Preparation method of piezoelectric composite material and driver

A technology of piezoelectric composite materials and piezoelectric materials, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc. It can solve the problems of difficulty in determining the flatness of thin slices, low efficiency, and difficult sintering of ceramic thin slices, and achieve the effect of high degree of processing automation, high degree of mechanical automation, and avoiding damage to the interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

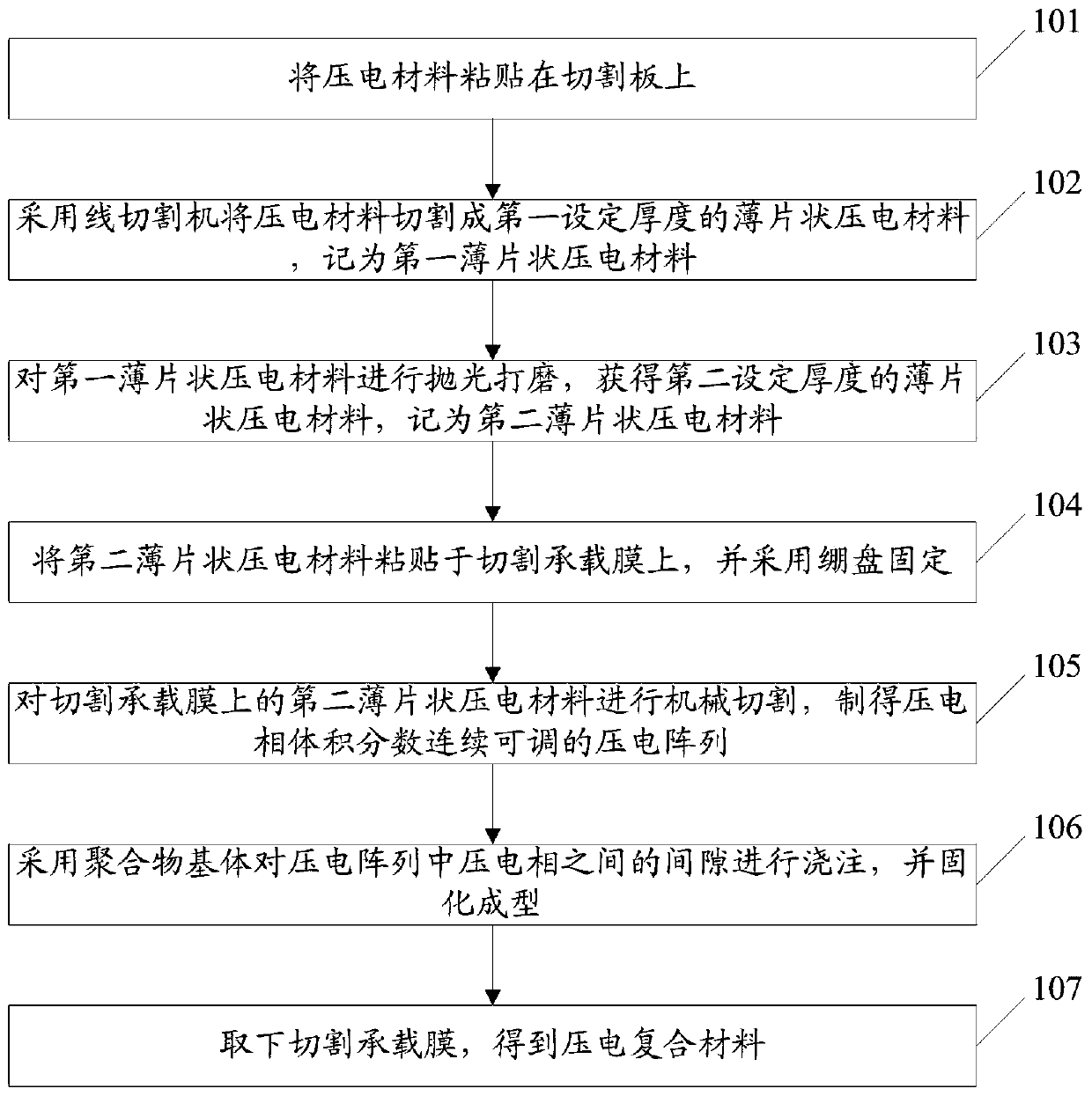

[0042] Such as figure 1 Shown, the preparation method of the piezoelectric composite material provided by the present invention comprises the following steps:

[0043]Step 101: Paste the piezoelectric material on the cutting board; the piezoelectric material here is a bulk piezoelectric material with a length and width of 5-150 mm and a thickness of 5-20 mm;

[0044] Step 102: Using a wire cutting machine to cut the piezoelectric material into a sheet-shaped piezoelectric material with a first set thickness, which is recorded as the first sheet-shaped piezoelectric material; the first set thickness can be 0.4-2.5mm;

[0045] Step 103: Polish and polish the first sheet-shaped piezoelectric material to obtain a sheet-shaped piezoelectric material with a second set thickness, wipe its surface with absolute ethanol, dry it for later use, and record it as the second sheet-shaped piezoelectric material; The second set thickness is the thickness of the target large sheet of ultra-th...

Embodiment 2

[0064] A 2-2 type ultra-thin piezoelectric composite material with a length of 120mm, a width of 80mm, and a thickness of 0.5mm. It is made of piezoelectric ceramic fibers and epoxy resin. The piezoelectric phase width is 0.2mm. The spacing is 0.1mm, prepared by the following steps:

[0065] (1) Stick an unpolarized PZT5 piezoelectric ceramic block with a length of 120mm, a width of 80mm, and a thickness of 10mm on the cutting board, place it on a multi-wire cutting machine, adjust the wire cutting speed, and cut the piezoelectric ceramic block into thickness 0.75mm piezoelectric sheet;

[0066] (2) Grinding and polishing the piezoelectric sheet prepared in (1) until the thickness is 0.5mm, and wiping its surface with absolute ethanol, and drying it for later use;

[0067] (3) Paste the piezoelectric sheet prepared in (2) on a white film whose length and width are 220 mm and whose thickness is 0.35 mm, so as to ensure that there is no air bubble between the cutting carrier fi...

Embodiment 3

[0076] A type 1-3 ultra-thin piezoelectric composite material with a length of 100mm, a width of 60mm, and a thickness of 0.35mm. It is composed of piezoelectric ceramic fibers and epoxy resin. The piezoelectric phase width is 0.5mm. The spacing is 0.2mm, prepared by the following steps:

[0077] (1) Stick an unpolarized PZT5 piezoelectric ceramic block with a length of 110mm, a width of 70mm, and a thickness of 10mm on the cutting board, place it on a multi-wire cutting machine, adjust the wire cutting speed, and cut the piezoelectric ceramic block into thickness 0.55mm piezoelectric sheet;

[0078] (2) Grinding and polishing the piezoelectric sheet prepared in (1) until the thickness is 0.35mm, and wiping its surface with absolute ethanol, and drying it for later use;

[0079] (3) Paste the piezoelectric sheet prepared in (2) on a white film whose length and width are 220 mm and whose thickness is 0.24 mm, so as to ensure that there is no air bubble between the cutting carr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com