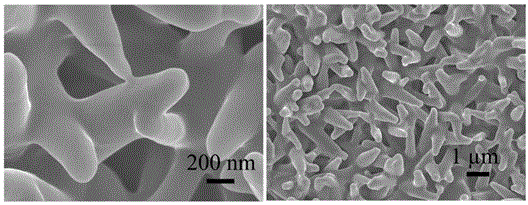

Three-dimensional carrier of microarray biochip and preparation method thereof

InactiveCN103147133ALarge specific surface areaIncrease surface densityPeptide librariesNucleotide librariesDiseaseZinc oxide nanorod

The invention discloses a three-dimensional carrier of a microarray biochip and a preparation method thereof. The three-dimensional carrier of a microarray biochip is prepared by growing a zinc oxide nanorod on the surface of a substrate material and growing a polymer brush on the surface of the zinc oxide nanorod. The preparation method comprises the following steps of: activating the surface of the substrate material, and growing a zinc oxide nanorod on the surface of the substrate material; performing surface modification on the grown zinc oxide nanorod; connecting the modified surface of the zinc oxide nanorod with an initiator; and finally, growing a polymer brush to obtain a three-dimensional carrier of a microarray biochip. The preparation method is simple, does not need special equipment, has low production cost and good repeatability, and can be used for realizing large-scale production; the prepared three-dimensional carrier has low price and high fixing density for probe molecule, can be used for effectively inhibiting non-specific protein adsorption and improving the sensitivity and the specificity, and can be widely applied to the fields of biology, basic medicine, disease diagnosis, drug screening, food safety, environmental monitoring and the like.

