A kind of continuous fiber reinforced thermoplastic resin composite material boat propeller blade and preparation method thereof

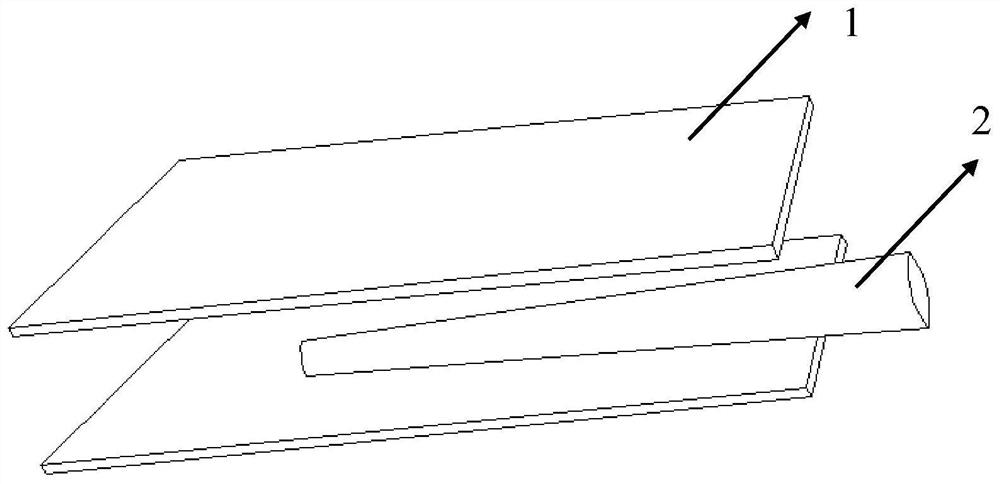

A technology of resin composite materials and enhanced thermoplasticity, which can be applied to other household appliances, coatings, household appliances, etc., and can solve the problems of poor mechanical properties of plastic blades, large thermal deformation, poor fatigue resistance of aluminum alloy blades, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

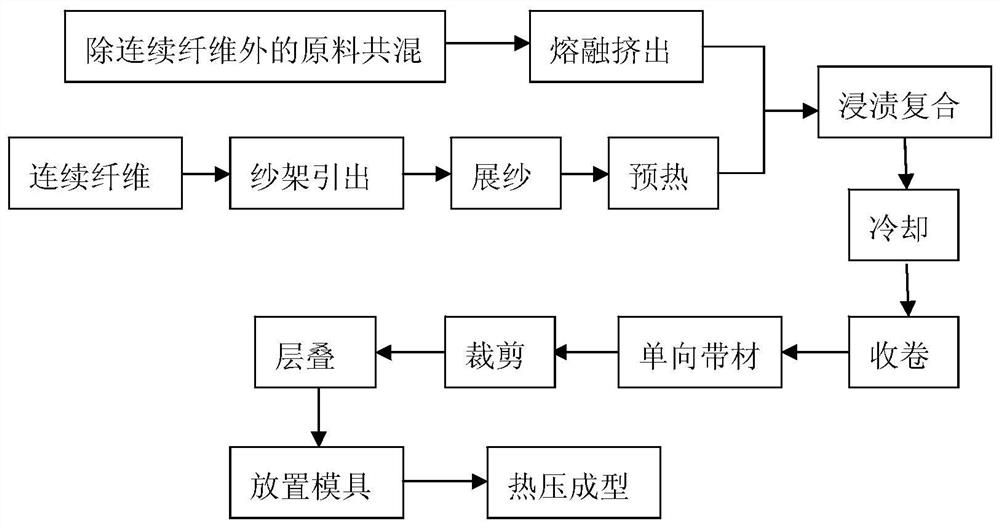

[0044] (1) Weigh 35 parts by weight of polypropylene, 0.1 part of antioxidant 1010, 1.5 parts of maleic anhydride grafted polypropylene, and 0.15 parts of calcium stearate, add them into a high-speed mixer and mix for 3 minutes, and mix well.

[0045] (2) The mixture obtained in step (1) is melted and extruded in a twin-screw extruder to obtain a uniform modified polypropylene resin film at the die; wherein the twin-screw extruder melt extrusion temperature is: 1 Zone 160°C, zone 2 180°C, zone 3 205°C, zone 4 220°C, zone 5 235°C, extruder host frequency 22Hz.

