Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Precise and controllable size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dendritic polymer with POSS group and preparation method thereof

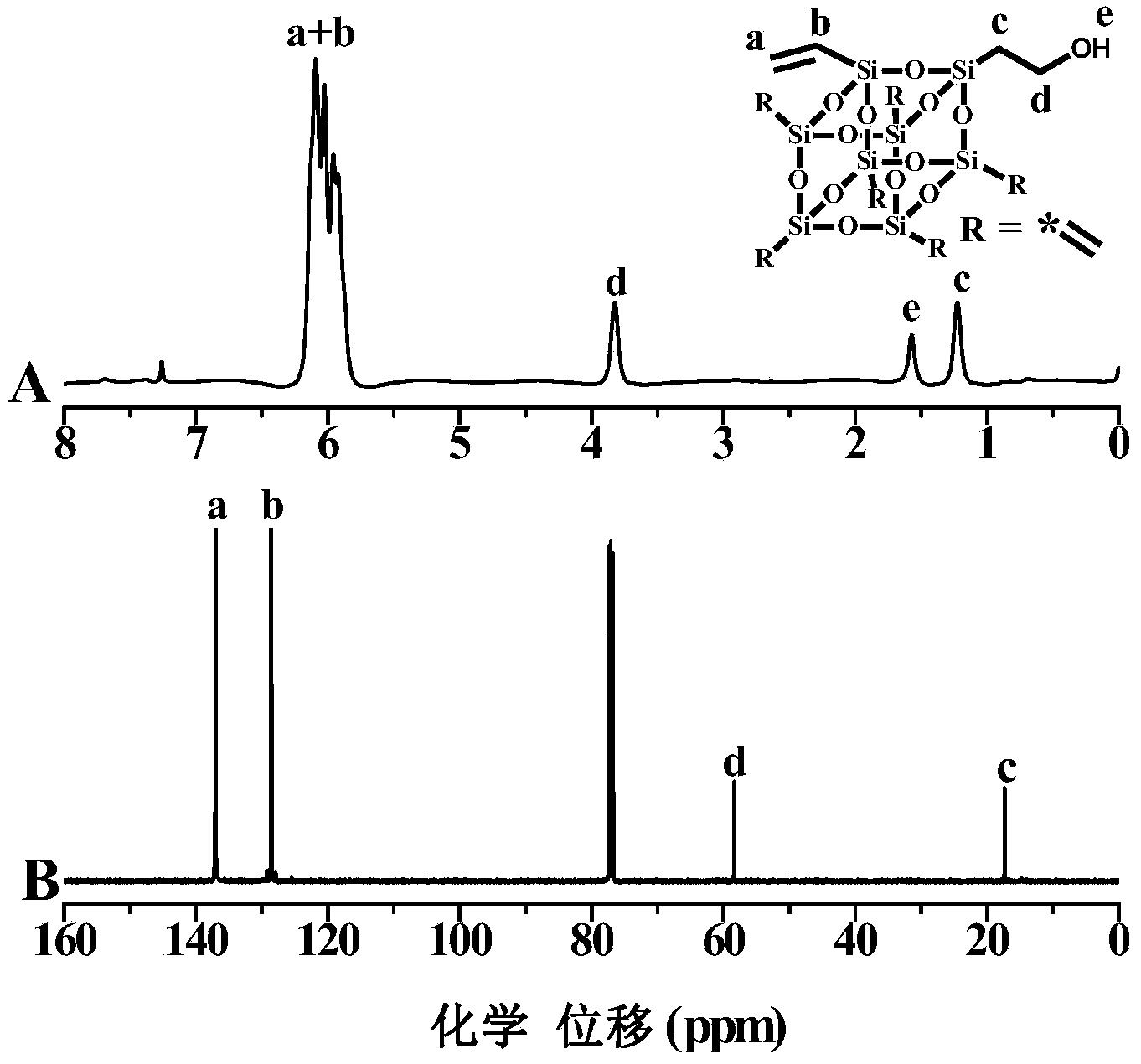

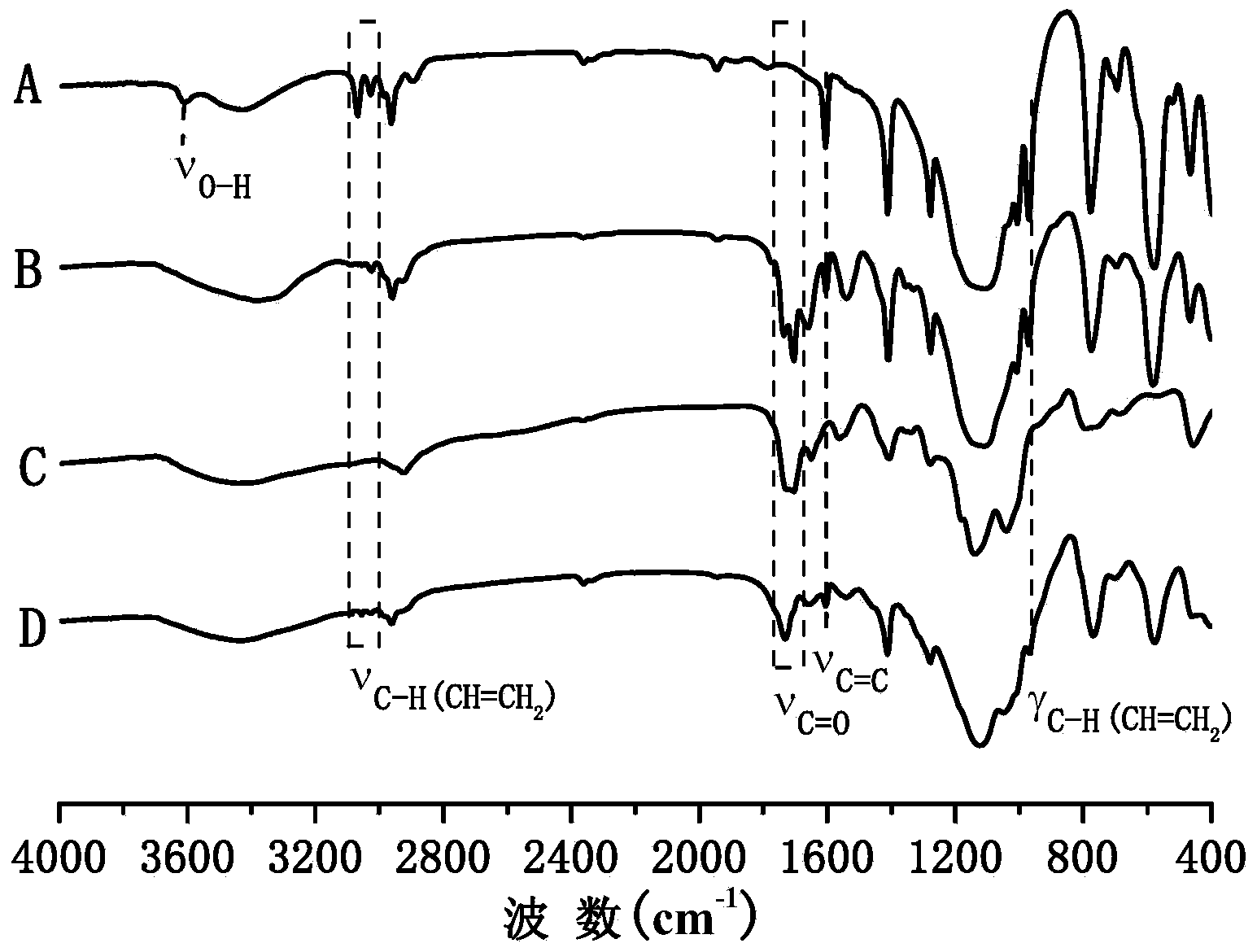

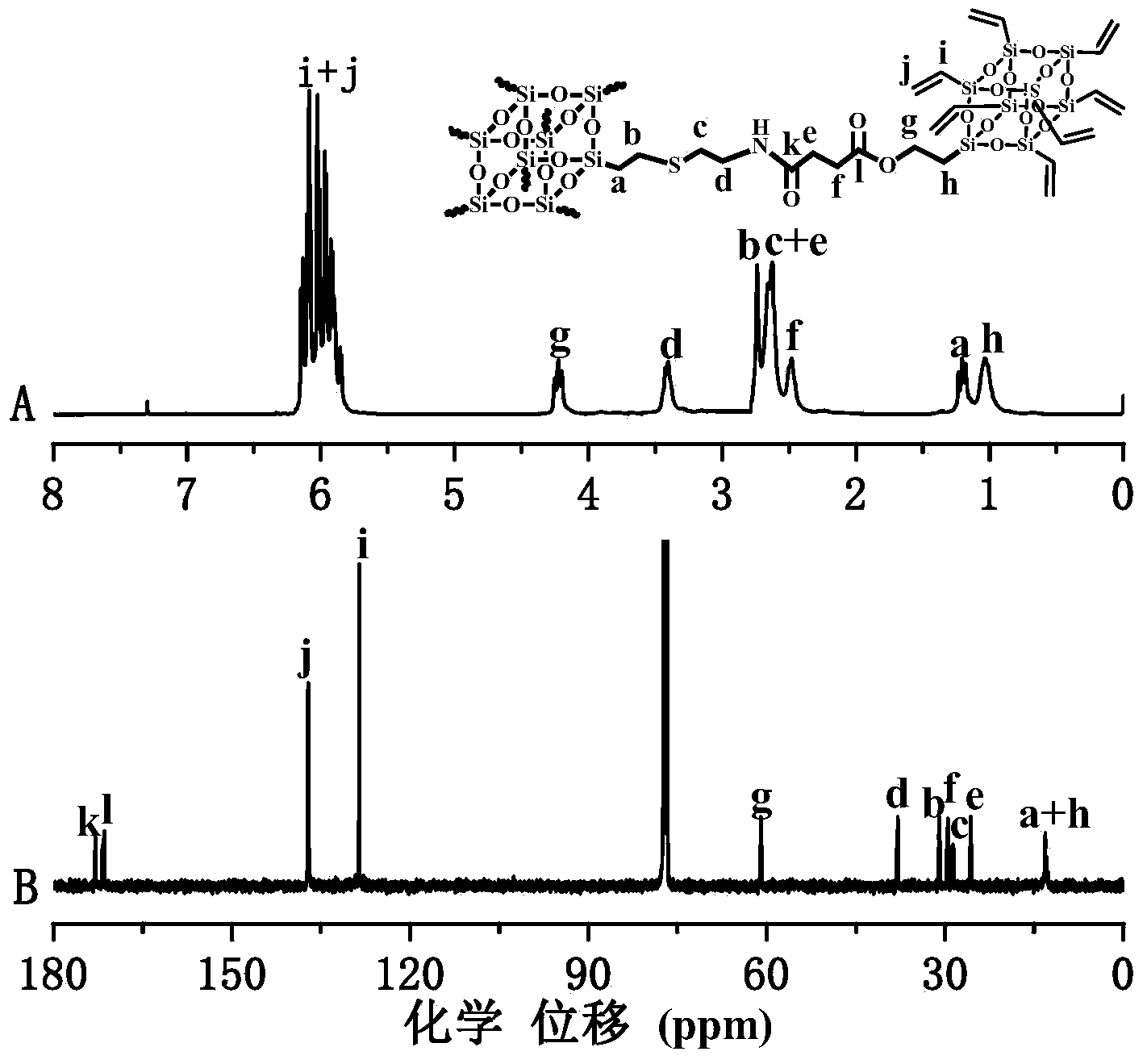

ActiveCN103642050AWide variety of sourcesRich varietySilicon organic compoundsChemical synthesisCrystallography

The invention relates to a dendritic polymer with POSS group and preparation method thereof. The preparation of the product comprises the following steps: designing a POSS group intermediate R2-POSS-(R1)n-1 (n=6, 8, 10, 12) with asymmetric structure, and then using a chemical synthetic method, and obtaining a dendritic polymer (containing derivatives thereof) containing POSS group and a lot of end functional groups. The product has the advantages of unique structure design and diversified selections, thereby the product has latent application prospects for the aspects of surfactant, biological medicine carrier, catalyst, photon crystallization, optical material, anti-corrosion material, electronic material, information recording material, printing material, battery material, magnetic material, electronic luminescent device, etc.

Owner:INST OF CHEM CHINESE ACAD OF SCI

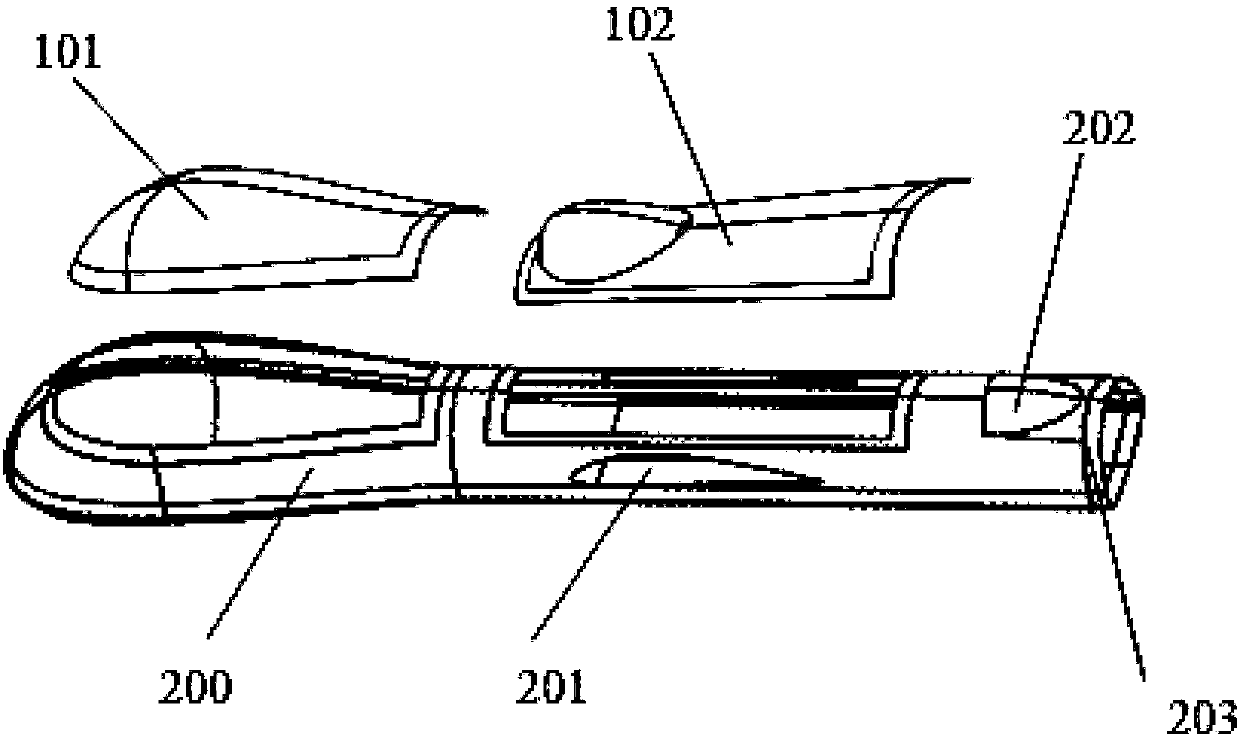

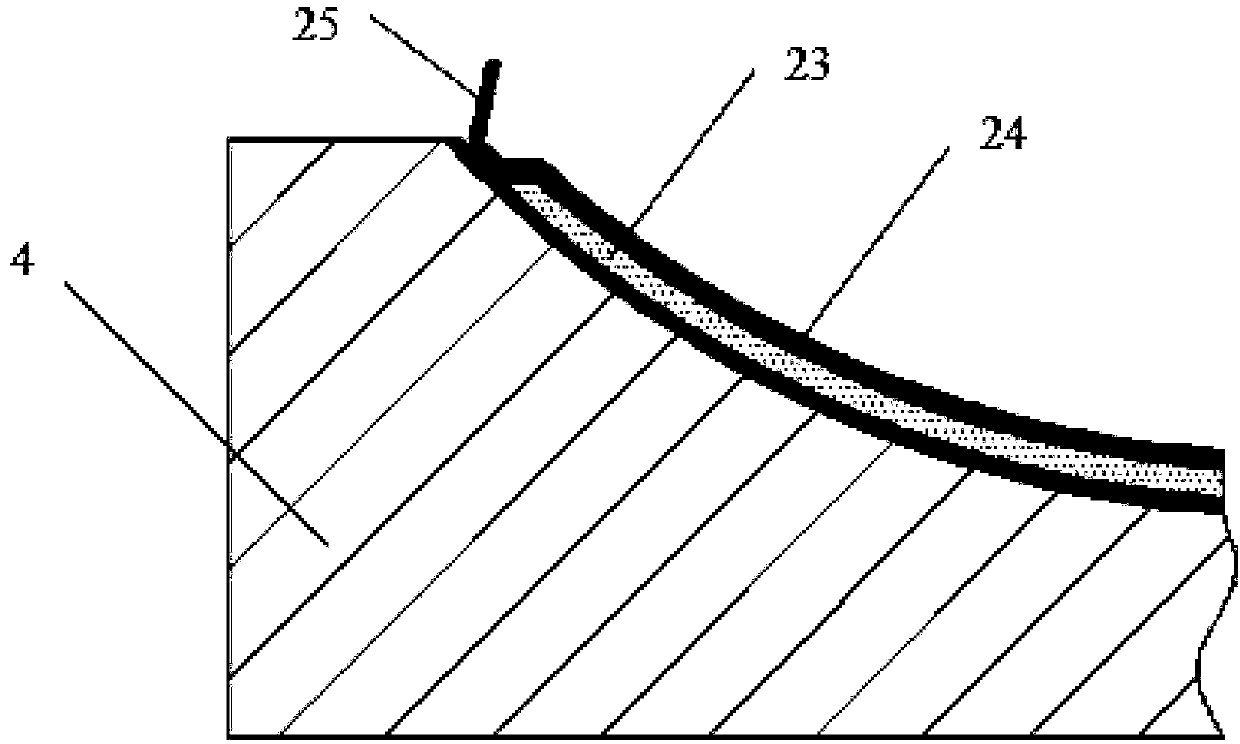

Unmanned aerial vehicle body integrated molding technology

InactiveCN107738457AImprove performanceImprove mobilityFuselage framesWeight reductionFiberCarbon fibers

The invention discloses an unmanned aerial vehicle body integrated molding technology. Carbon fiber prepreg and lightweight foam are used as raw materials, are paved on the inner wall of a double-female mold combination mold by adopting a prepreg lapping joint integral layering technology, and then are integrally solidified and molded by adopting an autoclave molding technology. The unmanned aerial vehicle body integrated molding technology has the beneficial effects that the technology is simple and is easy to operate; the molding time is short; the product size is accurate and controllable;and a manufactured unmanned aerial vehicle body has high strength, good rigidity, light dead weight and a smooth and fat surface, is easy to maintain routinely and is suitable for large batch production.