Owner:SOUTHWEST UNIV

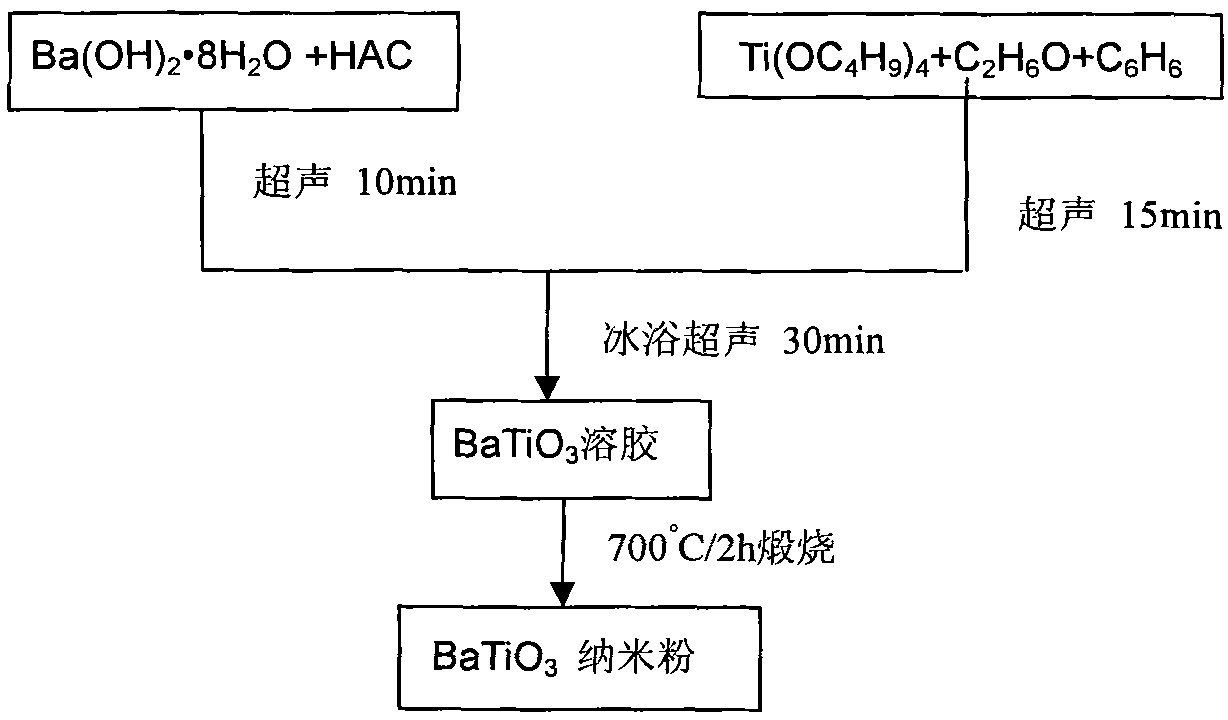

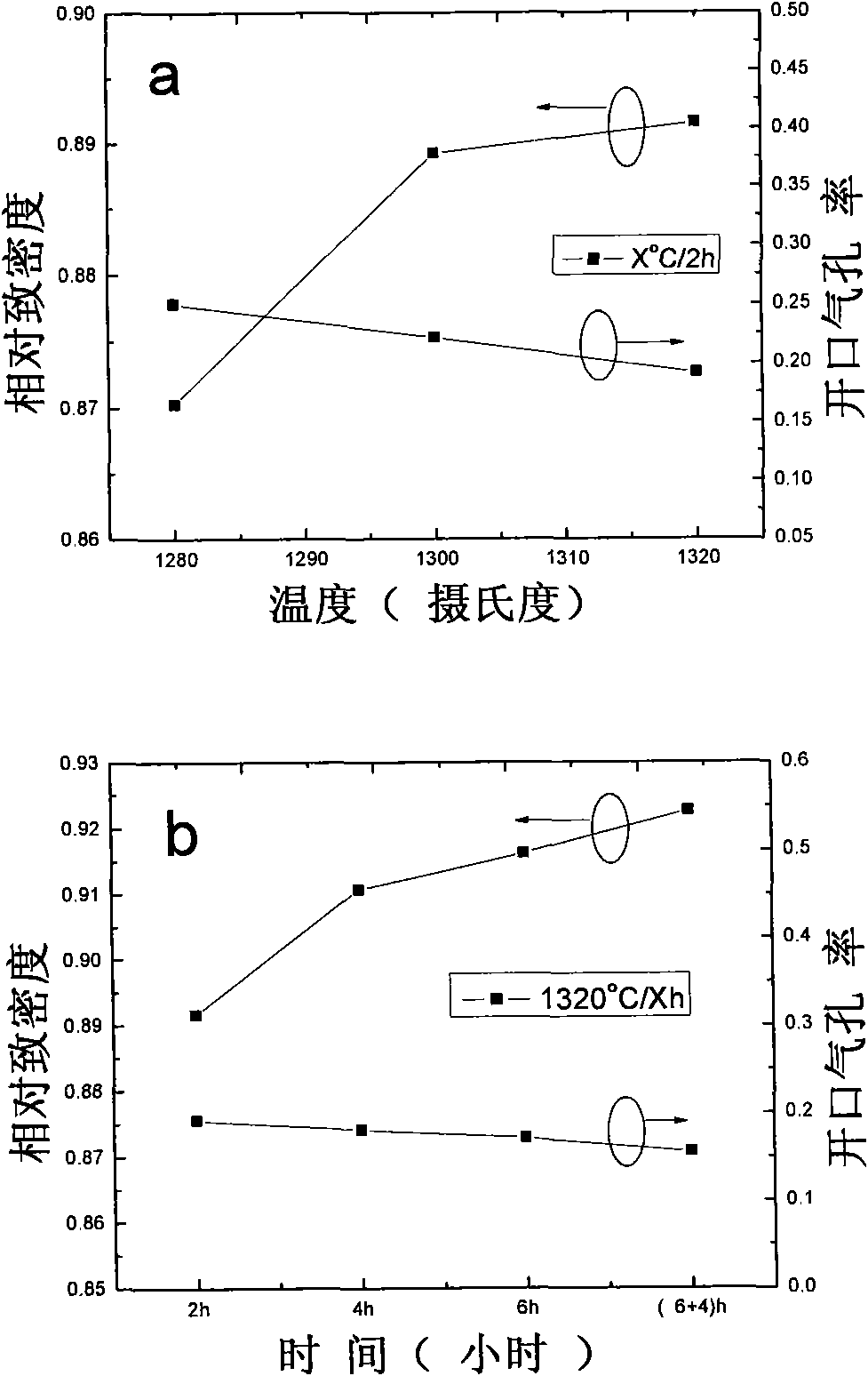

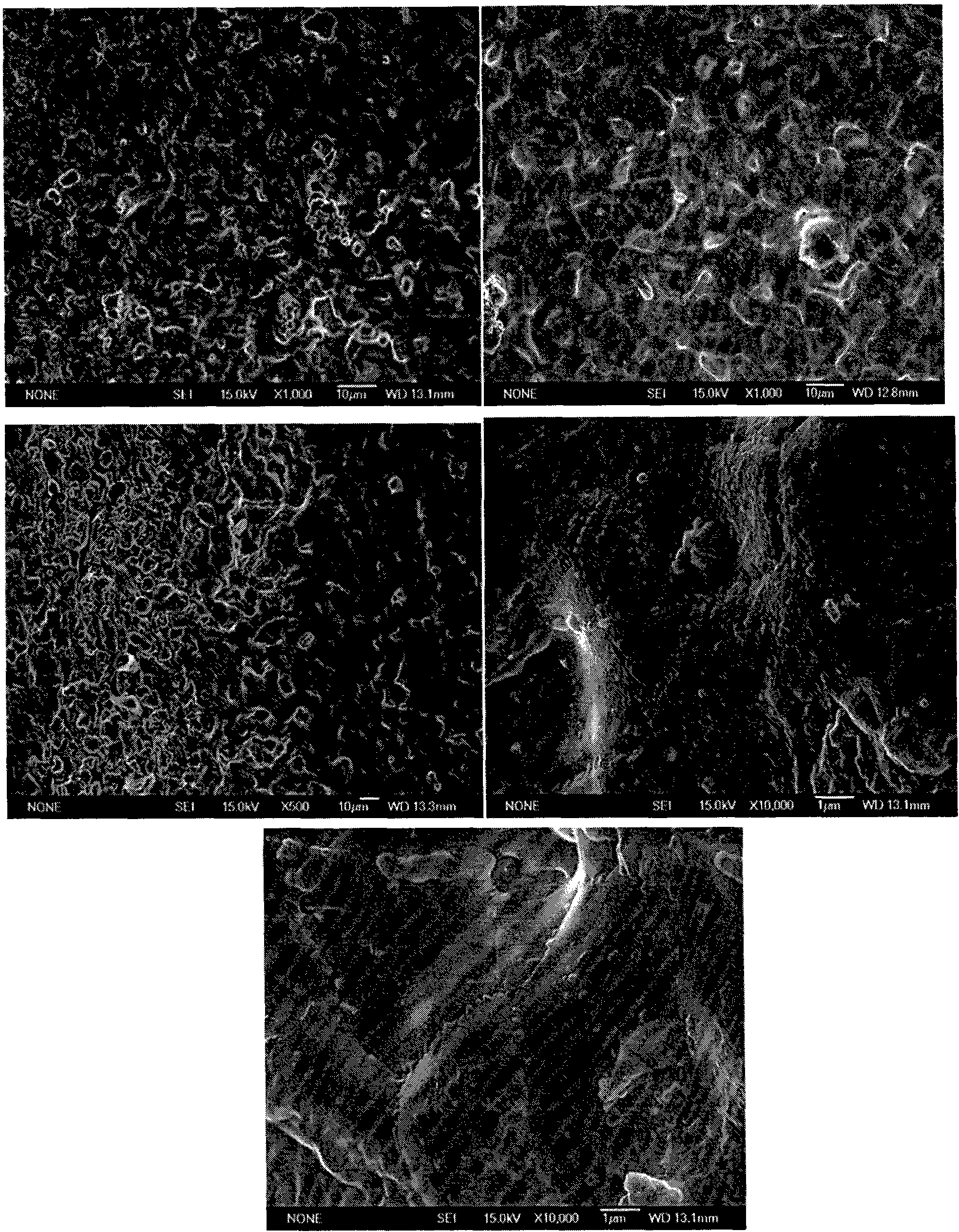

Preparation method of (Ba, Sr)TiO3 nanometer/micrometer/nanometer laminated structure ceramics

