A regenerator assembly for a heat engine

A technology for regenerators and hot air engines, applied in the field of regenerator components for hot air engines, can solve the problems of easy deformation and falling off, inability to disassemble and replace, and difficult to accurately control the size of the wire mesh body, so as to improve the maintainability, the size is accurate, and the Control and reduce the effect of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

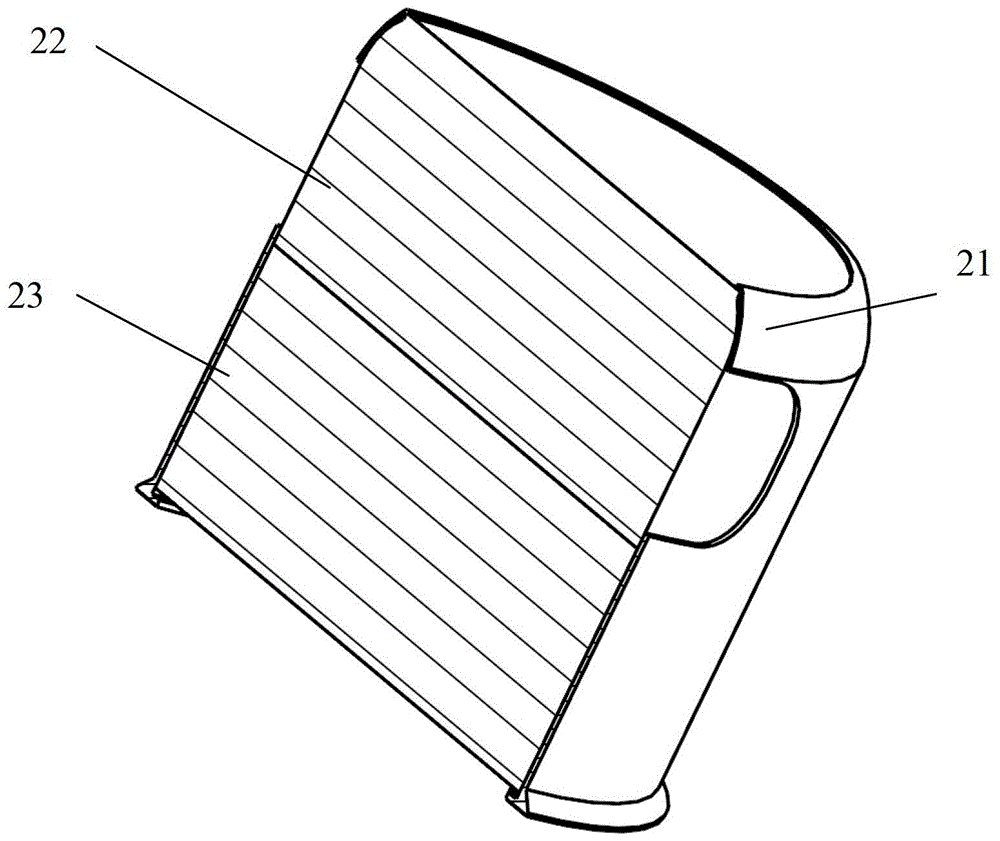

[0027] Figure 1-4 Shown is an embodiment of the present invention, the regenerator assembly 2 is installed inside the regenerator cylinder 1, and a cooler 3 is installed at the lower end, which is composed of an outer sleeve 21 and a wire mesh weldment, and the wire mesh weldment is built in Inside the outer sleeve 21. The wire mesh welding part is composed of a wire mesh welding part 1 22 and a wire mesh welding part 23, and may also be composed of a plurality of wire mesh welding parts. The wire mesh component is stacked with multi-layer wire mesh and then sintered by diffusion welding. The wire mesh is generally made of stainless steel, and the wire mesh of 200-250 mesh is mostly used. The larger the mesh number, the denser the heat recovery effect is, but the greater the flow resistance is, so the regenerator needs to be considered comprehensively in the design The type of wire mesh is selected according to the heat recovery capacity and resistance requirements of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com