Method for preparing carbon nano tube array

A technology of carbon nanotube array and deposition method, which is applied in the direction of oriented carbon nanotubes, nanotechnology, nanotechnology, etc., can solve problems such as difficult application, increased manufacturing cost, and inability to guarantee the straightness of carbon nanotube arrays. Clean smooth, high surface density results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] A method for preparing a carbon nanotube array provided by an embodiment of the present invention comprises the following steps:

[0014] (1) Provide a smooth base. The smooth substrate can be polished silicon wafer, polished silicon dioxide wafer and polished quartz wafer, and its surface flatness is preferably less than 300 nanometers; it can make the subsequent carbon nanotube growth catalyst layer can be evenly attached to the substrate surface.

[0015] (2) Forming a catalyst layer on the surface of the smooth substrate. The catalyst layer can be deposited on the substrate by electron beam evaporation or magnetron sputtering, and its thickness is generally 3-6 nanometers. The material of the catalyst layer can be selected from one or a combination of iron, cobalt, nickel or their alloys. The deposition rate for forming the catalyst layer, that is, the thickness change rate, is preferably lower than 0.5 nm / s, which enables the catalyst to be uniformly attached to...

no. 1 example

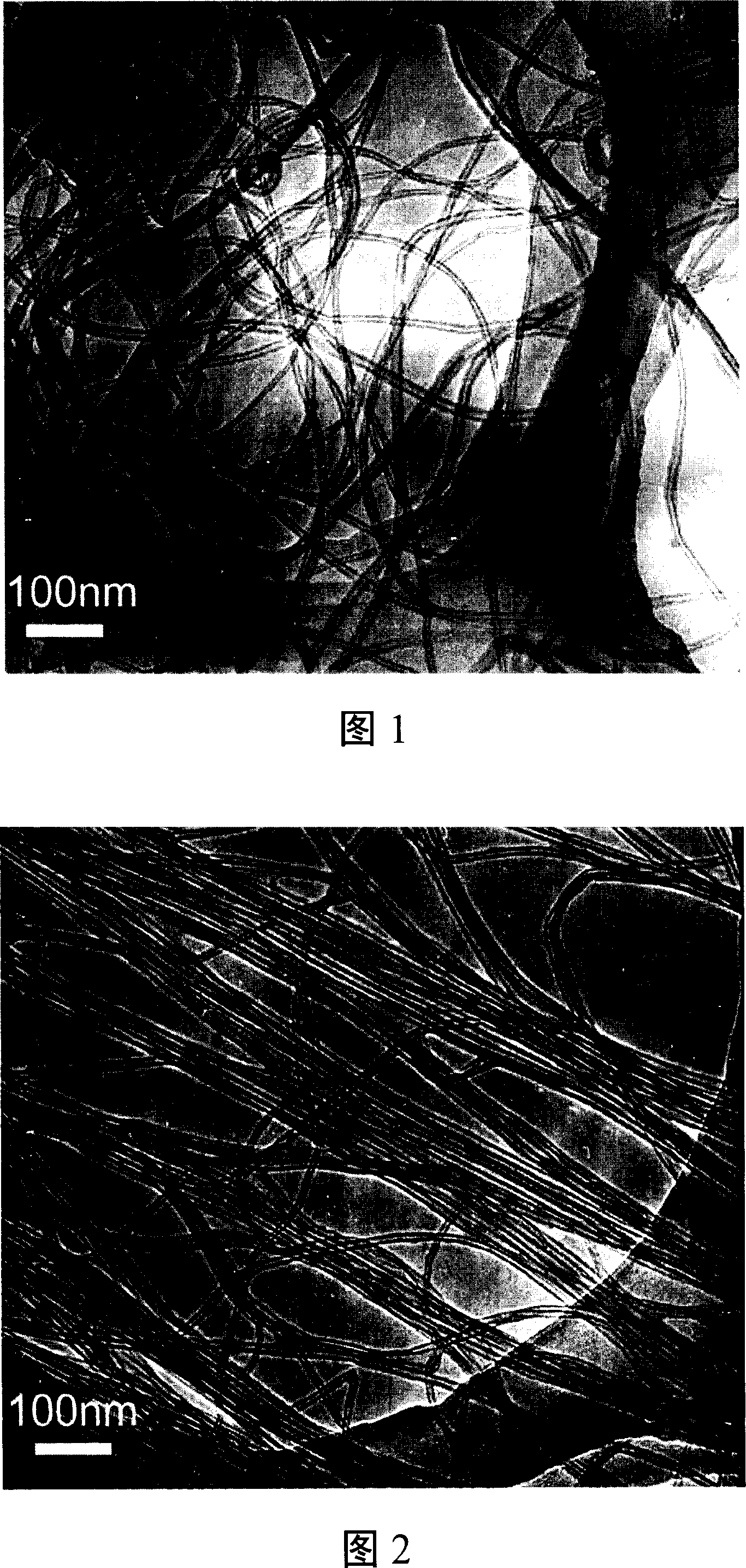

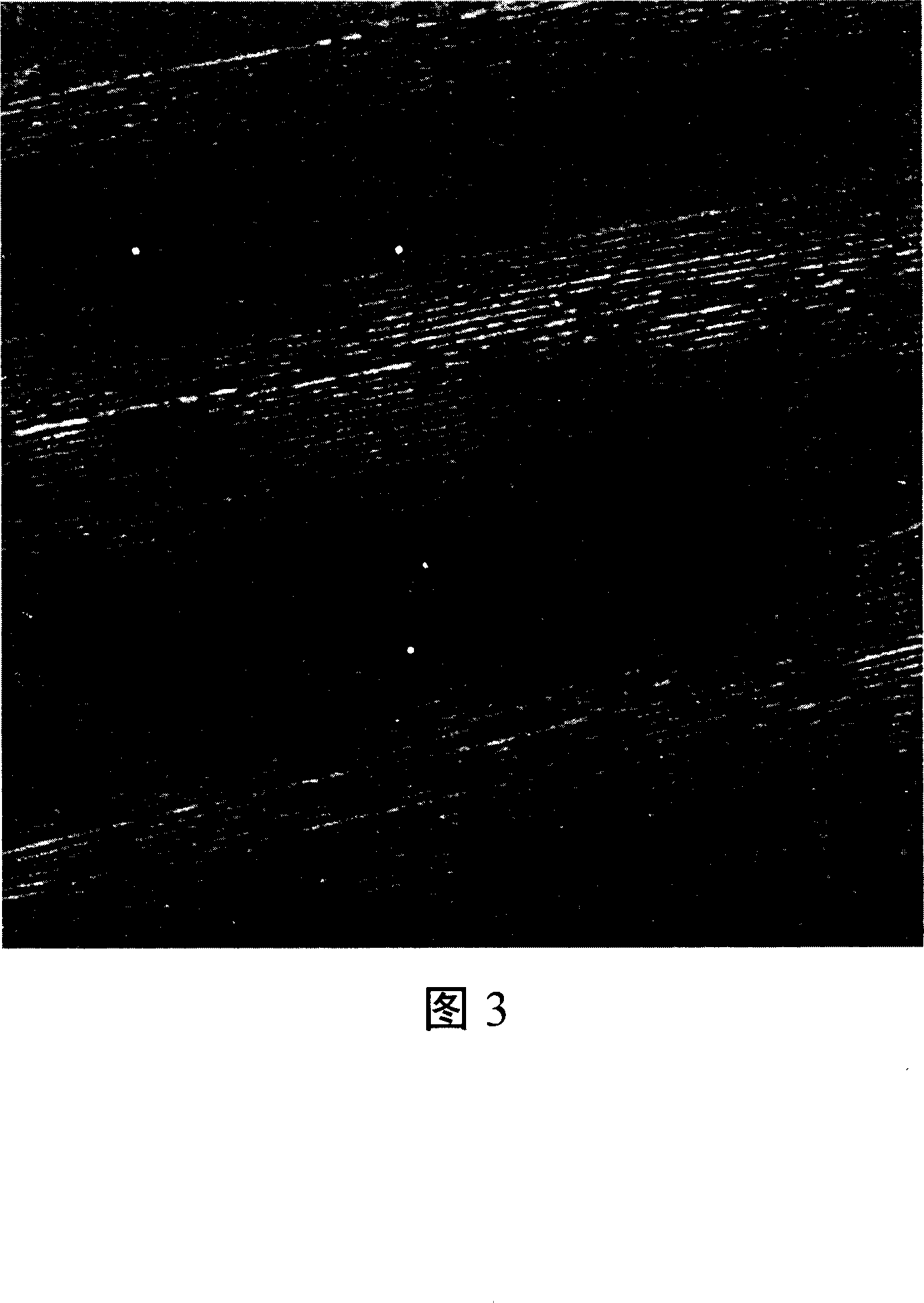

[0019] In this embodiment, carbon nanotube arrays are prepared by atmospheric pressure chemical vapor deposition. Usually, the pressure range of the atmospheric pressure chemical vapor deposition method is 10-760 Torr. In this embodiment, a polished silicon wafer is selected as the substrate, iron is selected as the catalyst, and a mixed gas of acetylene and hydrogen is selected as the reaction gas. An iron catalyst layer with a thickness of 3 to 6 nanometers is formed on a polished silicon substrate by using an electron beam evaporation method at a deposition rate of 0.01 nanometers / second. The substrate formed with the iron catalyst layer is put into a quartz furnace, fed with hydrogen and heated to 620-700 degrees Celsius. Add acetylene into the quartz furnace and keep it for 10-30 minutes; then a carbon nanotube array can be obtained. Wherein, the flow rate of acetylene can be 30 sccm; the flow rate of hydrogen gas can be set to 300 sccm; during the growth process of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com