The invention relates to a preparation method of (Ba, Sr)TiO3 nanometer / micrometer / nanometer laminated structure ceramics, belonging to the technical field of special structure ceramic preparation processes. The preparation method comprises the following steps of: to synthesizing BaSrTiO3 micrometer powder mainly with BaCO3, TiO2 and SrCO3 as raw materials; preparing BaTiO3 sol with Ba(OH)2.8H2O, glacial acetic acid, Ti(OC4H9)4, absolute ethyl alcohol and benzene as raw materials, and calcining the BaTiO3 sol at 700 DEG C to form BaTiO3 nanometer powder; and then carrying out dry pressing and moulding to form the nanometer / micrometer / nanometer laminated structure layer by layer according to the sequence of the BaTiO3 nanometer powder material, the (Ba, Sr)TiO3 micrometer powder material and the BaTiO3 nanometer powder material; carrying out isostatic pressing on the nanometer / micrometer / nanometer laminated structure to form a laminated structure ceramic bisque; and finally sintering the bisque at 1280-1320 DEG C to prepare the (Ba, Sr) TiO3 nanometer / micrometer / nanometer laminated structure ceramics.

Owner:SHANGHAI UNIV

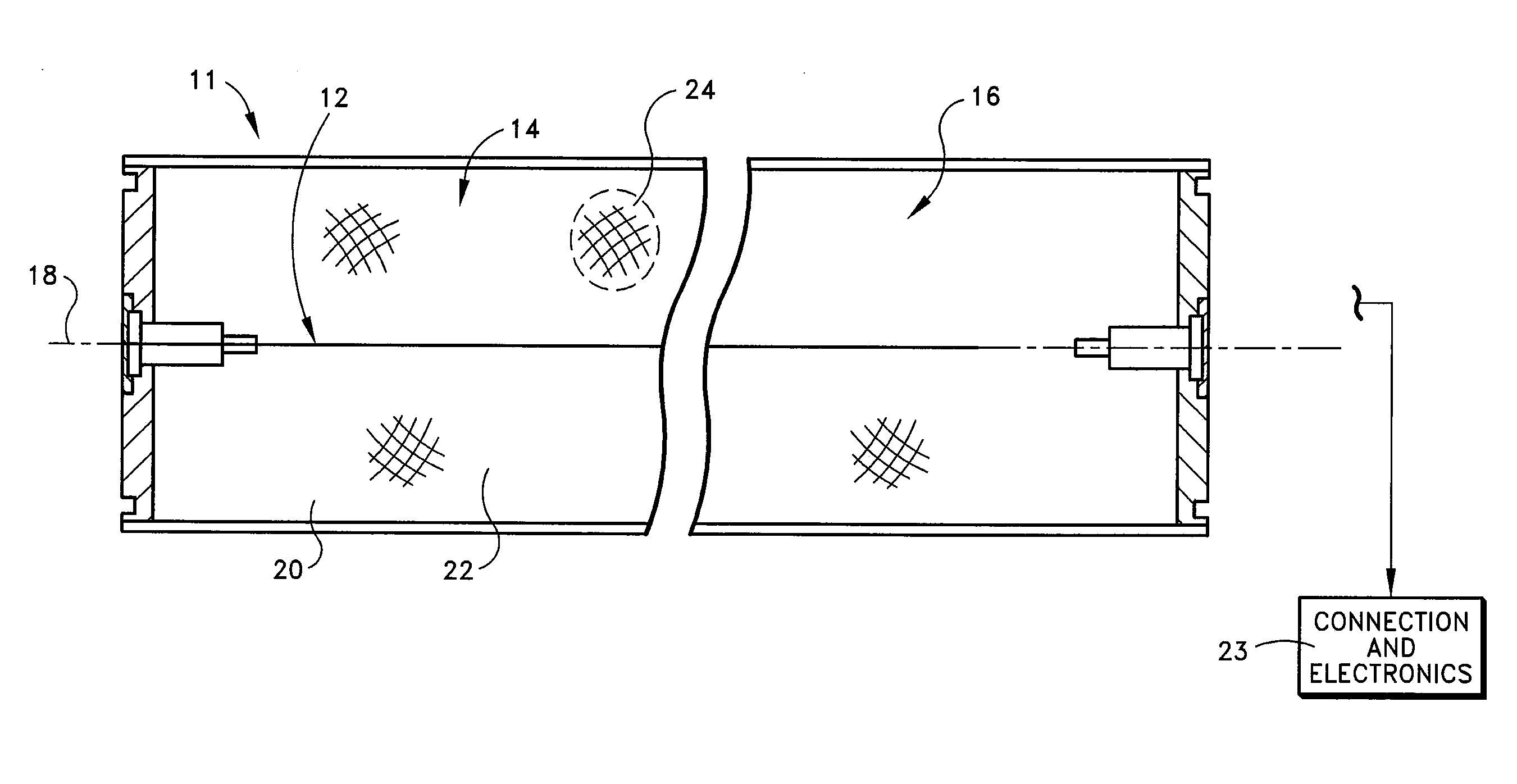

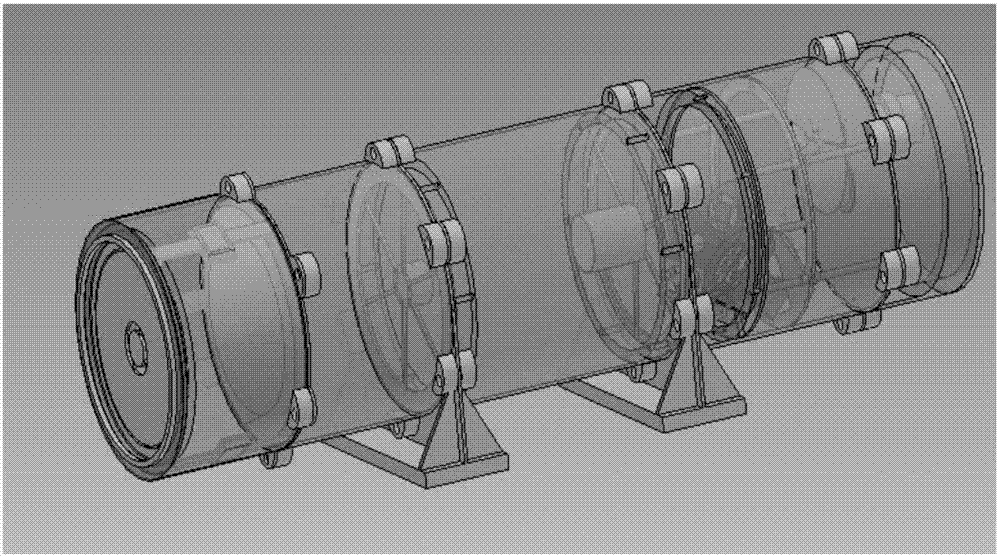

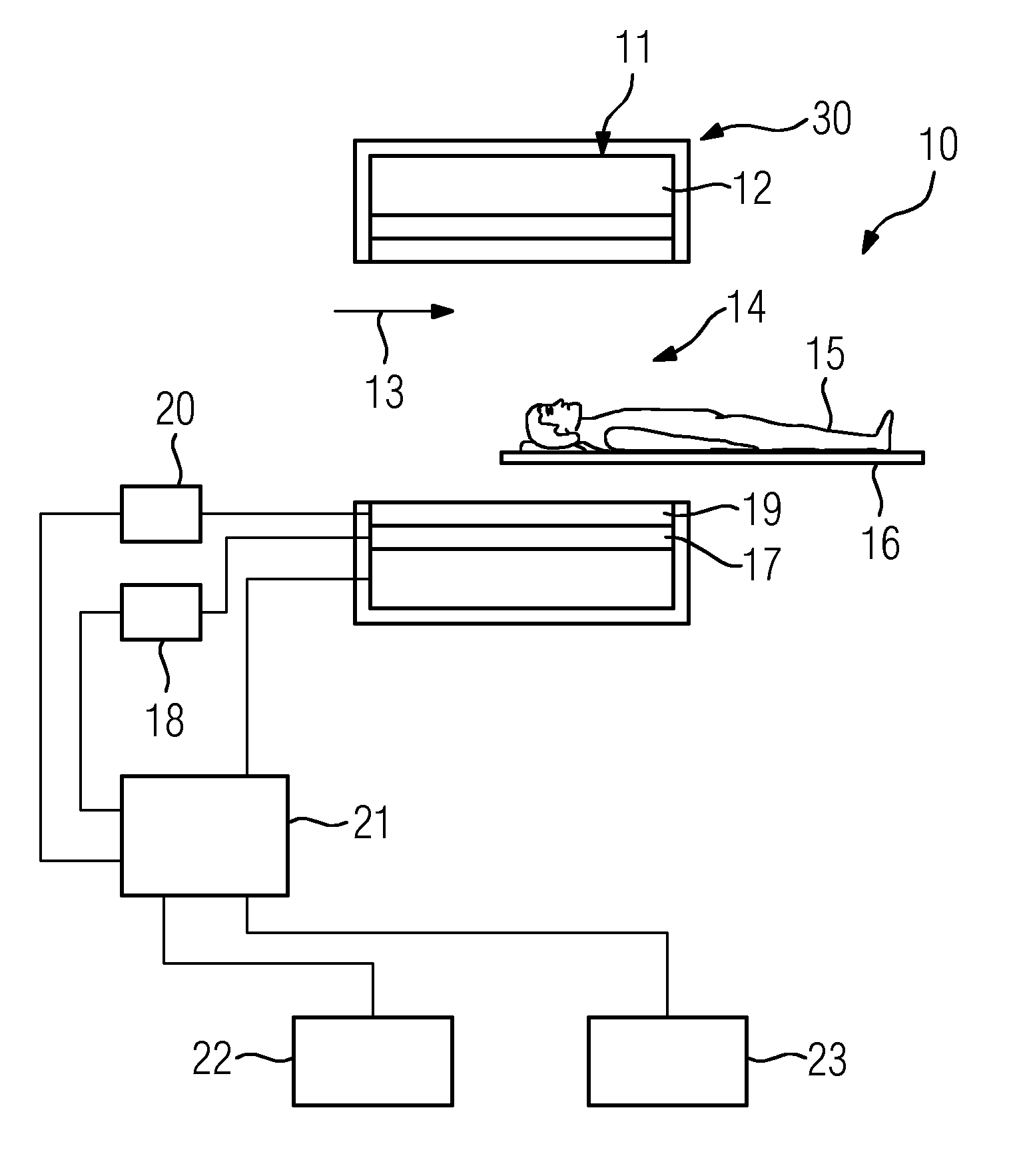

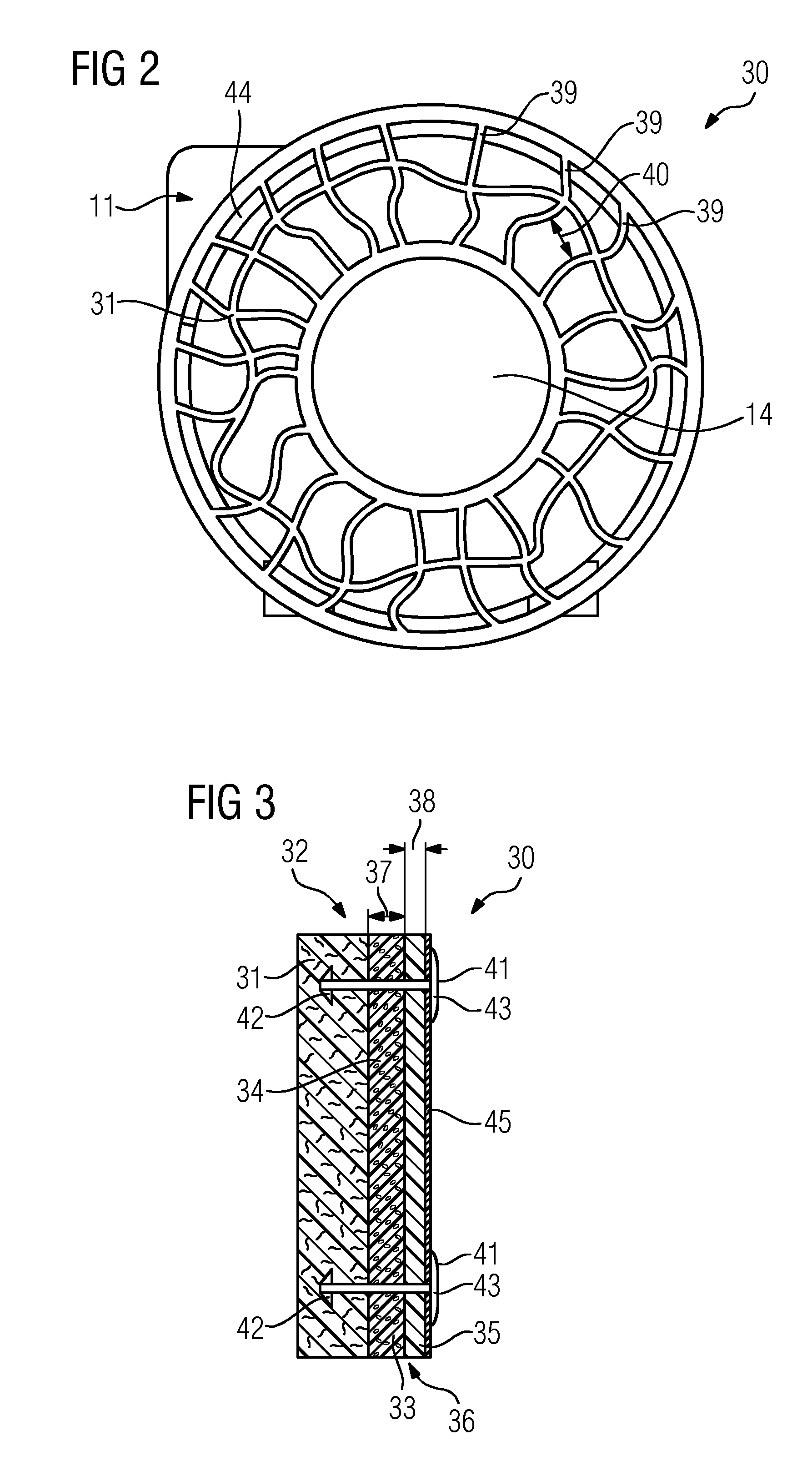

