Method for manufacturing uncooled infrared focal plane array pixel with silicon-germanium film

An uncooled infrared, focal plane array technology, applied in the field of infrared imaging device manufacturing, to achieve the effects of increased resistance, high TCR value, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

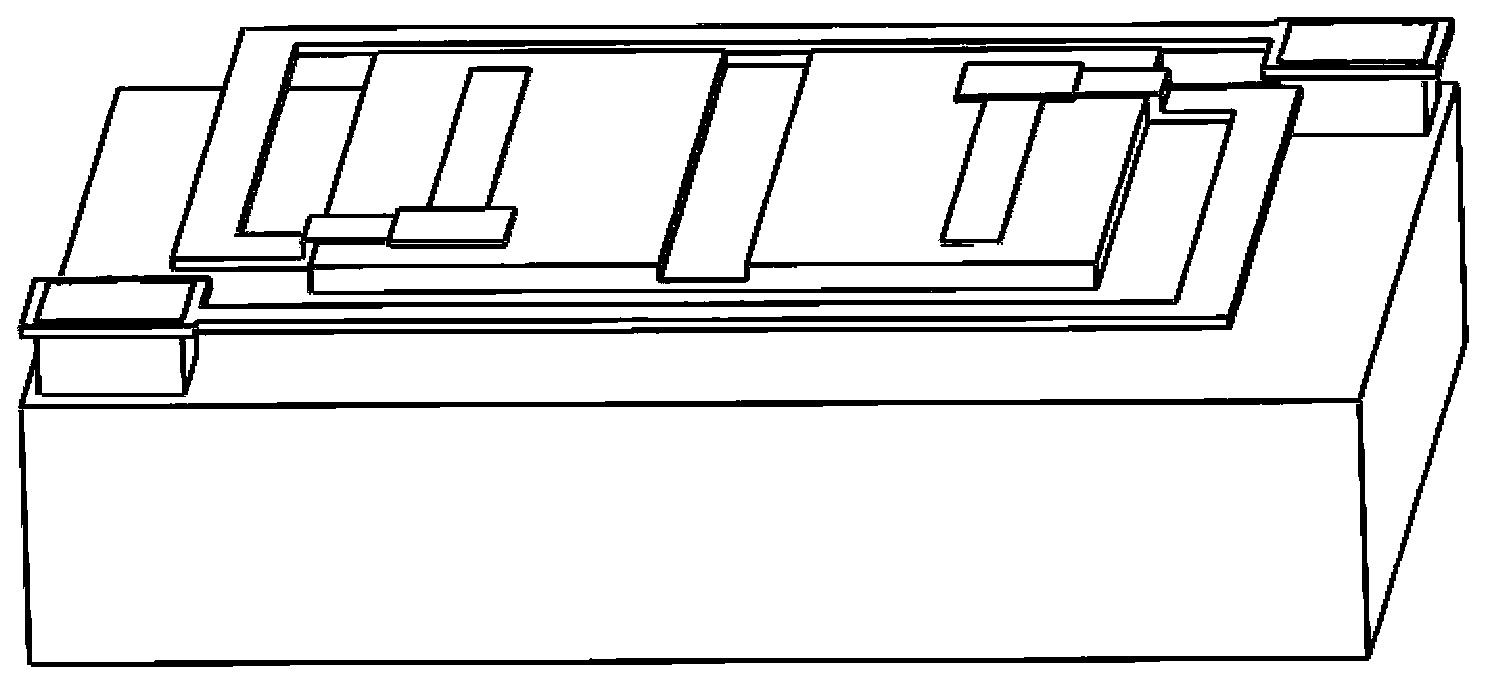

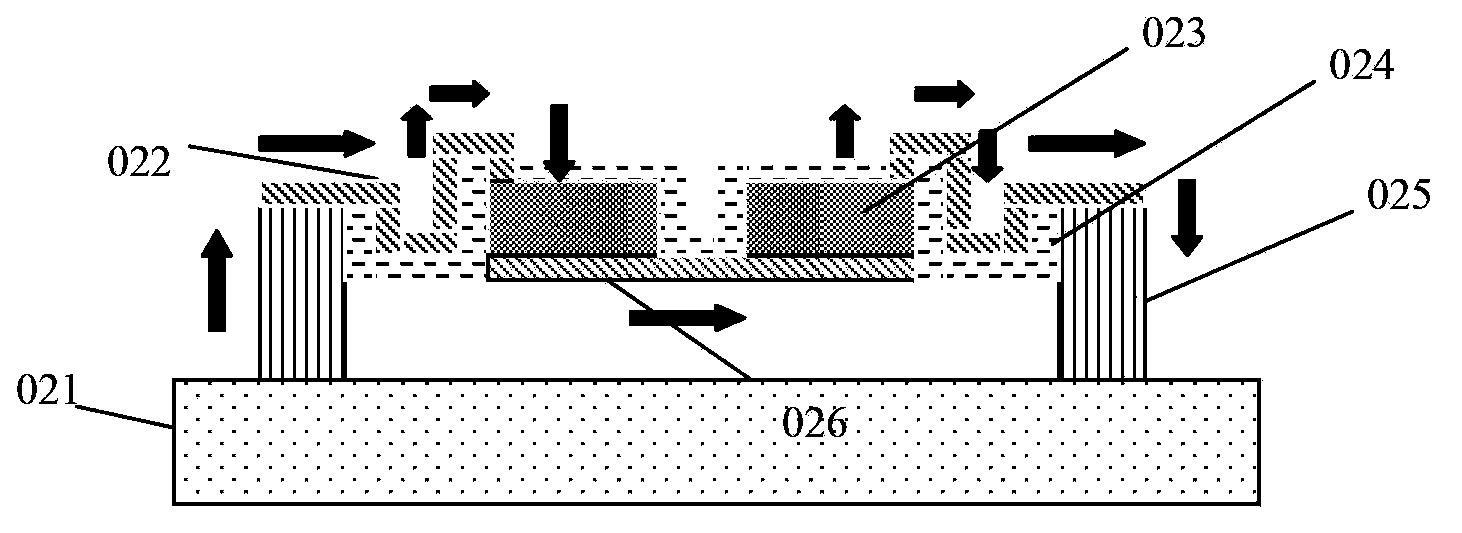

[0038] combine Figure 4 , the present invention is an uncooled infrared focal plane manufacturing pixel method using a silicon germanium film. Now, taking a 40×40 μm pixel as an example, the array manufacturing process is briefly described:

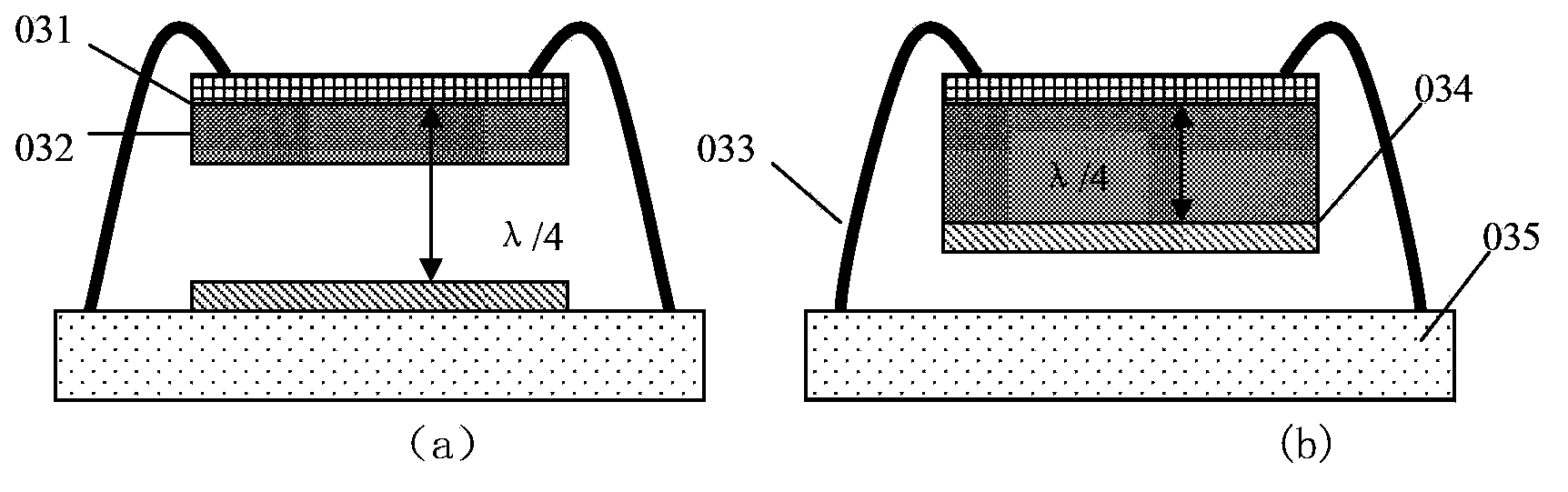

[0039]Step 1: Use SOI (Silicon-On-Insulator, silicon on insulating substrate) wafer as the carrier of quantum well type silicon germanium film 043, and apply bonding glue on the surface of the wafer to form a bond with a thickness of 1 μm-3 μm glue layer 048, and bond the SOI wafer and CMOS readout circuit 047 together by thermocompression adhesive bonding, and then use an ICP etching machine to etch away the SOI wafer silicon substrate 041, and then use BOE solution (Buffered Oxide Etch, composed of hydrofluoric acid and ammonium fluoride solution in a certain volume ratio, the usual ratio is 6:1) or BHF solution (dil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com