Owner:CGN JUNER NEW MATERIALS +1

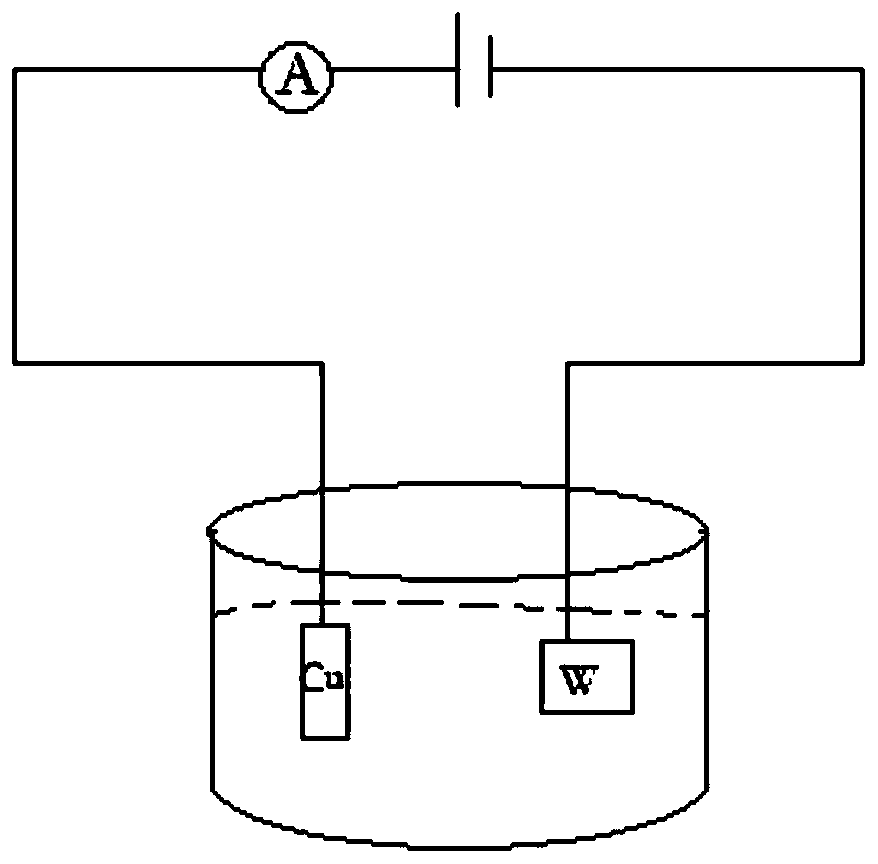

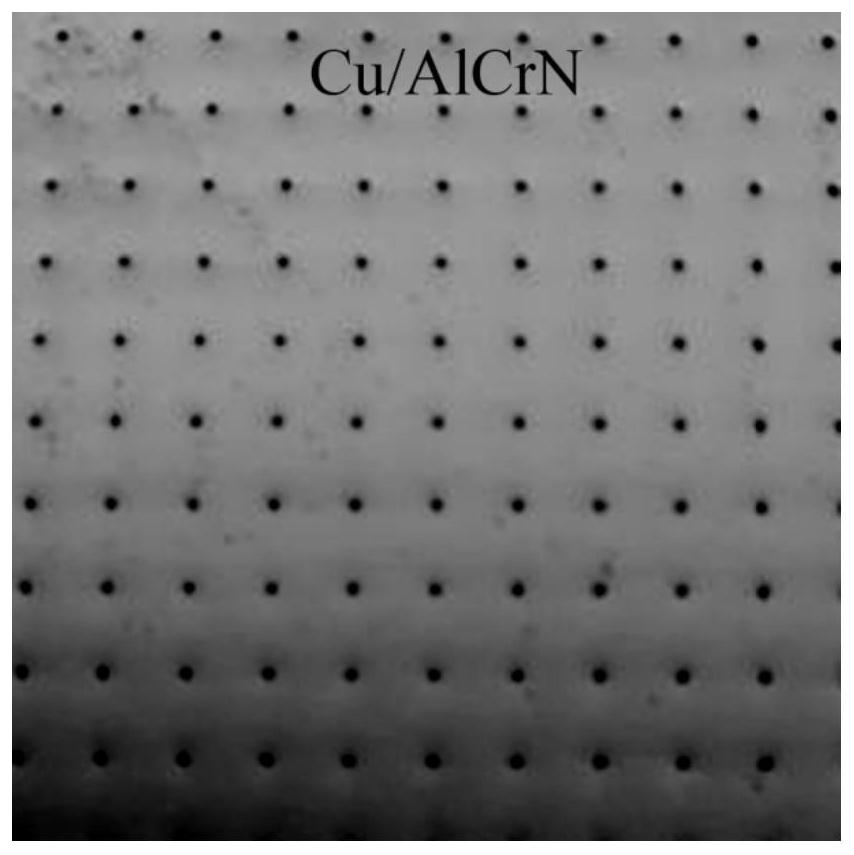

Tungsten enhancement copper composite and preparing method thereof

InactiveCN111411254AGive full play to high temperature characteristicsPrecise and controllable pore shapeAdditive manufacturing apparatusSelective laser meltingUltimate tensile strength

The invention discloses a tungsten enhancement copper composite. The tungsten enhancement copper composite comprises following components including, by volume fraction, no less than 50% of copper powder and the balance tungsten powder, and the sum of the volume percents of the components is 100%, and the invention further discloses a preparing method of the tungsten enhancement copper composite. According to the tungsten enhancement copper composite, a proportion of less tungsten and much copper is adopted, the high-temperature characteristics of refractory metal tungsten and high-conductivitycharacteristics of low-melting-point metal copper are sufficiently exerted, particular needs of high temperature resistance and good conduction can be met, according to the preparing method, the selective laser melting technology is adopted for preparing a porous tungsten framework, the tungsten framework pore shape, number and size are precisely controllable, the tungsten skeleton metallurgicalbonding is adopted, the strength is high, isotropy is achieved, a network shape is formed, bonding phase copper is sufficiently filled in the porous tungsten framework through the melt infiltration technology, the high-compactness tungsten enhancement copper composite used under multiple environments can be prepared, and good practical value is achieved.

Owner:XIAN UNIV OF TECH

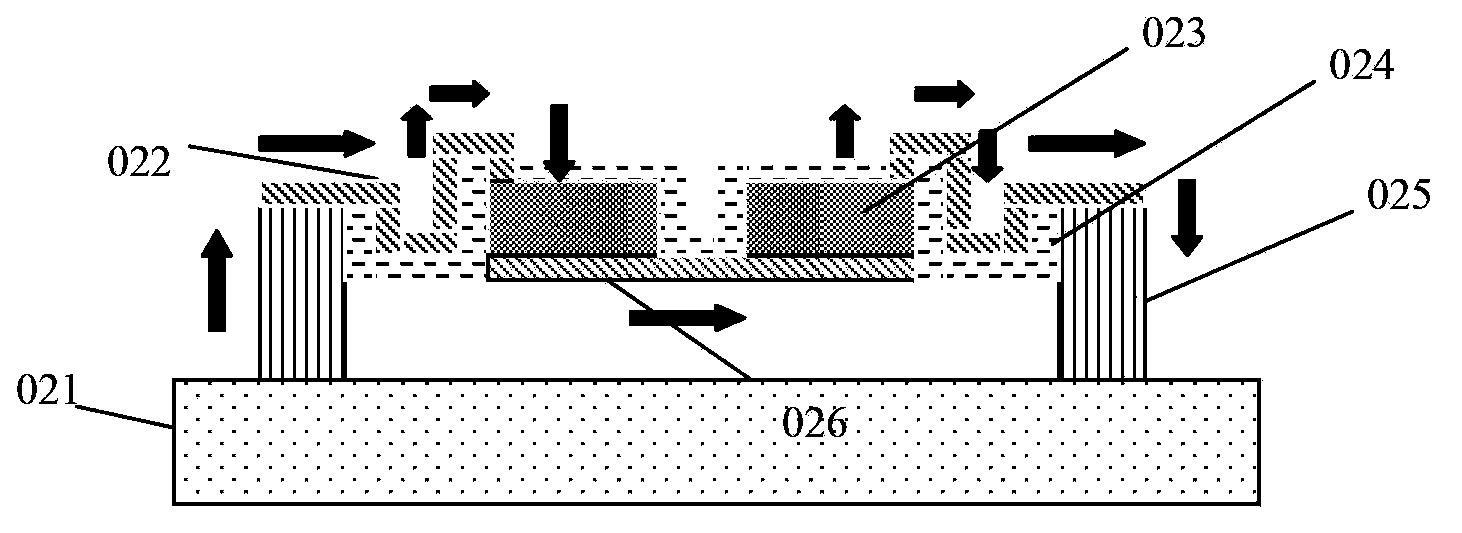

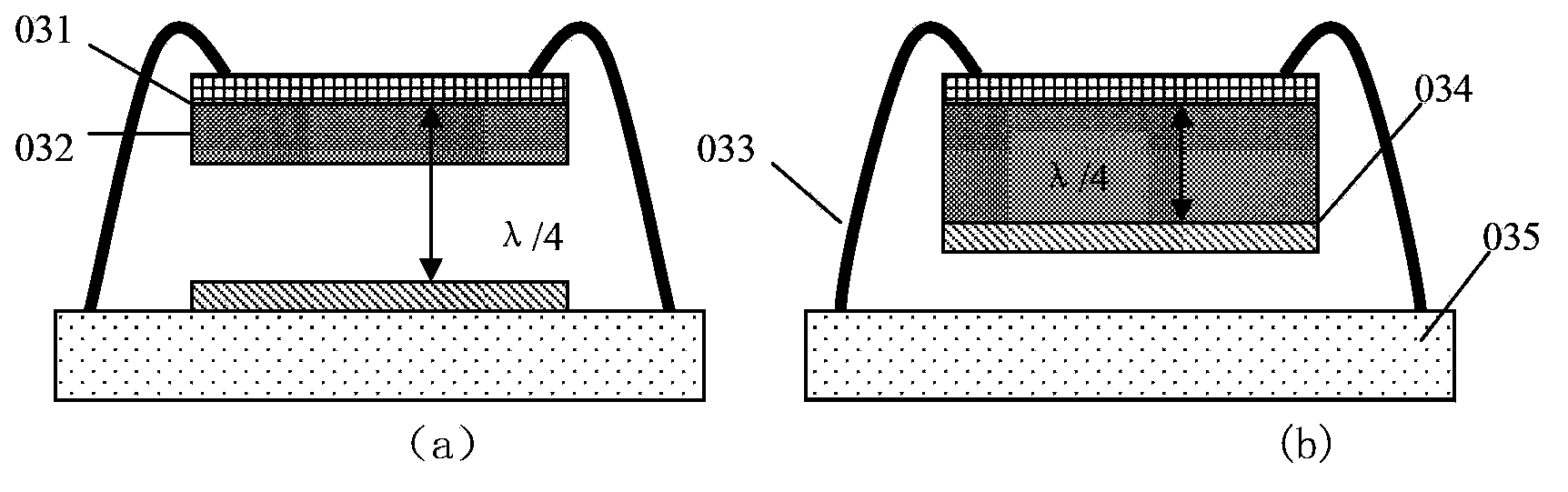

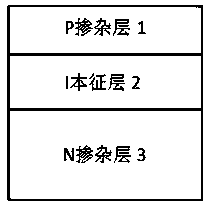

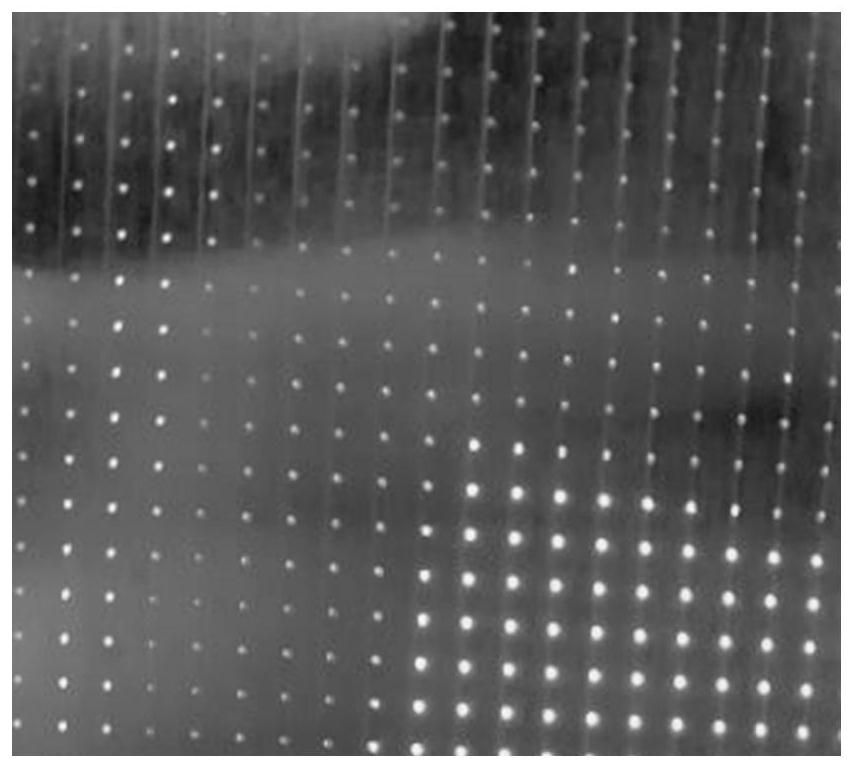

Method for manufacturing uncooled infrared focal plane array pixel with silicon-germanium film

ActiveCN103730535AHigh TCR valueLow intrinsic noiseFinal product manufactureRadiation controlled devicesCMOSSilicon nitride

The invention discloses a method for manufacturing an uncooled infrared focal plane array pixel with a silicon-germanium film. The method includes the steps of transferring the silicon-germanium film to a CMOS wafer from an SOI wafer, etching the silicon-germanium film to form a channel, forming a metal top electrode with a lift-off method, etching the silicon-germanium film to form a sensitive block, depositing a silicon nitride supporting film with a PECVD method, carrying out electroplating to grow metal electrode columns, sputtering TiW to form a circuit, sputtering an infrared absorption layer, etching a silicon nitride layer, a TiW layer and the like, forming an L-shaped cantilever beam and the like. According to the method, silicon-germanium / silicon quantum well materials are successfully applied to the field of micrometering bolometers, and the range of sensitive materials capable of being used for making an uncooled infrared focal plane is expanded; it is considered that the silicon-germanium / silicon quantum well materials are three-dimensional electric conducting materials, a U-shaped loop is formed in the mode of etching the channel, and the resistance of the sensitive area is improved; the silicon nitrogen film is introduced, a lambda / 4 resonance infrared absorption cavity is formed in the sensitive area, the size of the infrared absorption cavity is accurately controlled, and the infrared absorption rate is effectively improved.

