AlGaAs/GaAs high-electron-mobility transistor of multi-channel insulated fin-type gate composite trench gate and preparation method thereof

A high electron mobility, multi-channel technology, applied in the field of AlGaAs/GaAs high electron mobility transistors and its preparation, can solve problems such as gate leakage, and achieve small on-state resistance, reduced resistance, and high current drive capability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

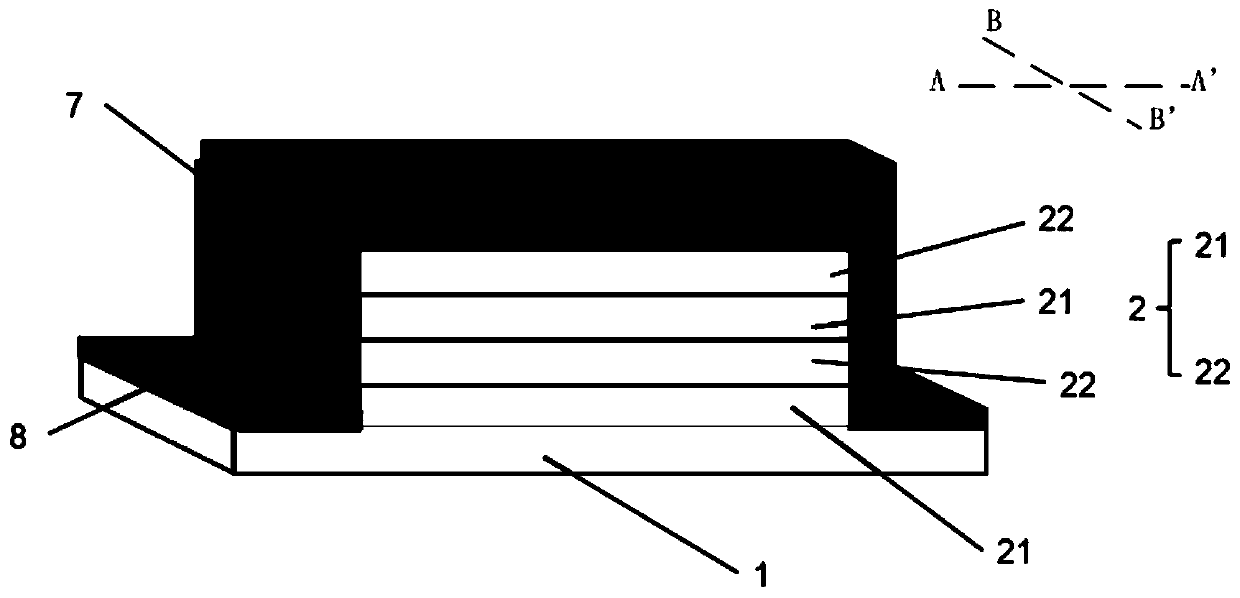

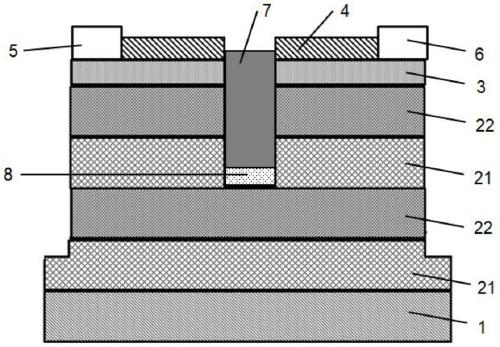

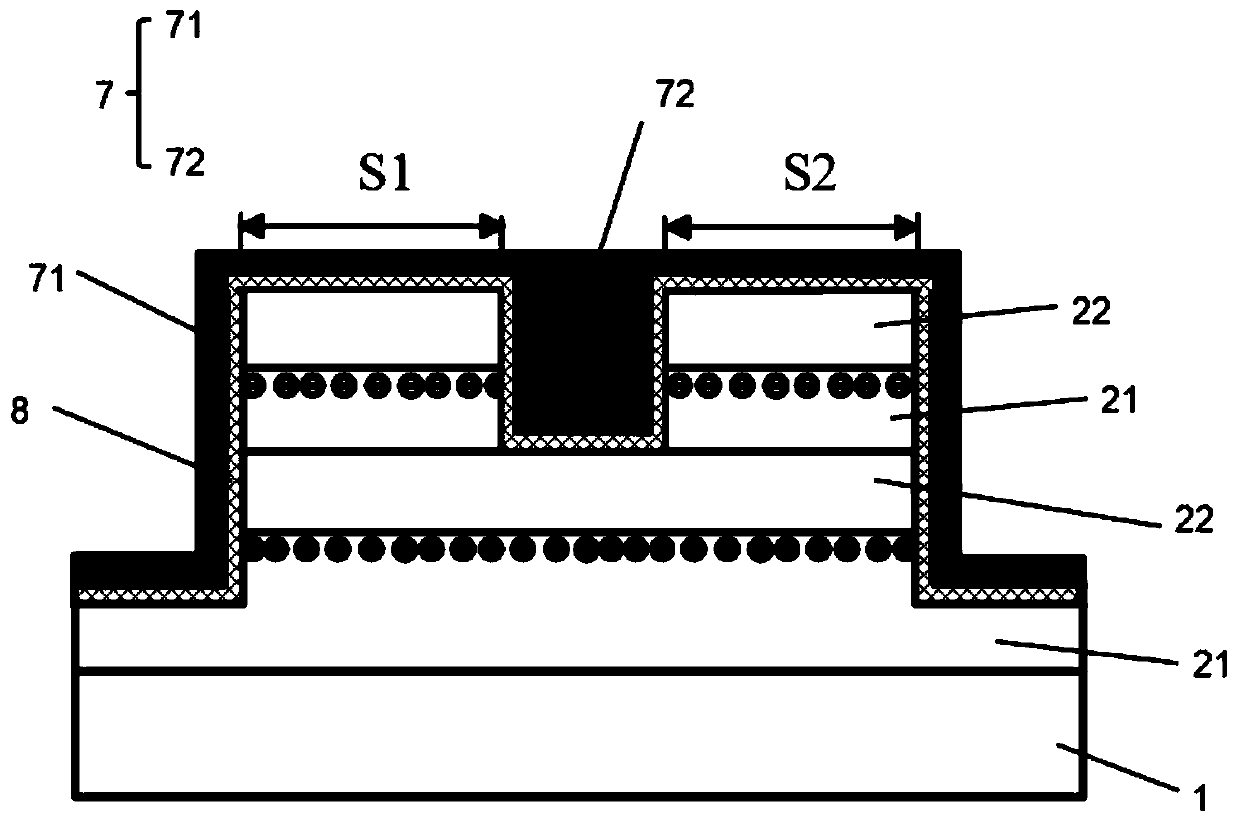

[0052] see Figure 1 to Figure 3 As shown, will figure 1 The A-A' direction in is defined as the end face of the high electron mobility transistor, and the BB' direction is defined as the side surface of the high electron mobility transistor. This embodiment provides a multi-channel insulating fin gate compound groove gate structure. AlGaAs / GaAs high electron mobility transistor, including GaAs or germanium substrate 1, several layers of AlGaAs / GaAs heterojunction 2, GaAs cap layer 3, SiN passivation layer 4, source electrode 5, drain electrode 6 from bottom to top and the gate electrode 7, the AlGaAs / GaAs heterojunction 2 includes a GaAs layer 21 and an AlGaAs barrier layer 22, and the GaAs layer 21 is close to the GaAs or germanium substrate 1, and the source electrode 5 and the drain electrode 6 are located on both sides of the SiN passivation layer 4, respectively. On the GaAs cap layer 3 on the side, the gate electrode 7 is located between the source electrode 5 and the ...

Embodiment 2

[0061] see Figure 4 to Figure 14 As shown, this embodiment also provides a method for preparing an AlGaAs / GaAs high electron mobility transistor with a multi-channel insulated fin gate composite groove gate structure, including the following steps:

