Nano thin film with separation and protection function and manufacturing method thereof

A nano-film, protective function technology, applied in the field of protective film and its manufacturing, can solve the problems of low speed, uneven thickness of the barrier layer, large porosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

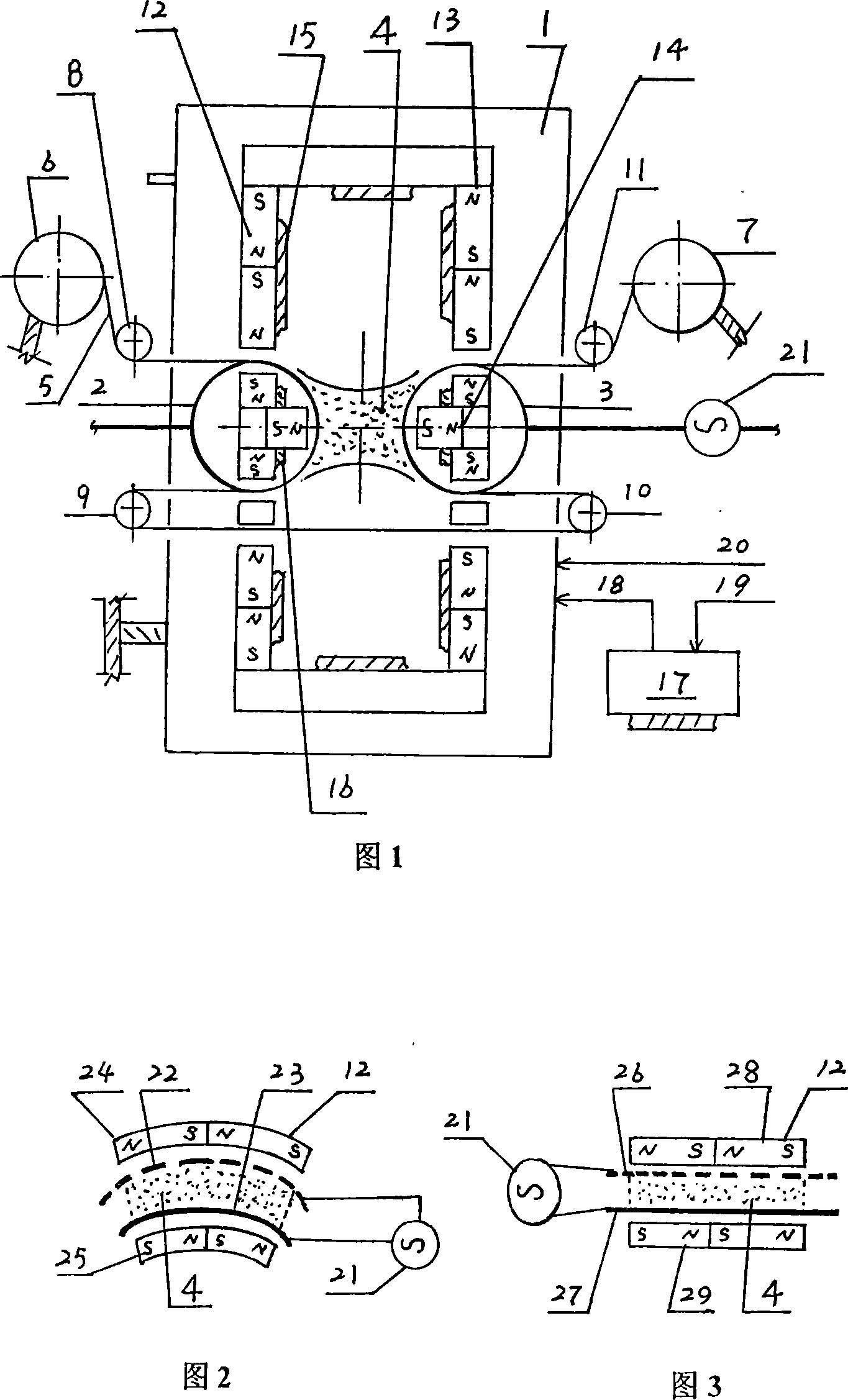

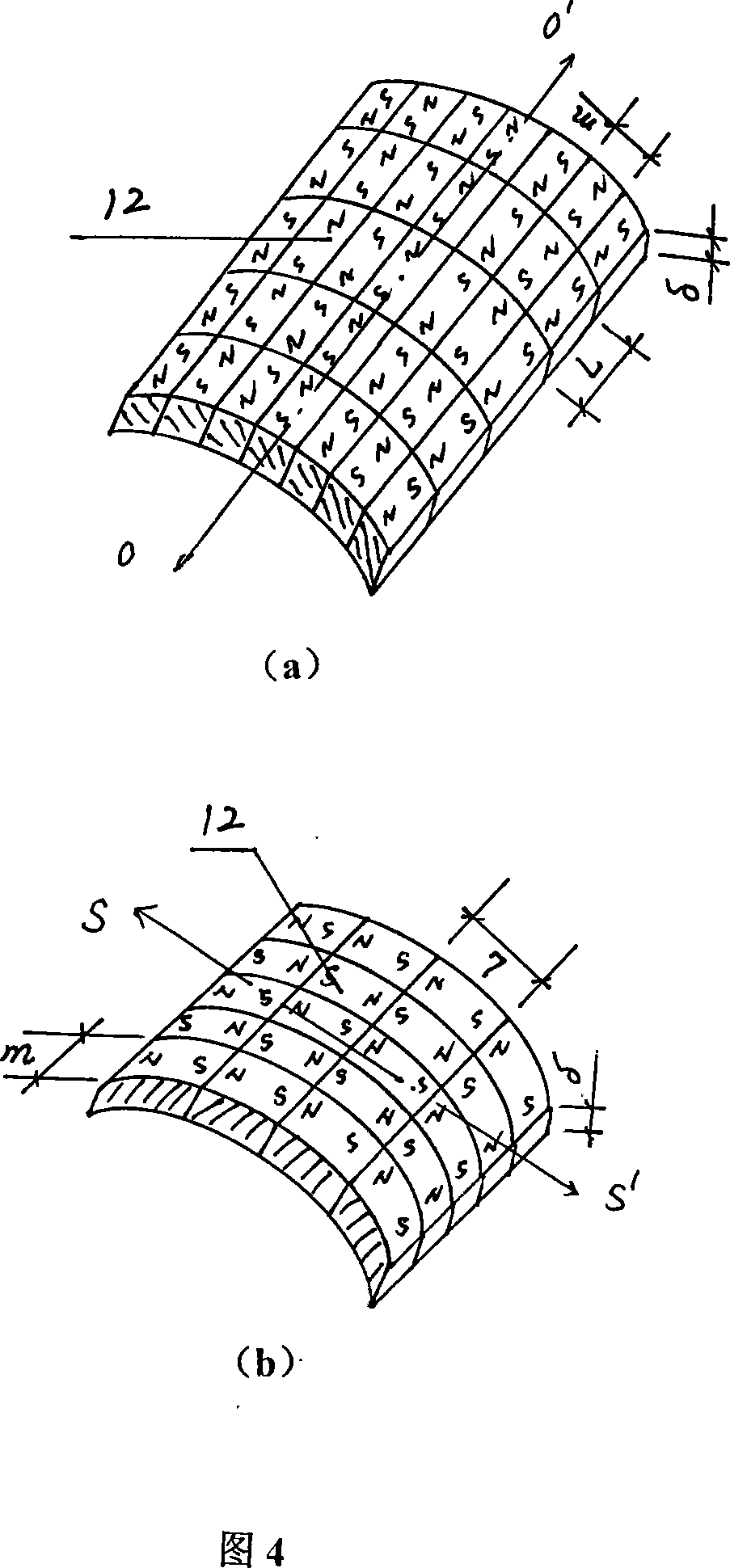

[0020] Further auspicious explanation in conjunction with accompanying drawing;

[0021] Described nano film is attached on the base material, and base material is flexible base material, is generally organic film, as polyethylene film (PE), polypropylene film (PP), oriented polypropylene film (OPP) and polyethylene terephthalic acid Ethylene glycol ester film, etc.; or the base material is regular or irregular ornaments, protective articles, cultural relics and functional devices, etc.

[0022] The organosilicon chemical monomer:

[0023] Hexamethyldisiloxane (C 6 h 18 OSi 2 ), octamethyltetrasiloxane (C 8 h 24 o 4 Si 4 ) or tetramethyldisiloxane (C 4 h 14 OSi 2 ); are all liquids, which are used as working gases after gasification.

[0024] The thickness of the nano-film is 1-1000nm, generally controlled at 50-200nm; the permeability to oxygen is less than 50ml / cm 2 / 24h, generally 15~25ml / cm 2 / 24h; the permeability to water vapor is less than 10g / m 2 / 24h, ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com