Owner:NANJING UNIV OF SCI & TECH

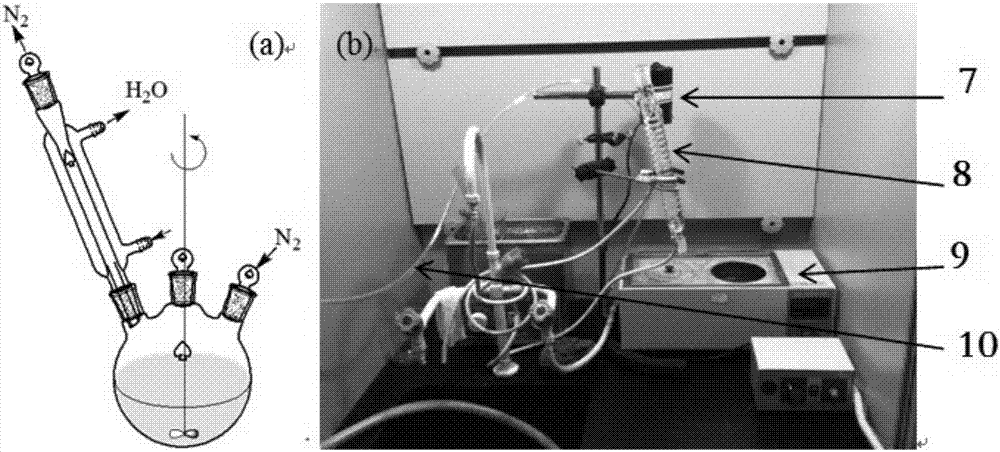

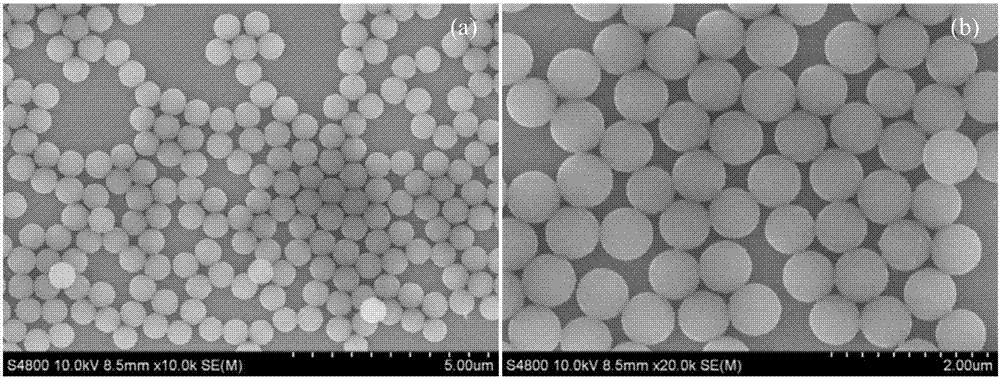

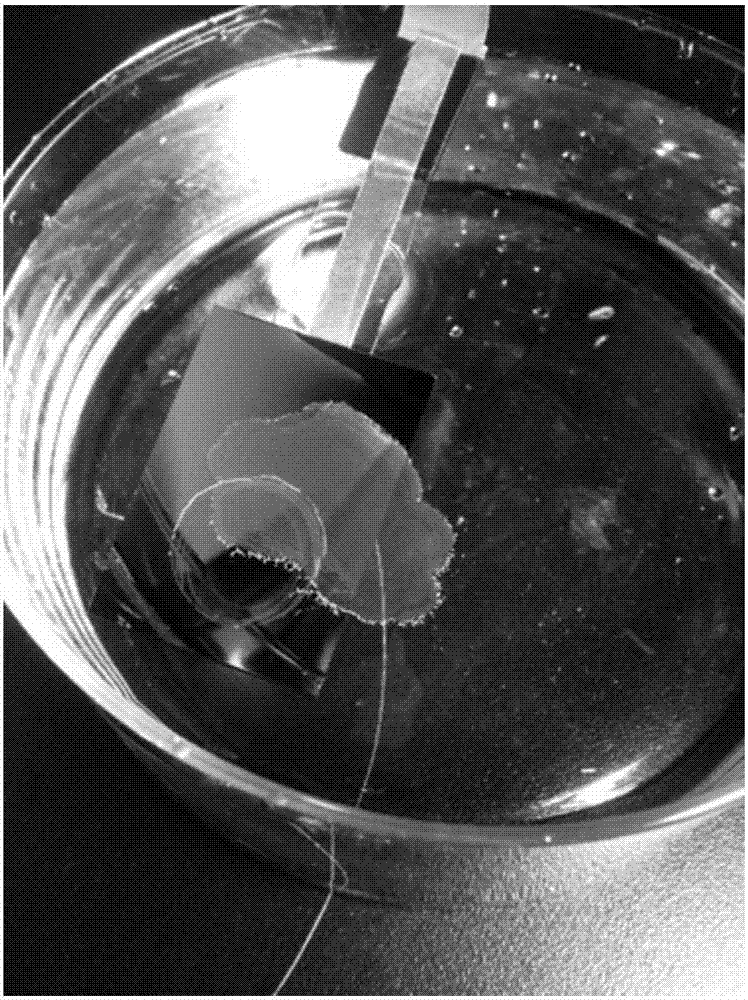

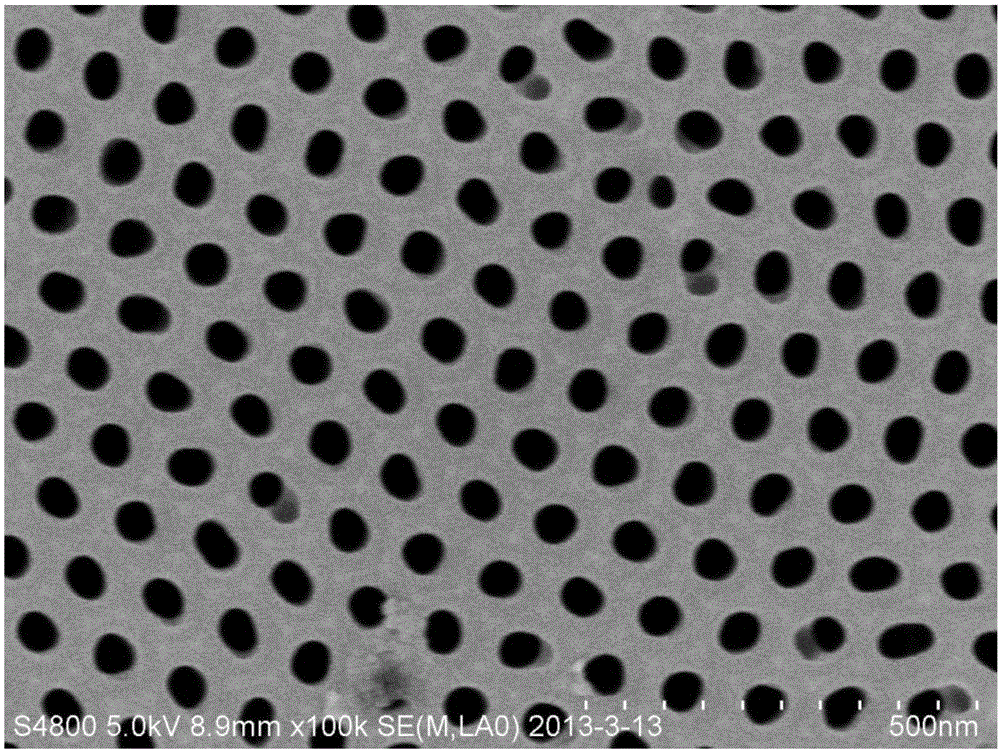

Method for preparing single-electron transistor by assembling gold particles on PS microsphere template

PendingCN106935501AEasy integration of batch preparationImprove gate control abilityNanostructure manufactureSemiconductor/solid-state device manufacturingGold filmAluminium oxide

The invention relates to a method for preparing a single-electron transistor by assembling gold particles on a PS microsphere template. According to the method, a silicon dioxide substrate is formed on the surface of a silicon base sheet; a coulomb island and an electrode are arranged on the silicon dioxide substrate in an integrated manner; an evenly and compactly-arranged PS microsphere single-layer film template is prepared on the silicon dioxide substrate; an electric beam evaporation coating method is utilized to plate a gold film on the surface of the PS microsphere single-layer film template; a chemical etching method and post-treatment are adopted, so that a gold nanoparticle array is obtained; an aluminum oxide barrier layer is formed on the gold nanoparticle array by using atomic layer deposition; the electrode is prepared by using electron beam exposure, electron beam evaporation coating and / or peeling methods; and an aluminum oxide protective layer is prepared on the electrode and the aluminum oxide barrier layer through using atomic layer deposition. The coulomb island is a size-controllable array, and therefore, positioning and batch preparation can be facilitated; and the size of the barrier between the coulomb island and the electrode can be precisely controlled. The method can be widely applied to fields such as photon, electronics, environment and security fields.

Owner:NAT UNIV OF DEFENSE TECH

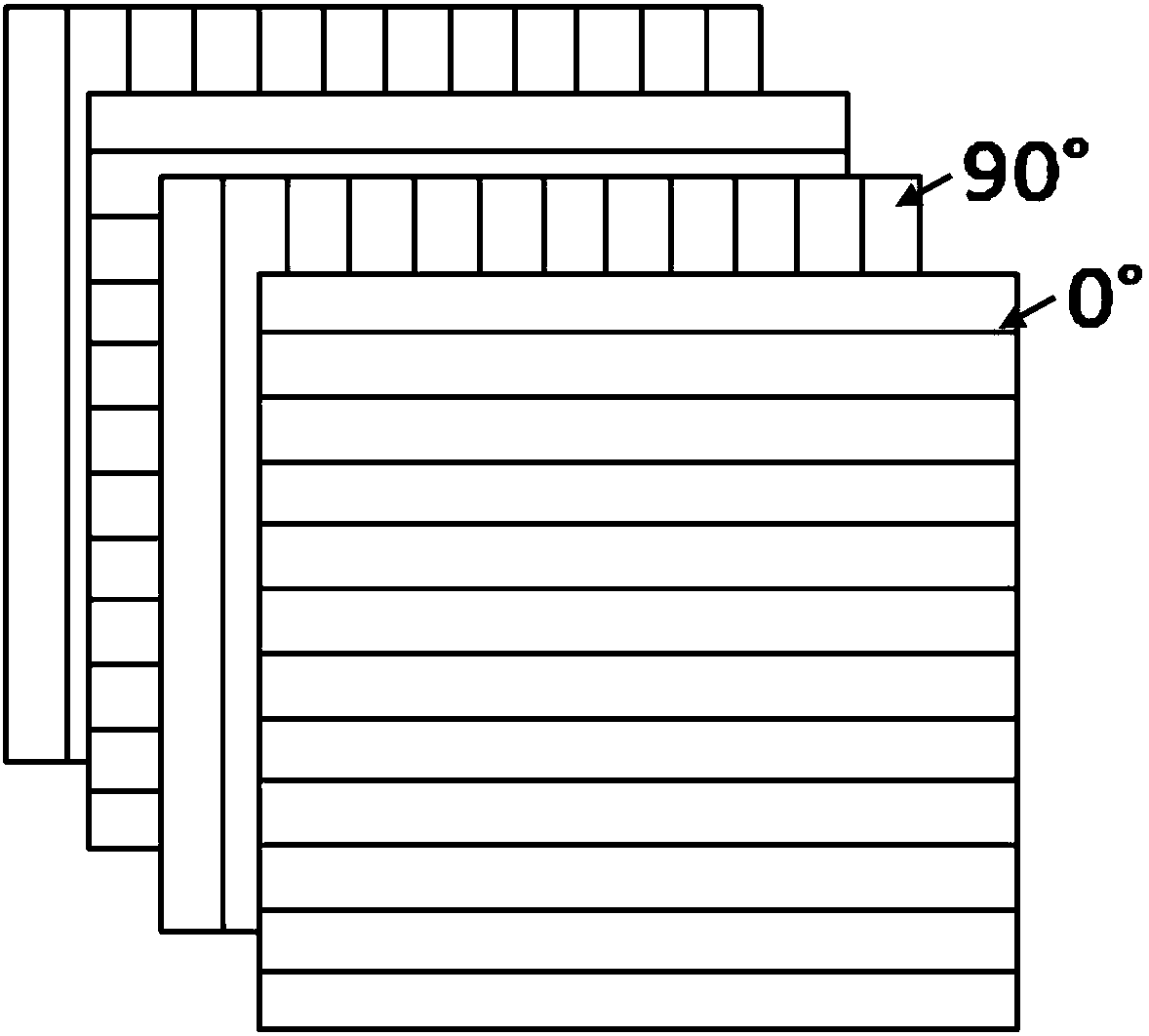

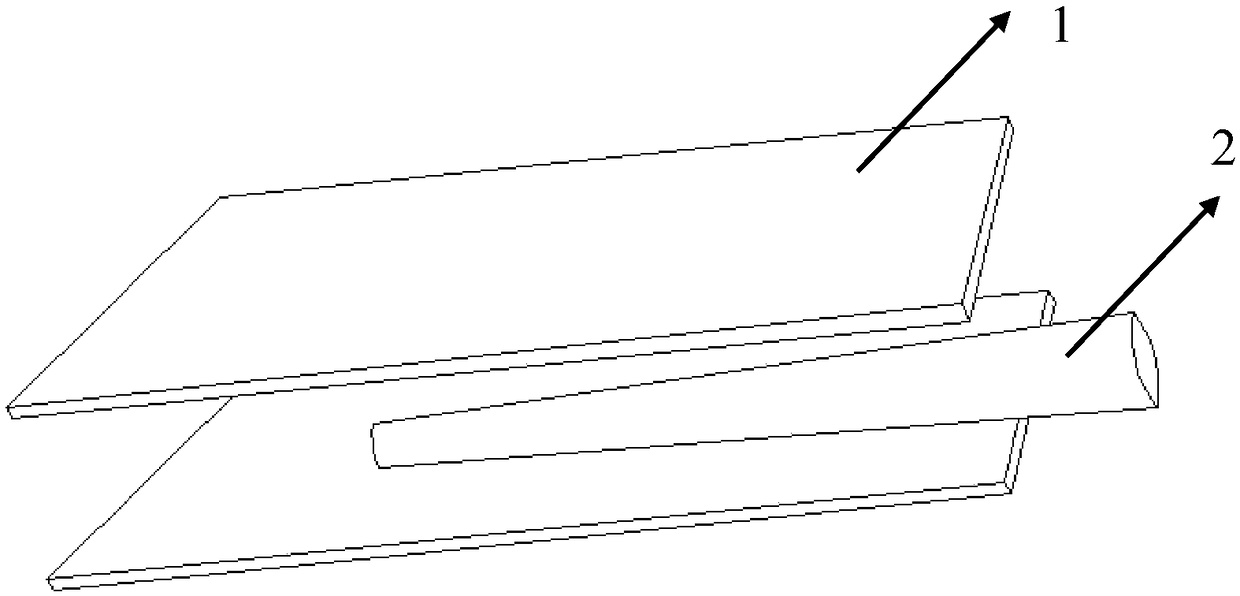

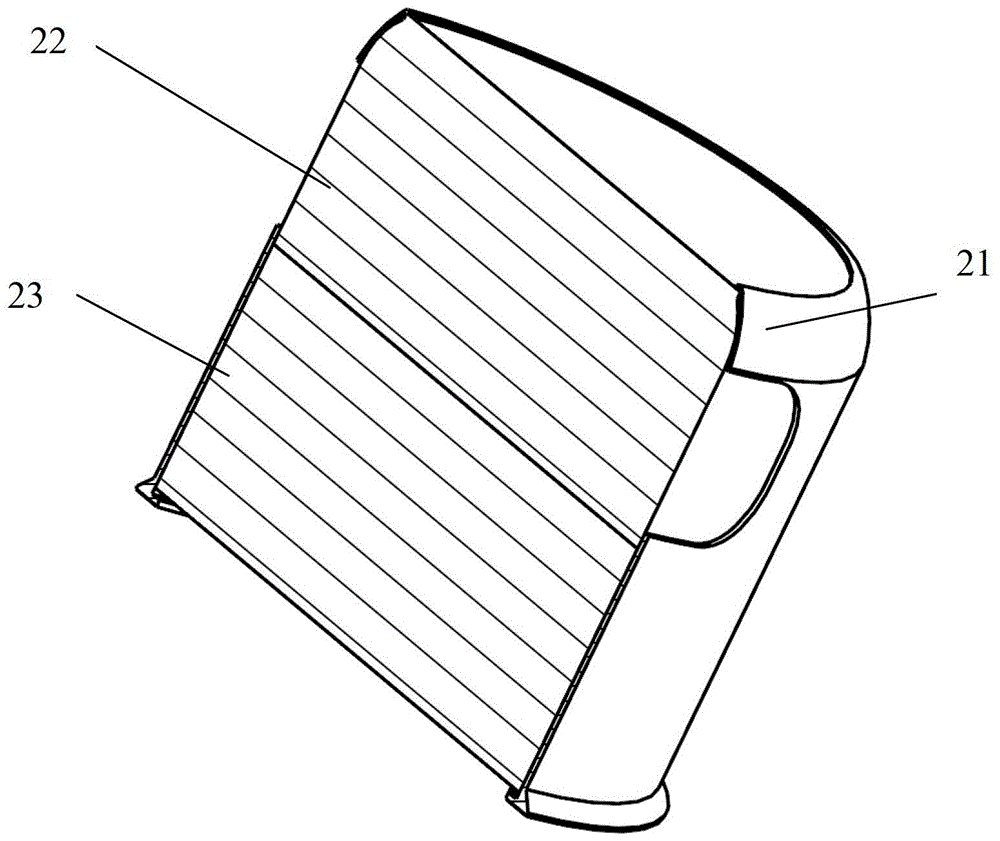

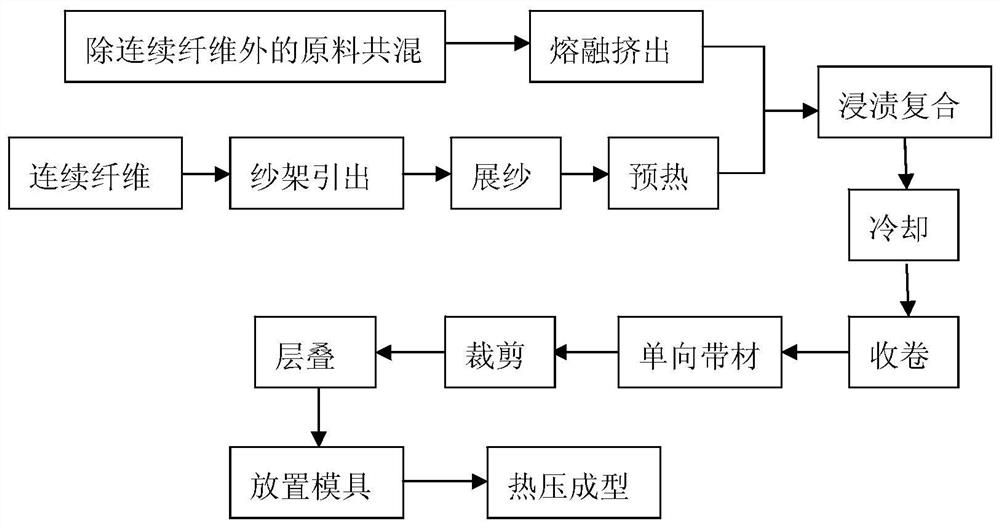

Continuous fiber enhanced thermoplastic resin composite paddle and preparation method thereof

ActiveCN108192201AIn line with the development trend of green environmental protectionHigh strengthDomestic articlesCoatingsMechanical propertyCorrosion resistant

