Preparation method of (Ba, Sr)TiO3 nanometer/micrometer/nanometer laminated structure ceramics

A nano-layered and nano-technology, which is applied in the field of preparation of special structural ceramics, can solve the problems of low density of thick films and limit the performance of thick films, and achieve the effect of improving surface density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

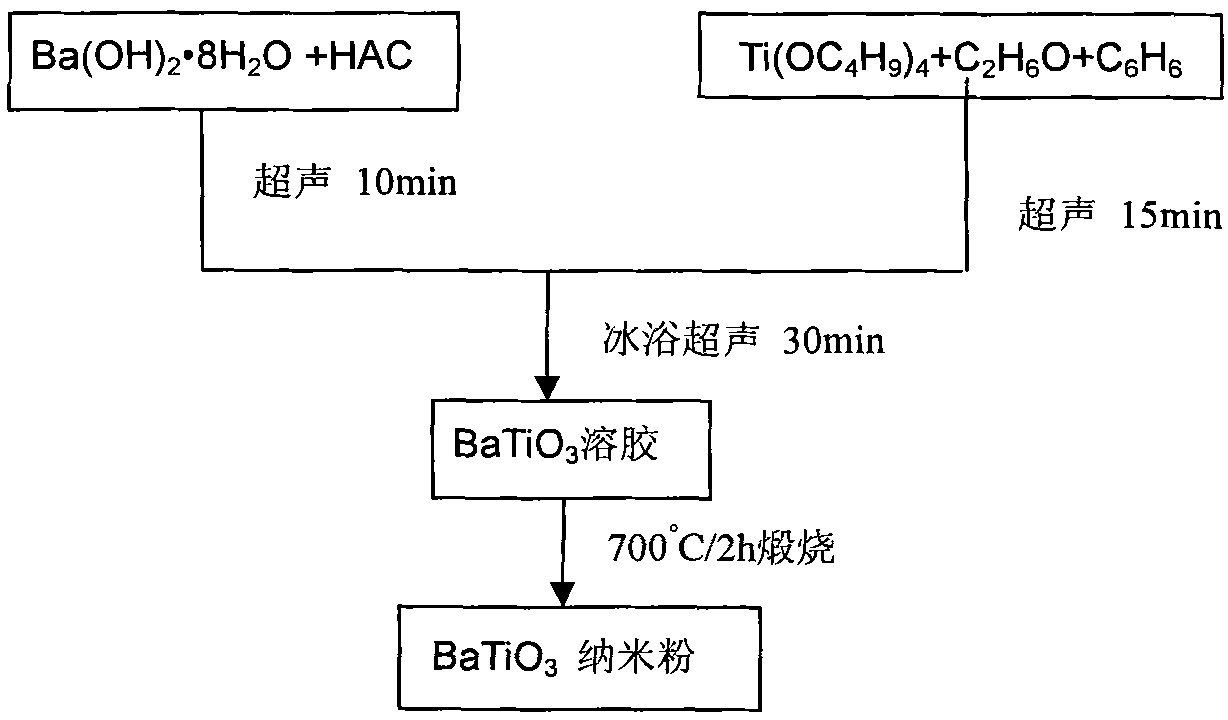

[0022] The preparation process and steps in this embodiment are as follows:

[0023] 1. (Ba, Sr)TiO 3 Preparation of micron powder

[0024] Raw material is BaCO 3 (Analytical pure), TiO 2 (Analytical pure), SrCO 3 (Purity 97%); First, weigh the above-mentioned raw materials into a ball milling tank at a stoichiometric ratio of 1:1, add deionized water and ball milling media in an appropriate proportion for ball milling for 24 hours; wherein the amount of deionized water added is about It is 2 / 3 of the volume of the ball milling tank, and the quality of the ball milling medium should be about 0.8 to 1.5 times of the total amount of raw materials; the purpose of ball milling is to mix different raw materials fully and uniformly, and grind the coarser particles fine; The ball-milled slurry is dried at 110°C and then ground and sieved to obtain a fine powder, which is placed in a sintering furnace for calcination at 1100°C to obtain (Ba, Sr)TiO 3 Micron powder; the function of pre-burn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com