Myocardial tissue sensor and myocardial tissue chip preparation method

A tissue chip and sensor technology, applied in instruments, scientific instruments, material inspection products, etc., can solve problems such as affecting the detection accuracy, difficult to ensure the coupling between cells and devices, and improve the acquisition accuracy, meet the accuracy requirements, and the size is accurate and controllable. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

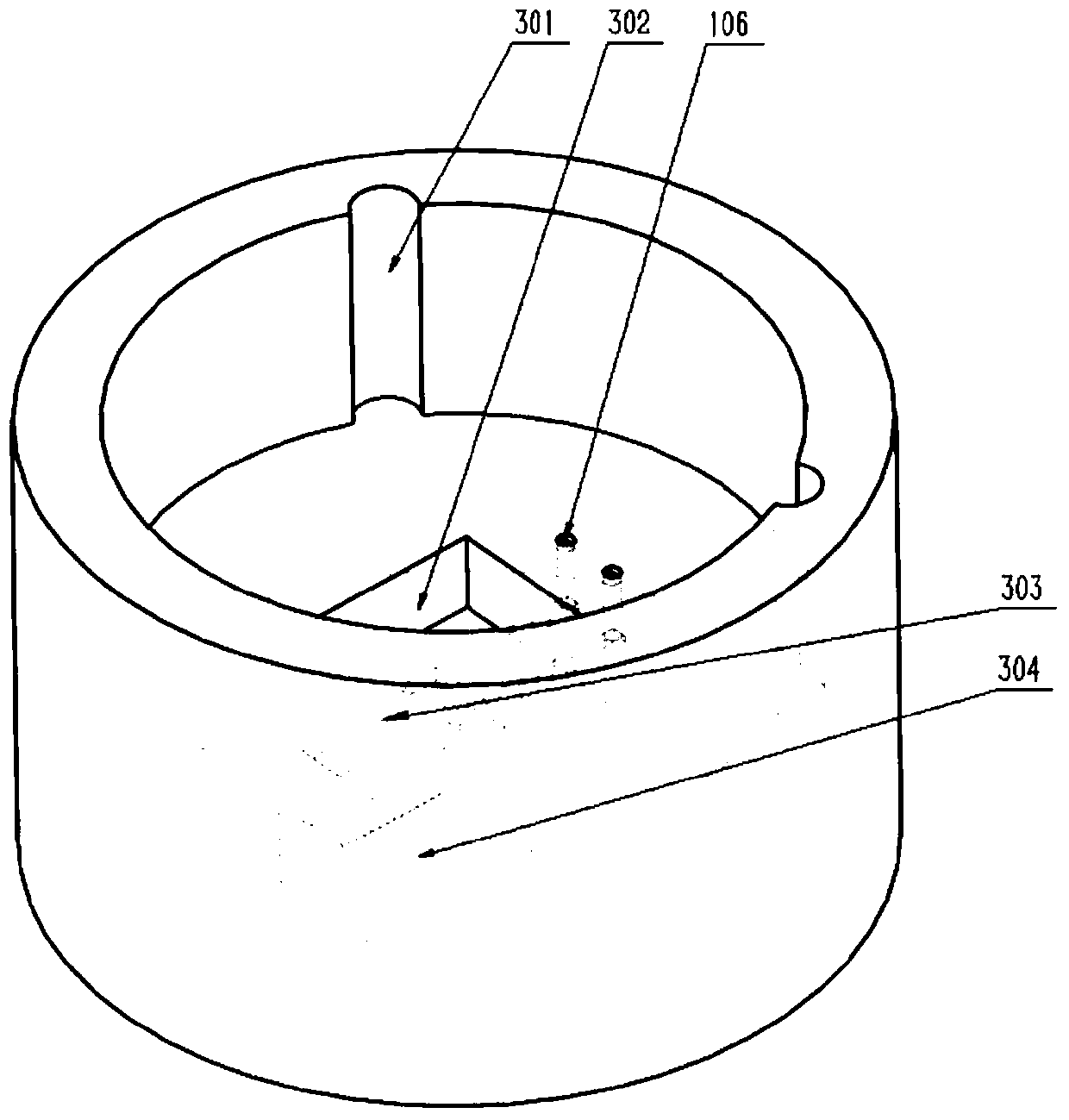

[0028] Figure 4 It is a partial schematic diagram of the manufacturing process of myocardial tissue chip. The preparation method of myocardial tissue chip includes the following steps:

[0029] 1) Paste a layer of tape 402 on the surface of a sterilized glass sheet 401;

[0030] 2) Use a laser forming machine to cut at least 5 square contours on the tape along the first cutting track 403. Each square contour is 6-8mm in length and 0.6-1mm in width, separated by 0.1-0.3mm, and moved Except for the cut square tape 404, such as Figure 4 As shown in (a);

[0031] 3) Prepare a poly-N-isopropylacrylamide solution with a mass volume concentration of 10% to 50%, and apply it evenly on the side of the glass sheet with adhesive by spin coating. After curing, remove the adhesive, leaving a square Poly-N-isopropylacrylamide layer 405, such as Figure 4 As shown in (b);

[0032] 4) After heating and melting the polydimethylsiloxane, apply it to the glass sheet by spin coating. After curing, use...

Embodiment 1

[0036] Example 1: Test the effect of cardiac glycoside drugs on myocardium:

[0037] 1) Select or make a square glass sheet with a cross-sectional size of 20×12mm and a thickness of 1mm, and paste a layer of tape on the surface after sterilizing in 75% alcohol for one hour;

[0038] 2) Use a laser forming machine to cut out 13 square contours with a length of 7mm, a width of 1mm, and an interval of 0.1mm on the tape as the first cutting track, and remove the cut square tape;

[0039] 3) Mix the poly-N-isopropylacrylamide solution with a mass volume concentration of 20% with 99% butanol in a volume ratio of 1:1 to make a 10% poly-N-isopropylacrylamide solution. Coating the poly-N-isopropylacrylamide solution on the side glass sheet containing the tape, and remove the remaining tape after curing. At this time, 13 pieces of 7×1mm square poly-N-isopropylacrylamide are left on the glass sheet Floor;

[0040] 4) Mix the polydimethylsiloxane solution and the curing agent at a mass ratio of ...

Embodiment 2

[0045] Example 2: Testing the therapeutic effect of compound Danshen tablets on diseased myocardium:

[0046] 1) Select or make a square glass sheet with a cross-sectional size of 20×12mm and a thickness of 1mm, and paste a layer of tape on the surface after sterilizing in 75% alcohol for one hour;

[0047] 2) Use a laser forming machine to cut 15 square contours with a length of 6mm, a width of 0.6mm, and a mutual interval of 0.2mm on the tape as the first cutting track, and remove the cut square tape;

[0048] 3) Mix the poly-N-isopropylacrylamide solution with a mass volume concentration of 40% with 99% butanol in a volume ratio of 1:1 to make a 20% poly-N-isopropylacrylamide solution, and spin-coat Coating the poly-N-isopropylacrylamide solution on the side glass sheet containing the tape, and remove the remaining tape after curing. At this time, 15 pieces of 6×0.6mm square poly-N-isopropyl propylene are left on the glass sheet Amide layer

[0049] 4) Mix the polydimethylsiloxane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com