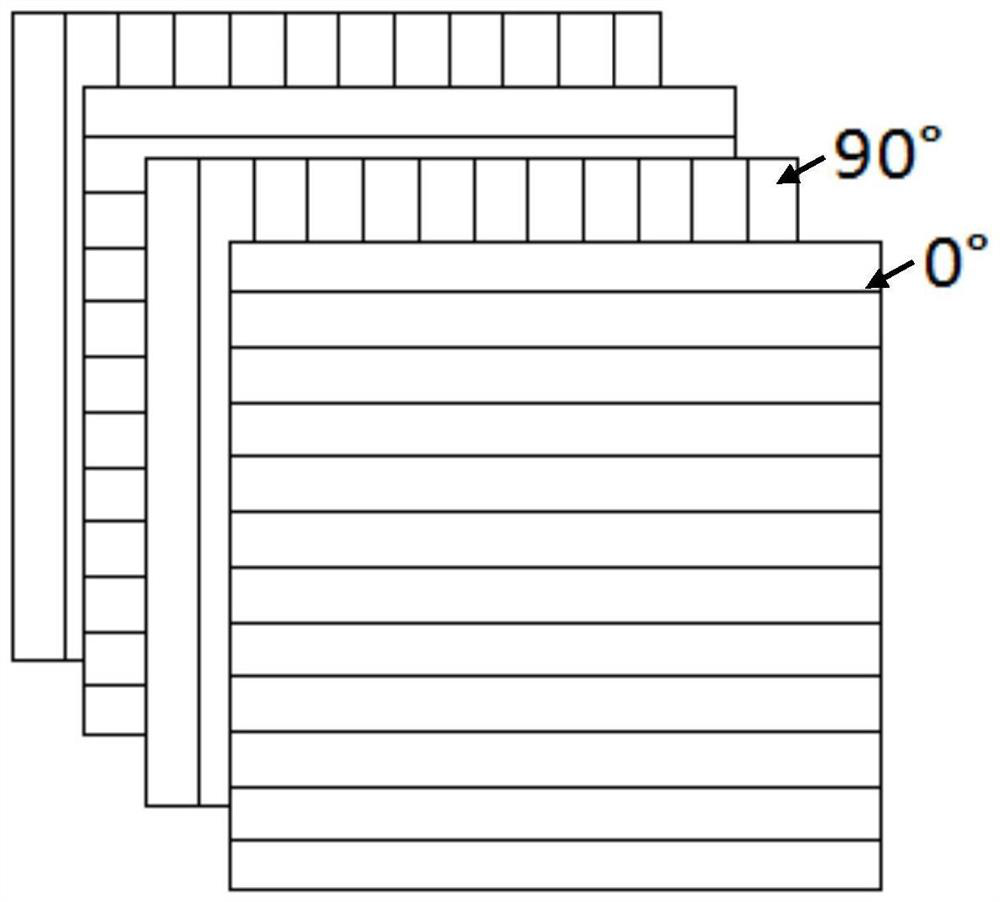

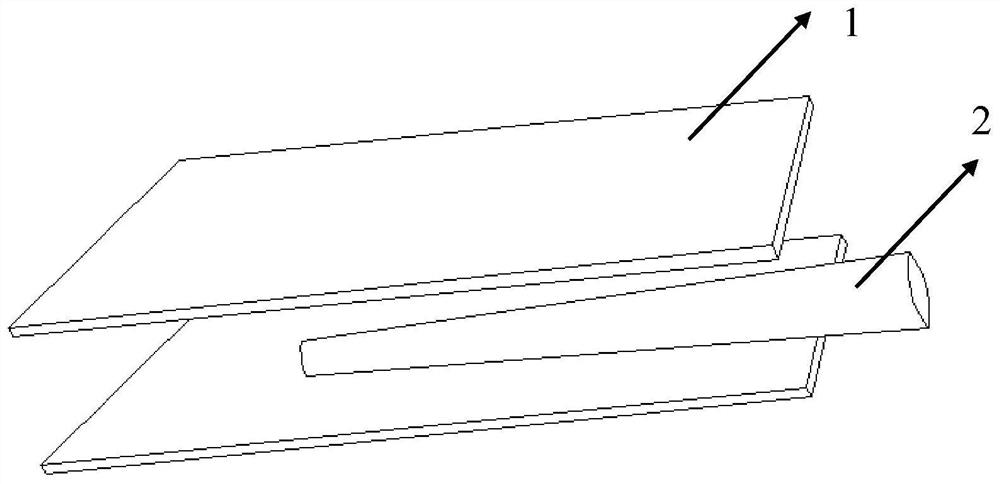

The invention discloses a preparation method of a continuous fiber enhanced thermoplastic resin composite paddle. The method comprises the following steps: preparing a continuous fiber enhanced thermoplastic resin unidirectional prepreg tape; clipping the unidirectional prepreg tape into two types of master slices along a 0-degree direction and a 90-degree direction, alternately stacking master slice groups formed by the two types of master slices in an orthometric manner, laying a core model in the middle of the master slice groups, transferring the master slice groups into a paddle die, performing hot press molding, and then performing machining trimming treatment, so as to obtain the paddle. The preparation method adopts hot-pressing technology, realizes one-step molding, is short in molding time, and ensures that product size is accurate and controllable; the formed paddle is excellent in mechanical property, anti-fatigue performance and corrosion-resistant performance, is light inweight and recyclable, and can be machined repeatedly.

Owner:CGN JUNER NEW MATERIALS +1

Integral molding process for fuselage of helicopter

The invention discloses an integral molding process for a fuselage of a helicopter, and belongs to the field of helicopter preparation. The integral molding process comprises the following steps of S1: tailoring a carbon fiber prepreg; S2, laying an isolating membrane; S3, laminating the tailored carbon fiber prepreg; S4, mounting a gas guiding system on the outer surface of the carbon fiber prepreg; S5, performing heating treatment by an autoclave; and S6: taking. The carbon fiber prepreg is used as a raw material, the fuselage of the helicopter in all angles has high strength through lay-updesign, a split module set and a vacuum bag enables the strength of the interior of the fuselage of the helicopter to reach the requirements through an autoclave molding technology, the assembly of the interior is ensured, the fuselage of the helicopter is high, the process is simple and easy to operate, the molding time is short, the product size is accurate and controllable, and the production efficiency is improved.

Owner:湖南欧亚碳纤维复合材料有限公司

Myocardial tissue sensor and myocardial tissue chip preparation method

InactiveCN104931683AHigh densityEfficient couplingBiological testingData acquisitionElectrical stimulations

The invention discloses a preparation method of myocardial tissue sensor and a myocardial tissue chip, and belongs to the technical fields of tissue engineering, biomedicine engineering and sensor. The myocardial tissue sensor comprises a myocardial tissue chip and auxiliary parts, wherein the auxiliary parts include an upper die, a lower die, an upper electrode, a lower electrode, a sensitive plate, a parallel light source and a data acquisition system. According to the invention, myocardial cells are sequentially printed on a glass sheet coated with N-isopropylacrylamide and polydimethylsiloxane by virtue of a cell printing technology so as to prepare the myocardial tissue chip; the myocardial tissue chip is kept in the auxiliary parts and is subjected to pulsatile cultivation to form myocardial tissues consistent in beating rhythm, and then the myocardial tissues are kept in a culture solution containing a medicine and undergo electrical stimulation; and a contractile change signal is collected to evaluate the effect of the medicine on cardiac muscle, so as to achieve the purposes of drug screening, testing and the like. The myocardial tissue sensor disclosed by the invention has the advantages of simple device, wide scope of testing medicine, easy detection and processing of signal, and the like.

Owner:TSINGHUA UNIV

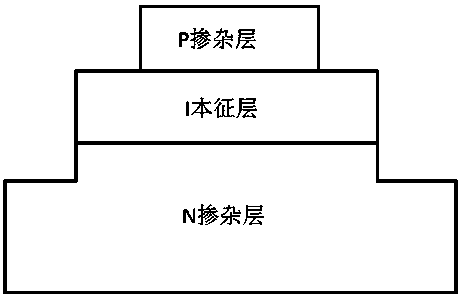

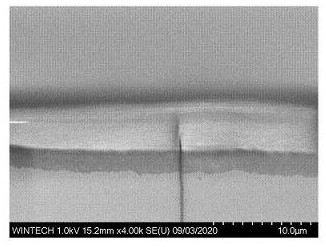

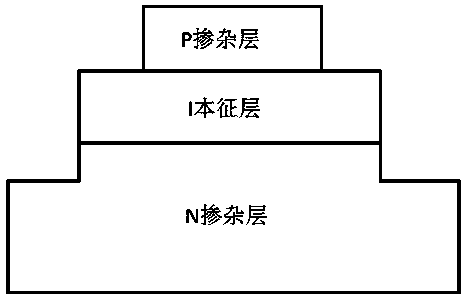

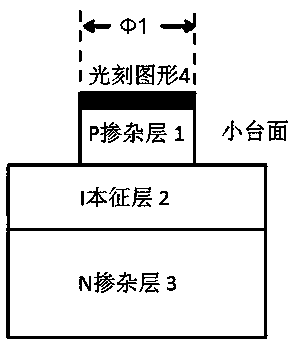

Self-aligning dual mesa device structure making method

InactiveCN108054235APrecise alignmentPrecise and controllable sizeFinal product manufactureSemiconductor/solid-state device manufacturingLithographic artistEngineering

The invention relates to a self-aligning dual mesa device structure making method. Based on the photoresist reflow process, one-step photolithography is used to make a dual mesa device structure, anddual mesa center self-aligning is carried out. The method is advantaged in that one step of lithography is omitted, flow sheet efficiency is improved, flow sheet cost is reduced, the edge interval between a large mesa and a small mesa can be smaller than 1um and can be further adjusted through photoresist reflow technology control, and the method is especially suitable for making a focal plane array with the high duty ratio.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

Porous liquid guiding, heating and atomizing assembly with supporting shell and preparation method thereof

PendingCN111436666ASolve the strength problemSolve sizeTobaccoInjection molding processElectric heating

The invention discloses a porous liquid guiding, heating and atomizing assembly with a supporting shell. The assembly includes a porous liquid guide body used for absorbing and transferring liquid, one or more supporting shells used for supporting the porous liquid guide body, an electric heating track used for heating, evaporating and atomizing the liquid after being powered on, and one or moreoil inlet holes which are through front and back are formed in each supporting shell. The invention provides a porous liquid guiding, heating and atomizing assembly with a supporting shell and a preparation method thereof. The porous liquid guide body and a mold injection molding process are creatively combined, the problems that the porous liquid guide body is poor in strength, large in dimensional tolerance, rough in surface and prone to damage are solved on the basis that the liquid guide characteristic of the porous liquid guide body is guaranteed, the strength of the porous liquid guide body is good, the size is accurate and controllable, and large-batch automatic production is facilitated.

Owner:SHENZHEN HUACHENGDA PRECISION IND CO LTD

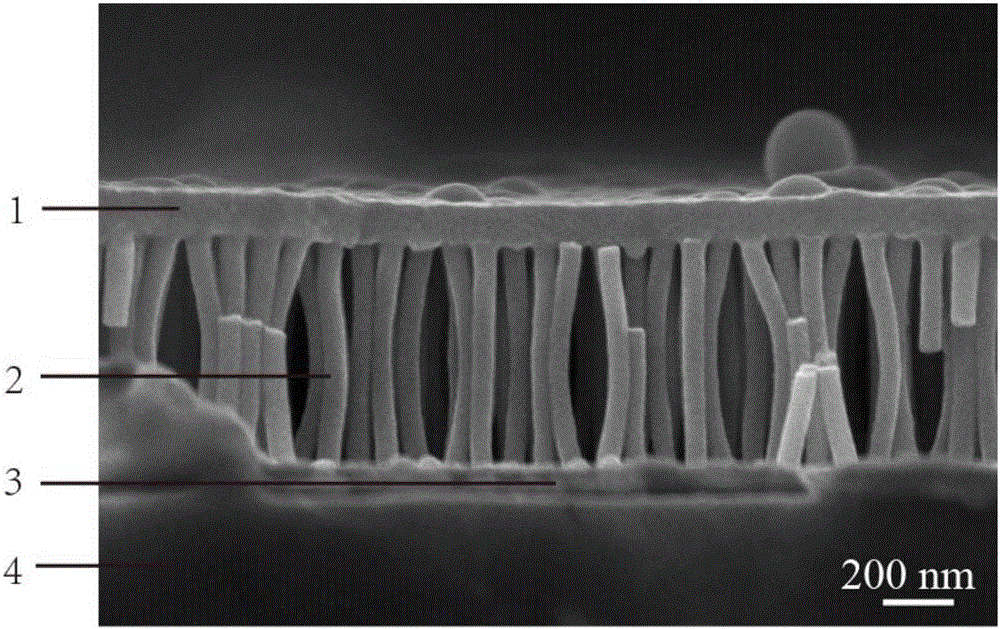

Optical waveguide sensing chip, preparation method thereof, and use

InactiveCN104991088AFirmly connectedGood size controlScanning probe techniquesIonTetraethyl orthosilicate

A preparation method of an optical waveguide sensing chip comprises immersing a gold film substrate in an organic solution of mercapto silance to be processed, processing the processed gold film substrate by utilizing an acid solution, pasting a porous anodic aluminum oxide film to a surface of a gold film, immersing the aluminum oxide film pasted to the surface of the gold film in a mixed solution of cetyltrimethyl ammonium bromide (CTAB), water, ethyl alcohol, concentrated ammonia liquor and tetraethyl orthosilicate (TEOS) and standing for a period of time, and processing the processed product by utilizing an acid solution to remove the porous aluminum oxide film. The invention discloses the optical waveguide sensing chip and use of the optical waveguide sensing chip for non-labeled optical biological detection or heavy metal ion detection. The optical waveguide sensing chip is an optical waveguide sensing chip prepared by the method based on a nano-column array film. The optical waveguide sensing chip can be used to perform the high-sensitivity non-labeled optical biological detection or the high-sensitivity heavy metal ion detection.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

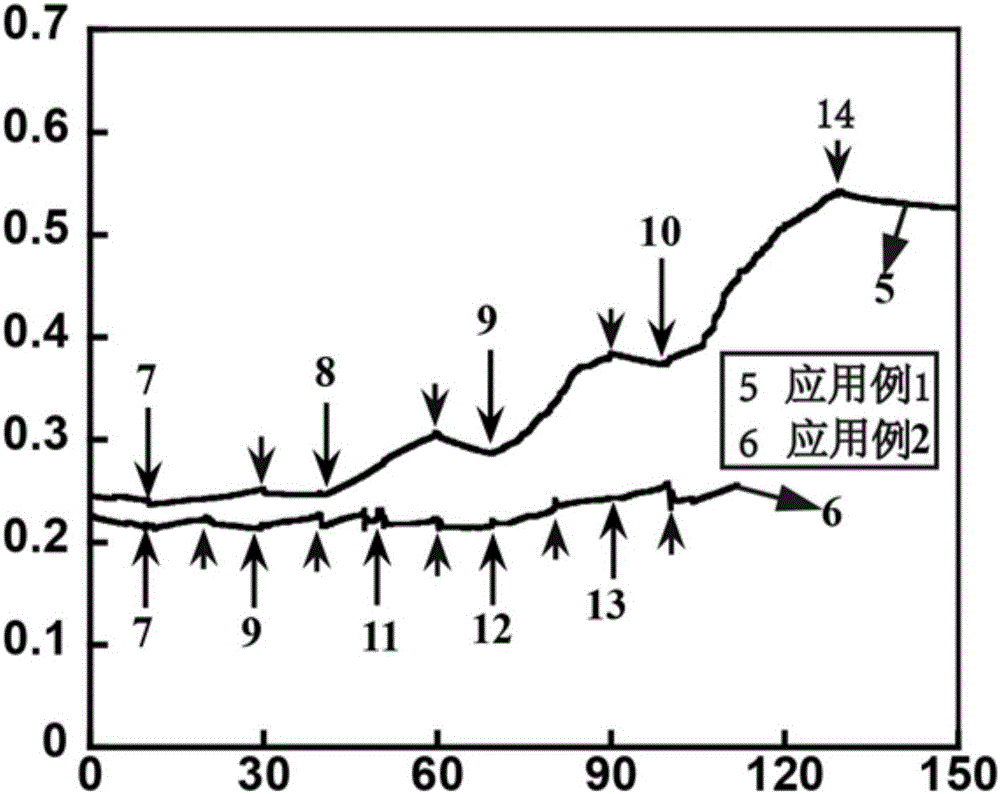

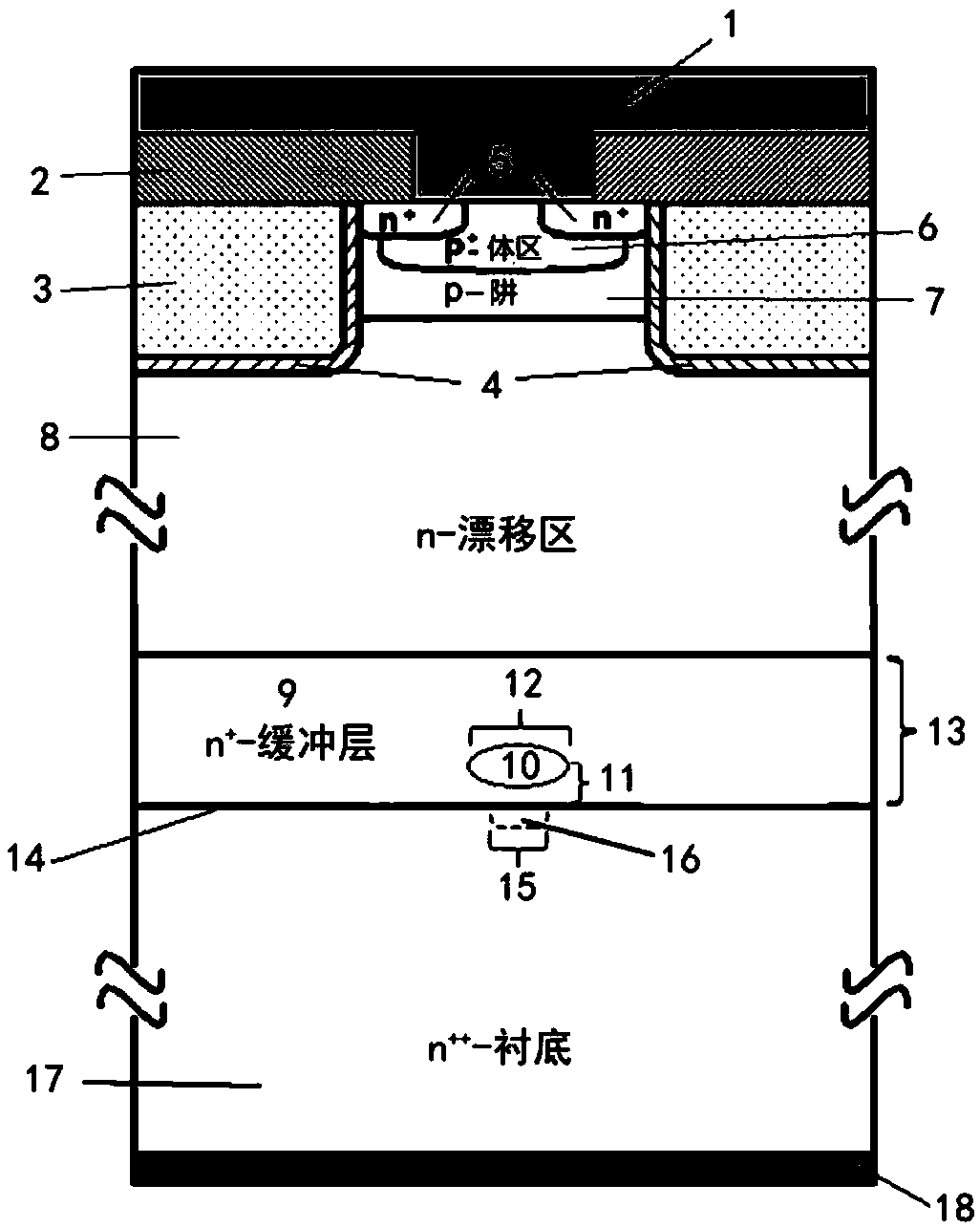

A method for fabricating n-MOSFET with composite double-layer epitaxy by boron implantation before epitaxy

ActiveCN109087866AGuaranteed to workHigh voltageSemiconductor/solid-state device manufacturingSemiconductor devicesSingle event burnoutPower MOSFET

The invention relates to a method for fabricating n-MOSFET with composite double-layer epitaxy by boron implantation before epitaxy which includes carry out p-type island photolithography and boron implantation before epitaxy process, and carrying out buffer lay epitaxy and voltage-resistant layer epitaxy after junction substrate material is selected and epitaxy process is carried out. The subsequent process is the same as that of conventional power MOSFETs. The implantation window size of p-type island and the implantation dose of boron are strictly controlled to ensure that the device is inunipolar mode when conducting. At that same time, when the device is in the blocking state, the p-type island pair buffer layer The electric field near the high and low junctions of the substrate canbe adjusted to improve the electric field distribution near the high and low junctions and to increase the single event burnout threshold of the device.

