Connecting structure of engineering mechanical chassis

A technology for connecting structures and construction machinery, which is applied in the substructure, transportation and packaging, vehicle parts, etc., can solve the problems of limited bearing capacity, stress concentration, and single load-bearing structure, and achieve reduced welding costs, less stress concentration, and reliable connections sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

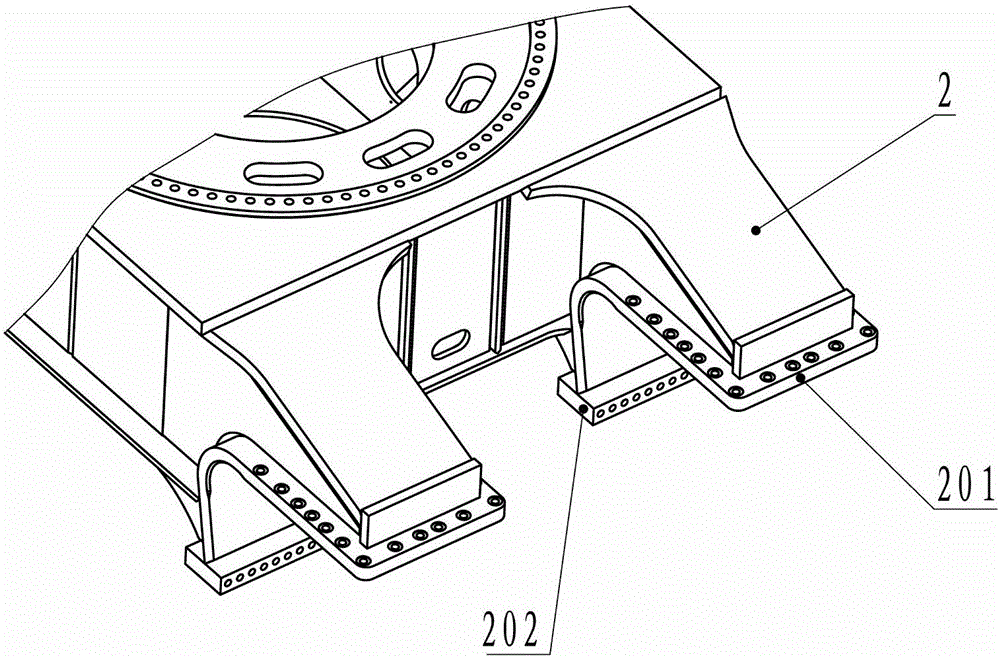

[0021] Such as Figure 1 to Figure 3 As shown, a construction machinery chassis connection structure includes a longitudinal beam 1 and an H frame 2, and also includes an H frame bending connecting plate 201 and an H frame horizontal connecting plate 202 for connecting the H frame 2 to the longitudinal beam 1, and the H frame The frame bending connecting plate 201 and the H frame horizontal connecting plate 202 are welded to form a Z-shaped structure; the H frame bending connecting plate 201 is used as the Z-shaped horizontal folding upper part and the H frame horizontal connecting plate 202 as the Z-shaped horizontal bottom edge The welding is in a Z-shaped structure; the H frame bending connecting plate 201 is welded under one end of the H frame 2; the H frame 2 is fixedly connected with the longitudinal beam top plate 101 of the longitudinal beam 1 through the H frame be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com