Magnetic resonance apparatus

InactiveUS20130234709A1Inhibition of excitementAvoid squeezingElectric/magnetic detectionMeasurements using magnetic resonanceResonanceEngineering

A magnetic resonance apparatus is proposed. The magnetic resonance apparatus has a magnet unit, magnet housing and a housing unit surrounding the magnet unit. The housing unit includes at least one support structure unit and a cladding unit. The cladding unit has at least one first layer, which includes a sound absorption element, and at least one second layer, which includes a heavy mass layer.

Owner:SIEMENS HEALTHCARE GMBH

Macromolecule anticorrosion paint and preparing method thereof

InactiveCN101012348AIncrease surface densityThe preparation method is scientific and reasonableWax coatingsNatural rubber coatingsAdjuvantEmulsion

The invention discloses a macromolecular preservative paint and preparing method, which comprises the following steps: allocating raw material with 55% filming material, 11% solvent, 11% paint adjuvant and 23% dye and fill; heating filming material to dissolve; stirring to add emulsion to emulsify; adding solvent, paint adjuvant to grind; beating; stirring; filtering; detecting viscosity; selecting filming material from oil-water amphiprotic acrylic acid resin, natural rubber, chlorcosane and zinc stearic acid; making isopropanol as solvent.

Owner:包洪钧

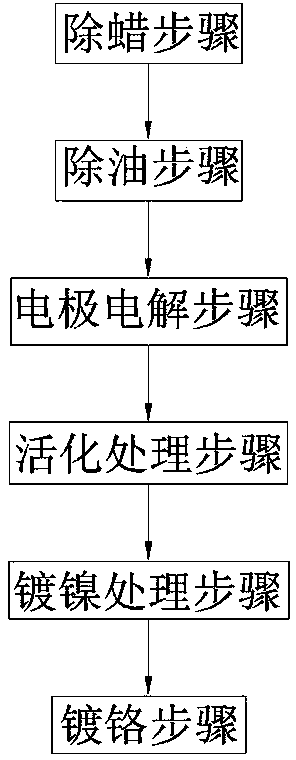

Sanitary product surface treatment method

InactiveCN103361688AImprove surface densityImprove coating qualityVolumetric Mass DensityWax removal

The invention aims to provide a sanitary product surface treatment method which can be adopted to strengthen density of a coating on the surface of a sanitary product, raise quality of the coating of the product and prolong service life of the product. The method provided by the invention comprises the following steps: wax removal step, oil removing step, electrode electrolysis step, activating treatment step, nickel plating processing step and chrome plating step. By the adoption of the method for processing a sanitary product, density of the surface of the sanitary product is higher, the thicknesses of a nickel coating and a chromium coating are increased, and quality of the coating of the sanitary product is improved. Thus, the service life of the sanitary product in a general environment is prolonged, the sanitary product can be suitable for more other complex environments, and the service life can be guaranteed. The Sanitary product surface treatment method provided by the invention can be applied in the field of production of sanitary equipment.

