Preparation method of microporous atomizing sheet, microporous atomizing sheet and microporous atomization device

A technology of microporous atomization and atomization sheet, applied in the field of atomization, can solve the problems of large specific surface area of aerosol particles, hindering the atomization of aerosol particles, affecting the amount of mist and the rate of atomization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

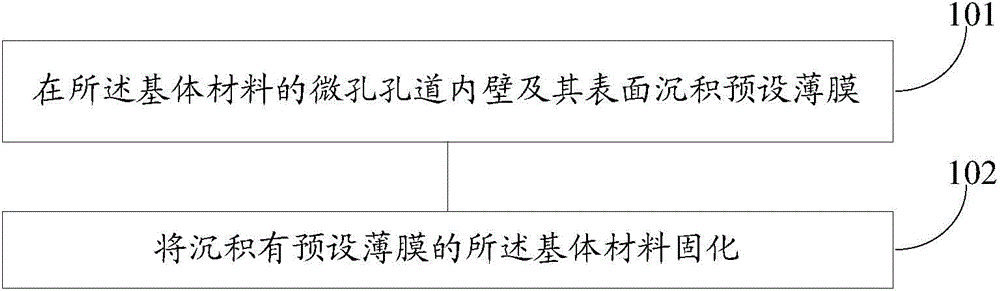

[0054] figure 1 It is a schematic diagram of the realization process of the preparation method of the microporous atomized sheet in the embodiment of the present invention Figure 1 , using the atomized sheet as the base material; such as figure 1 As shown, the method includes:

[0055] Step 101: Depositing a thin film on the inner wall of the micropore channel and its surface of the base material;

[0056] Wherein, the atomizing sheet is any one of metal atomizing sheet, ceramic atomizing sheet and organic material atomizing sheet.

[0057] Specifically, the base material is placed in the reaction chamber, each precursor is alternately passed into the reaction chamber in the form of pulsed gas, and a thin film is deposited on the inner wall of the micropore channel and the surface of the base material;

[0058] Here, in order to make the front and rear two precursors not appear in the reaction chamber at the same time, use a cleaning gas such as an inert gas to purge the g...

Embodiment 1

[0143] A method for preparing a microporous atomized sheet, the specific steps comprising:

[0144] Step 1: using the metal atomized sheet as the base material, and ultrasonically cleaning the base material;

[0145] Wherein, the micropore diameter of the metal atomized sheet is 21 μm;

[0146] Step 2: place the base material in the reaction chamber, and evacuate to reduce the pressure in the reaction chamber to 10Pa; then, after first pulse trimethylaluminum (TMA) for 50s, the flow rate of 100sccm N 2 Air purging described reaction cavity 120s; Next, pulse water vapor H 2 After O30s, feed the N with a flow rate of 120 sccm 2 The reaction chamber is purged with gas for 120s, so alternately pulse TMA and H 2 O, until 4200 layers of Al are deposited on the inner wall of the micropore channel of the base material and its surface 2 o 3 film; wherein, the Al 2 o 3 The thickness of the film is about 500nm;

[0147] Step 3: Put the base material with the film deposited on it ...

Embodiment 2

[0151] A method for preparing a microporous atomized sheet, the specific steps comprising:

[0152] Step 1: using the ceramic atomized sheet as the base material, and ultrasonically cleaning the base material;

[0153] Wherein, the micropore diameter of the ceramic atomizing sheet is 10 μm;

[0154] Step 2: placing the base material in the reaction chamber, and vacuuming to reduce the pressure in the reaction chamber to 10 -1 Pa; subsequently, after first pulse trimethylaluminum (TMA) 10s, pass into flow and be that the Ar gas of 50sccm is purged described reaction chamber 80s; Then pulse water vapor H 2 After 05s, the Ar gas that passes into flow is 50sccm to purge described reaction cavity 100s, so pulse TMA and H alternately 2 O, until 1000 layers of Al are deposited on the inner wall of the micropore channel of the base material and its surface 2 o 3 thin film, wherein the Al 2 o 3 The thickness of film is about 120nm; Finally, after pulse tetradimethylaminotitanium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com