Owner:BEIJING UNIV OF TECH

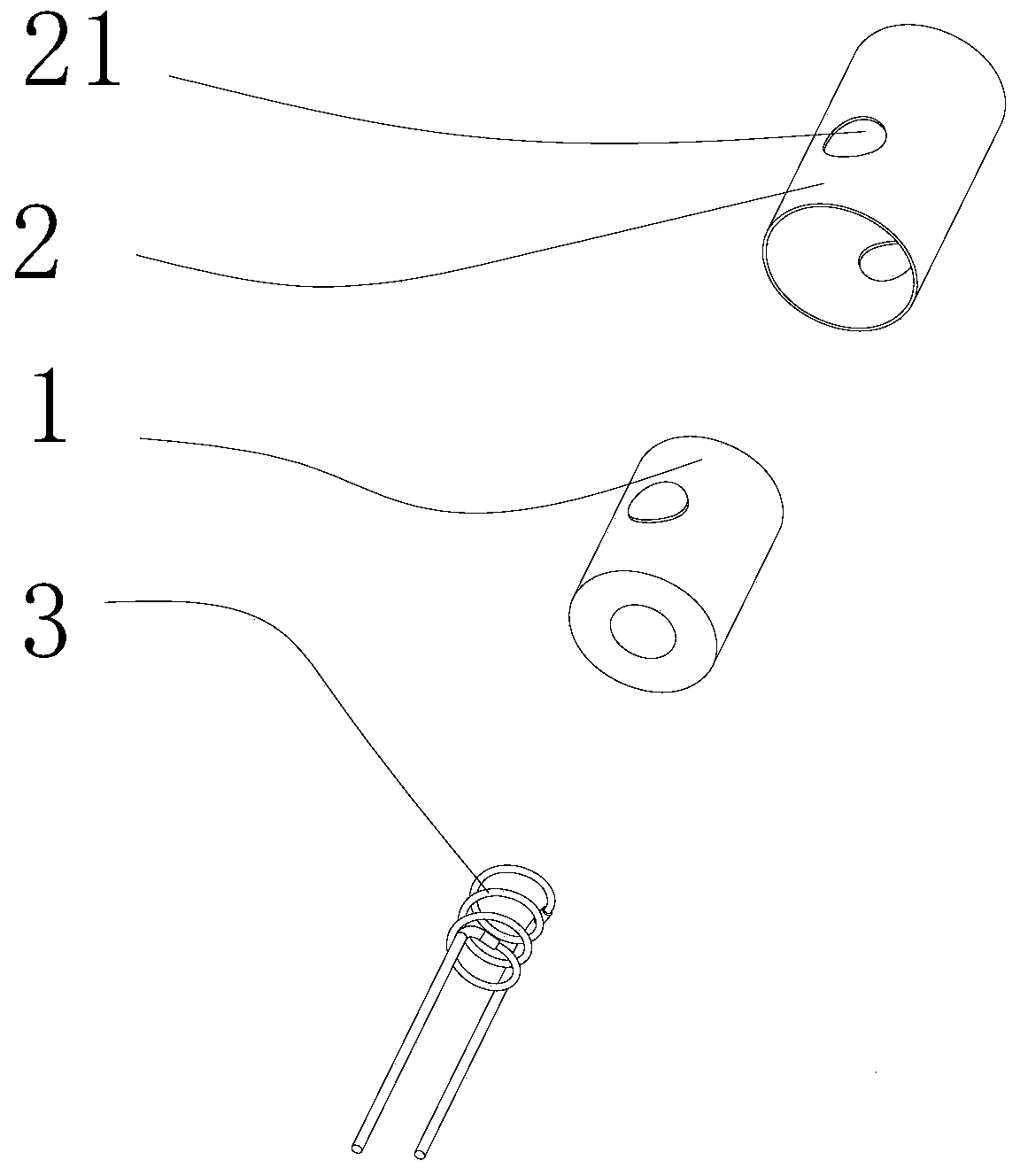

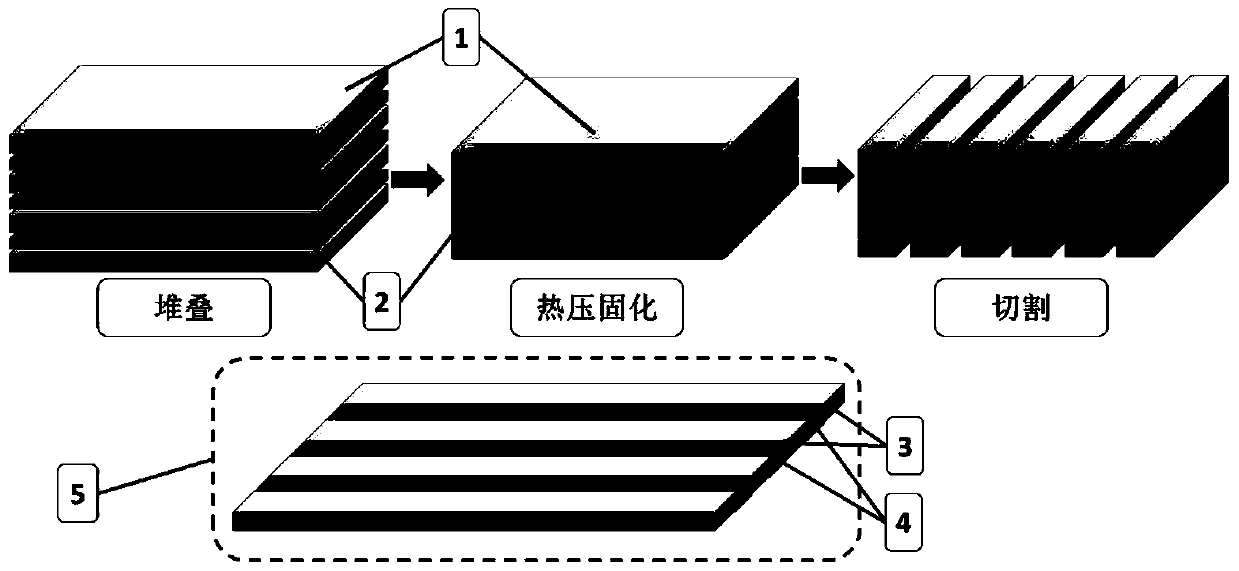

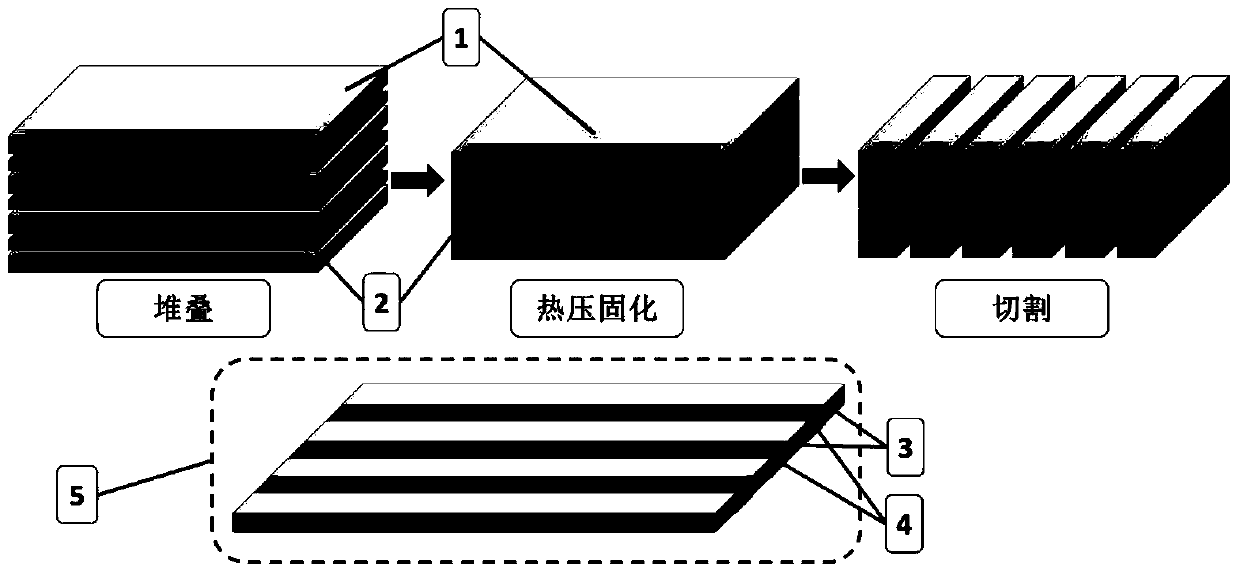

A kind of preparation method of piezoelectric fiber composite structure layer

ActiveCN105405964BGood flexibilityEasy to serializePiezoelectric/electrostrictive device manufacture/assemblyFiberPolymer adhesive

The invention relates to a preparation method of a piezoelectric fiber composite structure layer. A piezoelectric ceramic or piezoelectric single crystal thin layer is prepared by a cutting method or a molding method to obtain piezoelectric thin layers of different thicknesses; Prepare polymer thin layers of different thicknesses, cut the polymer thin layers to be consistent with the piezoelectric thin layers in length and width; stack and align the piezoelectric thin layers and polymer thin layers alternately from bottom to top, press Polymer glue is coated between the electric thin layer and the polymer thin layer, and the uppermost layer is controlled to be a piezoelectric thin layer, and the above-mentioned stack is cured by hot pressing to obtain a 2-2 type piezoelectric composite structure; according to The thickness requirements of the finished piezoelectric fiber composite structure layer can be obtained by cutting the 2-2 type piezoelectric composite structure along the stacking direction. It can precisely control the structural parameters of the piezoelectric fiber composite layer, prepare a composite structure layer with serialized fiber volume fraction and size, and effectively improve the production efficiency of the piezoelectric fiber composite material with MFC structure.

Owner:WUHAN UNIV OF TECH

Positioning dowel pin hole pairing auxiliary tool for automobile stamping die machining

InactiveCN113635153APrecise positioningImprove grinding effectGrinding carriagesRevolution surface grinding machinesMachiningDowel

The invention belongs to the technical field of automobile die manufacturing, and discloses a positioning dowel pin hole pairing auxiliary tool for automobile stamping die machining. The positioning dowel pin hole pairing auxiliary tool comprises a workpiece and a fixed cylinder, the outer surface of the fixed cylinder is provided with supporting mechanisms, the top of the fixed cylinder is movably sleeved with a cross-shaped column, the top of the cross-shaped column is provided with a top disc, a driving disc is fixedly installed at the bottom of the cross-shaped column, and the outer surface of the cross-shaped column is movably sleeved with a connecting spring. According to the positioning dowel pin hole pairing auxiliary tool, a lower pushing block is driven to move upwards, synchronous opposite movement of an upper pushing block and the lower pushing block is finally achieved, an inner plate is extruded to be pushed outwards, then moving columns and an attaching plate are driven to move outwards, and the outer side face of the attaching plate is attached to the inner wall of the dowel pin hole, so that the center of the dowel pin hole is accurately positioned through a diameter-variable concentric circle formed by a positioning and grinding mechanism, the grinding effect is better, and the grinding position is more accurate.