Owner:ZHUHAI XIANGJIN HARDWARE & ELECTRICAL APPLIANCE

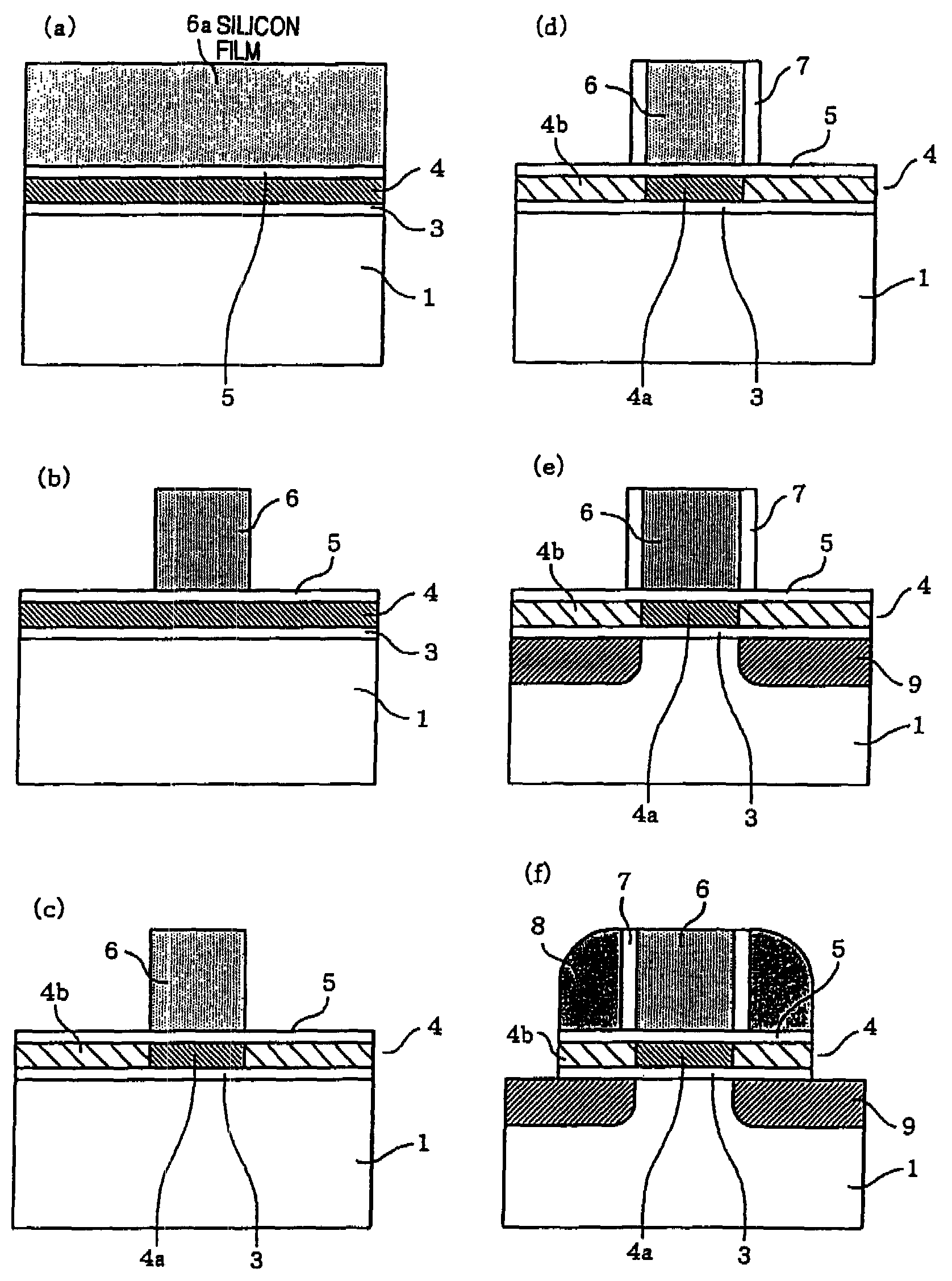

Semiconductor device and method of producing the same including a charge accumulation layer with differing charge trap surface density

InactiveUS7791129B2Improve propertiesImprove retentionTransistorSolid-state devicesElectrical conductorTrapped surface

There is provided a trap memory device suppresses electric charges from flowing from the outside into a charge accumulation region and accumulated electric charges from diffusing to the outside or flowing out due to a defect. A gate conductor 6 is formed through a laminate insulating film including a first gate insulating film 3, a charge accumulation layer 4 and a second gate insulating film 5 on a silicon substrate 1. The laminate insulating film (3 to 5) projects outside the gate conductor 6 and extends to under the outer end of a side wall 8. The charge accumulation layer 4 includes a high trap surface-density region 4a immediately under the gate conductor and a low trap surface-density region 4b outside the gate conductor.

Owner:NEC CORP

Lignin phenolic resin environment-friendly plate

ActiveCN106476367AIncrease surface densityHigh strengthConjugated diene hydrocarbon coatingsNatural rubber coatingsOperabilityMoisture resistance

The invention relates to a lignin phenolic resin environment-friendly plate and belongs to the technical field of building materials. The environment-friendly plate comprises an upper coating, an upper plate, a middle coating, a lower plate and a lower coating sequentially arranged from top to bottom. The lignin phenolic resin environment-friendly plate is high in surface layer density, high in strength, less prone to deformation, simple in production process, high in production efficiency, definite in process parameter, high in operability and capable of directly serving as a material for furniture and indoor decoration, has the advantages of high anti-seismic performance, flame retardance, low smoke, nontoxicity, water resistance, moisture resistance, corrosion resistance, resistance to high temperature, insulativity, light weight, quickness in mounting, antiaging resistance and wear resistance and is pollution-free, safe, environment-friendly and long in service life, and artificial forest soft wood does not need to be treated in a sealed container.