[0062] S1: see Figure 5 As shown, a GaAs or germanium substrate 1 is provided first, and then a GaAs layer 21 and an AlGaAs barrier layer 22 are sequentially grown on the GaAs or germanium substrate 1 by MOCVD process to form the first layer of AlGaAs / GaAs heterojunction 2, Wherein, the thickness of the AlGaAs barrier layer 22 is 15-25 nm, and the Al component in the AlGaAs barrier layer 22 is 25-35%;

[0063] S2: see Figure 6 As shown, step S1 is repeated several times on the first layer of AlGaAs / GaAs heterojunction 2 to obtain several layers of AlGaAs / GaAs heterojunction 2 to form a multi-channel structure, wherein the thickness of the AlGaAs barrier layer 22 is 15- 25nm, the Al composition in the AlGaAs barrier layer 22 ...

Embodiment 3

[0080] This embodiment provides a method for preparing an AlGaAs / GaAs high electron mobility transistor with a multi-channel insulated fin gate composite groove gate structure, which specifically includes the following steps:

[0081] Step 1. Epitaxial material growth.

[0082] 1.1) On the germanium substrate, the intrinsic GaAs layer is grown by MOCVD process;

[0083] 1.2) On the intrinsic GaAs layer, grow a 15nm-thick AlGaAs barrier layer, wherein the Al composition is 35%, and the doping concentration is 4×10 17 cm -3 , forming a 2DEG at the contact position between the intrinsic GaAs layer and the AlGaAs barrier layer;

[0084] 1.3) growing a second intrinsic GaAs layer on a 15nm thick AlGaAs barrier layer;

[0085] 1.4) A second 15nm thick AlGaAs barrier layer is grown on the second intrinsic GaAs layer, wherein the Al composition is 35%, and the doping concentration is 4×10 17 cm -3 , forming a heterojunction material structure with double channels.

[0086] 1.5) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com