Owner:黄小林

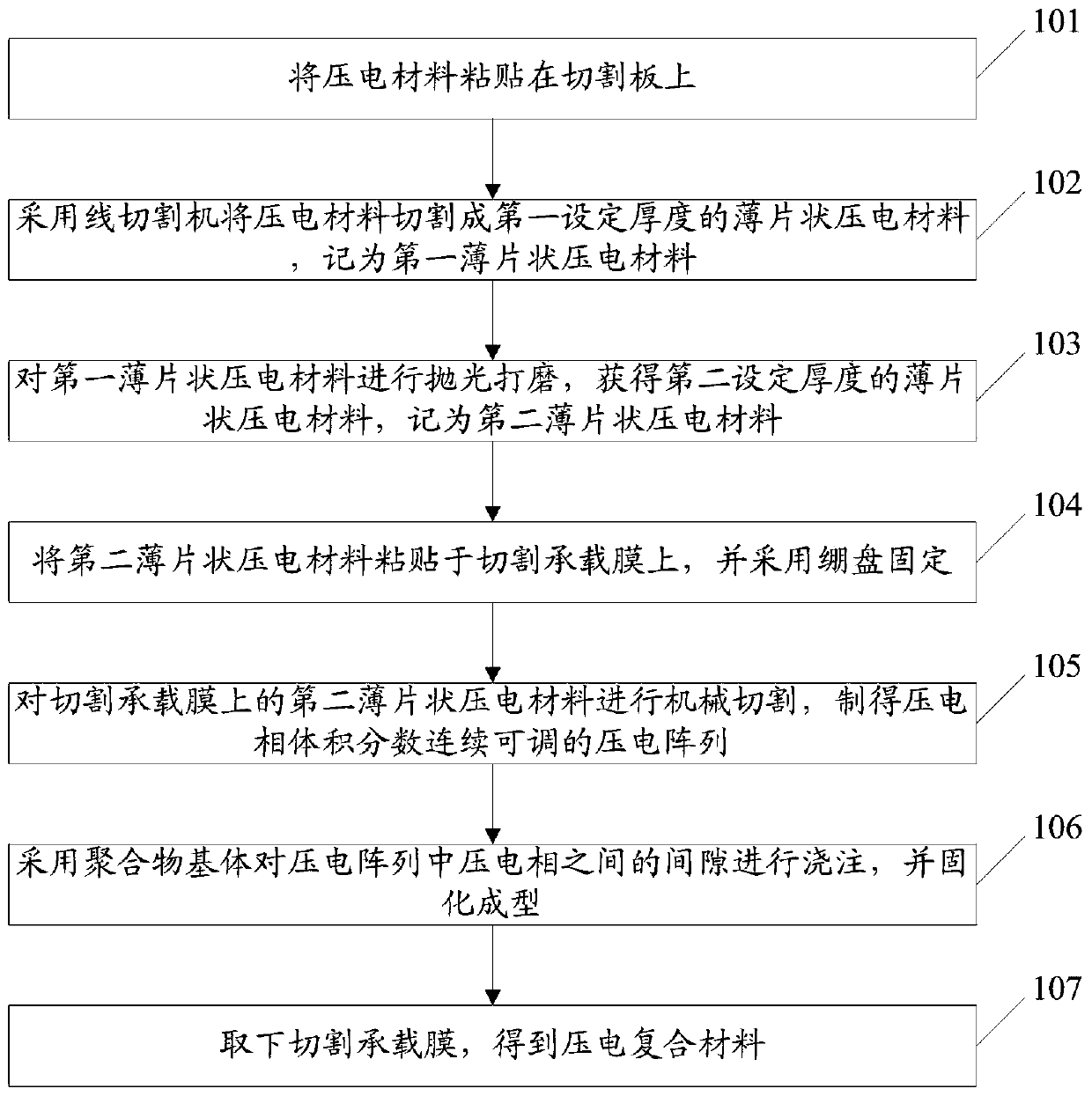

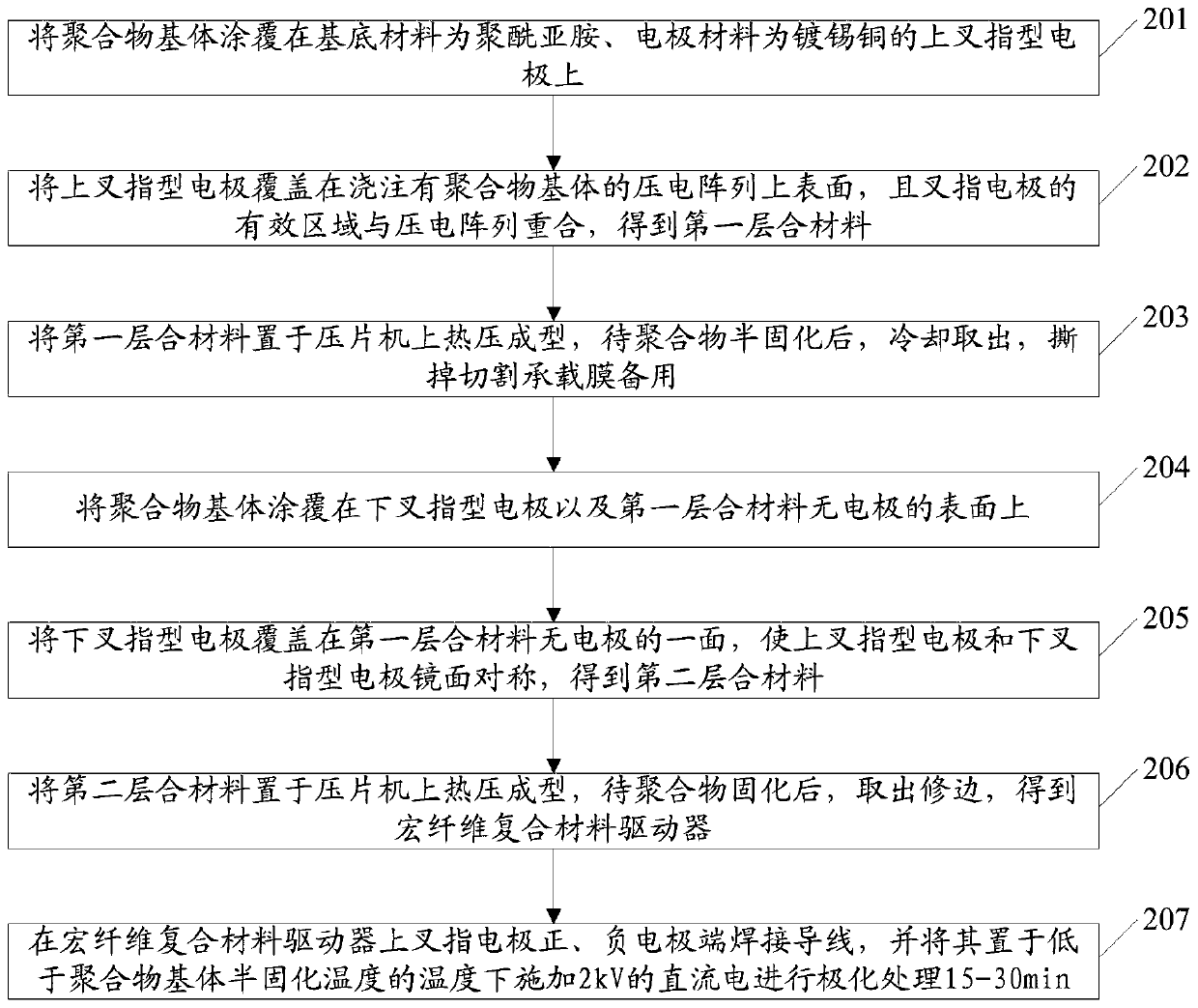

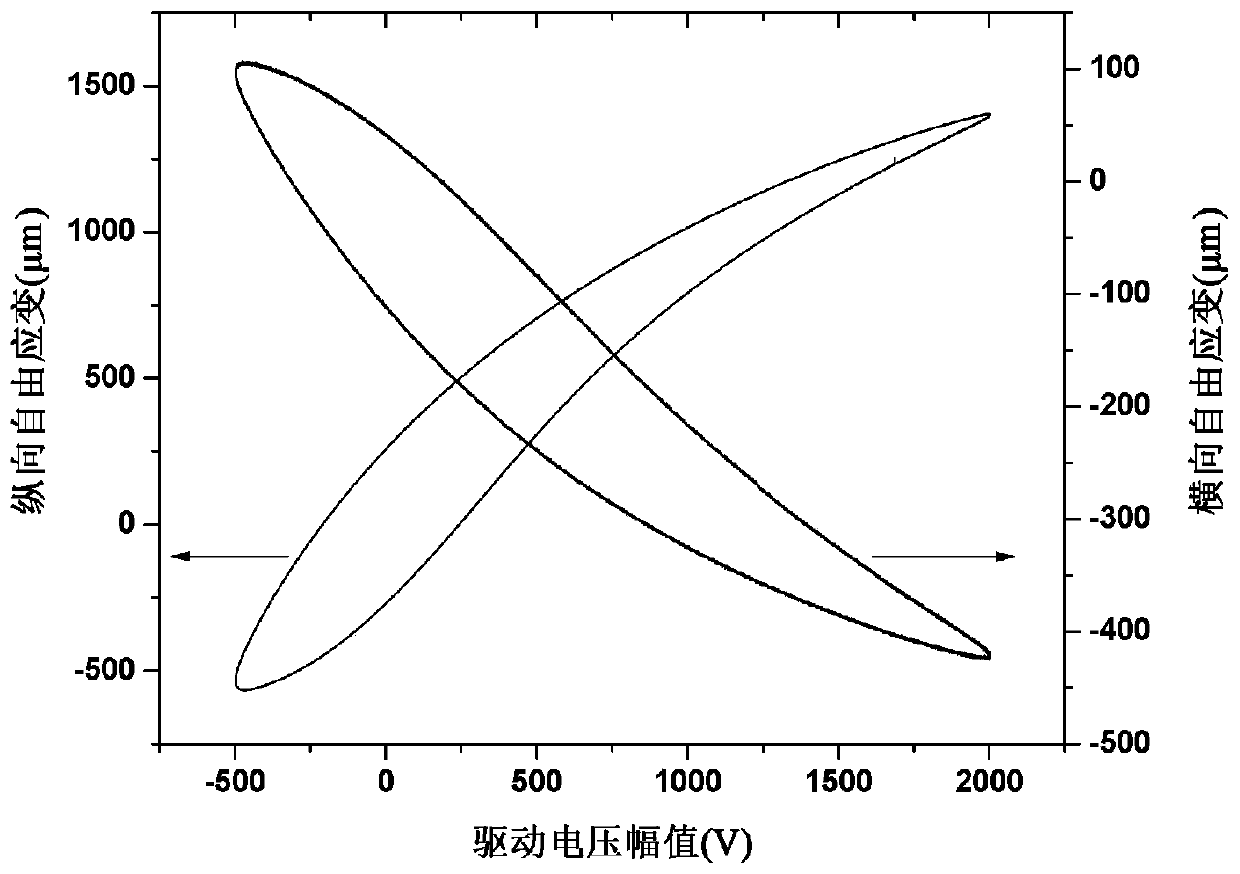

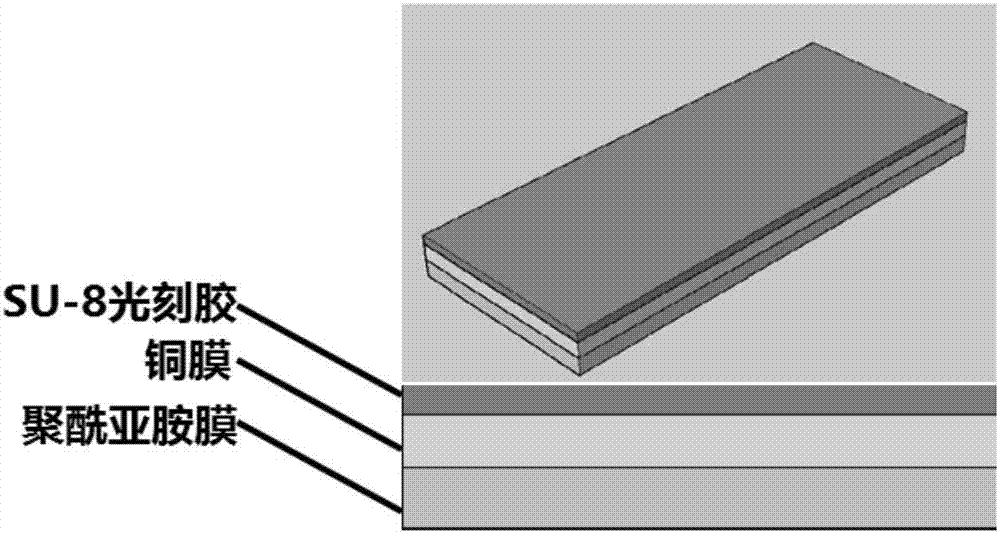

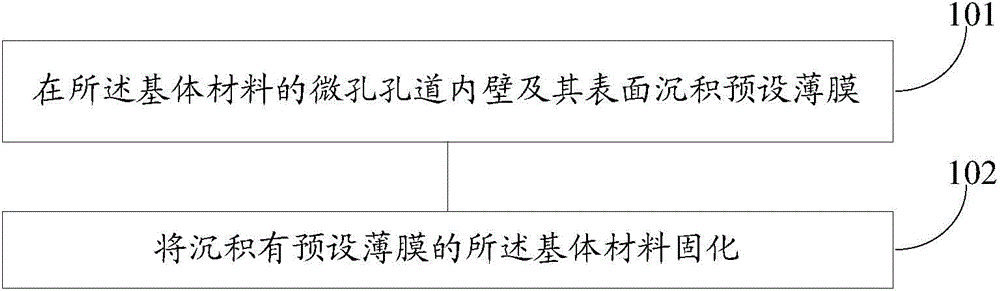

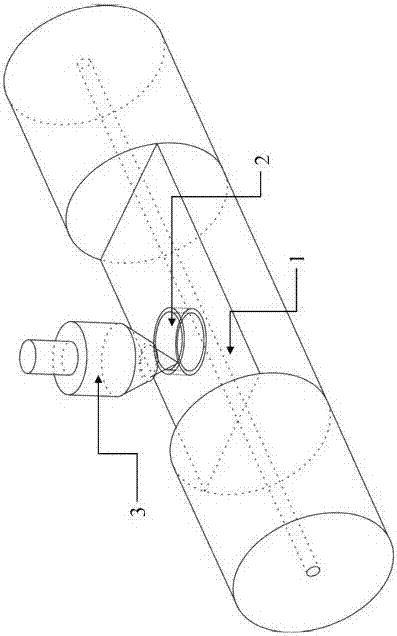

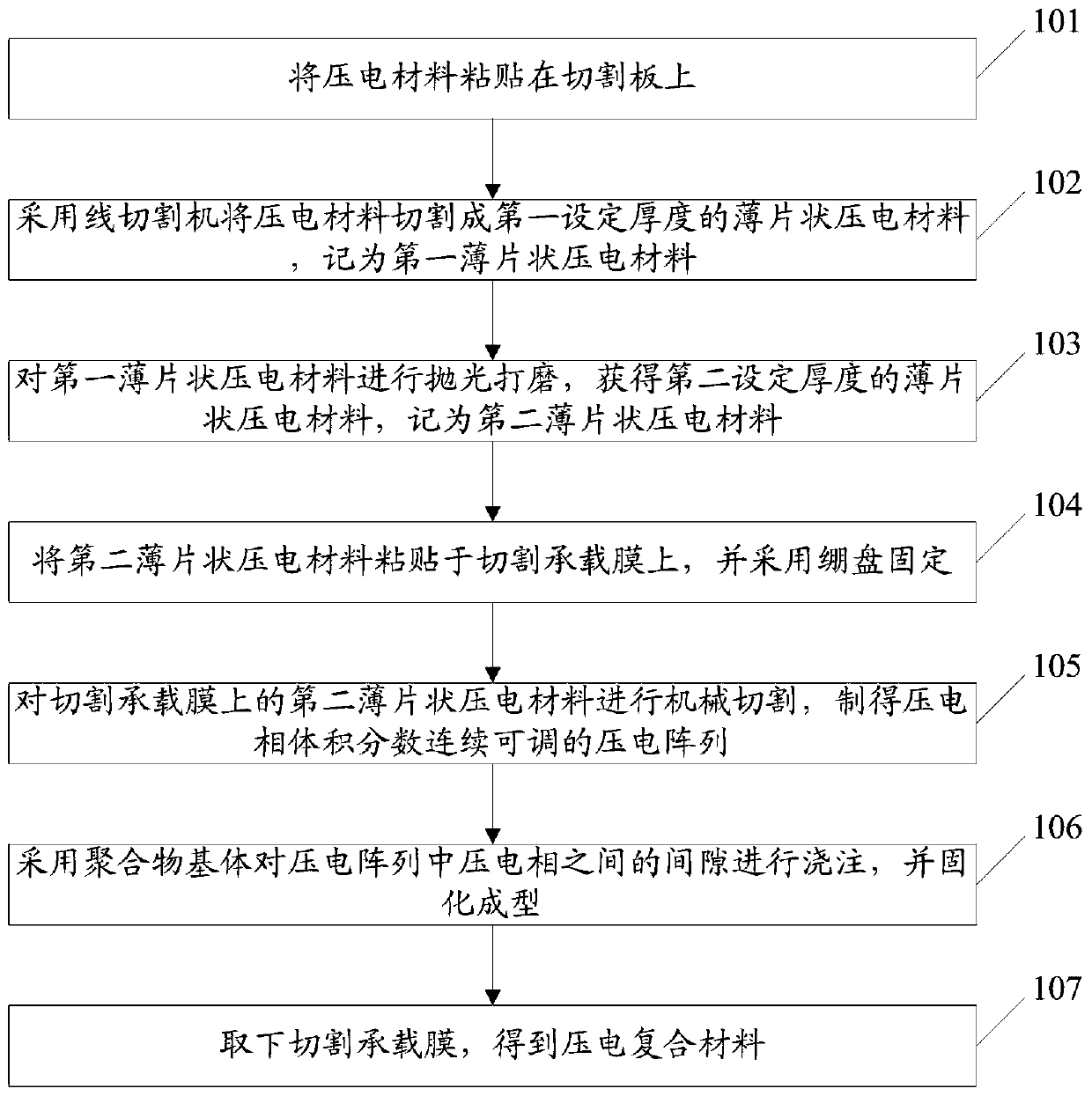

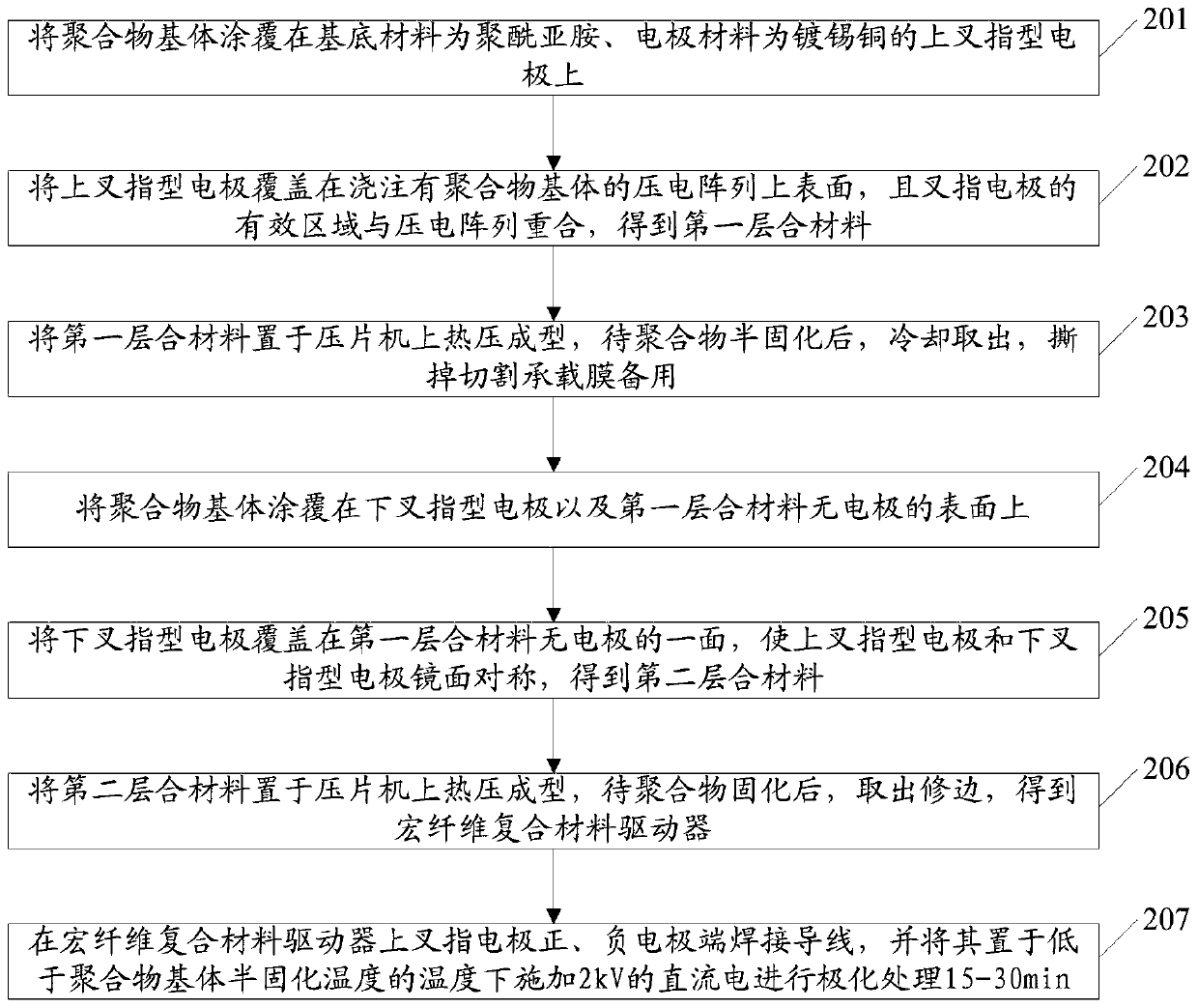

Preparation method of piezoelectric composite material and driver

ActiveCN109742228AImprove yieldAvoiding Binding Damage ProblemsPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive devicesWire cuttingPiezoelectric composite

The invention discloses a preparation method of a piezoelectric composite material and a driver. The preparation method comprises the following steps of pasting a piezoelectric material on a cutting board; cutting the piezoelectric material into a laminar piezoelectric material with a first set thickness by adopting a wire cutting machine, and recording the material as a first laminar piezoelectric material; performing polishing and grinding on the first laminar piezoelectric material to acquire a laminar piezoelectric material with the second set thickness, and recording the material as the second laminar piezoelectric material; pasting the second laminar piezoelectric material on a cutting carrier film, and conducting fixing by adopting a tightening disk; performing mechanical cutting onthe second laminar piezoelectric material borne on the cutting carrier film, and manufacturing a piezoelectric array with the continuously adjustable piezoelectric phase volume fraction; pouring theclearance between the piezoelectric phases in the piezoelectric array by adopting a polymer matrix, and curing and forming; taking off the cutting carrier film to obtain the piezoelectric composite material. The preparation method of the piezoelectric composite material and the driver provided by the invention has the features of being simple in preparation process and high in efficiency.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

