Method for preparing single-electron transistor by assembling gold particles on PS microsphere template

A single-electron transistor, gold particle technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problem of inability to precisely control the size of Coulomb island assembly and positioning of the potential barrier between Coulomb islands and electrodes, so as to facilitate integrated batch preparation, reduce Difficulty, the effect of improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

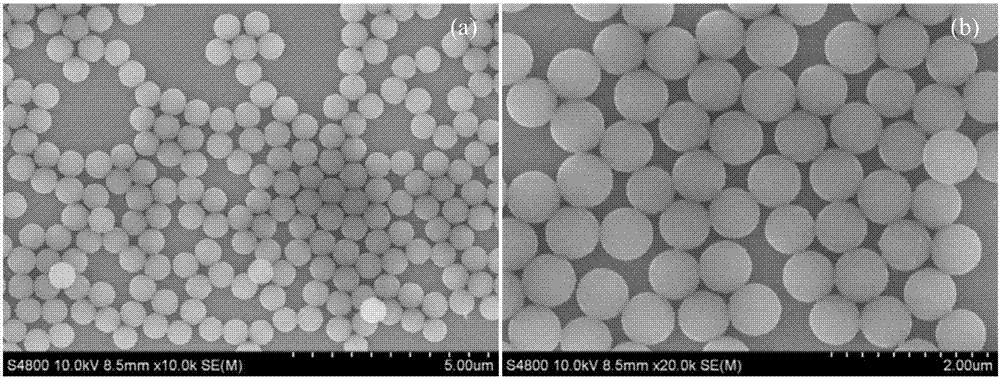

[0064] The invention utilizes the PS microsphere monolayer film to assemble the gold nanoparticle array to realize the precise control of the Coulomb island size, and its array arrangement is convenient for positioning and integration during processing; the thickness of the barrier layer is precisely controlled by atomic layer deposition technology; the present invention The technical difficulty of the invention is low, the feasibility is high, and a room-temperature single-electron transistor can be prepared.

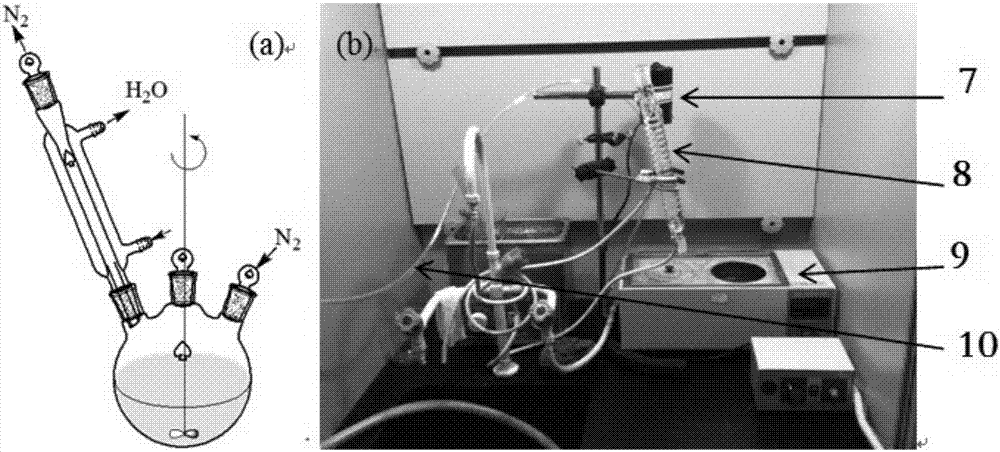

[0065] Below in conjunction with accompanying drawing, the concrete implementation of technical scheme of the present invention is described in further detail:

[0066] Such as Figure 14 As shown, the single-electron transistor of the present invention is mainly composed of a silicon substrate, a source, a drain, a gate, a barrier layer, a Coulomb island, and a protective layer, and is integrated on a silicon dioxide substrate, which is made of thermally oxidized pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com