Owner:ANHUI GEYI CYCLIC ECONOMY IND PARK

Method for producing nanocrystals with controlled dimensions and density

ActiveUS20170186612A1Reduced dimensionIncrease surface densitySemiconductor/solid-state device manufacturingNoble gasIon bombardment

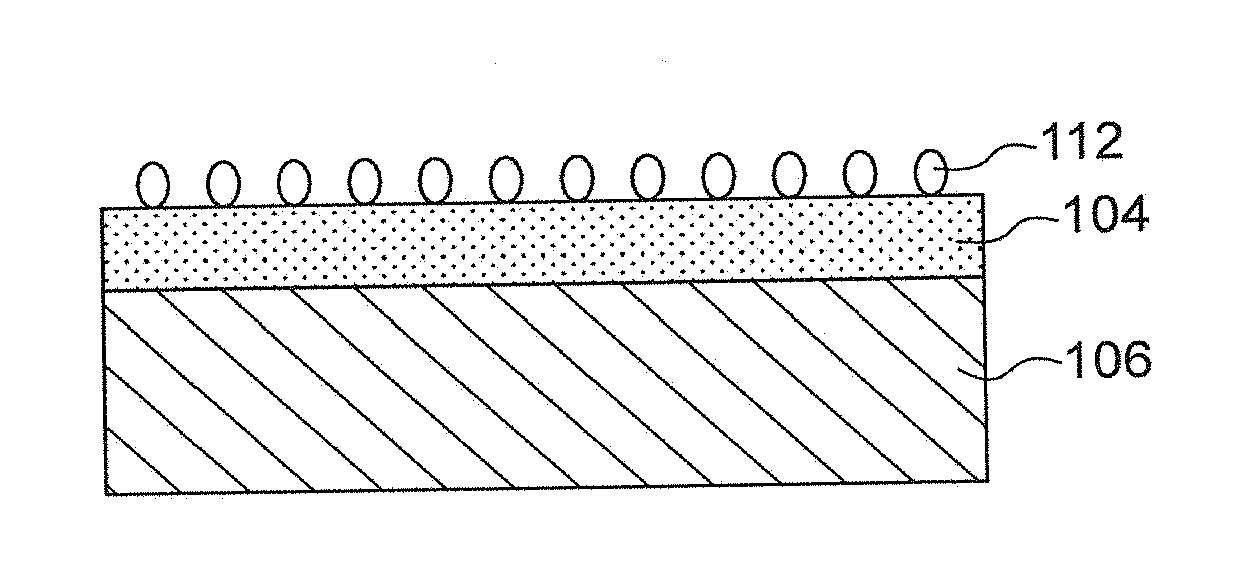

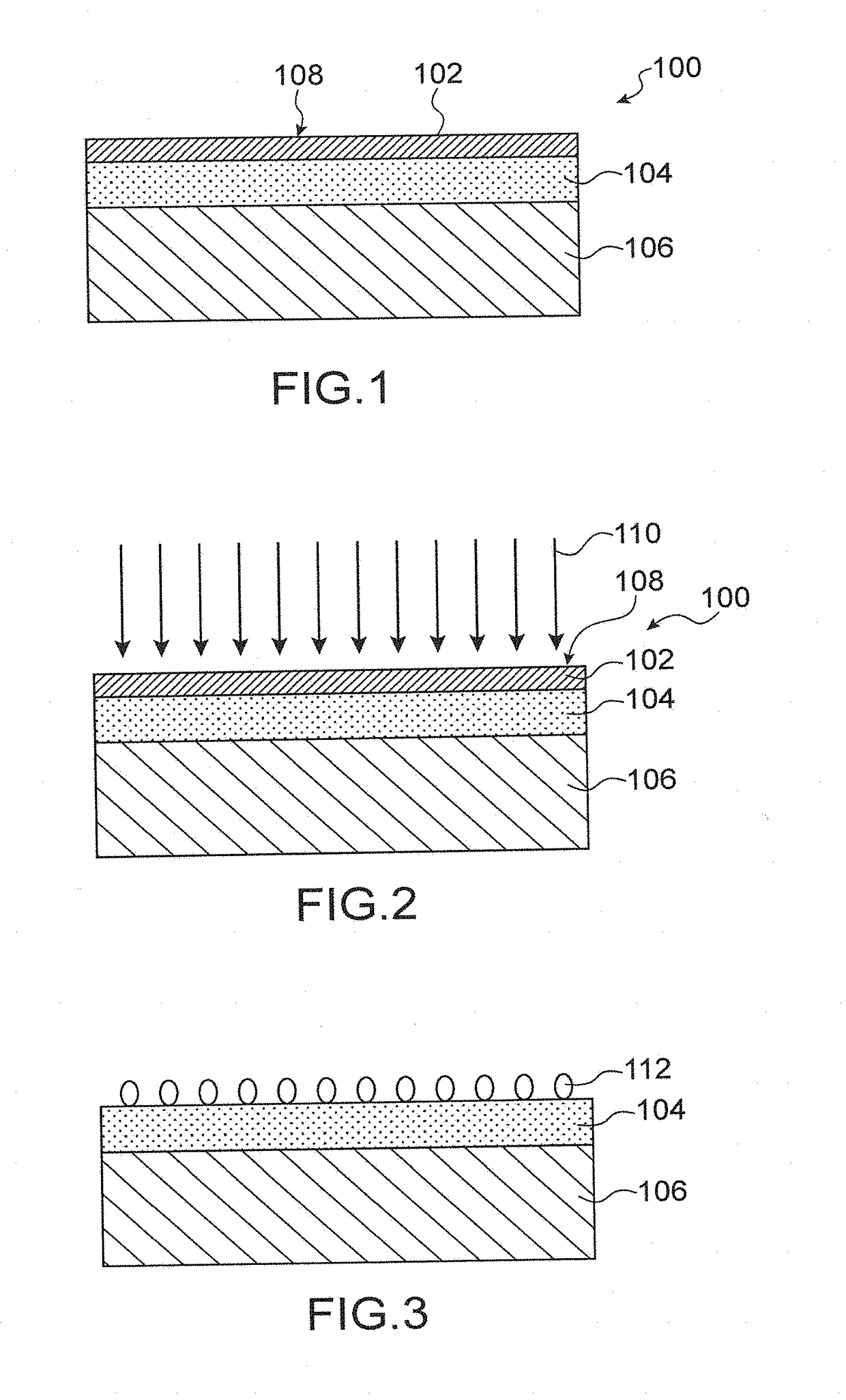

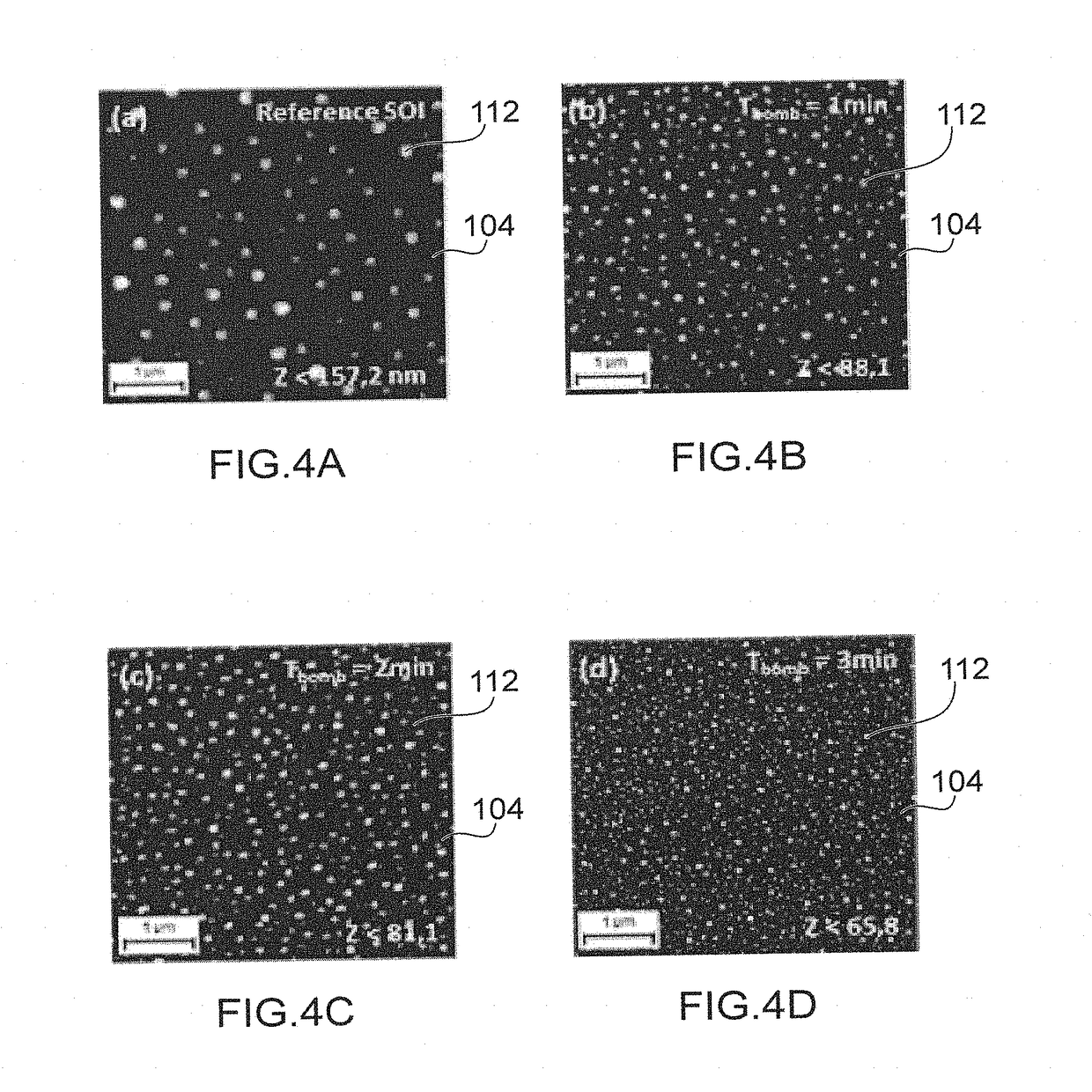

Method for producing nanocrystals of semiconductor, comprising at least:ion bombardment of a thin layer of semiconductor arranged on at least one dielectric layer, achieving at least one among an implantation of ions of at least one chemical element of rare gas type and an implantation of ions of at least one semiconductor element of same nature as that of the thin layer, in at least one part of the thickness of the thin layer;annealing of the thin layer achieving a dewetting of the semiconductor of the thin layer and forming, on the dielectric layer, nanocrystals of semiconductor.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Patterned layer for absorbent article

InactiveUS20050143699A1Reduce riskClearly visibleBaby linensPrintingVolumetric Mass DensityComputer science

Owner:SCA HYGIENE PROD AB

Method for preparing anti-oxidation coating of carbon/carbon composite material

ActiveCN103030427AImprove surface densityImproves antioxidant propertiesOxidation resistantCarbon composites

The invention belongs to the field of inorganic functional coating materials and is mainly applied to preparation for a high-temperature anti-oxidation coating of a carbon / carbon composite material. The preparation method comprises the following steps: introducing a silicon-enriched layer into the surface of the carbon / carbon composite material in advance; depositing carbon on the surface of and in the holes of the silicon-enriched layer through chemical vapor deposition to form a continuous carbon layer; and forming a continuous silicon carbide coating through reactive sintering. Compared with a gradient transition silicon carbide coating obtained by the traditional sintering method, the silicon carbide coating obtained by the method provided by the invention greatly improves the surface density and improves the anti-oxidation performance by more than one time; and after the coating is sealed and glazed, the long-time service performance is greatly improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com