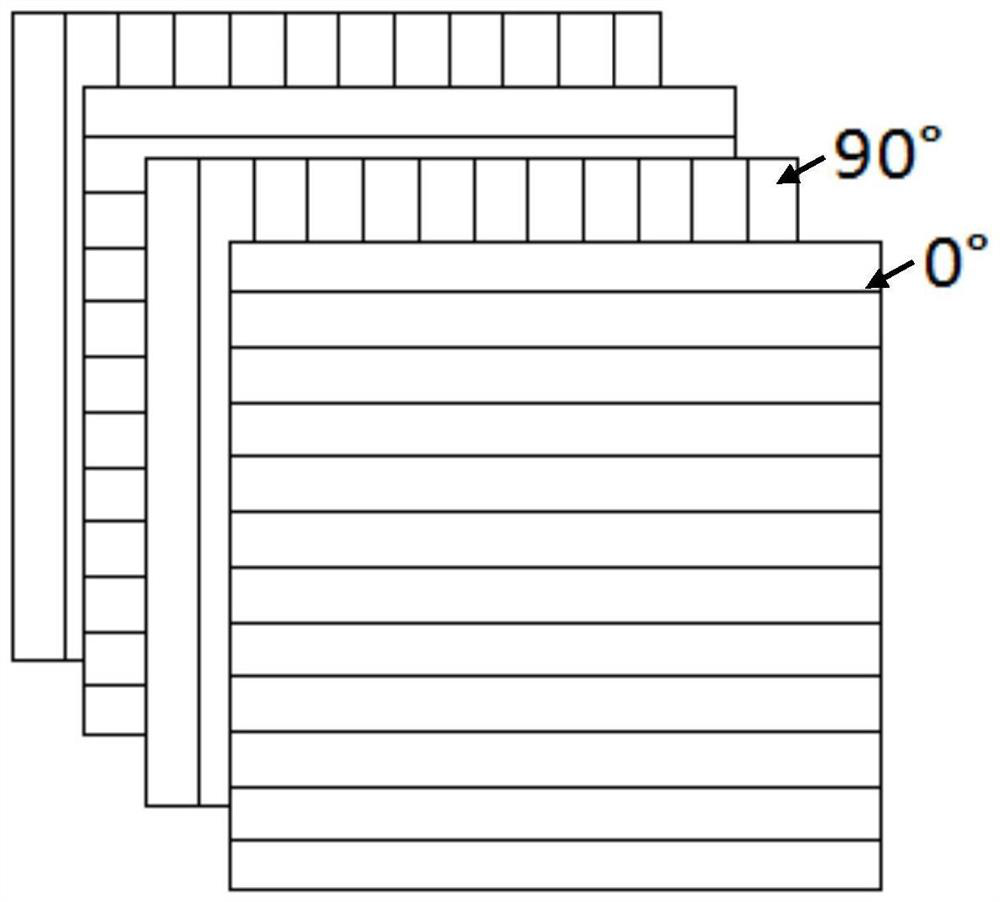

[0046] (3) The continuous glass fiber of 65 parts by weight is drawn out from the textile creel, after the tension adjustment device, the yarn spreading unit, the preheating unit, the modified polypropylene resin film extruded with the die is fully carried out in the composite unit After impregnation, cooling unit and winding unit, the continuous glass fiber reinforced polypropylene unidirectional prepreg tape is obtain...

Embodiment 2

[0050] (1) Weigh 40 parts by weight of polycarbonate, 0.15 parts of antioxidant 1076, 1.5 parts of silane coupling agent KH550, and 0.2 parts of ethylene bisstearyl, add them to a high-speed mixer and mix for 3 minutes, and mix well.

[0051] (2) the mixture that step (1) is obtained is melted and extruded in a twin-screw extruder, and a uniform modified polycarbonate resin film is obtained at the die; wherein the twin-screw extruder melt extrusion temperature is 1 Zone 235°C, zone 2 255°C, zone 3 275°C, zone 4 290°C, zone 5 300°C, extruder host frequency 17Hz.

[0052] (3) The continuous glass fiber of 60 parts by weight is drawn out from the textile creel, and after the tension adjustment device, the yarn spreading unit and the preheating unit, the modified polycarbonate resin film extruded from the die is carried out in the composite unit. Fully impregnated, then passed through the cooling unit and winding unit to obtain continuous glass fiber reinforced polycarbonate unidire...

Embodiment 3

[0056] (1) Weigh 45 parts by weight of nylon 6, 0.2 parts of antioxidant 168, 2 parts of silane coupling agent KH560, and 0.3 parts of silicone powder, add them to a high-speed mixer and mix for 3 minutes, and mix well.

[0057] (2) the mixture that step (1) is obtained is melted and extruded in a twin-screw extruder, and a uniform modified polycarbonate resin film is obtained at the die; wherein the twin-screw extruder melt extrusion temperature is 1 Zone 210°C, zone 2 235°C, zone 3 255°C, zone 4 275°C, zone 5 290°C, extruder host frequency 18Hz.

[0058] (3) The continuous carbon fiber of 55 parts by weight is drawn from the spinning creel, after the tension adjustment device, the yarn spreading unit, and the preheating unit, the modified nylon 6 resin film extruded from the die is fully impregnated in the composite unit , and then through the cooling unit and winding unit, a continuous carbon fiber reinforced nylon 6 unidirectional prepreg tape is obtained.

[0059] (4) Cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com