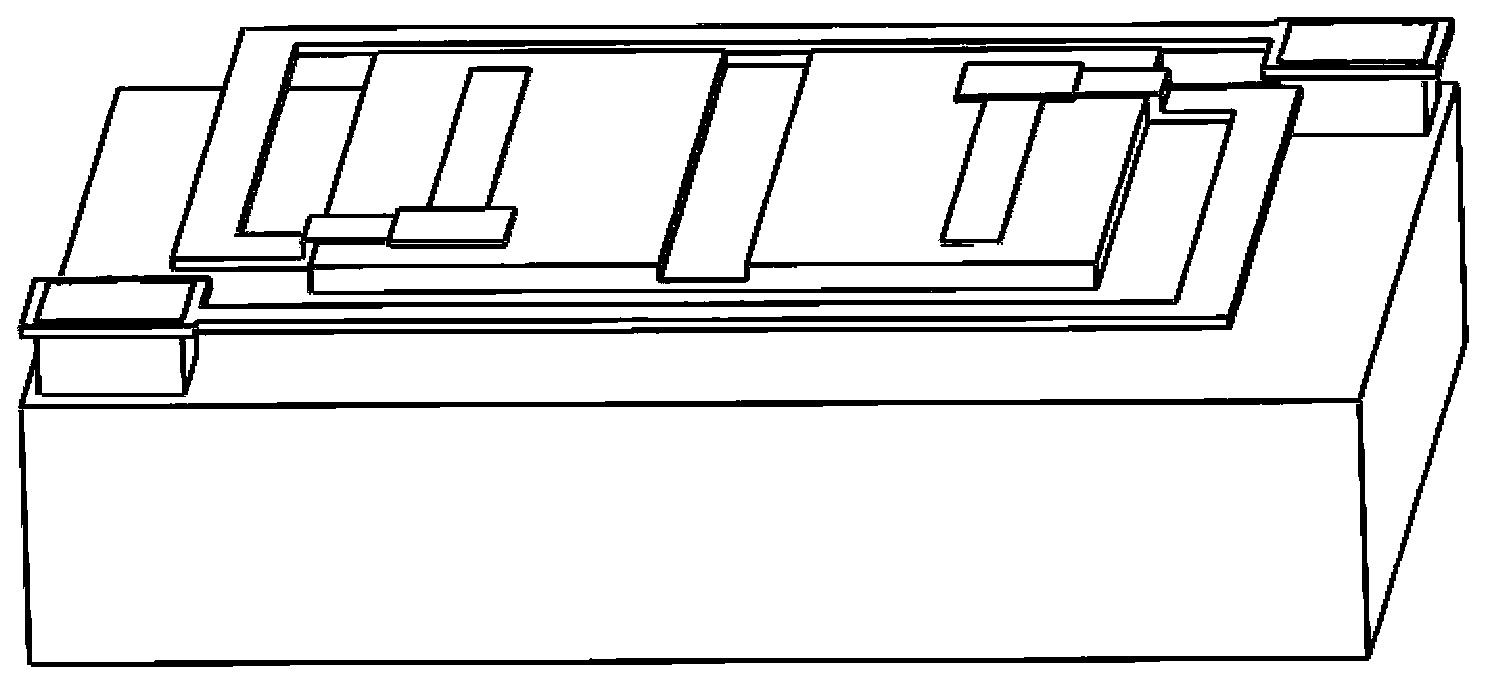

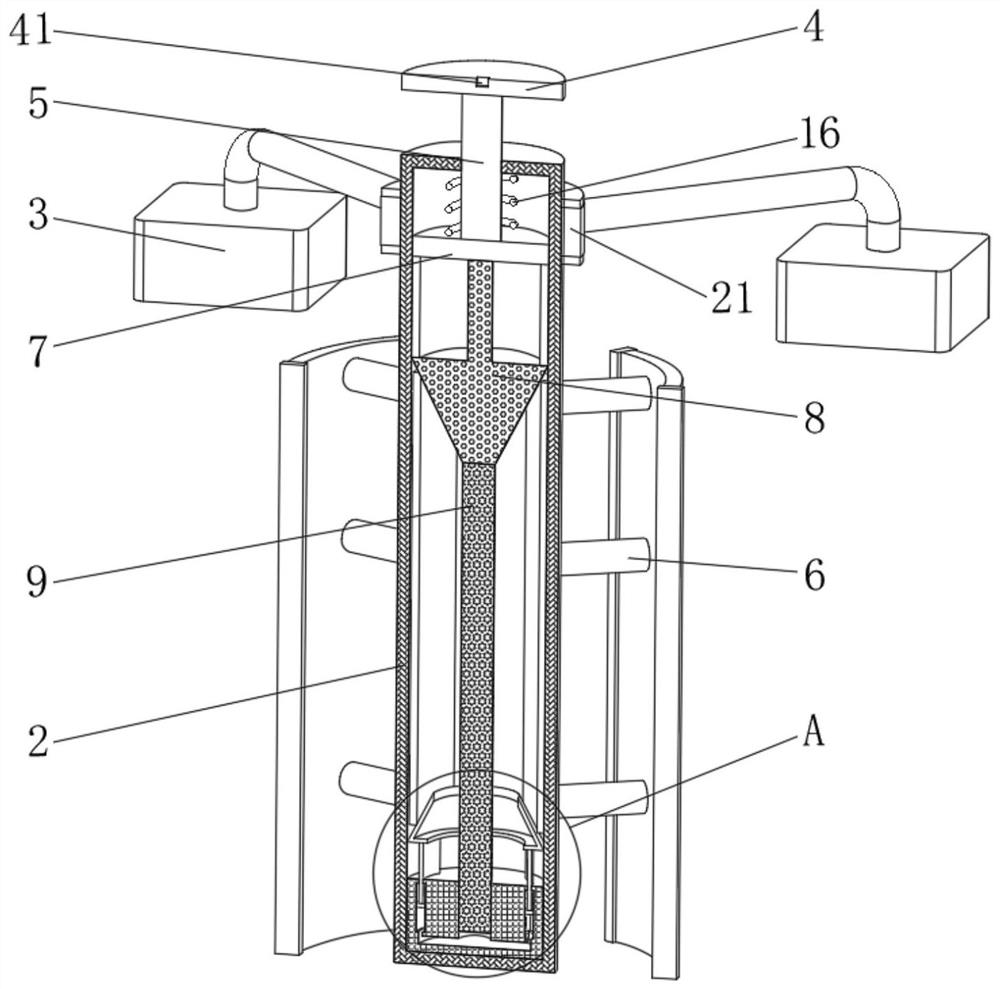

Device for generating liquid electro-rotation

InactiveCN107243365AFlexible designPrecise and controllable sizeLaboratory glasswaresFluid controllersCopper electrodeEngineering

The invention discloses a device for generating liquid electro-rotation, and relates to the technical field of hydrodynamics, electrodynamics and microfluidics. A microcavity is made of medical glass; a flexible single-sided copper-cladded polyimide film is processed by a soft lithography technology to produce a copper electrode; the copper electrode is placed in the microcavity in a way of attaching a wall; fluorescent particle suspension is placed in the microcavity; a chip is connected with a direct-current voltage source and placed on a microscope observation platform; the motion of the fluorescent particles is observed by a CCD camera in real time; moreover, an image of motion trajectories of the fluorescent particle suspension in the chip is shot and inputted to a computer for image storage and analysis. The method is simple, can effectively avoid shortcomings of an experimental method of a liquid film motor at the present stage, and provides richer research means for application of electro-rotation effect.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for preparing yttrium oxide refractory material product through gel casting and crucible

PendingCN114380596AImprove mechanical propertiesImprove thermal shock resistanceCrucible furnacesCrucibleRefractory

The invention belongs to the technical field of refractory materials, and particularly relates to a method for preparing an yttrium oxide refractory material product through gel casting and a crucible. Aiming at the problem that pure-phase yttrium oxide is only suitable for preparing a crucible with a relatively small size and cannot meet the smelting and casting requirements of a large-size cast ingot, the invention provides the method for preparing the yttrium oxide refractory material product, which is simple in preparation process, controllable in size and excellent in performance, and four kinds of Y2O3 particles or micron fine powder with different sizes are adopted; y2O3 with different sizes is added according to a reasonable sequence and proportion, and the obtained product has good mechanical properties and thermal shock resistance at the same time. Meanwhile, by combining the reasonable selection of the dispersing agent and the suspending agent and the precise system of glue discharging and sintering, the finally obtained product, especially the yttrium oxide crucible, has excellent comprehensive performance.

Owner:NORTHEASTERN UNIV

Preparation method of microporous atomizing sheet, microporous atomizing sheet and microporous atomization device

InactiveCN105177530APrecise and controllable micropore sizePrecise control of micropore sizeLiquid spraying apparatusChemical vapor deposition coatingMaterials science

Owner:王长津

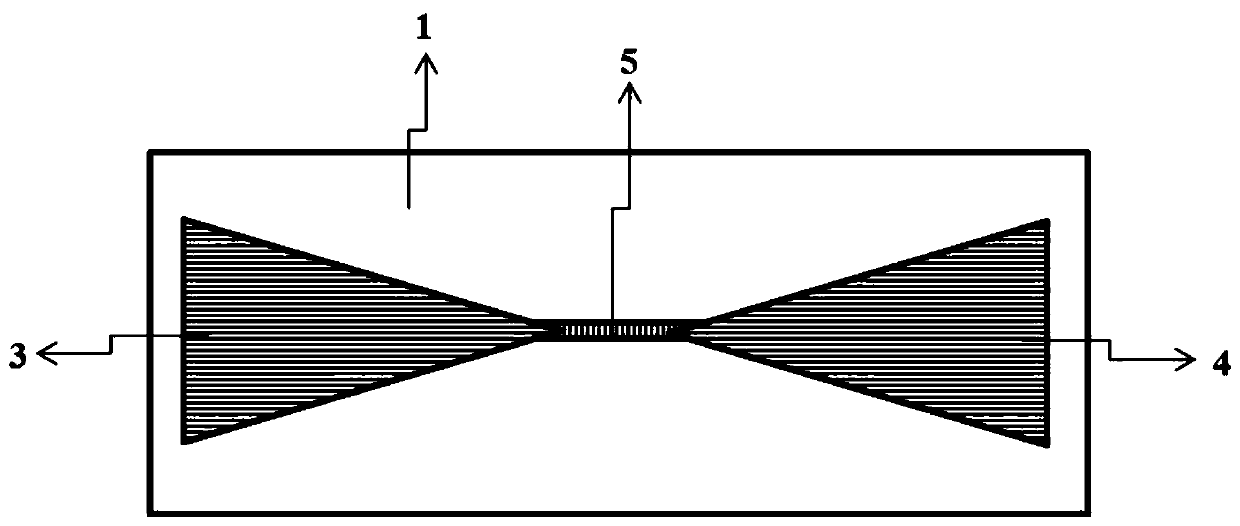

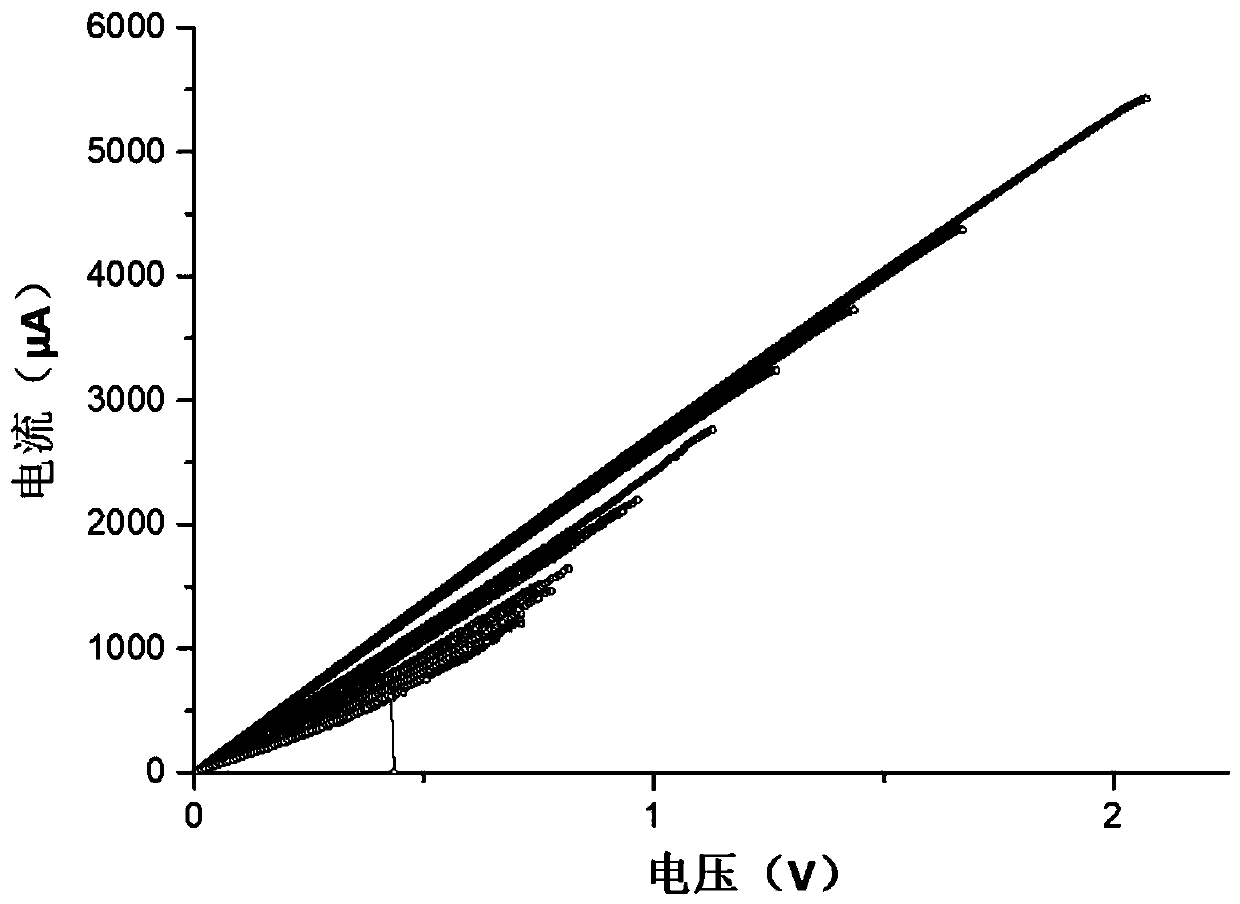

Field effect transistor and preparation method and application thereof

ActiveCN111463289AImprove performanceIncrease power consumptionTransistorSemiconductor/solid-state device manufacturingEngineeringField effect

The invention provides a field effect transistor and a preparation method and application thereof. The field effect transistor comprises an insulating substrate and a two-dimensional nano material layer arranged on an insulating layer of the insulating substrate, a source electrode and a drain electrode are arranged on the two-dimensional nano material layer, and the width of a conducting channelbetween the source electrode and the drain electrode is 0.5-10nm. According to the field effect transistor, the performance and the power consumption of the field effect transistor can be effectivelyimproved by controlling the conducting channel between the source electrode and the drain electrode. The conductive channel of the field effect transistor is prepared by an electric feedback method, and the electric feedback method realizes accurate control of the size of the conductive channel, so that the size of the conductive channel can be reduced to below 3nm, and the requirements of small size and high performance of a silicon-based integrated circuit technology can be met.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

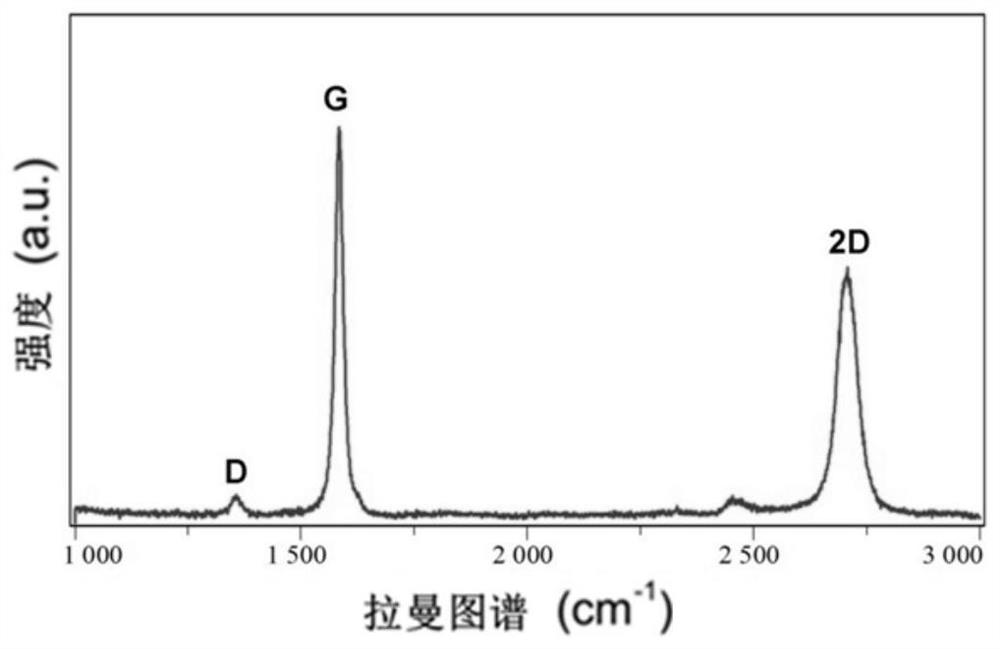

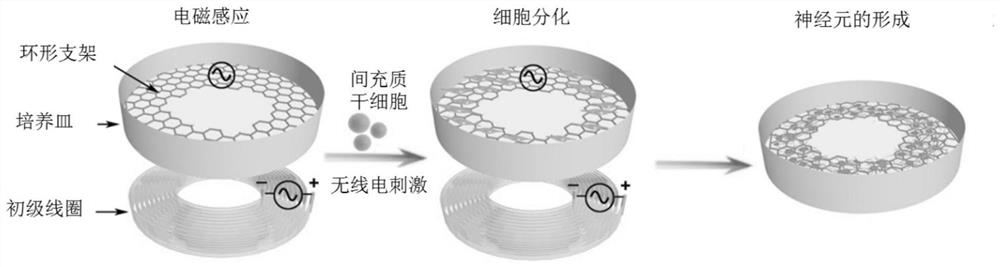

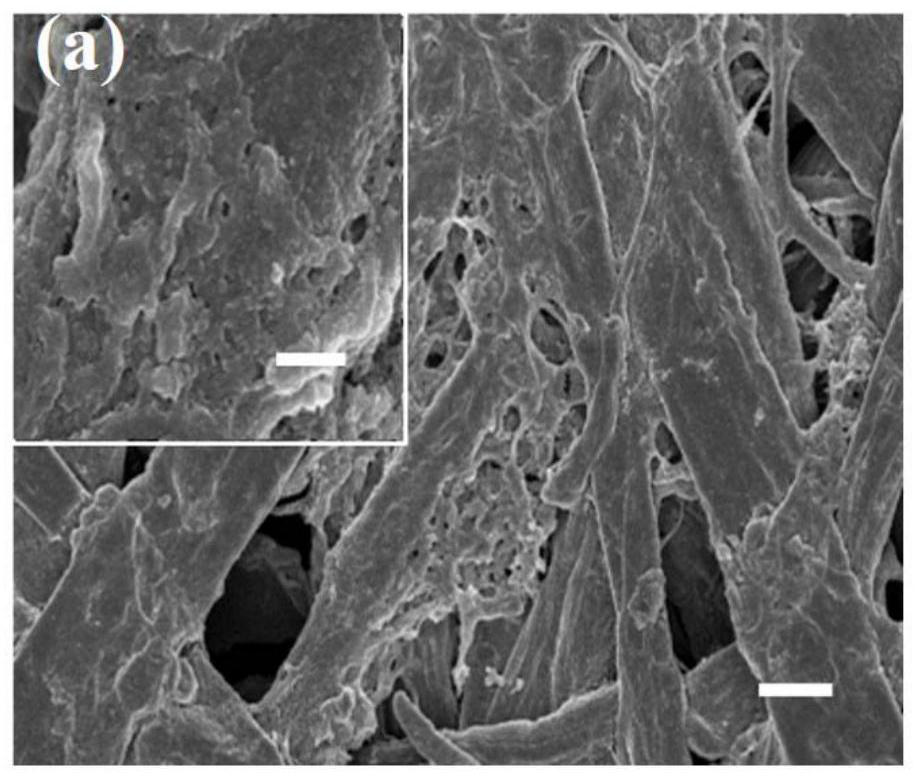

Three-dimensional annular cytoskeleton in response to radio stimulation and preparation method and application thereof

PendingCN111944750AReduce defectsQuality improvementElectroconductive/antistatic filament manufactureCulture processFiberAnuclear cell

The invention discloses a three-dimensional annular cytoskeleton in response to radio stimulation and a preparation method and application thereof. The preparation method comprises the following steps: growing graphene on a copper / nickel template by adopting a chemical vapor deposition method to prepare a three-dimensional annular cytoskeleton; or blending a conductive substance and a fiber to form a conductive fiber, and then performing treatment by adopting a template method to prepare the three-dimensional annular cytoskeleton; or printing conductive hydrogel and / or conductive aerogel by adopting a 3D printing method to prepare the three-dimensional annular cytoskeleton. The prepared three-dimensional annular cytoskeleton is accurate and controllable in size and good in conductivity; and meanwhile the three-dimensional annular cytoskeleton inoculated with the mesenchymal stem cells by using radio stimulation is simple and convenient to use, the trouble of wire connection is solved,the problems of intra-tissue flowing and low survival rate of the mesenchymal stem cells and cell transplantation injury are reduced, and cell behaviors can be controlled.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

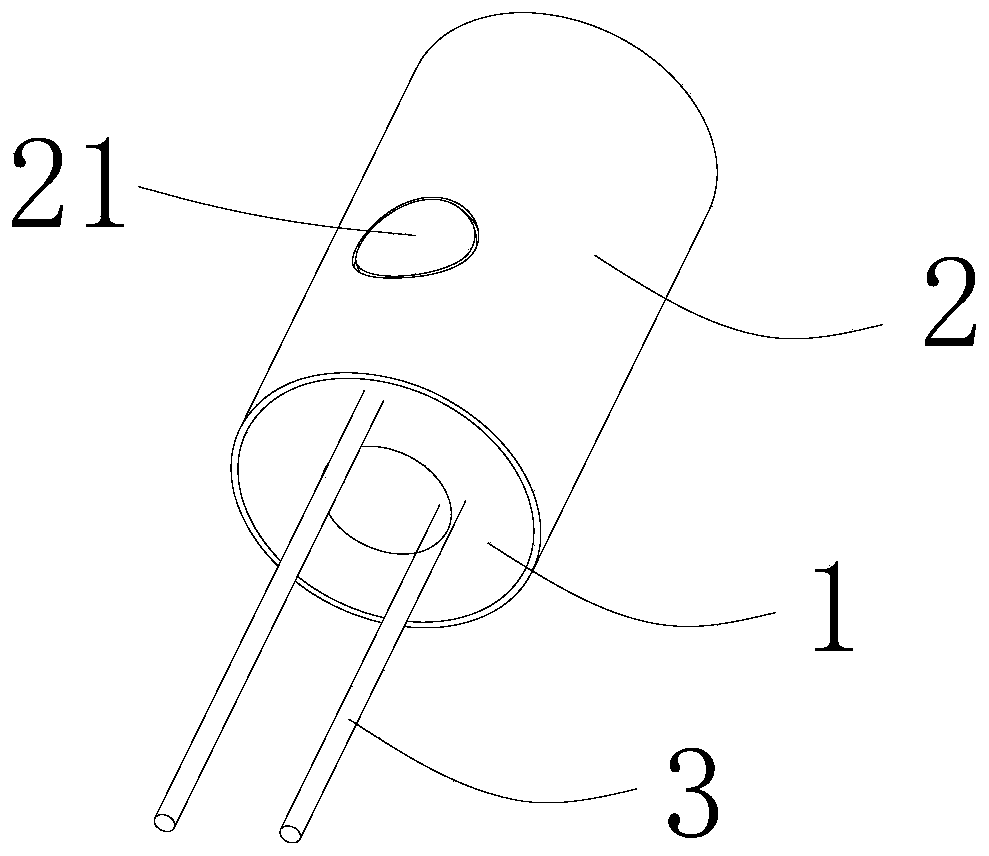

In-fiber optical whispering gallery microcavity structure and its manufacturing method

ActiveCN104932057BPrecise and controllable sizeEasy to operateCoupling light guidesLaser beam welding apparatusWhispering galleryEngineering

Owner:CHONGQING UNIV

Method for preparing large-size, high-purity and high-density molybdenum trioxide target material

ActiveCN112359333APrecise and controllable sizeImprove preparation efficiencyVacuum evaporation coatingSputtering coatingAmmonium molybdateHot isostatic pressing

The invention discloses a method for preparing a large-size, high-purity and high-density molybdenum trioxide target material. The method comprises the specific steps: 1, carrying out roasting treatment on ammonium molybdate to obtain high-purity molybdenum trioxide powder; 2, carrying out ball milling treatment on the high-purity molybdenum trioxide powder; 3, adding a certain amount of forming agent to the molybdenum trioxide powder subjected to ball milling treatment to be uniformly mixed; 4, pressing the uniformly mixed molybdenum trioxide powder into a blank; 5, drying the molybdenum trioxide blank, putting the molybdenum trioxide blank into a sheath to be vacuumized, welded and sealed, then carrying out hot isostatic pressing treatment, and removing the sheath to obtain a molybdenumtrioxide target material crude product; and 6, machining and cleaning the obtained molybdenum trioxide target material crude product to finally obtain the high-purity and high-density molybdenum trioxide target material. According to the method for preparing the large-size, high-purity and high-density molybdenum trioxide target material, the large-size, high-purity and high-density molybdenum trioxide target material can be prepared, and the preparation rate is high.

Owner:JINDUICHENG MOLYBDENUM CO LTD

A kind of preparation method of piezoelectric composite material and driver

ActiveCN109742228BImprove yieldAvoiding Binding Damage ProblemsPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive devicesWire cuttingPiezoelectric composite

The invention discloses a piezoelectric composite material and a preparation method of an actuator. The preparation method includes: pasting the piezoelectric material on a cutting board; using a wire cutting machine to cut the piezoelectric material into a sheet-shaped piezoelectric material with a first set thickness, which is recorded as the first sheet-shaped piezoelectric material; The flake piezoelectric material is polished to obtain a flake piezoelectric material with a second set thickness, which is recorded as the second flake piezoelectric material; the second flake piezoelectric material is pasted on the cutting carrier film and stretched using a stretcher. The disk is fixed; the second sheet-like piezoelectric material on the cutting carrier film is mechanically cut to obtain a piezoelectric array with a continuously adjustable volume fraction of the piezoelectric phase; a polymer matrix is used to adjust the gap between the piezoelectric phases in the piezoelectric array. The gap is poured and solidified; the cutting carrier film is removed to obtain the piezoelectric composite material. The piezoelectric composite material and the preparation method of the actuator provided by the present invention have the characteristics of simple preparation process and high efficiency.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A seawater evaporation desalination membrane material, its preparation method and application

ActiveCN111072083BPrecise and controllable sizeHigh fade rateSemi-permeable membranesGeneral water supply conservationComposite filmPolymer thin films

The invention discloses a seawater evaporation desalination membrane material, its preparation method and application. The seawater evaporation and desalination membrane material includes a support layer and a polymer-nanoparticle composite film layer arranged on the support layer, and the polymer-nanoparticle composite film layer includes a polymer film layer and a composite film layer with the polymer film. Composite nanoparticles. The preparation method comprises: contacting the support layer with an oxidant solution, a polymer material solution and a nanoparticle material solution in sequence to react to obtain a seawater evaporation desalination membrane material. The seawater evaporation and desalination membrane material of the present invention has the advantages of high desalination rate, high retention rate, antibacterial, high mechanical properties, etc., and its preparation process is simple, low in requirements on environmental factors, low in cost, does not require expensive and complicated experimental equipment, and does not require It will cause adverse effects on the surrounding environment and can meet the needs of industrial production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method of nanofluidic chip based on carbon nanotubes

The invention provides a high-precision processing method for a nano channel based on a carbon nano tube, a corresponding application and a product. The processing method comprises the following steps: etching a mark on a substrate, growing a carbon nano tube horizontal array, protecting a required carbon nano tube by photoresist, etching the carbon nano tube by oxygen plasma, constructing a micro-channel by photoetching, breaking the carbon nano tube, bonding PDMS and installing a liquid inlet tube and a liquid outlet tube. The method is high in machining precision, easy to operate, high in compatibility with a traditional technology and large in designable space, the prepared nano-channel has the high length-diameter ratio and has good uniformity and stability in the axis direction of the nano-tube, the minimum size can be reduced to 0.4 nm, the size is accurate and controllable, the sealing performance is good, and the method is suitable for large-scale production. When a fluid medium moves along the nano channel, liquid leakage is not prone to occurring.

Owner:TSINGHUA UNIV

A kind of tungsten reinforced copper composite material and preparation method thereof

InactiveCN111411254BGive full play to high temperature characteristicsPrecise and controllable pore shapeAdditive manufacturing apparatusCopperUltimate tensile strength

A tungsten-reinforced copper composite material disclosed by the present invention comprises the following components according to the volume fraction, copper powder is not less than 50%, the balance is tungsten powder, and the sum of the volume percentages of the above components is 100%; A method for preparing a tungsten-reinforced copper composite material is disclosed. A tungsten-reinforced copper composite material of the present invention adopts the ratio of less tungsten and more copper, fully exerts the high-temperature characteristics of insoluble metal tungsten and the high-conductivity characteristics of low-melting-point metal copper, and realizes high-temperature resistance and good conduction. Special requirements; the preparation method of the present invention adopts laser selective melting technology to prepare porous tungsten skeleton. The shape, quantity and size of tungsten skeleton pores are precisely controllable, and the tungsten skeleton is metallurgically combined with high strength, isotropy, and network shape. The binder phase copper is fully filled in the porous tungsten skeleton by infiltration technology to prepare high-density tungsten-reinforced copper composite materials that can be used in various environments, which has good practical value.

Owner:XIAN UNIV OF TECH

A method for fabricating a self-aligned double-mesa device structure

InactiveCN108054235BPrecise alignmentPrecise and controllable sizeFinal product manufactureSemiconductor/solid-state device manufacturingLithographic artistEngineering

The invention relates to a self-aligning dual mesa device structure making method. Based on the photoresist reflow process, one-step photolithography is used to make a dual mesa device structure, anddual mesa center self-aligning is carried out. The method is advantaged in that one step of lithography is omitted, flow sheet efficiency is improved, flow sheet cost is reduced, the edge interval between a large mesa and a small mesa can be smaller than 1um and can be further adjusted through photoresist reflow technology control, and the method is especially suitable for making a focal plane array with the high duty ratio.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

A kind of 5g metal/ceramic composite circuit board and preparation method thereof

ActiveCN110565056BAchieve alternate depositionImprove yieldVacuum evaporation coatingSputtering coatingCeramic compositeUltimate tensile strength

The present invention relates to a 5G metal / ceramic composite circuit board and a preparation method therefor. The preparation method comprises the following steps: alternately depositing metal layers and ceramic layers on a metal substrate with a preset hole by using a PVD technique, to obtain a 5G metal / ceramic composite circuit board. According to the preparation method for a metal / ceramic composite circuit board of the present invention, the difficulties of a conventional technique (a ceramic / metal thermal diffusion bonding method) for a metal / ceramic composite circuit board, such as being complex, low in yield, high in price, low in efficiency and undeveloped in terms of technique, are avoided. In addition, according to the preparation method of the present invention, a metal substrate with a hole is selected, such that the problems of laser / mechanical composite drilling of a ceramic substrate whereby same is low in yield, large in terms of workload, and undeveloped in terms of drilling technique, are solved. In the present invention, a combined technique of a physical vapor deposition technique and a template technique is used to deposit the metal layer and the ceramic layer, all the layers in the obtained metal / ceramic composite circuit board are high in terms of bonding strength and are not prone to stripping, and the technique is simple.

Owner:GUANGDONG UNIV OF TECH

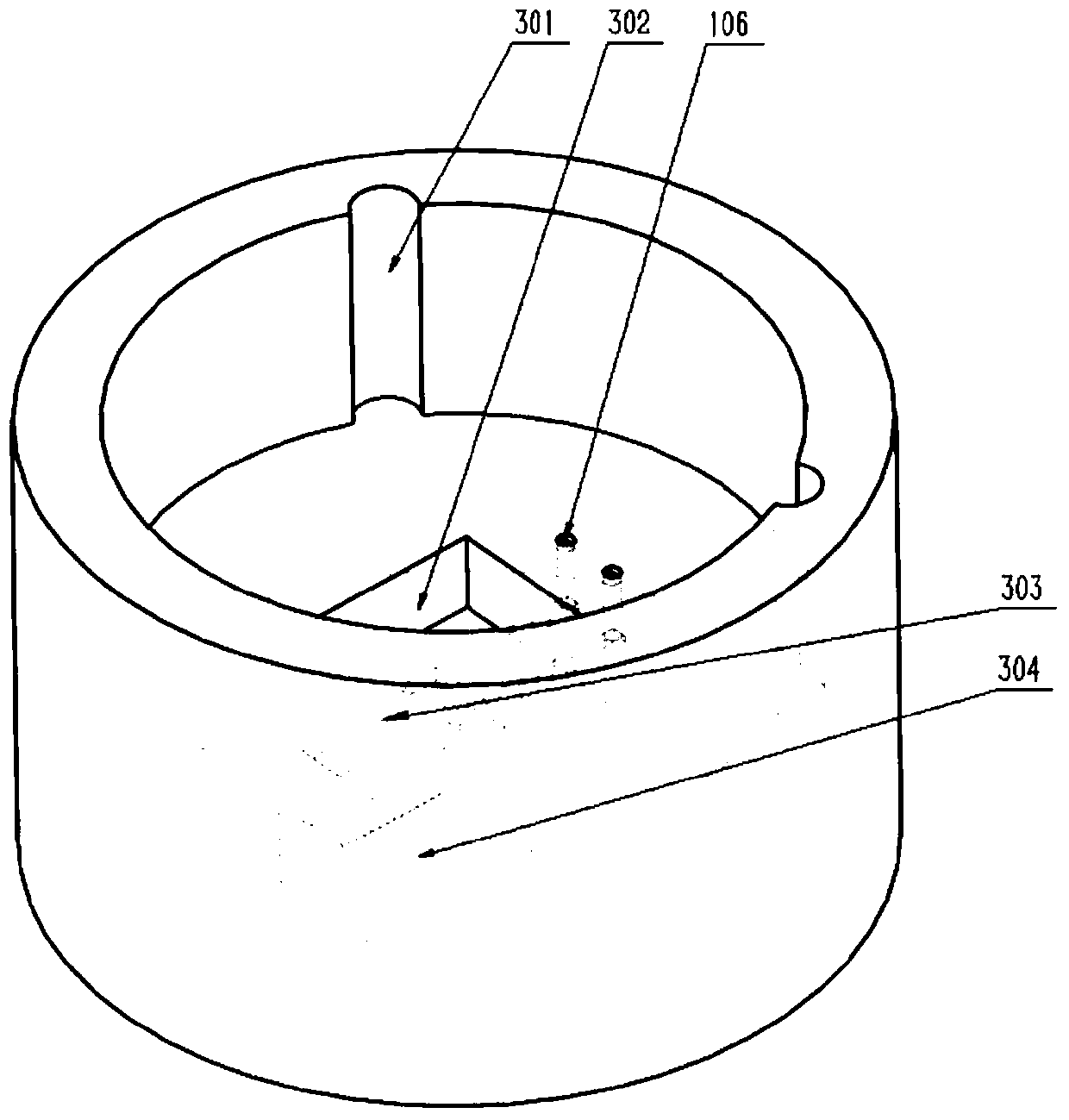

A regenerator assembly for a heat engine

ActiveCN103047046BGuaranteed total heightReduce processing difficultyHot gas positive displacement engine plantsWhole bodyEngineering

The invention discloses a heat regenerator assembly of a heat engine. The heat regenerator assembly of the heat engine comprises a wire screen assembly formed by overlaying a multi-layer metal wire screen and an outer sleeve, the wire screen assembly is arranged in the outer sleeve, the wire screen assembly is composed of two or a plurality of wire screen welding parts, the periphery of the wire screen assembly and the outer sleeve are welded into a whole body by adopting a diffusion welding method, the wire screen welding parts are formed by overlaying a plurality of layers of stainless steel screens with 220-250 mesh, and two vertical adjacent wire screens are welded into an integral body by adopting the diffusion welding mode. The heat regenerator assembly of the heat engine has the advantages of being good in usability, convenient to dismantle and replace, high in reliability and suitable for being applied to Stirling engines.

Owner:SHANGHAI MICROPOWERS

A kind of continuous fiber reinforced thermoplastic resin composite material boat propeller blade and preparation method thereof

The invention discloses a method for preparing a continuous fiber-reinforced thermoplastic resin composite material boat oar blade, comprising: preparing a continuous fiber-reinforced thermoplastic resin unidirectional prepreg tape; Cut into two kinds of master pieces, and then stack the two kinds of master pieces alternately and orthogonally, place the core mold in the middle and transfer it to the blade mold, after hot pressing, and then trim the edges by machining Process to obtain the paddle blade. The invention discloses a method for preparing continuous fiber-reinforced thermoplastic resin composite paddle blades, which adopts a hot pressing process for one-time molding, with short molding time and accurate and controllable product size; the prepared paddle blades have mechanical properties and excellent fatigue resistance. Excellent performance, corrosion resistance, lightweight, recyclable and reprocessable.

Owner:CGN JUNER NEW MATERIALS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com